Method for preparing crystalline silicon solar cell electrode through laser melting

A technology of solar cells and laser melting, applied in photovoltaic power generation, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. To achieve the effect of maintaining the flow viscosity, lowering the adhesive strength, and increasing the peelability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

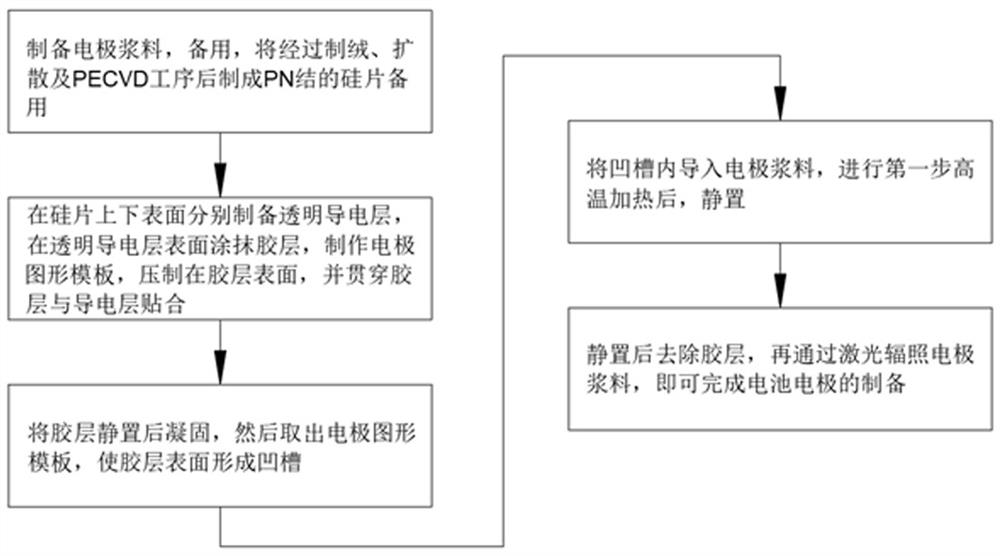

Image

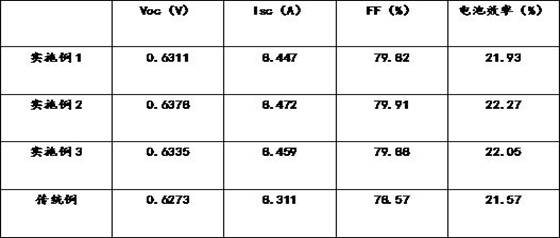

Examples

Embodiment 1

[0026] Embodiment 1 A method for preparing a crystalline silicon solar cell electrode by laser melting, including:

[0027] 1. Preparation of electrode paste

[0028] 1. Heat and melt 1 part of acrylic resin, add 3 parts of ethyl cellulose, stir and mix, then add the mixture to terpineol and butyl carbitol acetate solution and blend to obtain an organic carrier;

[0029] 2. Add 1 part of lead-free low-melting glass powder and 30 parts of nano-silver powder into 15 parts of organic carrier, disperse and stir, and grind to a small particle size by a grinder after drying to prepare electrode slurry, and its particle size is 10 -12um, providing powder with smaller particle size, which can optimize the conductivity of the electrode;

[0030] 2. Preparation of solar cell electrodes

[0031] 1. Prepare electrode slurry for standby, and prepare silicon wafers with PN junction after texturing, diffusion and PECVD processes for standby;

[0032] 2. Prepare a transparent conductive la...

Embodiment 2

[0037] Embodiment 2 A method for preparing a crystalline silicon solar cell electrode by laser melting, comprising:

[0038] 1. Preparation of electrode paste

[0039] 1. Heat and melt 2 parts of acrylic resin, add 5 parts of ethyl cellulose, stir and mix, then add the mixture to terpineol and butyl carbitol acetate solution and blend to obtain an organic carrier;

[0040] 2. Add 3 parts of lead-free low-melting glass powder and 35 parts of nano-silver powder into 17 parts of organic carrier, disperse and stir, and grind it to a small particle size by a grinder after drying, and then the electrode slurry can be prepared, and its particle size is 10 -12um, providing powder with smaller particle size, which can optimize the conductivity of the electrode;

[0041] 2. Preparation of solar cell electrodes

[0042] 1. Prepare electrode slurry for standby, and prepare silicon wafers with PN junction after texturing, diffusion and PECVD processes for standby;

[0043] 2. Prepare a ...

Embodiment 3

[0047] Embodiment 3 A method for preparing a crystalline silicon solar cell electrode by laser melting, comprising:

[0048] 1. Preparation of electrode paste

[0049] 1. Heat and melt 3 parts of acrylic resin, add 7 parts of ethyl cellulose, stir and mix, then add the mixture to terpineol and butyl carbitol acetate solution and blend to obtain an organic carrier;

[0050] 2. Add 5 parts of lead-free low-melting glass powder and 40 parts of nano-silver powder into 20 parts of organic carrier, disperse and stir, and grind to a small particle size by a grinder after drying to prepare electrode slurry, and its particle size is 10 -12um, providing powder with smaller particle size, which can optimize the conductivity of the electrode;

[0051] 2. Preparation of solar cell electrodes

[0052] 1. Prepare electrode slurry for standby, and prepare silicon wafers with PN junction after texturing, diffusion and PECVD processes for standby;

[0053] 2. Prepare a transparent conductive l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com