Patents

Literature

34results about How to "Provides antioxidant protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

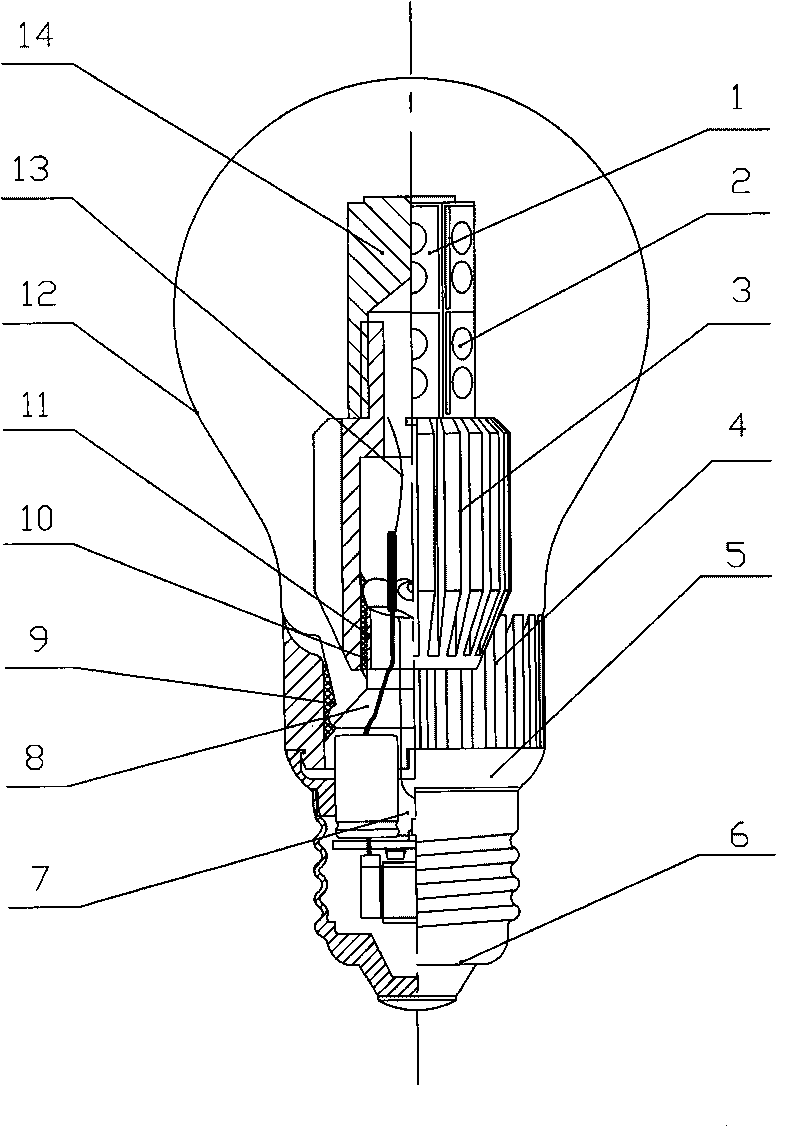

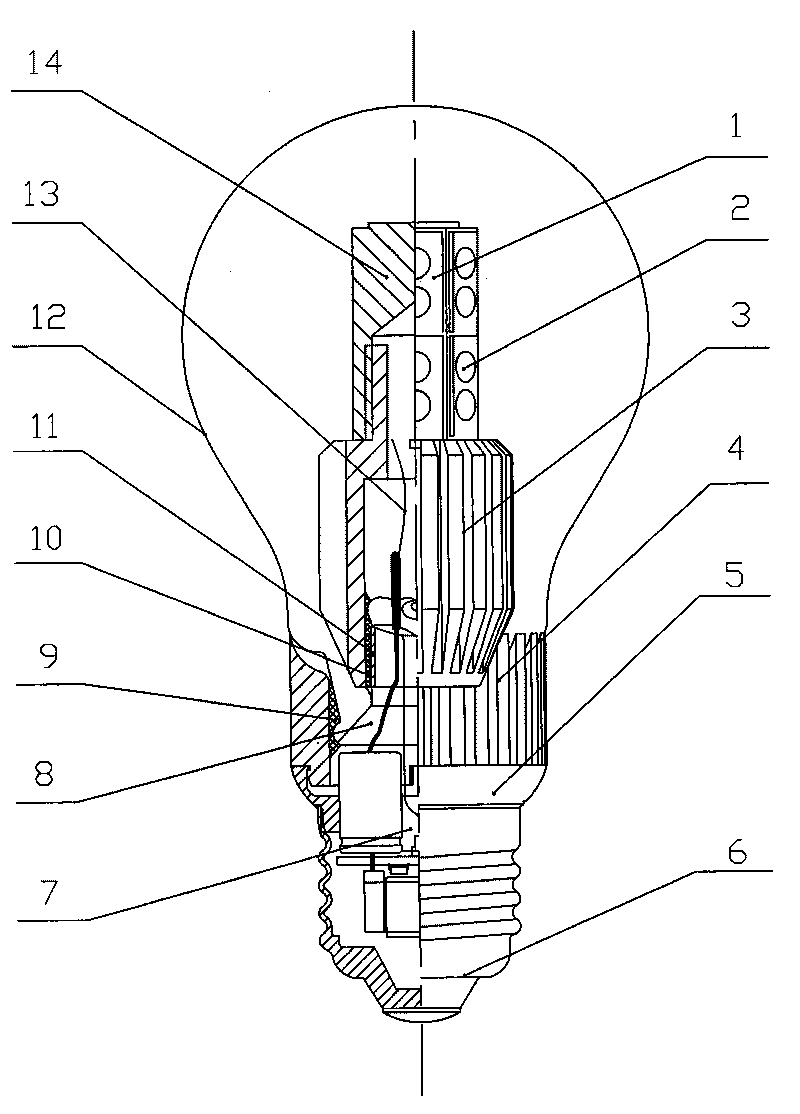

Common LED lamp bulb

InactiveCN101699135AReduce thermal resistanceImprove cooling conditionsPoint-like light sourceSemiconductor/solid-state device detailsAdhesiveRadiation

The invention provides a common LED lamp bulb, which comprises a core column and a lamp holder which are in sealing connection with a glass envelope, wherein the bottom part of a hollow metal heat-conducting lamp column is connected with the core column through a heat-conducting adhesive; the side wall of the top part of the hollow metal heat-conducting lamp column is embedded with LED lamp beads; the tail part of the glass envelope is connected with the lamp holder through an external metal radiation piece and a plastic transitional piece; the heat-conducting adhesive is arranged between the tail part of the glass envelope and the metal radiation piece; a heat-conducting gas is charged in the glass envelope. The common LED lamp bulb solves a radiation problem that a component formed by assembling a plurality of groups of LED lamp beads influences the service life of the LEDs in use when a common lamp envelope is adopted.

