Method for spraying aluminum oxide-silicon carbide whisker anti-oxidation coating on surface of carbon fiber

A silicon carbide whisker, anti-oxidative coating technology, applied in the processing of textile materials, spray/jet textile material processing, textiles and papermaking, etc., can solve the problems of low fracture toughness, limited application, high porosity, etc. Improve the strength and fracture toughness, improve the comprehensive mechanical properties, the effect of accurate composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

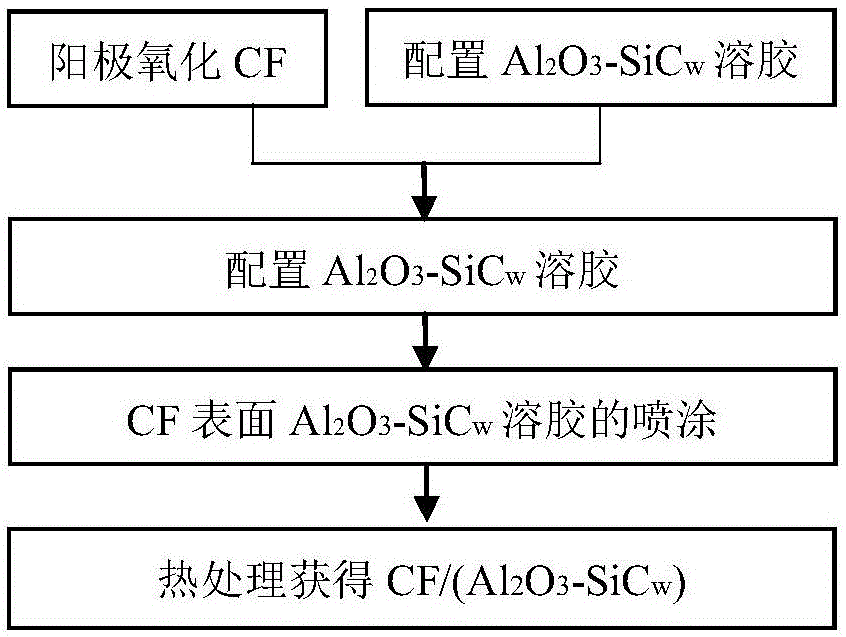

[0032] The method for spraying the aluminum oxide-silicon carbide whisker anti-oxidation coating on the carbon fiber surface of the present embodiment comprises the following steps:

[0033] Step 1, pretreatment of CF. First, the CF is ultrasonically cleaned with deionized water, acetone, ethanol, and deionized water, and dried in the air. With the graphite electrode as the cathode, the cleaned CF and the flake graphite electrode are placed At 40°C, in 0.5mol / L phosphoric acid electrolyte, carry out ultrasonic anodic oxidation treatment on CF, the ultrasonic assisted ultrasonic frequency used is 40KH z , the ultrasonic power is 100W, the oxidation time is 20min, and the current density is 50mA / cm 2 ; Finally, the CF was taken out, washed with deionized water and dried to obtain the CF after surface pretreatment.

[0034] Step 2, Al 2 o 3 -SiC w The preparation of sol, utilizes the sol-gel method to configure the aluminum oxide sol of 0.4mol / L; Preliminarily weighs 4.896g a...

Embodiment 2

[0039] The method for spraying the aluminum oxide-silicon carbide whisker anti-oxidation coating on the carbon fiber surface of the present embodiment comprises the following steps:

[0040] Step 1, pretreatment of CF. First, the CF is ultrasonically cleaned with deionized water, acetone, ethanol, and deionized water, and dried in the air. With the graphite electrode as the cathode, the cleaned CF and the flake graphite electrode are placed At 40°C and 1.0mol / L phosphoric acid electrolyte, carry out ultrasonic anodic oxidation treatment on CF, the ultrasonic assisted ultrasonic frequency used is 25KH z , the ultrasonic power is 80W, the oxidation time is 30min, and the current density is 25mA / cm 2 ; Finally, the CF was taken out, washed with deionized water and dried to obtain the CF after surface pretreatment.

[0041] Step 2, Al 2 o 3 -SiC w The preparation of sol, utilizes sol-gel method to configure the aluminum oxide sol of 0.8mol / L; Preliminarily weighs 9.792g alumin...

Embodiment 3

[0046] The method for spraying the aluminum oxide-silicon carbide whisker anti-oxidation coating on the carbon fiber surface of the present embodiment comprises the following steps:

[0047] Step 1, pretreatment of CF. First, the CF is ultrasonically cleaned with deionized water, acetone, ethanol, and deionized water, and dried in the air. With the graphite electrode as the cathode, the cleaned CF and the flake graphite electrode are placed At 40°C, in 0.5mol / L phosphoric acid electrolyte, carry out ultrasonic anodic oxidation treatment on CF, the ultrasonic assisted ultrasonic frequency used is 40KH z , the ultrasonic power is 100W, the oxidation time is 20min, and the current density is 50mA / cm 2 ; Finally, the CF was taken out, washed with deionized water and dried to obtain the CF after surface pretreatment.

[0048] Step 2, Al 2 o 3 -SiC w The preparation of sol, utilizes sol-gel method to configure the aluminum oxide sol of 0.6mol / L; Preliminarily weighs 7.344g alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com