Silicon nitride porous ceramic composition and preparation method thereof

A technology of porous ceramics and silicon nitride, applied in the field of silicon nitride porous ceramics formulation and preparation, can solve the problems of unpleasant hydrocarbon gas, unfavorable environmental protection, toxicity, etc., achieve superior economy and reliability, and shorten process time , the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

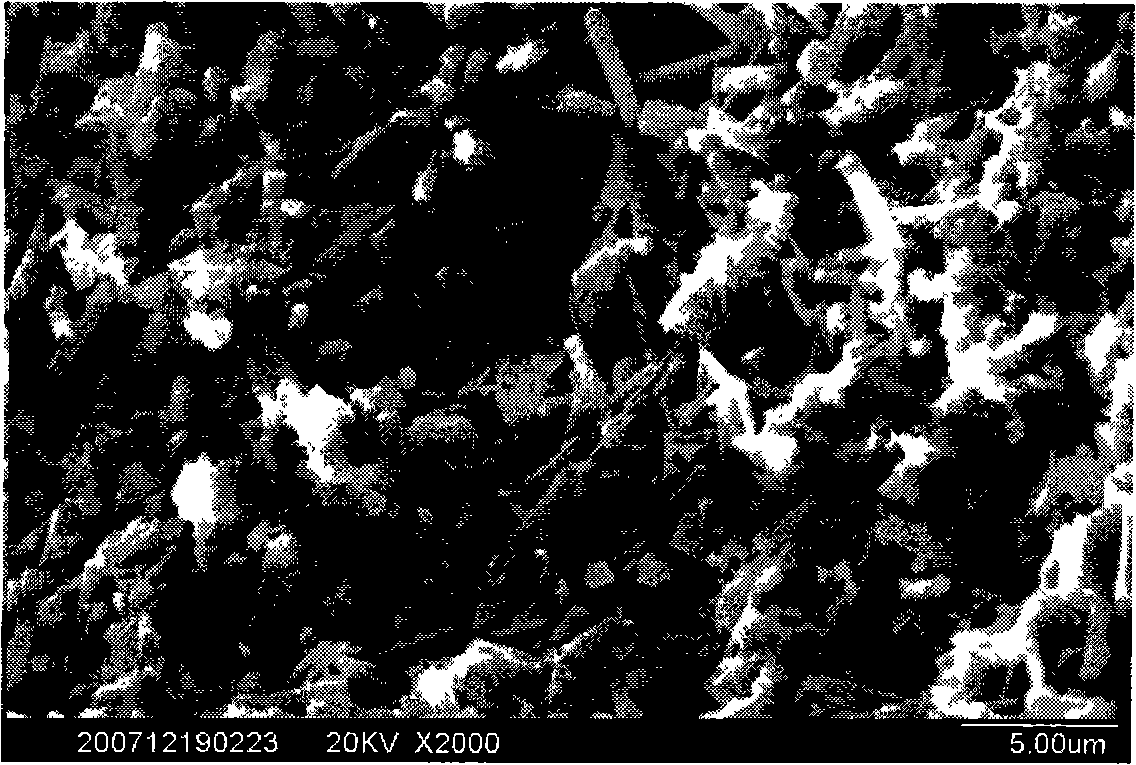

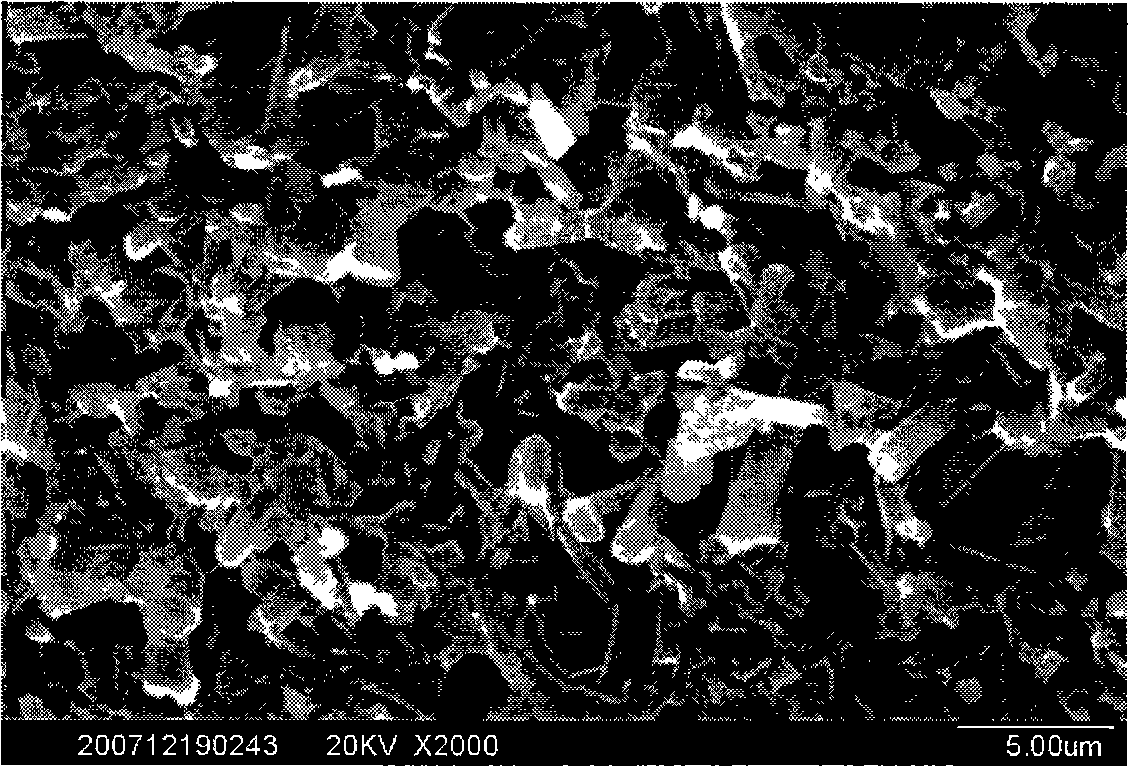

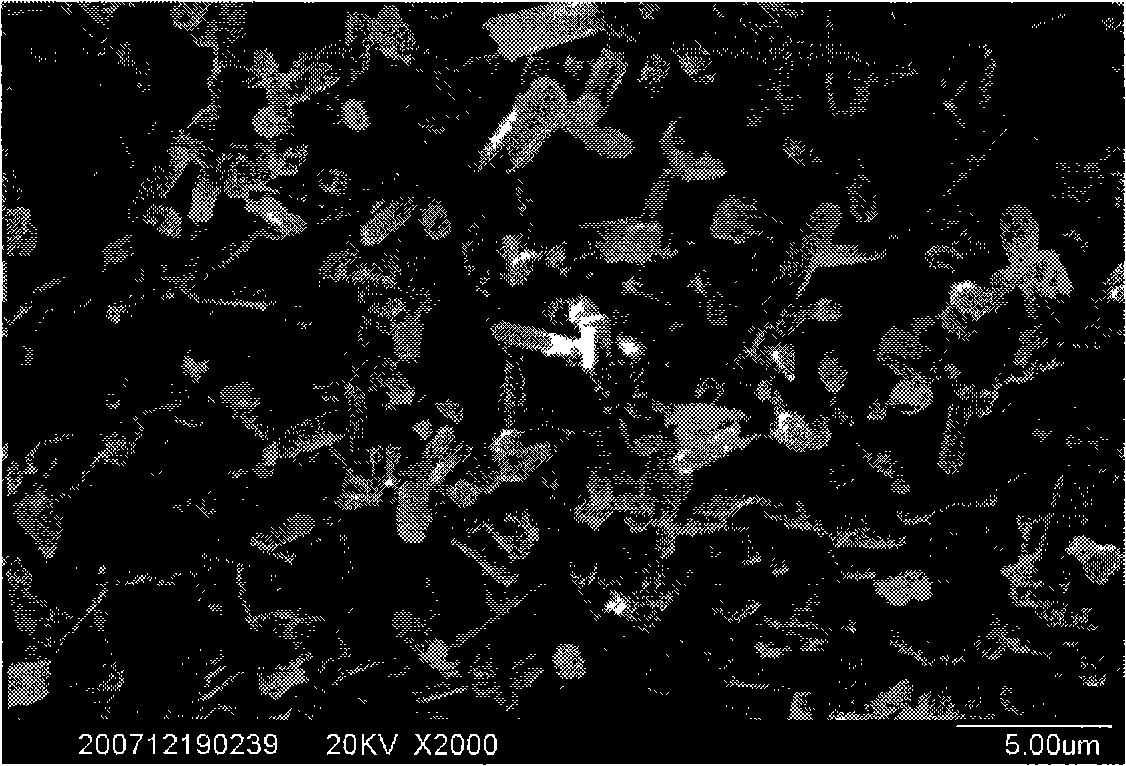

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with specific embodiments.

[0022] A silicon nitride porous ceramic composition, as shown in Table 1, in Examples 1 to 9 shown in Table 1, the silicon nitride powder content is generally 50 to 70%, if less than 50%, the nitrogen in the sintered body The silicon nitride content is also small, the reinforcing effect of the rod-shaped silicon nitride grains is limited, and the mechanical properties of the fired body are reduced. If it is greater than 70%, the amount of bentonite added will be reduced accordingly, and the plasticity of the corresponding mud will be poor, and liquid phase migration will easily occur during extrusion, resulting in large fluctuations in the density of the extruded green body. The average particle diameter of silicon nitride powder is preferably 0.5-1 micron, and its crystal form can be expressed as different Si 3 N 4 particles. Such as α-type, β-type, or amorpho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com