Owner:SHANGHAI HAIFENG ELECTRICAL LIGHTING

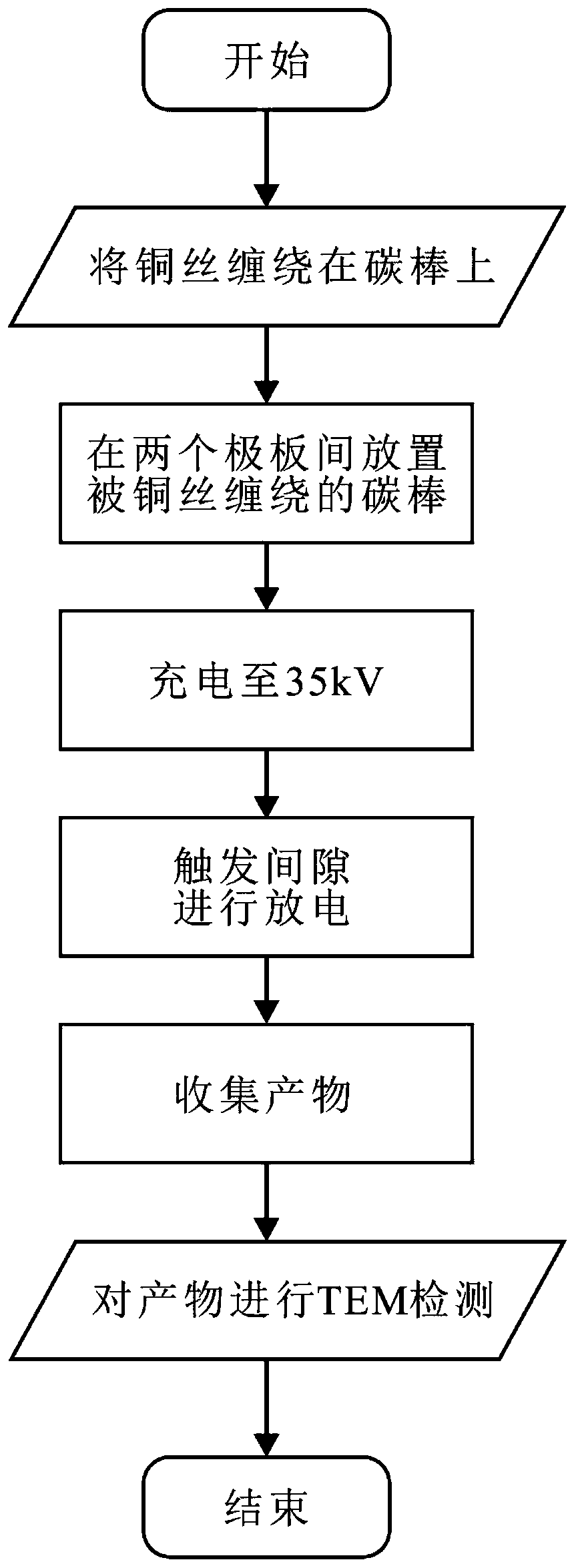

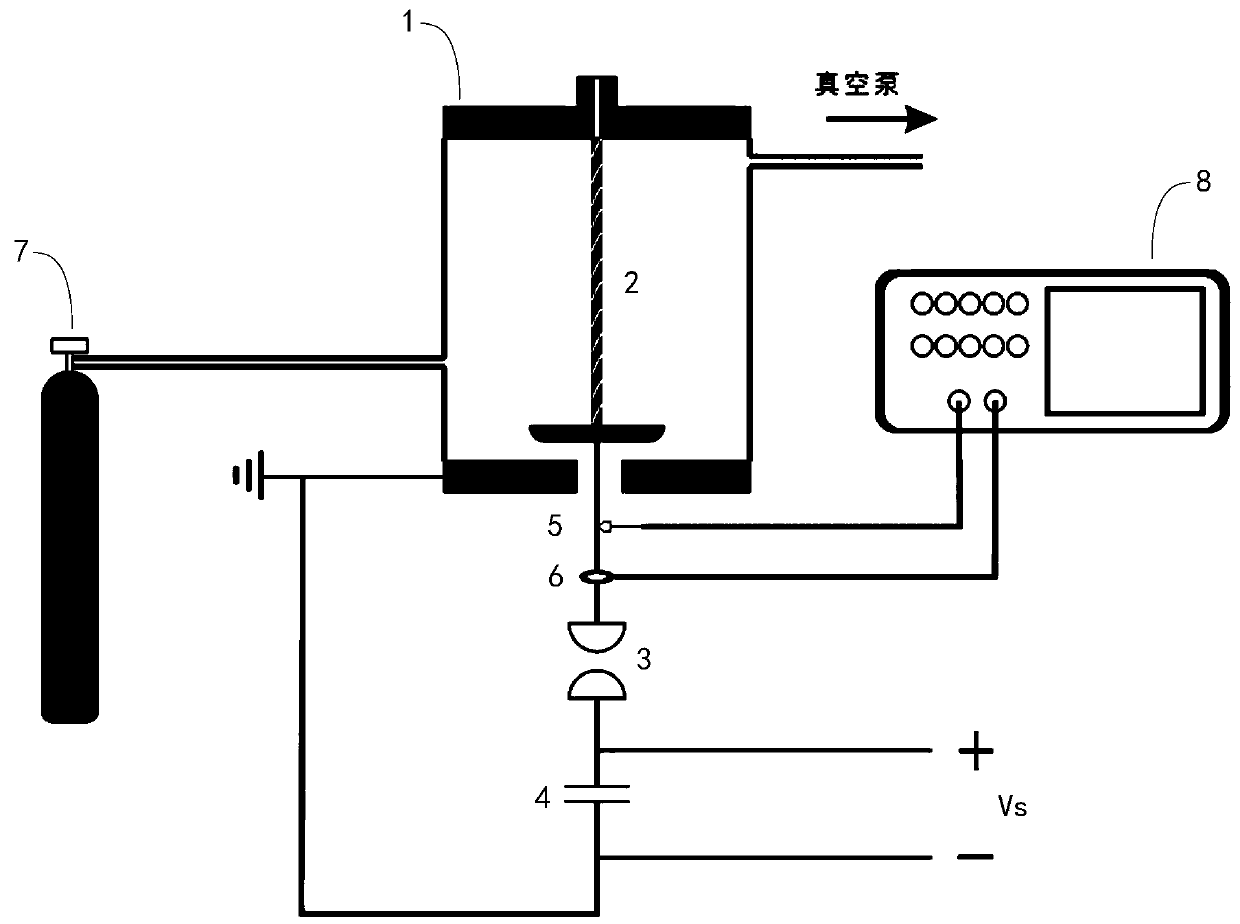

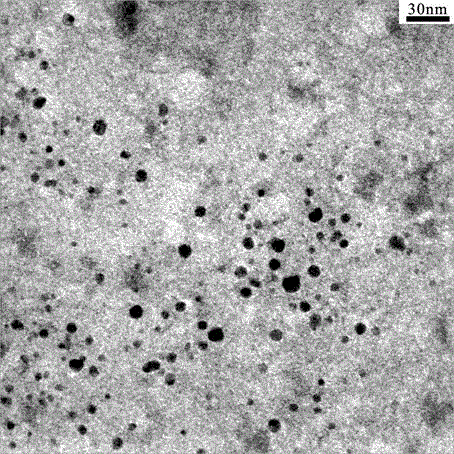

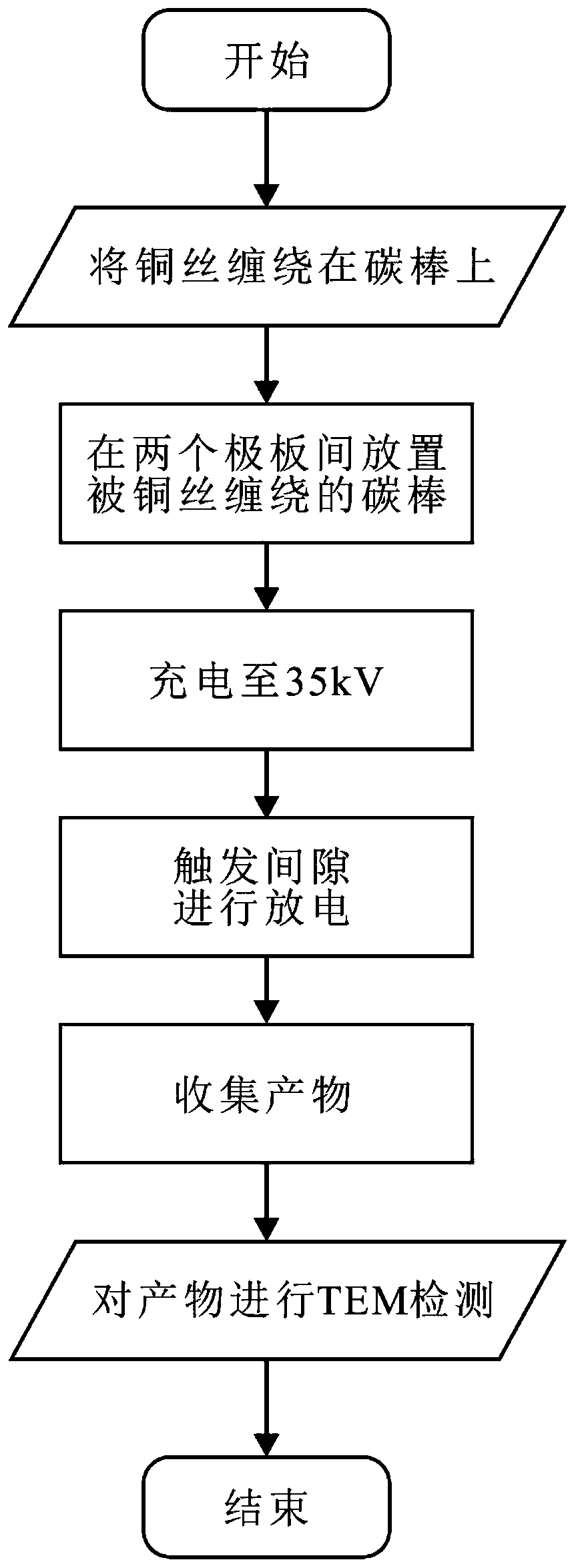

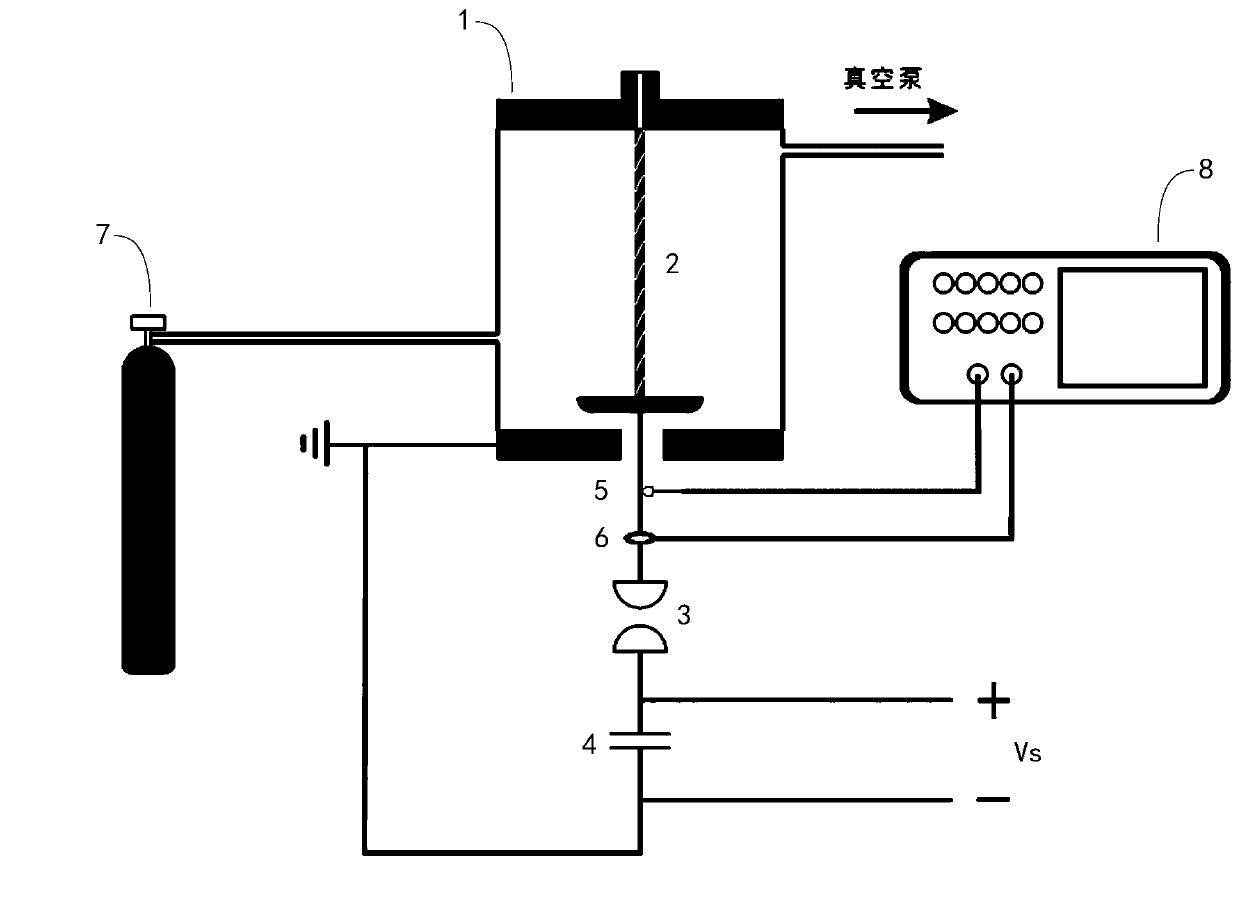

Method and device for preparing carbon-coated copper nano-particles by metal wire electric explosion method

ActiveCN110116215AProvides antioxidant protectionImprove performanceMaterial nanotechnologyTransportation and packagingCopper atomSmall droplet

The invention discloses a method and device for preparing carbon-coated copper nano-particles by a metal wire electric explosion method. The method comprises the following steps: winding a carbon rodwith a copper wire with a certain length and a certain diameter uniformly; and applying high voltage and large current to the metal wire in argon atmosphere so that the electric explosion of metal wire occurs, and collecting the carbon-coated copper nano-particles. A copper metal is heated to cause phase transition in an electric explosion process; the copper metal is subjected to the processes ofmelting, gasifying, plasma and the like successively, and produces copper atoms under the high-temperature heating of the plasma; part of carbon atoms can be formed by the carbon rod after high current is applied, and then the copper atoms and the carbon atoms nucleate and condense into atom clusters spontaneously and uniformly from a gas phase and form initial small droplets; the droplets grow continuously, and then a carbon-coated layer is formed through two mechanisms, namely, internal carbon atom separating out and external carbon atom precipitation; and finally, the carbon-coated coppernano-particles are formed through cooling. The new method for preparing the carbon-coated copper nano-particles is provided, and has great application value in industrial production and scientific research.

