Continuous starch cooking equipment for papermaking

A technology for cooking equipment and starch, which is applied in the field of paper production equipment, can solve the problems of blending, black substances on the surface of finished paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

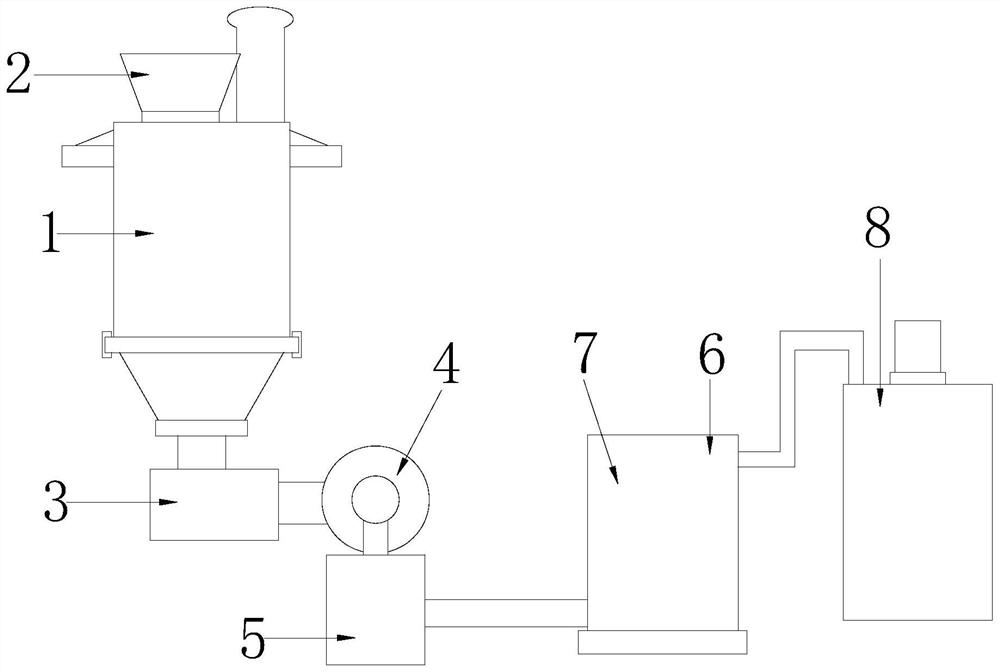

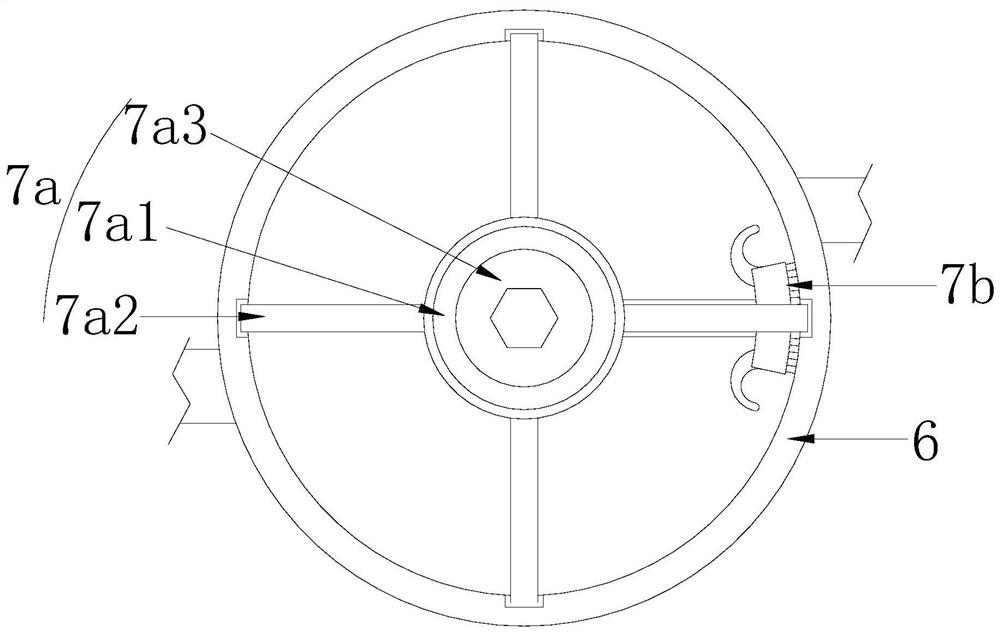

[0030] like Figure 1-Figure 5 As shown, the present invention provides a technical scheme of a continuous starch cooking equipment for papermaking:

