One-step forging die of porcelain insulator cap

A technology for forming molds and porcelain insulators, which is applied in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve problems such as heating and explosion of insulator heads, threats to safe operation of power grids, and grounding of wires. Achieve the effect of reducing the discharge of three wastes, reducing production costs and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

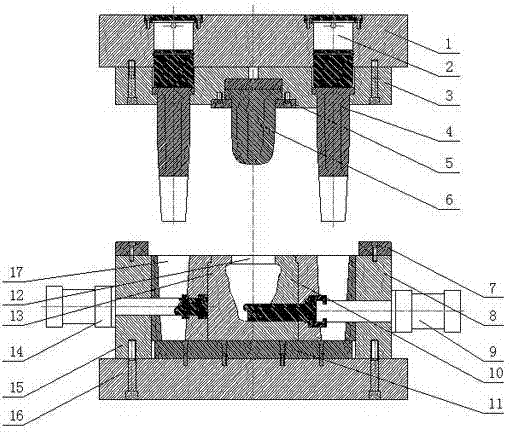

[0011] Such as figure 1 From the schematic diagram shown, it can be known that the one-time forming mold for forging the iron cap of the porcelain insulator of the present invention mainly includes an upper mold and a lower mold.

[0012] The upper mold mainly includes a locking insert 4, a locking insert cylinder 2, a molding die 6, an upper movable platform 3 and an upper base 1, and the upper movable platform 3 is arranged at the lower end 1 of the upper base, and is set at the bottom of the upper movable platform 3. There are locking inserts 4 and forming dies 6. There are two locking inserts 4, which are symmetrically arranged at both ends of the forming die 6. The cross section of the locking inserts 4 is rounded and the forming dies 6 are arranged At the center of the bottom end of the movable platform, the cross section of the forming die 6 is in a T shape, and the bottom end of the forming die 6 is chamfered. Set screw is fixed with movable platform 3.

[0013] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com