Owner:XI AN JIAOTONG UNIV

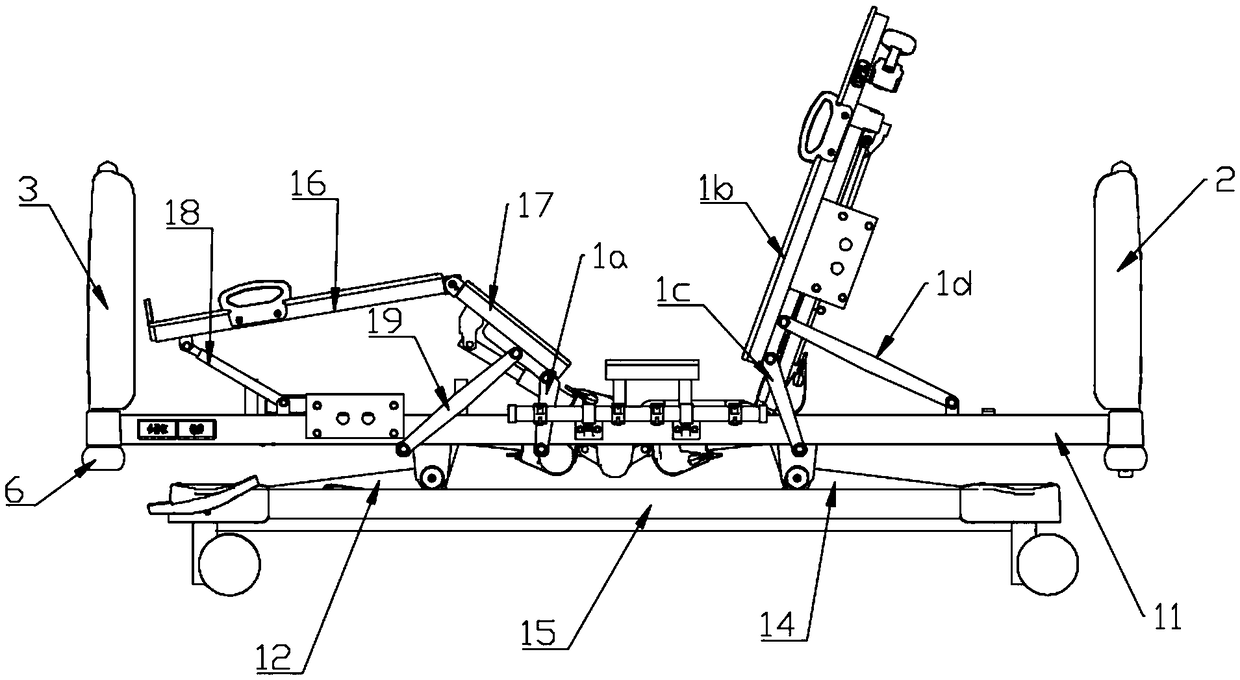

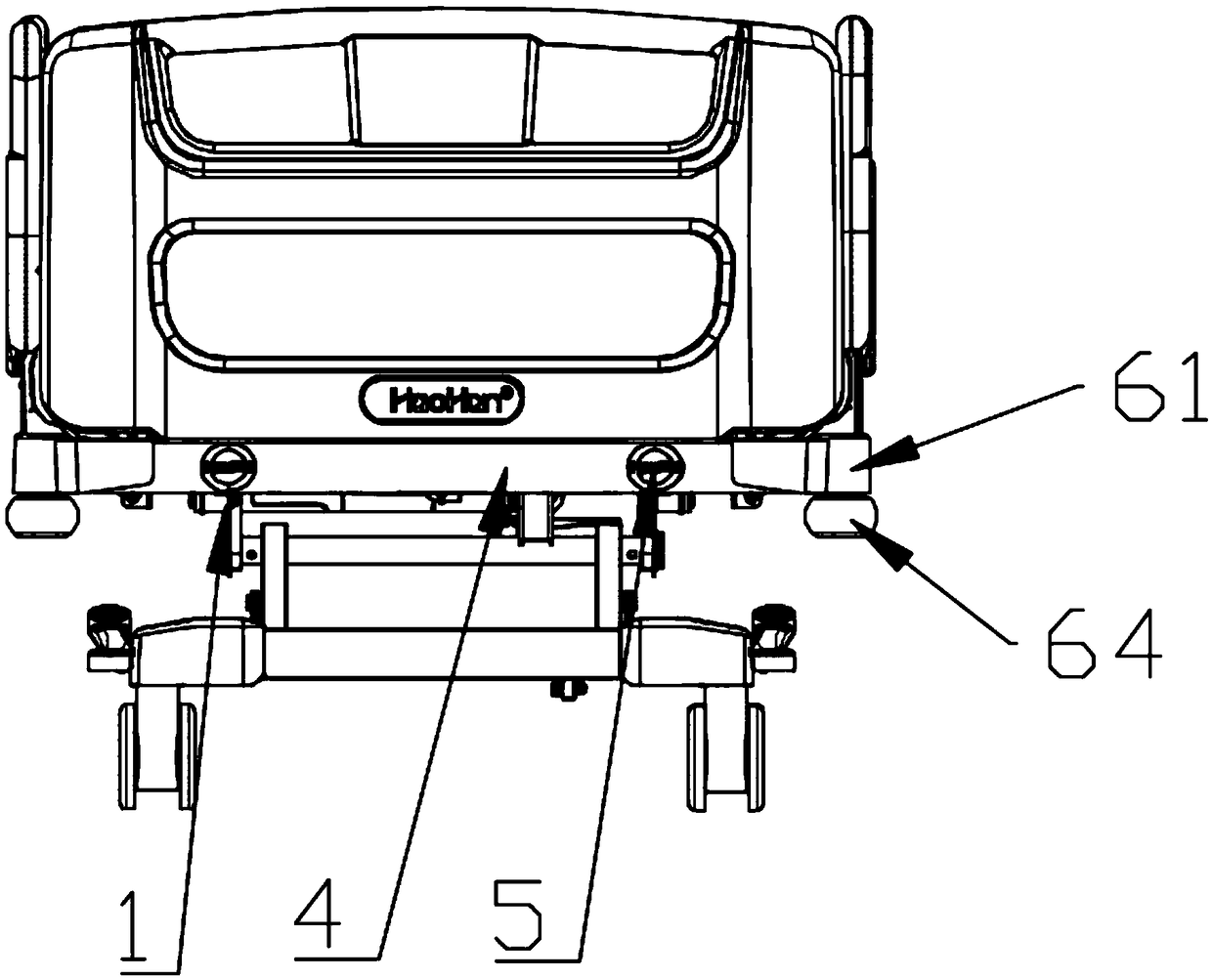

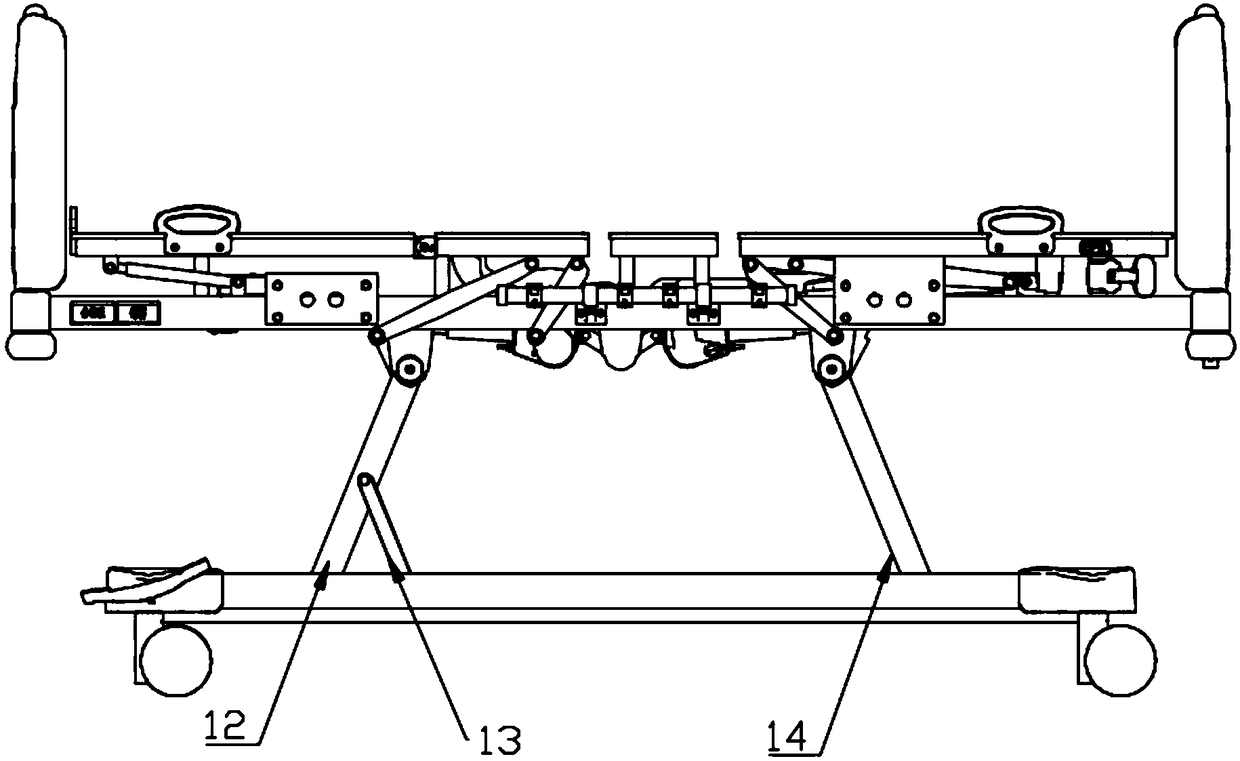

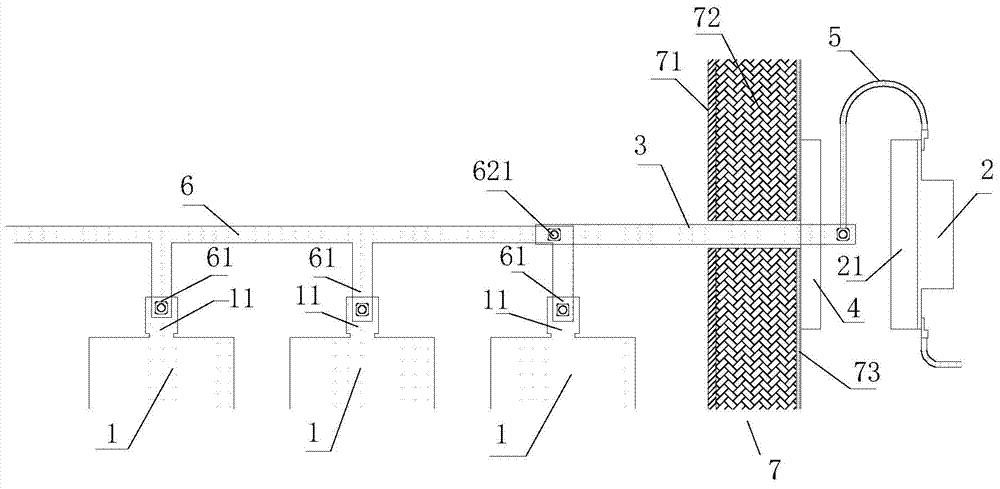

Multifunctional medical bed

PendingCN109223368AReduce usageRealize multi-directional adjustment functionNursing bedsAmbulance serviceEngineeringMedical treatment

The invention discloses a multifunctional medical bed, relating to the technical field of medical instruments, and comprising a bed body structure adjustable in multiple directions, a headboard, a tailboard, a bed frame crossbar, a locking structure of a bed frame and a bed body anti-collision assembly, wherein the bed head board and the bed tail board are installed on the bed frame cross bar through the bed frame locking structure, the bed frame cross bar is connected with the bed body structure for multi-orientation adjustment, and the bed body anti-collision assembly is installed at the endof the bed frame cross bar. The invention can realize the multi-orientation adjustment function and reduce the risk of locking, and simultaneously has the anti-collision and storage functions.

Owner:CHENGDU HAOHAN MEDICAL EQUIP

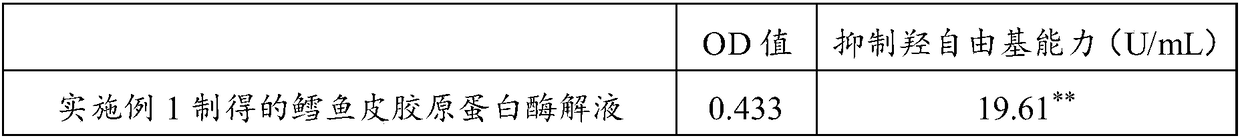

Collagen as well as preparation method and application thereof

InactiveCN108276489AInhibit tyrosinase contentReduce formationCosmetic preparationsConnective tissue peptidesMedicineHigh doses

The invention relates to the technical field of biology, in particular to collagen as well as a preparation method and application thereof. The collagen provided by the invention can significantly increase skin moisture content of a D-galactose senile-induced nude mouse model; compared with a model control group, the contents of MDA in the skin and animal liver in high and medium dose groups of the collagen are obviously decreased, the content of hydro-xyproline in the skin in the high dose group of the collagen is obviously increased, the contents of SOD in the skin and animal liver in the high dose group of the collagen are obviously increased, and the content of T-AOC in animal plasma in the high dose group of the collagen is significantly increased. The test result shows that the collagen has the effects of resisting oxidation and scavenging free radicals, and has better effects on maintaining skin moisture and improving the content of the collagen in the skin.

Owner:INFINITUS (CHINA) CO LTD

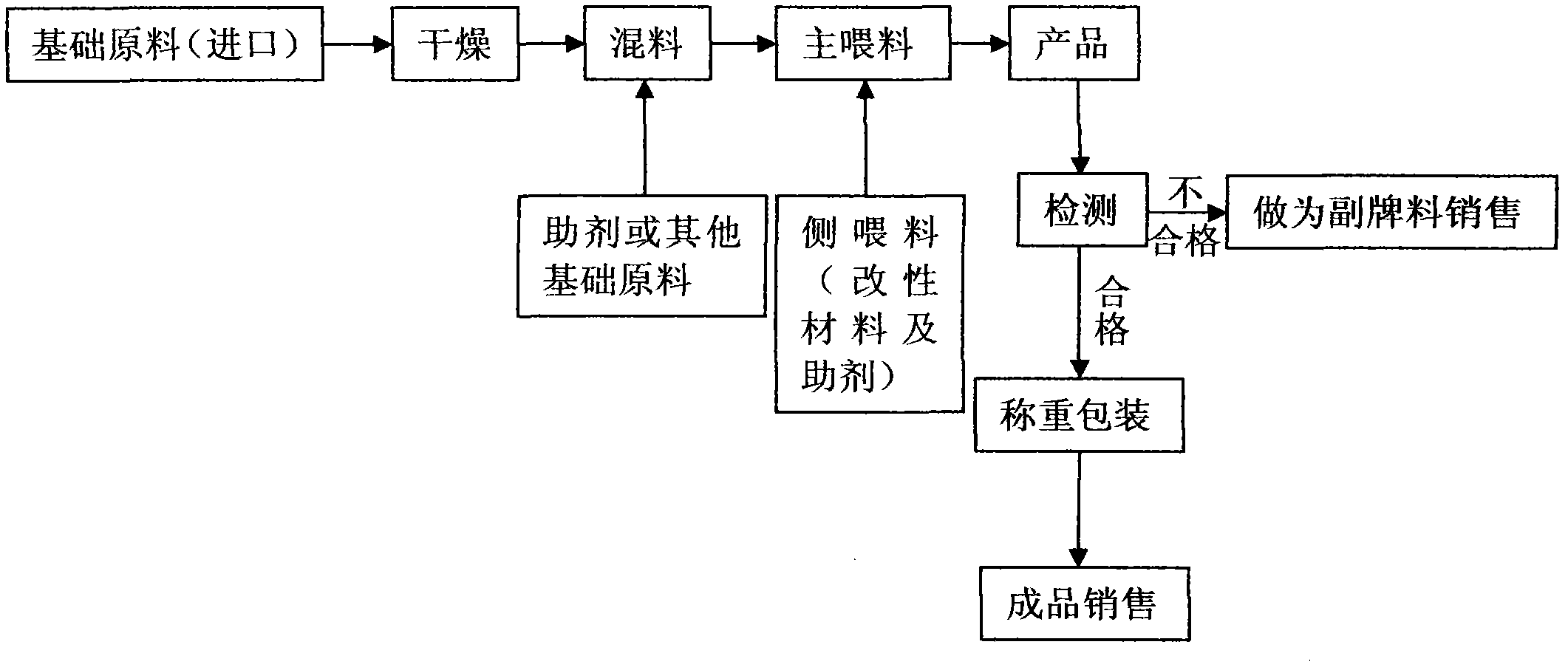

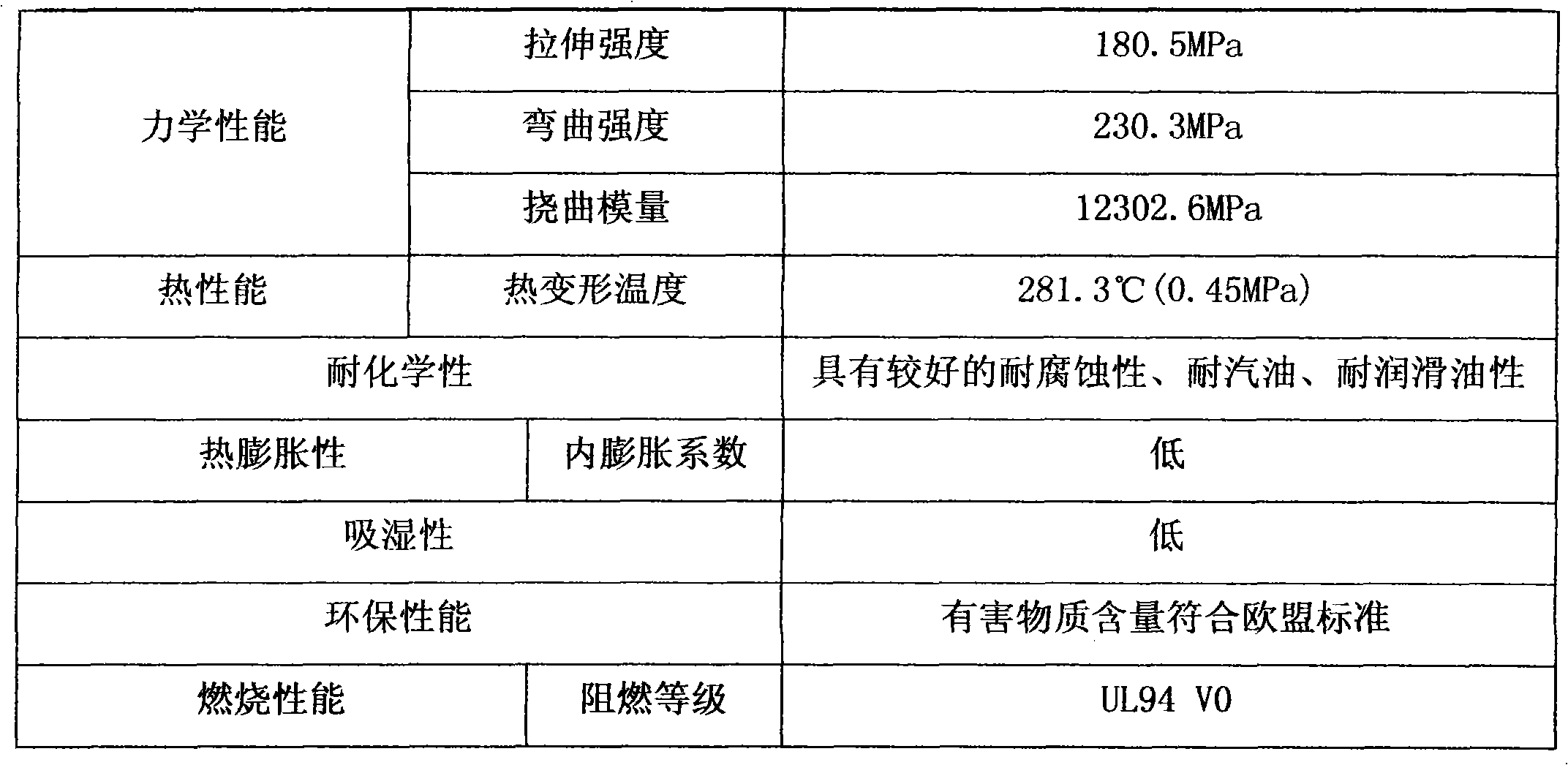

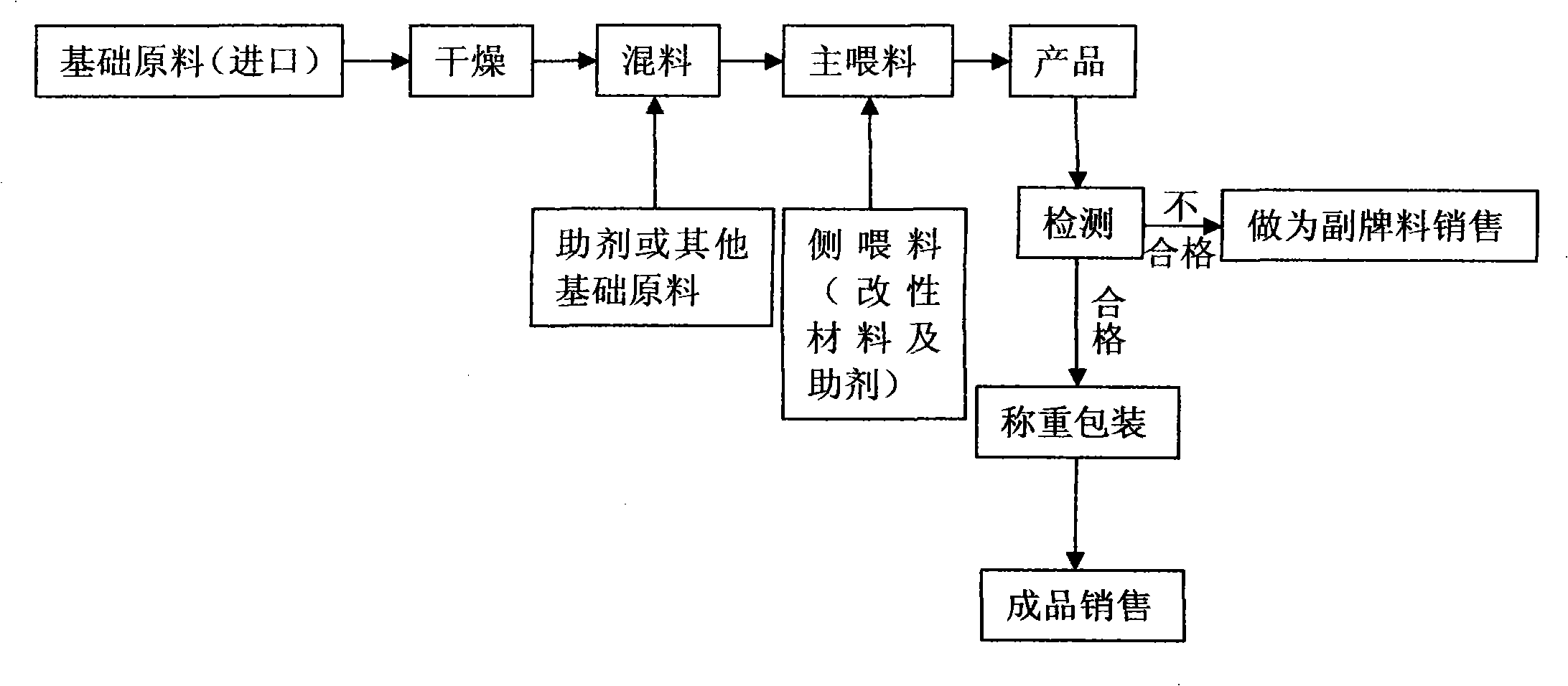

Environmentally-friendly white halogen-free reinforced flame-retardant high-temperature nylon and preparation process thereof

The invention relates to environmentally-friendly white halogen-free reinforced flame-retardant high-temperature nylon. The nylon comprises the following components in part by weight: 35 to 75 parts of high-temperature nylon resin, 4 to 25 parts of flame retardant, 0.1 to 0.5 part of auxiliary agent and 10 to 50 parts of reinforced material. The preparation method for the nylon comprises the following steps of: 1) drying; 2) mixing; 3) extruding; and 4) molding and pelletizing. The product has the advantages of high strength, high flame resistance, high size stability, high temperature resistance, environment friendliness and the like. An antioxidant can play a role in anti-oxidizing protecting, maintains the stability of materials of the product in production, and protects the flame retardant and the high-temperature nylon resin from oxidative discoloration and decomposition; and a nucleating agent and a lubricating agent can improve the fluidity of the product, speed up the cooling and the forming of the product, improve the production efficiency of the product in injection machining, and contribute to demoulding the products in the injection molding. The environmentally-friendly white halogen-free reinforced flame-retardant high-temperature nylon can be used in circuit breakers, socket connectors such as power connectors, storage card connectors and sockets, motor components, computers and auxiliary equipment thereof, electric products, household electric appliance and the like.