[0031] like Figure 1-Figure 2 As shown, a continuous starch cooking equipment for papermaking, its structure includes a silo 1, a starch hopper 2, a connecting box 3, a screw conveyor 4, a dissolving tank 5, a cooking drum 6, a turbidity suppression device 7, and a storage drum 8 , the starch hopper 2 is installed on the upper surface of the silo 1, the connecting box 3 is arranged on the lower surface of the silo 1 and connected, the screw conveyor 4 is connected with the connecting box 3, the dissolving tank 5 is connected to The screw conveyor 4 is matched, the cooking cylinder 6 is connected with the dissolving tank 5, the turbidity suppression device 7 is arranged in the upper part of the cooking cylinder 6 and is welded, the storage cylinder 8 is connected with the cooking cylinder 6, and the The turbidity suppression d...

no. 2 example

[0042] like Image 6 Shown, the present invention provides a kind of technical scheme of continuous starch cooking equipment for papermaking:

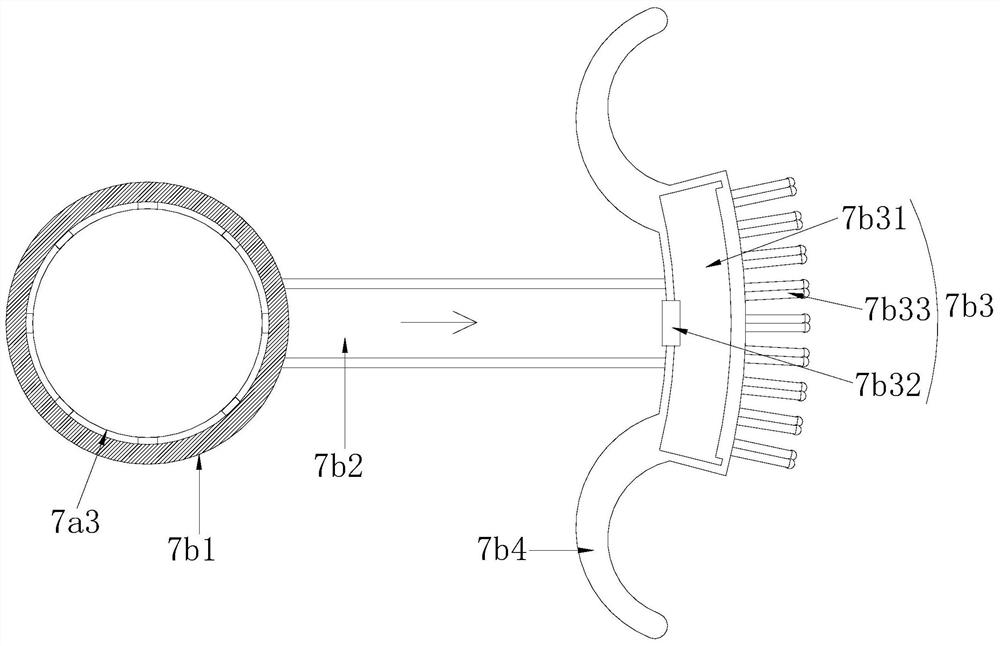

[0043] like Image 6 As shown, a kind of starch continuous cooking equipment for papermaking, its structure includes that the collecting member 7b4 includes an arc 7b41, a receiving groove 7b42, and an elastic bar 7b43, and the end of the arc 7b41 is connected through the arc frame 7b31. The receiving groove 7b42 is provided with several and installed on the inner wall of the arc 7b41 respectively. The receiving groove 7b42 and the arc blocking 7b41 are an integrated structure. The end of the elastic strip 7b43 is set inside the receiving groove 7b42 and connected with the arc stop 7b41, which is beneficial to realize the scorched starch after being strangled, and to collect and attach it synchronously after scraping, so as to prevent it from being integrated into the starch being cooked .

[0044] like Image 6 As shown, the insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com