Magnesium alloy plate rolling device

A magnesium alloy and sheet technology, applied in the direction of metal rolling, can solve the problems of cracks in bending and low stamping performance of magnesium alloy sheets, and achieve the effect of avoiding cracks and improving formability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

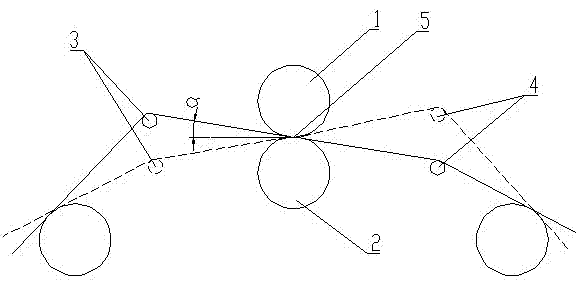

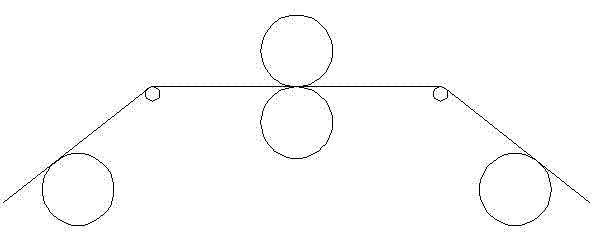

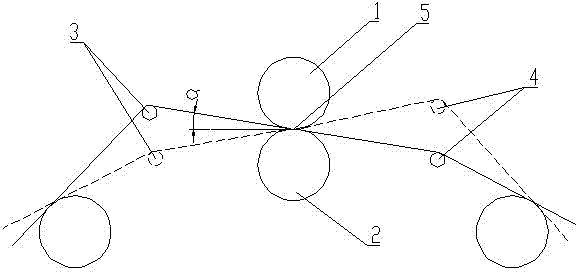

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings, as shown in the figure: the magnesium alloy plate rolling device of the present embodiment includes a roll pair consisting of an upper roll 1 and a lower roll 2, and a front tension force distributed on both sides of the roll pair. Roller 3 and rear tension roller 4, the tensioning part of the front tension roller 3 to the plate is higher than the roll gap 5 between the upper roll 1 and the lower roll 2 to form a structure in which the plate is obliquely bitten into the roll gap 5, due to the inclination of the slab Bite into the roll gap, so that there is a time difference in the rolling time of the upper and lower rolls on the slab, which can tilt the grain orientation of the rolled magnesium alloy sheet, which is conducive to improving the forming performance of the sheet and avoiding the appearance of bends during forming. defects such as cracks. Of course, the ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com