Owner:QINGDAO COMPOLY HIGH PERFORMANCE POLYMERS

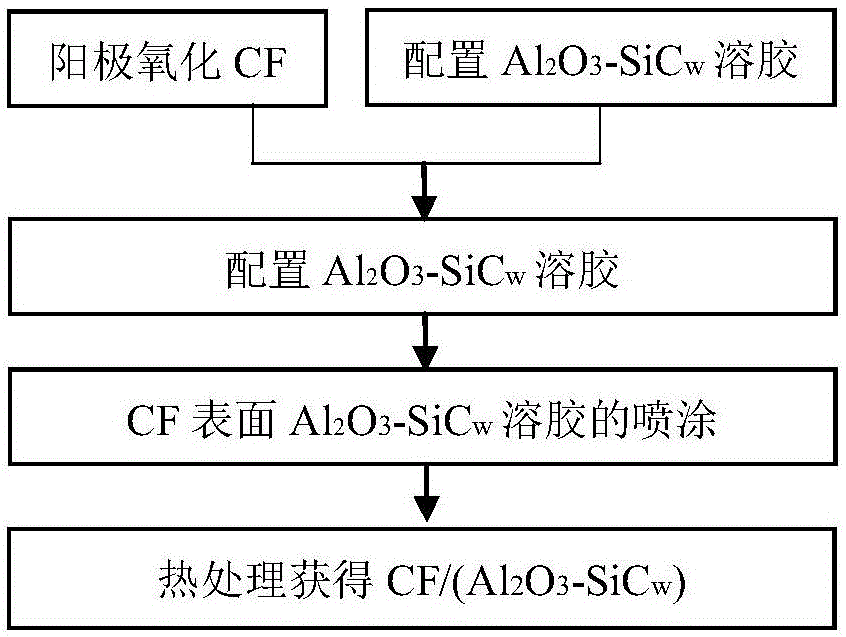

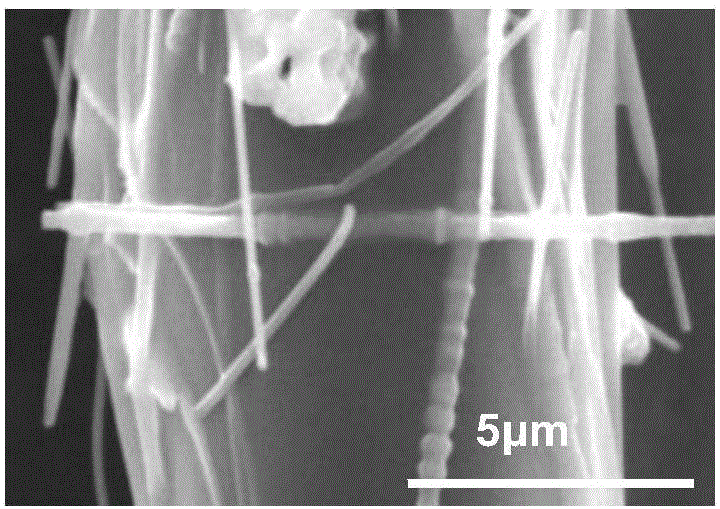

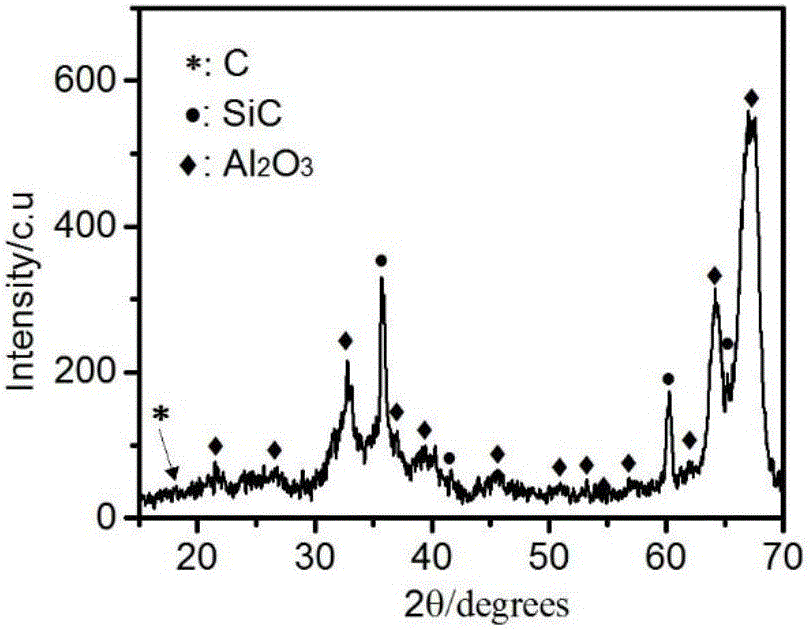

Method for spraying aluminum oxide-silicon carbide whisker anti-oxidation coating on surface of carbon fiber

ActiveCN107523825AGood lookingAccurate ingredientsLiquid/gas/vapor removalTextile treatment by spraying/projectingFiberCarbon fibers

The invention discloses a method for spraying an aluminum oxide-silicon carbide whisker anti-oxidation coating on the surface of a carbon fiber (CF). The method comprises the three steps of CF pretreatment and preparation of Al2O3-SiCw sol, spraying of the Al2O3-SiCw sol on the surface of the CF and heat treatment of the Al2O3-SiCw coating on the surface of the CF. The Al2O3-SiCw (aluminum oxide-silicon carbide whisker) anti-oxidation coating is prepared on the surface of the CF through a sol spraying method, the anti-oxidation performance of the CF under the aerobic atmosphere is improved, and the certain research foundation is laid for preparing a CF / HA composite with the good mechanical performance.

Owner:SHAANXI UNIV OF SCI & TECH

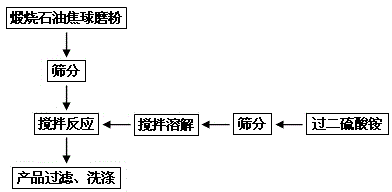

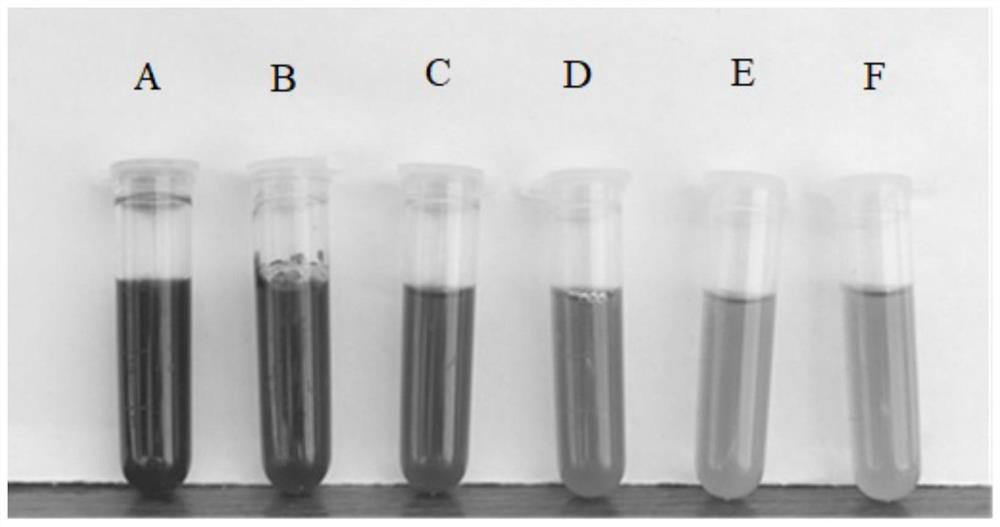

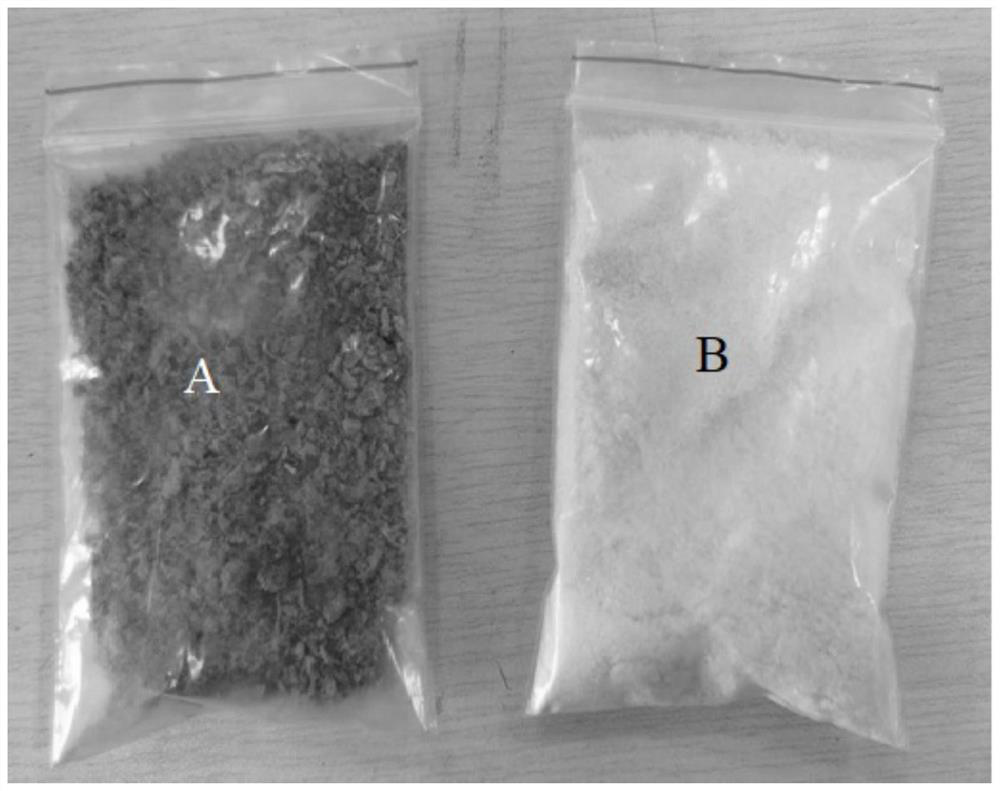

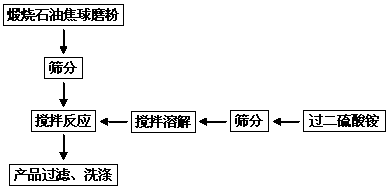

Method for preparing anode surface antioxidation protective agent used for carbon-base aluminum

ActiveCN106319570AIncreased Response Residual RateReduce the amount of diffusionInorganic saltsSoftened water

The invention relates to a method for preparing an anode surface antioxidation protective agent used for carbon-base aluminum. The method includes the steps that a raw material is screened, calcined petroleum coke ball-milled powder is selected as the carbon-base raw material, and ammonium peroxydisulfate is used as a modifying agent; industrial softened water is used for dissolving the ammonium peroxydisulfate at first so that a solution can be obtained, and then the carbon-base raw material screened in advance is added into the solution; an oxidation modified reaction is carried out in an electric heating reactor with a stirring function at the temperature of 80-100 DEG C; and the industrial softened water is used for washing residual inorganic salt ions after the reaction is completed, and thus a carbon-base antioxidation protective agent product can be obtained. The method has the advantages and effects that depositions are directly coated to be attached to the surfaces of anode carbon blocks, the air reaction residual rate of anode products can be increased by 3%-4%, and anode net consumption is effectively reduced.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Mild decolorization method of abelmoschus manihot polysaccharide

ActiveCN112694541AHigh decolorization ratePrevent oxidationEthylene diamine tetra aceticEthylene diamine

The invention discloses a mild decolorization method of abelmoschus manihot polysaccharide. The method comprises the following steps of S1, preparing abelmoschus manihot corolla powder, S2, preparing degreased abelmoschus manihot corolla powder, S3, preparing a preservation solution, S4, judging whether a protein absorption peak exists or not, S5, preparing crude polysaccharide powder, S6, preparing a polysaccharide concentrated solution, and S7, preparing decolorized abelmoschus manihot polysaccharide powder, and measuring the content of components of the abelmoschus manihot polysaccharide powder; The method has the beneficial effects that the corolla of the abelmoschus manihot is ground and crushed, washed and degreased by acetone and absolute ethyl alcohol, repeatedly extracted for multiple times, subjected to calcium chloride and pH control and dialyzed by a dialysis bag, so that protein is precipitated and separated from a polysaccharide solution, and finally, the disodium ethylene diamine tetraacetate and the exchange resin are combined, so that the structure of the polysaccharide is not damaged, the activity is not lost, the decolorization rate is improved, the loss rate of the polysaccharide is relatively low, and the utilization efficiency of the device is improved.

