Compound pipeline weld joint repair method for media rich in hydrogen

A composite pipeline and repair method technology, applied in the field of hydrogen-rich medium composite pipeline weld repair, can solve the problems of delayed cracks, repair failure, and high failure rate of composite pipelines, and achieve the effect of avoiding pores and cracks and improving the success rate of repair welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following is a detailed description of the weld repair method for 20# carbon steel + 304 stainless steel composite pipes:

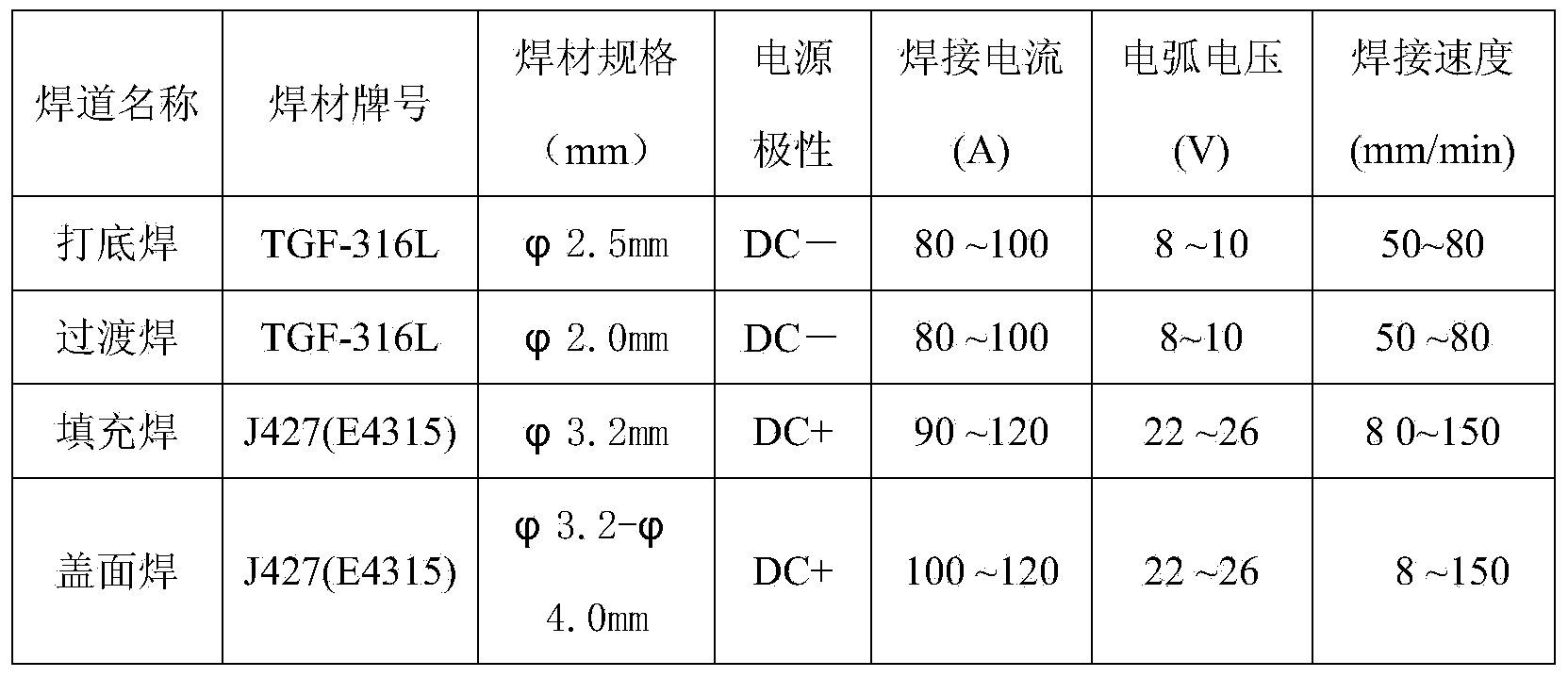

[0012] A hydrogen-rich medium composite pipeline weld repair method, which includes the following steps: (1) pressure reduction replacement; (2) groove processing; (3) groove processing; (4) welding groove; wherein,

[0013] (1) Pressure reduction replacement: reduce the hydrogen-rich medium in the composite pipeline to normal pressure, and perform nitrogen replacement, so that the volume percentage of combustible gas in the composite pipeline is less than 0.5%;

[0014] (2) Groove processing: the cracked joint of the composite pipe is ground and cleaned with an angle grinder, and the base pipe wall thickness of the composite pipe is carefully ground when the wall thickness margin is 1-2mm, leaving the The blunt edge of the composite pipeline liner removes burrs and impurities visible to the naked eye, performs coloring inspection to ensure tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com