Owner:CHENGDU UNIV

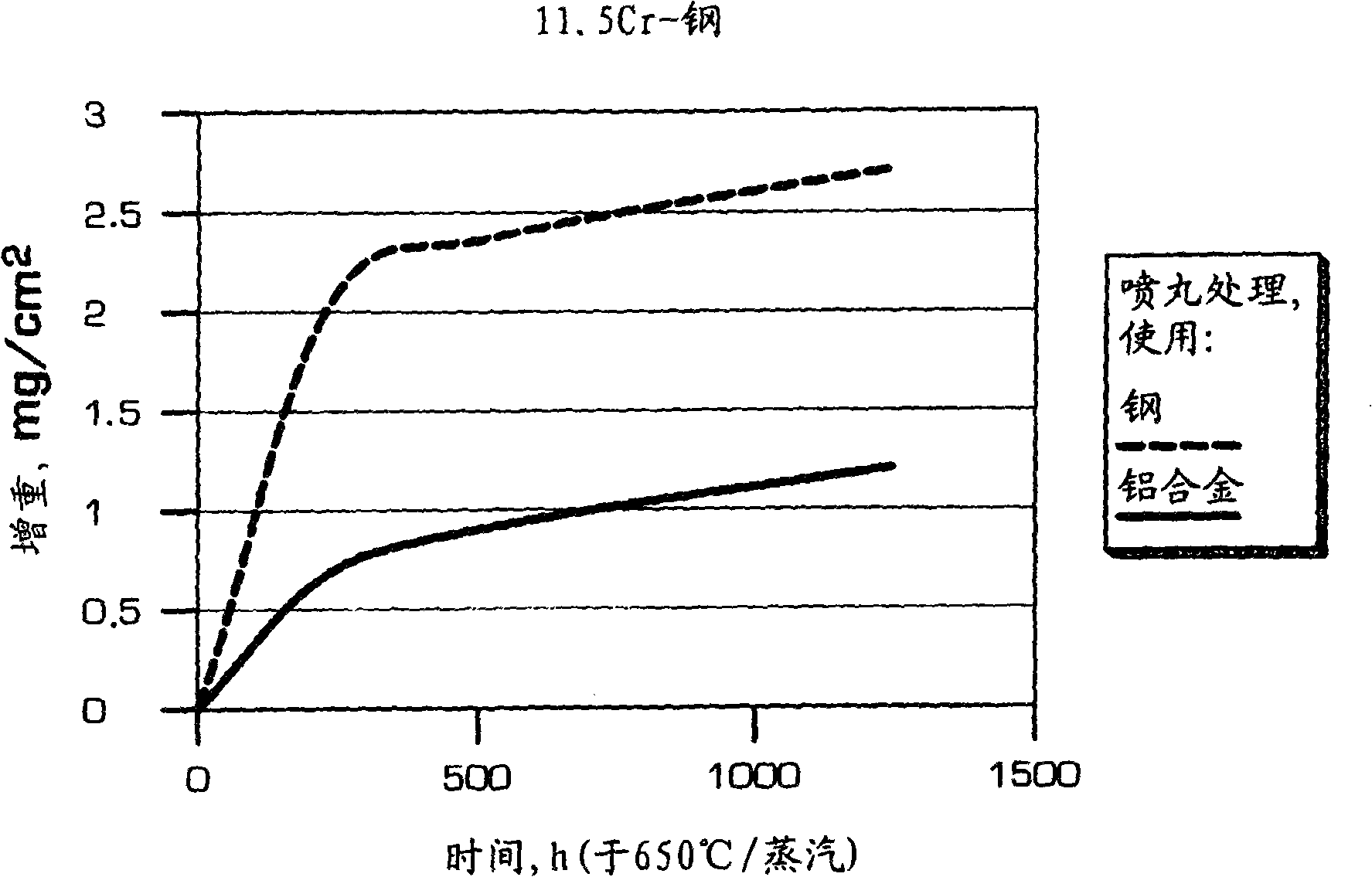

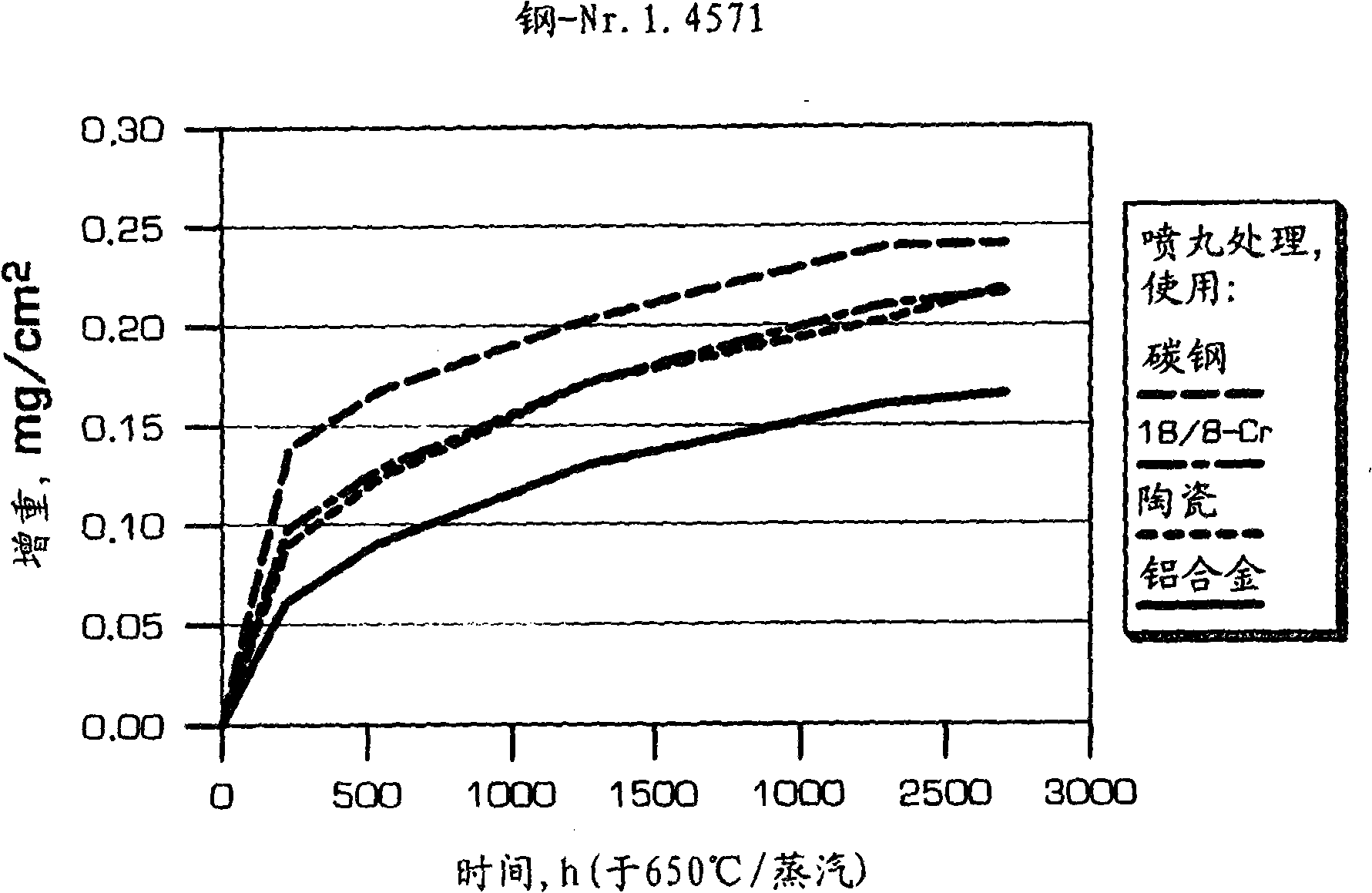

Method for surface treatment of Cr-steel

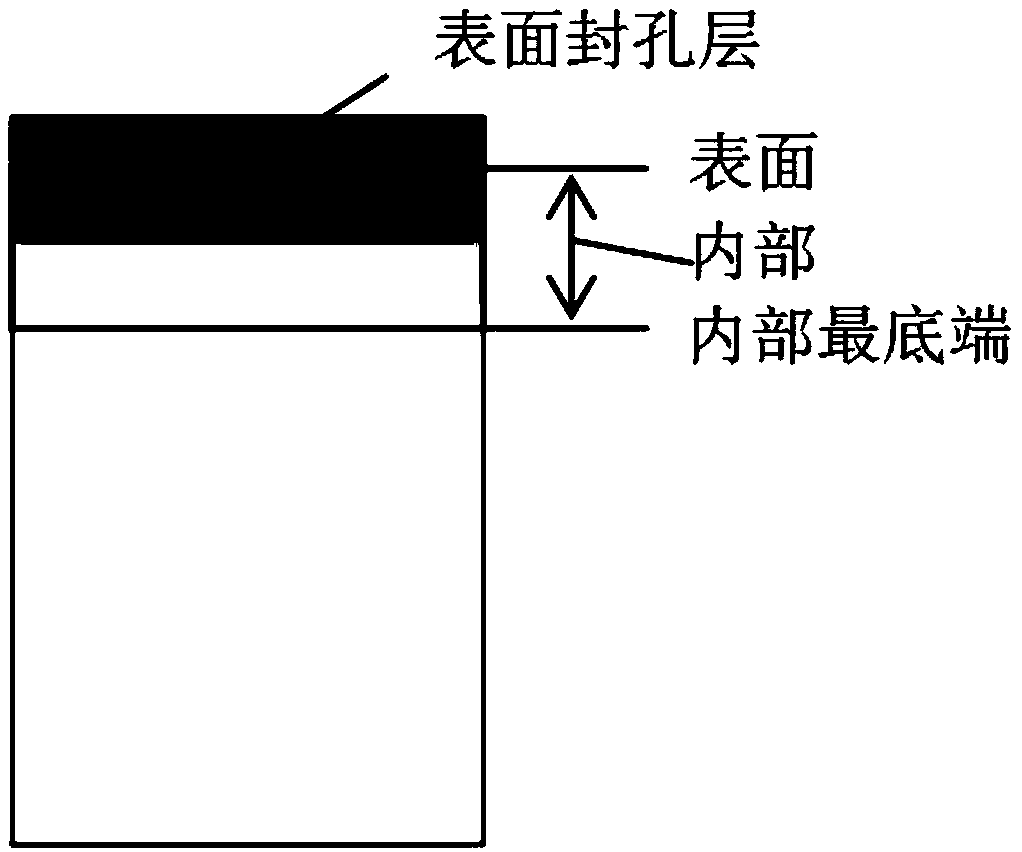

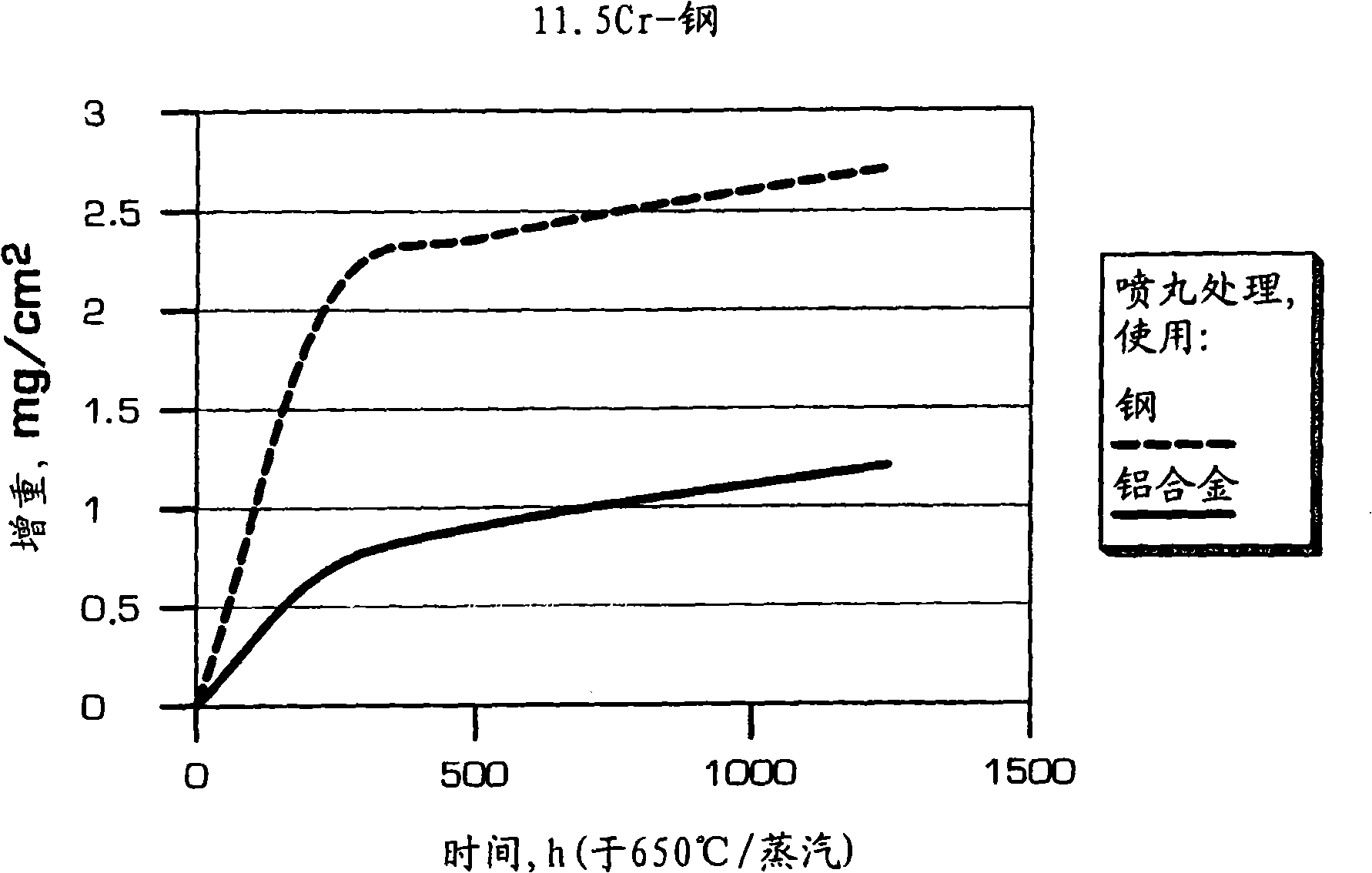

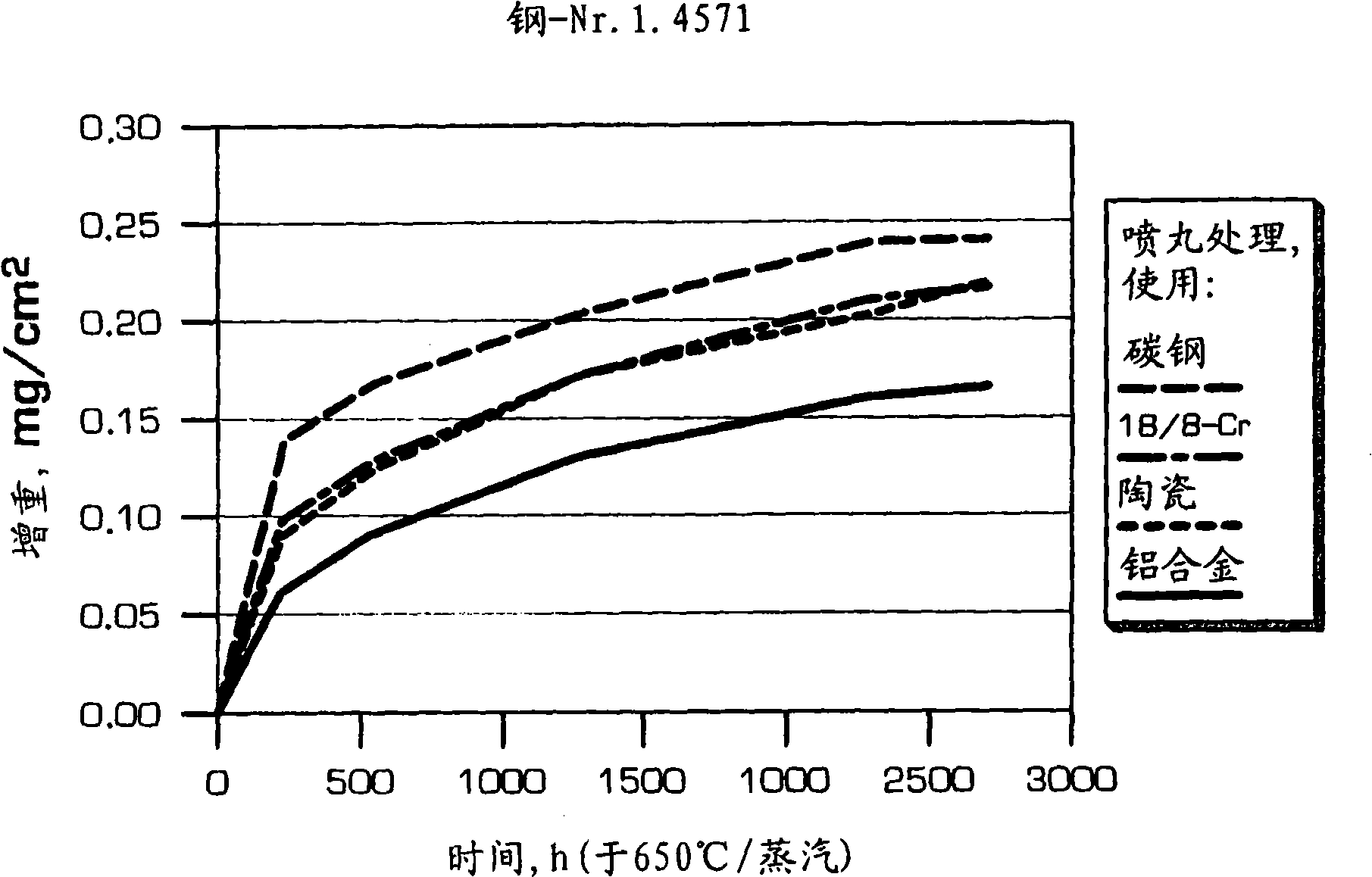

InactiveCN101328532AImprove antioxidant capacityLess weight gainBlade accessoriesMachines/enginesSolid particleMartensite

The invention relates to a chrome steel surface treatment method, especially a method for surface treatment of ferrite / martensite containing 9-12% of chrome steel and austenite chrome steel, in order to increase antioxidation and solid particle corrosion resistance in steam when the use temperature is above 500 DEG C, especially about 650 DEG C. The steel surface is subjected to shot blasting byaluminium particles or aluminium alloy pellets, wherein selectively the steel surface is flattened to the roughness less than 0.5 Mum, preferably less than 0.3 Mum in the next steps. The subsequentlyadditional hot treatment is not necessary and the treated chrome steel can be used, such as blade in steam turbine.

Owner:GENERAL ELECTRIC TECH GMBH

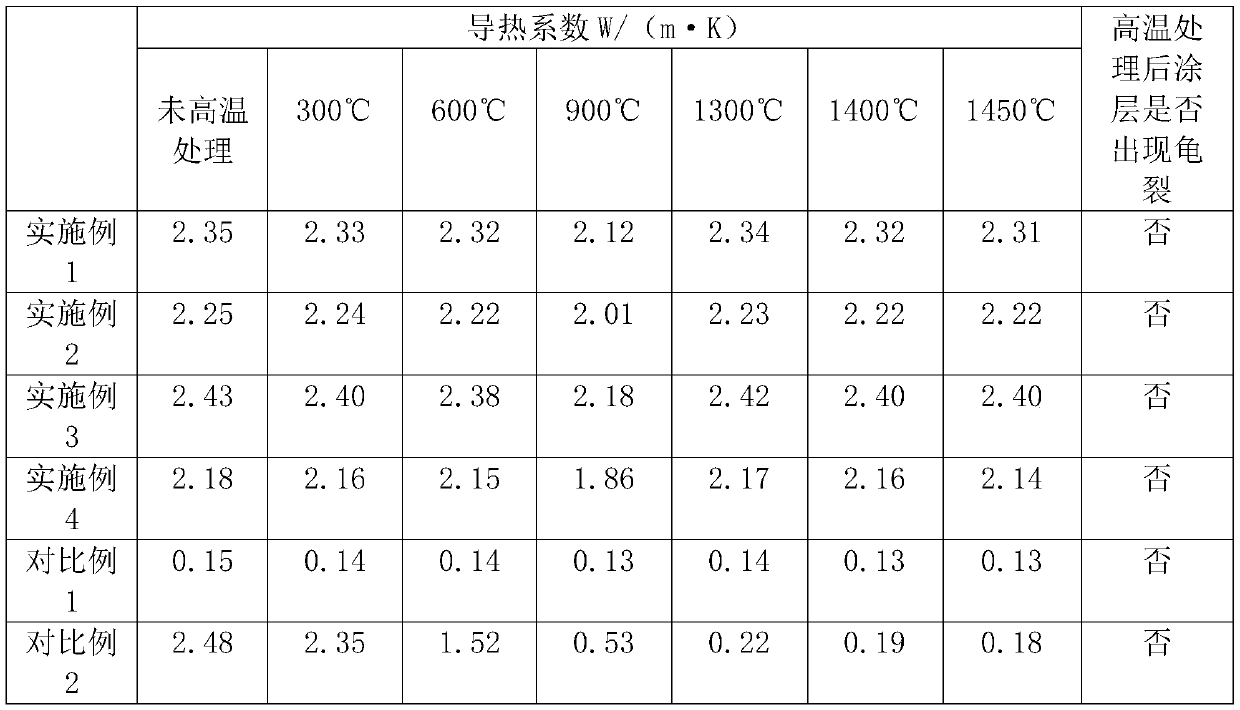

1300-1500 DEG C-resistant and low-density carbon tile surface anti-oxidation coating and production method thereof

ActiveCN106242643AExcellent high temperature heat insulation performanceSimple preparation processMetallurgyOxidation resistant

The invention relates to a 1300-1500 DEG C-resistant and low-density carbon tile surface anti-oxidation coating and a production method thereof, and especially relates to an anti-oxidation coating used for low-density carbon tiles, and a production method of the coating. The anti-oxidation coating is a composite system composed of Zr, Si, B, C and O, and is produced through brushing cracking and pre-oxidation technologies. The coating has the advantages of excellent high temperature resistance, excellent heat insulation performance, simple production process and short production period, and belongs to the technical field of heat protection materials. The 1300-1500 DEG C-resistant and low-density carbon tile surface anti-oxidation coating and the production method thereof are provided against demands of a novel near space aerocraft and reuse of a vehicle heat protection system for a high temperature-resistance, light-weighting and heat-insulation function integrated heat protection material. The coating is the composite system composed of Zr, Si, B, C and O, is produced through brushing cracking and pre-oxidation technologies and has the advantages of excellent high temperature resistance, excellent heat insulation performance, simple production process and short production period.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Artichoke polyphenol-chitosan nanoparticle starch gelatin composite film and preparation method and application thereof

InactiveCN108623851AImprove performanceSmall size effectFlexible coversWrappersChitosan nanoparticlesComposite film

The invention discloses an artichoke polyphenol-chitosan nanoparticle starch gelatin composite film and a preparation method and application thereof. Natural edible bio-macromolecular chitosan capableof forming a film and polyphosphates are used for firstly preparing artichoke polyphenol-chitosan-polyphosphate nanoparticles, and then, the nanoparticles are added into starch and gelatin to preparethe artichoke polyphenol-chitosan nanoparticle starch gelatin composite film. The edible film obtained by the invention has good film forming characteristics, has good barrier property and tensile strength, has anti-oxidative and anti-bacterial effects, can be applied to packaging of fruits, vegetables and the like, is an innovative edible film, and belongs to an innovative food packaging technology.

Owner:HUAQIAO UNIVERSITY

Proliferation culture medium for human skin fibroblasts and preparation method thereof

InactiveCN112391336AIncrease proliferative activityGuaranteed stabilityEpidermal cells/skin cellsCulture processApoptosisPancreatic hormone

The invention discloses a proliferation culture medium for human skin fibroblasts. The proliferation culture medium comprises a basal culture medium and an additive. The additive comprises the following raw materials of insulin, inositol hexaphosphate, germinated brown rice powder, feruloyl glycan, nano-zinc oxide, chitin and sodium selenite. The proliferation culture medium for the human skin fibroblasts is clear in components, free of exogenous serum and animal-derived protein and higher in safety. The inositol hexaphosphate and germinated brown rice powder in the additive are beneficial tomaintaining the proliferation stability of the human skin fibroblasts in the proliferation process and increasing the cell growth rate. The feruloyl glycan and nano-zinc oxide in the additive can improve the proliferation activity of the human skin fibroblasts and avoid cell apoptosis, so that the proliferation efficiency is improved. The chitin and sodium selenite are also added, so that an antioxidant protection effect on cells is achieved. The invention further provides a preparation method of the proliferation culture medium for the human skin fibroblasts. The preparation process is simpleand convenient, and commercialization is facilitated.

Owner:郑州佐爵生物科技有限公司

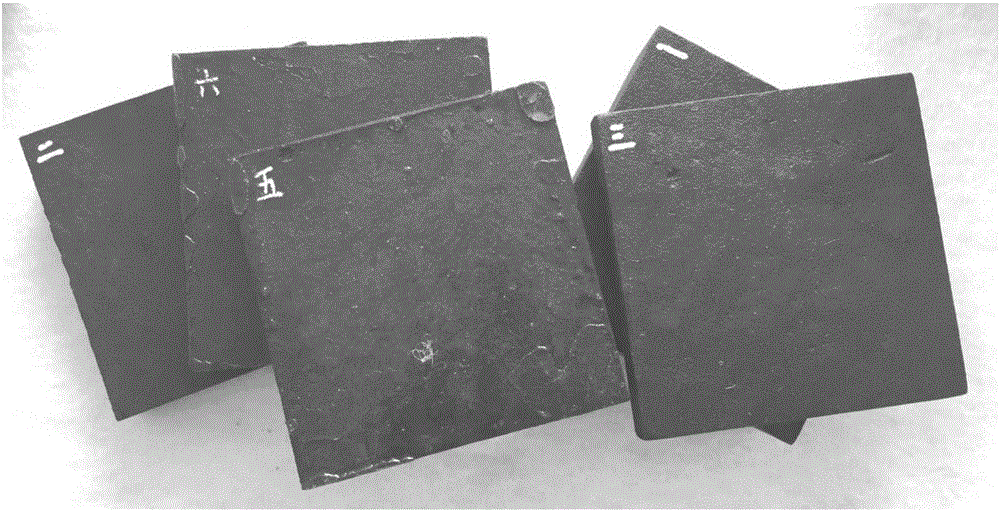

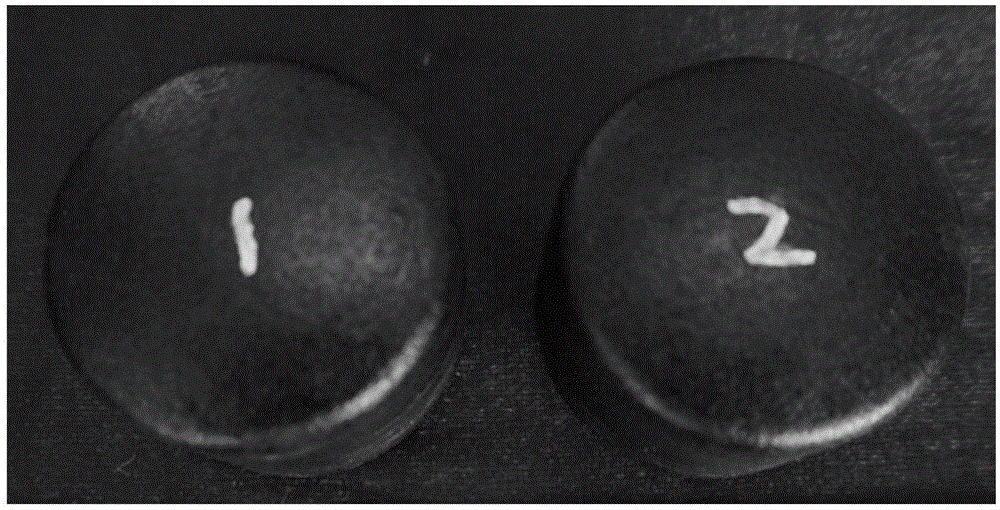

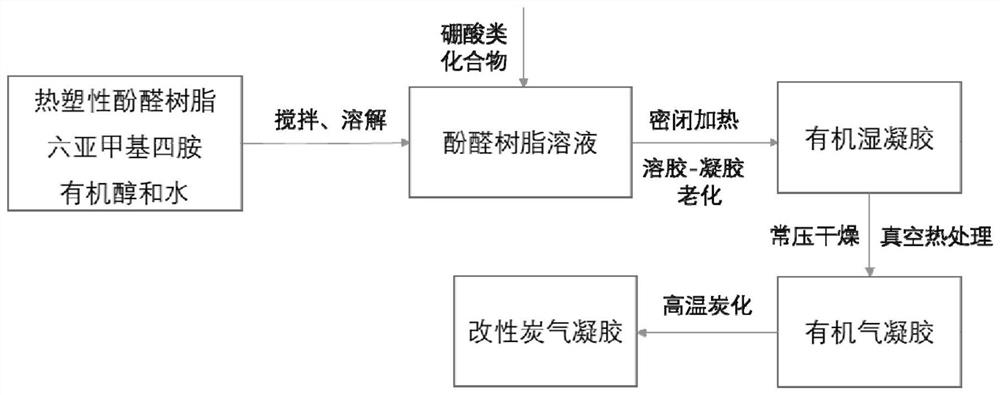

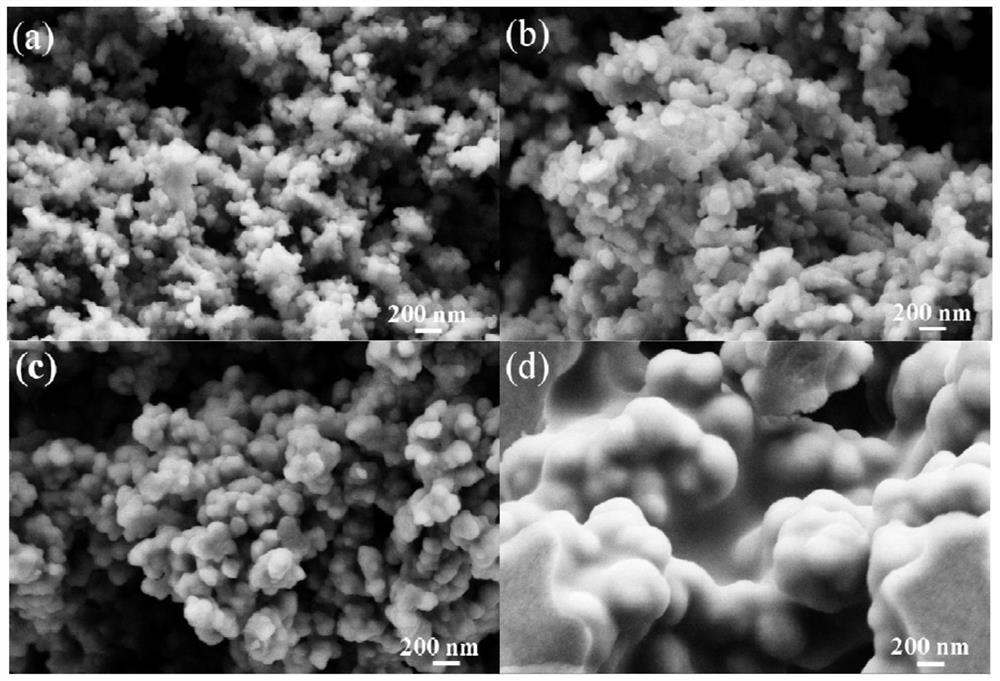

Modified carbon aerogel and its preparation method and application

ActiveCN110482525BComplete appearanceImprove antioxidant capacityCarbon preparation/purificationSupercritical dryingModified carbon

The invention provides a modified carbon aerogel, a preparation method and application thereof, and relates to the technical field of aerogel. The modified carbon aerogel of the present invention is mainly prepared from the following raw materials in parts by mass: 5-60 parts of thermoplastic phenolic resin, 1-20 parts of curing agent, 40-100 parts of solvent and 1-10 parts of boron-containing compound. The method effectively avoids conventional complex processes such as solvent replacement and supercritical drying, has simple preparation process, low cost, easy processing and shaping and later dimension cutting; at the same time, the prepared modified carbon aerogel has excellent anti-oxidation performance, It has certain application prospects in the field of industrial thermal insulation and thermal protection in aerospace.

Owner:TANGSHAN NORMAL UNIV

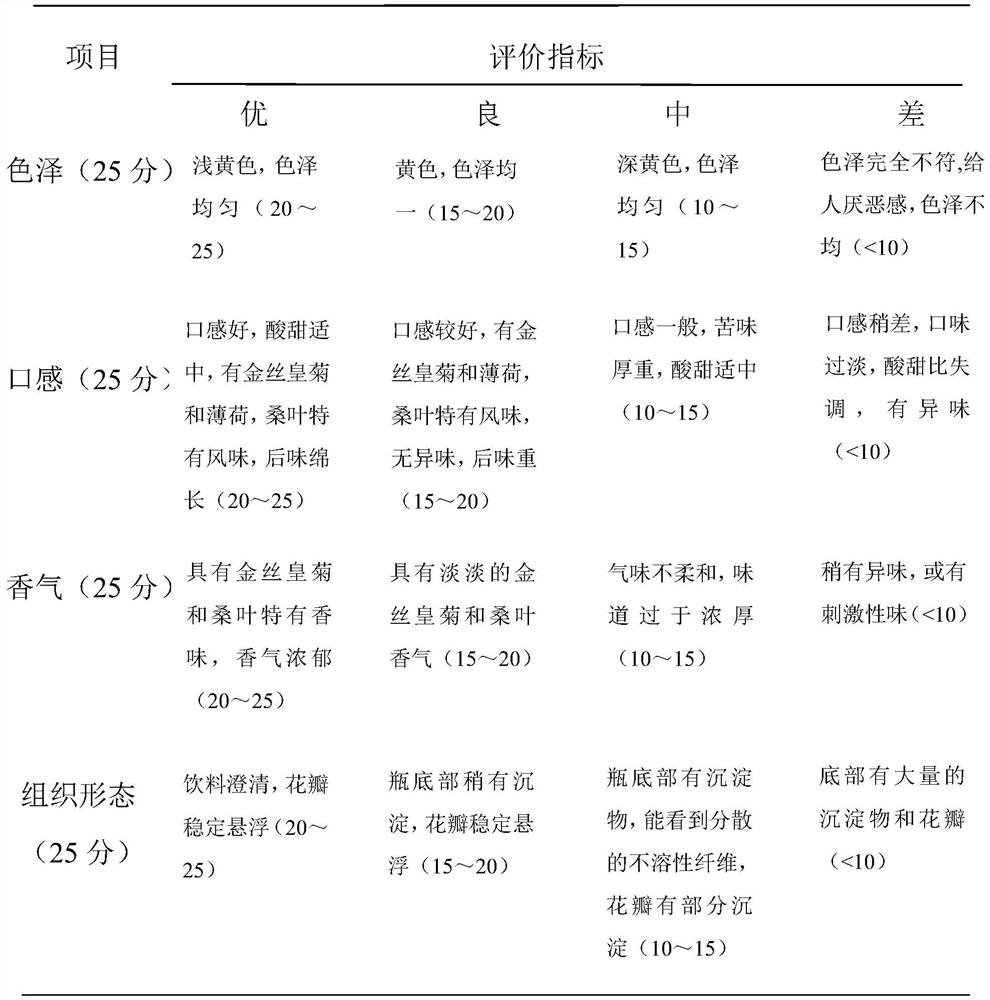

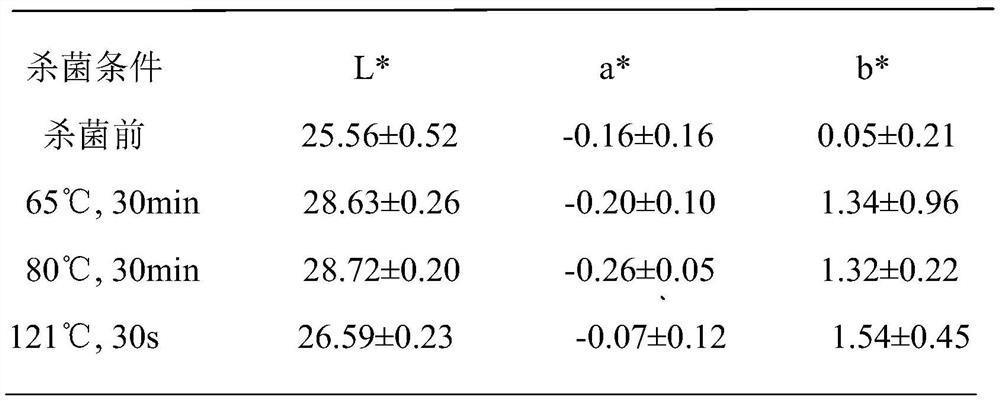

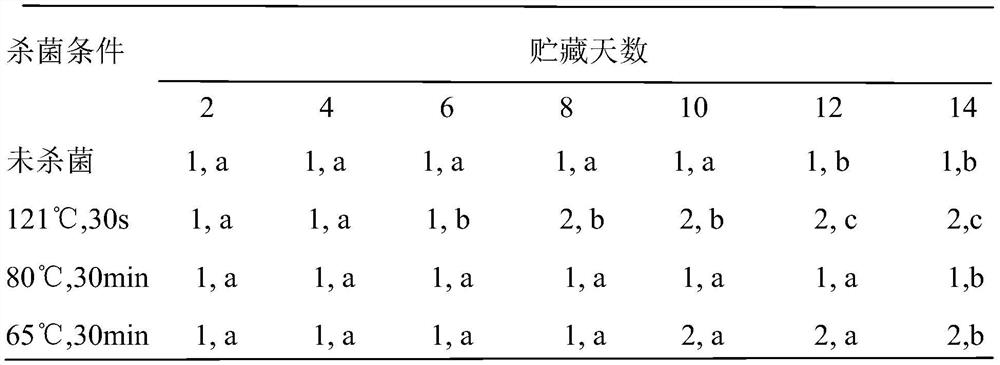

Dendranthema morifolium compounded suspension beverage and preparation method therefor

PendingCN112205550AAchieve eye-catching effectIt can calm the liver and improve eyesightNatural extract food ingredientsFood ingredient functionsBiotechnologyCarrageenan

The invention discloses a dendranthema morifolium compounded suspension beverage and a preparation method therefor. The dendranthema morifolium compounded suspension beverage comprises the following ingredients in parts by mass: 45-55 parts of dendranthema morifolium lixiviate, 4-6 parts of herba menthae lixiviate, 18-23 parts of mulberry leaf lixiviate, 4-6 parts of cassia seed lixiviate, 1-2 parts of dendranthema morifolium petals, 2-4 parts of sweetener, 0.03-0.06 part of vitamin C, 0.02-0.04 part of xanthophyll and 0.47-0.66 part of suspension stabilizer, wherein the suspension stabilizercomprises Gellan gum, carrageenan, sodium citrate, citric acid and calcium chloride. Dendranthema morifolium has the effects of calming the liver to improve eyesight and clearing away heat and toxic materials, mulberry leaves have the actions of calming the liver to improve eyesight and dispelling wind and heat from the body, herba menthae has the effects of soothing liver and regulating Qi, and cassia seeds have the action of reducing fact to improve eyesight, so that the compound beverage can better achieve the effect of improving eyesight from source.

Owner:HUNAN KANGDEJIA FORESTRY TECH CO LTD +1

Water-soluble fullerene nanomaterial and its preparation method and anti-oxidation application

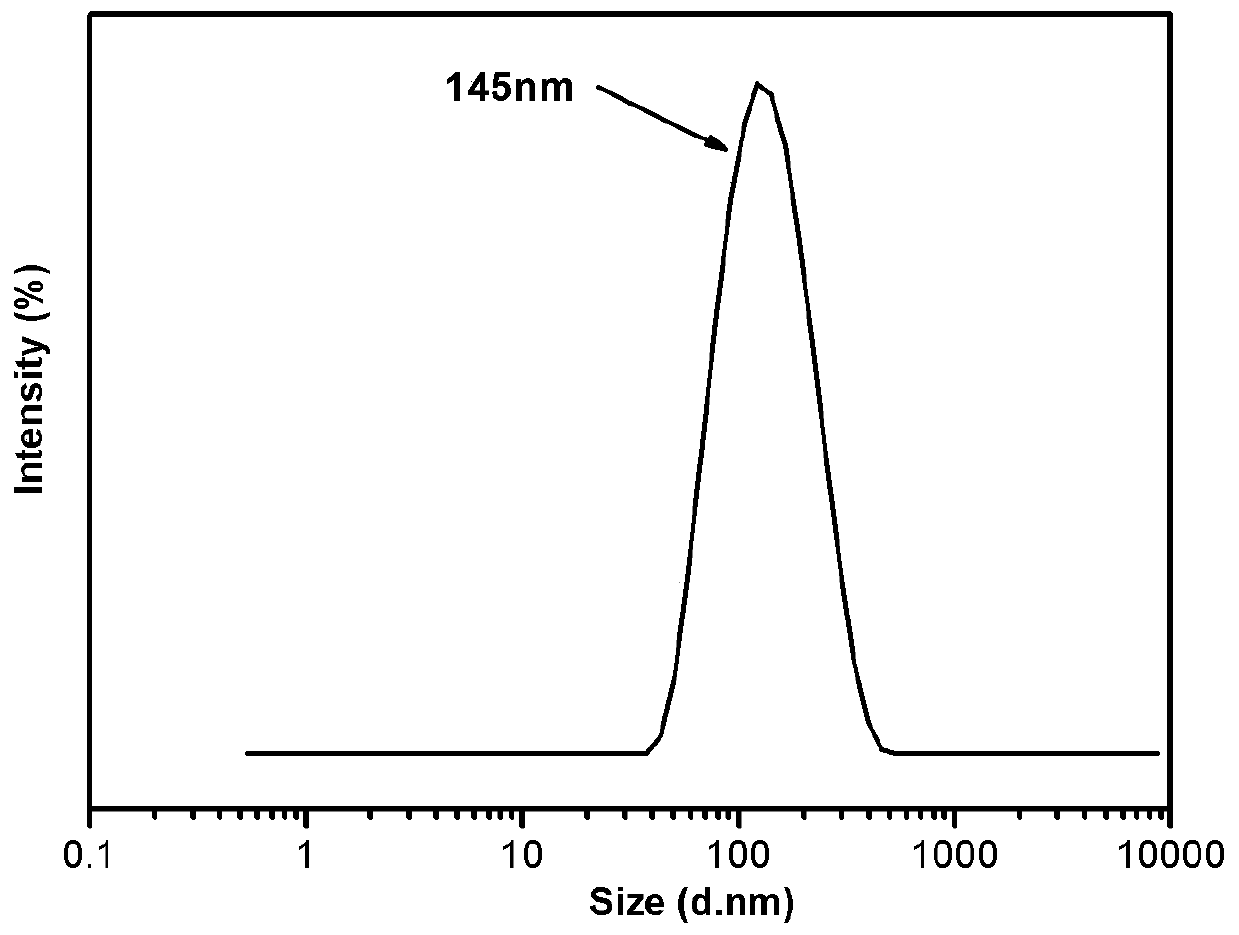

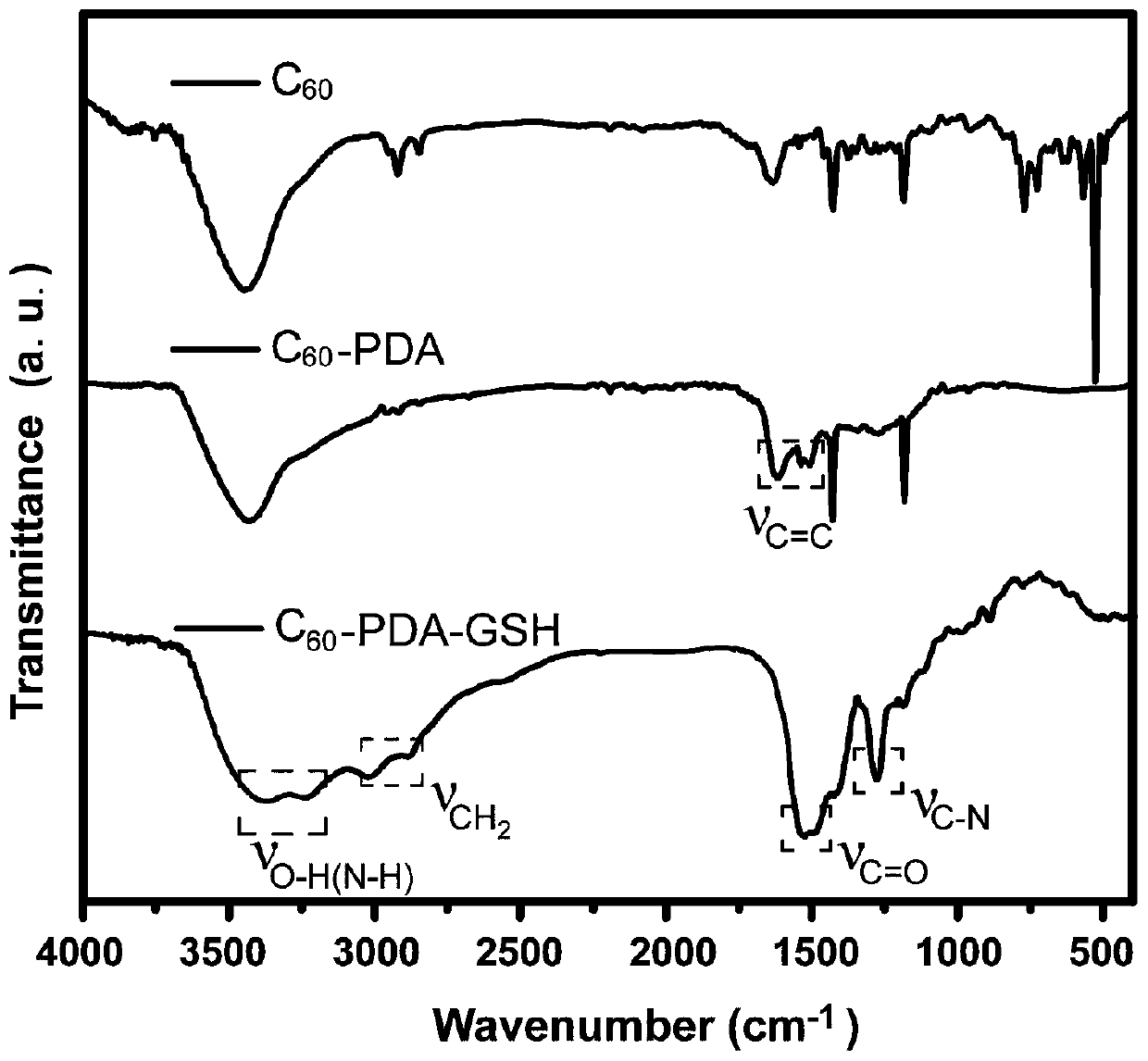

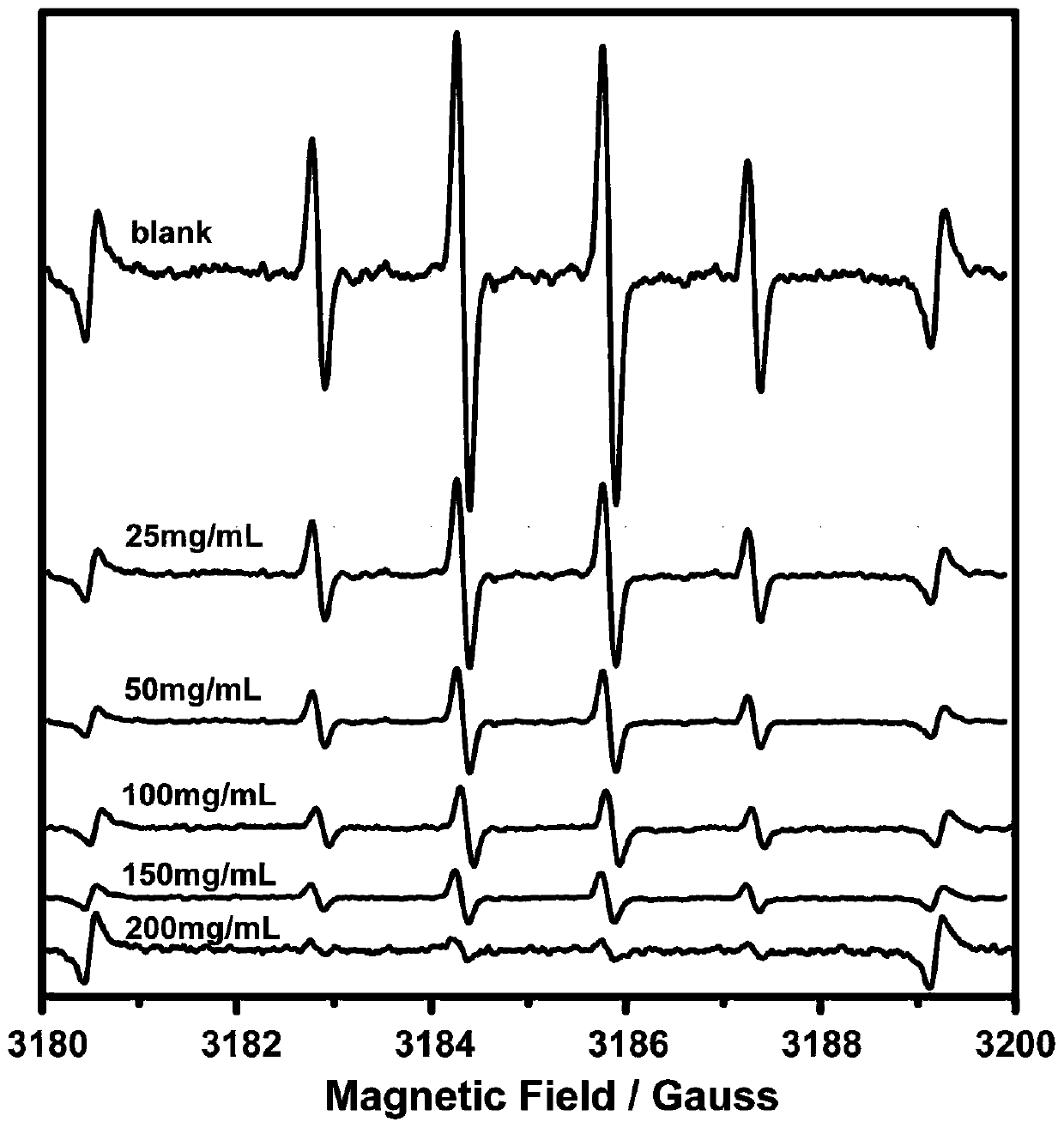

InactiveCN108079019BImprove solubilityImprove performanceCosmetic preparationsToilet preparationsAqueous solubilityAqueous solution

The invention discloses a water-soluble fullerene nano material. The water-soluble fullerene material is a fullerene C60-polydopamine-glutathione compound and is characterized in that fullerene and adopamine alkaline aqueous solution are subjected to mixing reaction directly to obtain a fullerene modified material of which the surface is attached with a polydopamine crosslinking composite layer,and the obtained fullerene modified material and water-soluble polypeptide glutathione with sulfhydryl radicals are subjected to Michael addition to obtain a water-soluble product. The invention alsodiscloses a preparation method and anti-oxidation application of the water-soluble fullerene nano material. The water-soluble fullerene nano material disclosed by the invention has good biocompatibility, good physical and chemical stability and mild and controllable preparation conditions; and as a scavenging agent and an antioxidant for free radicals in vivo, the water-soluble fullerene nano material shows very high potential values in the application fields of biomedicine and cosmetics.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

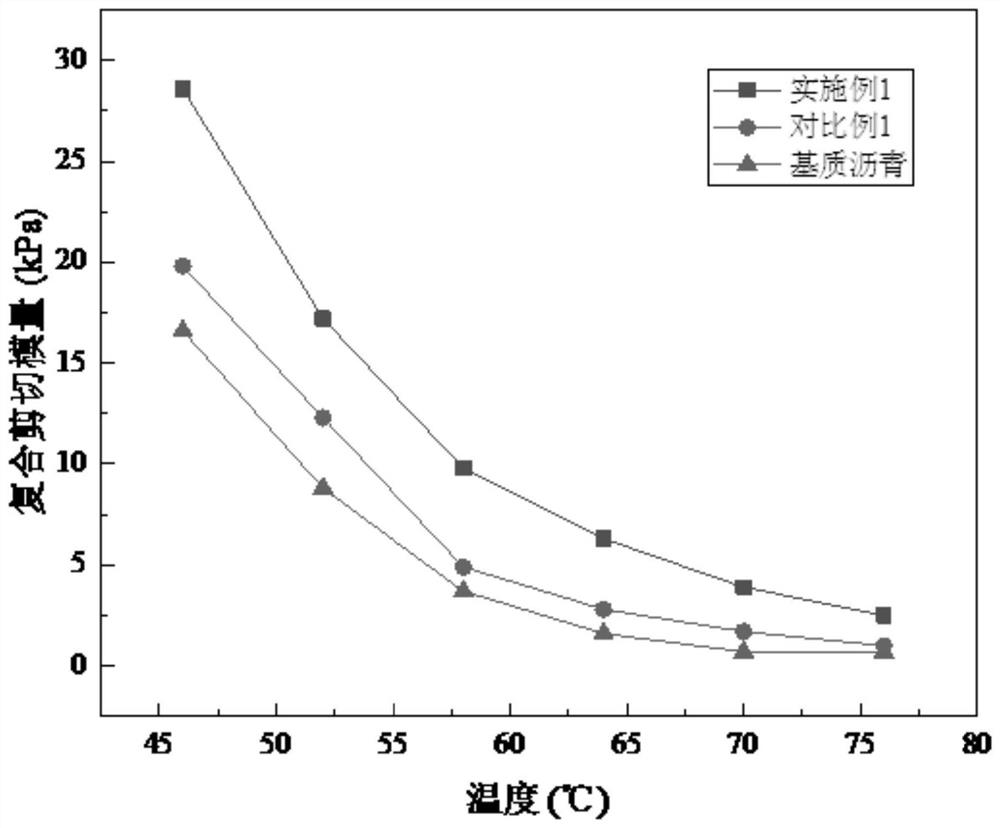

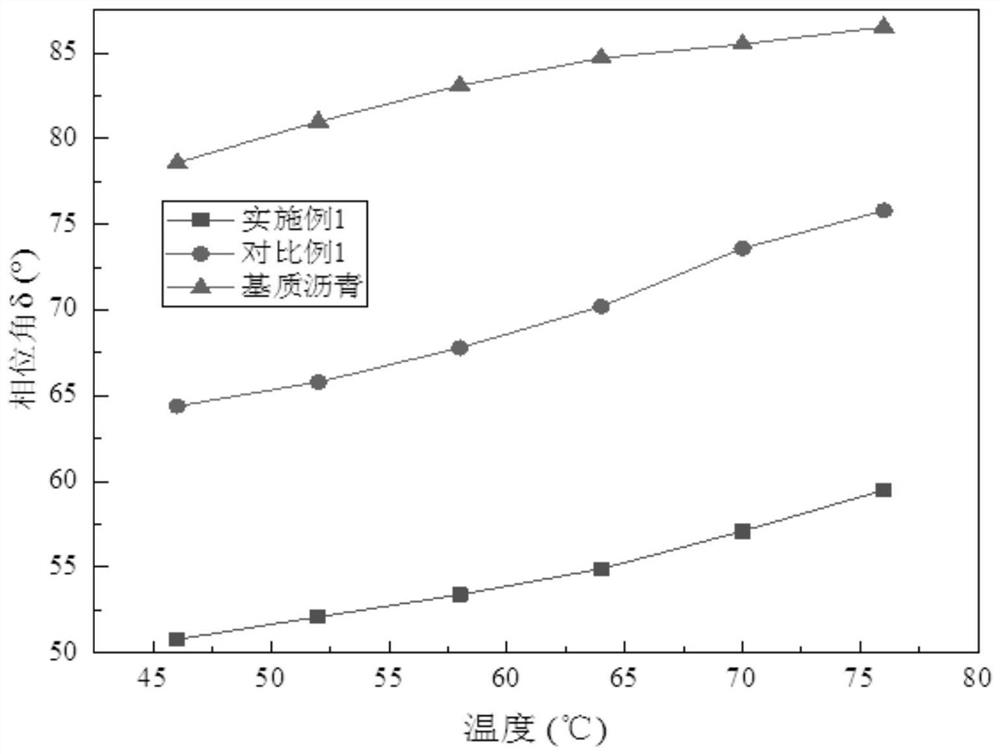

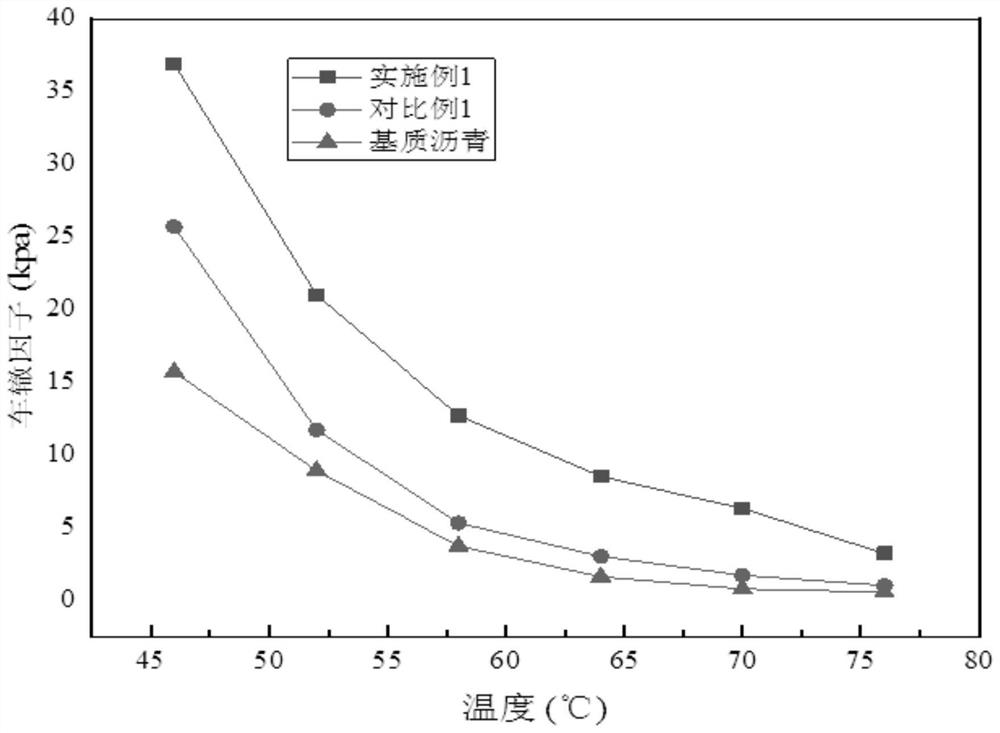

Preparation method of desulfurized rubber modified asphalt

ActiveCN114479496AProvides antioxidant protectionProtection against thermo-oxidative agingPlastic recyclingBuilding insulationsPolymer scienceStearic acid

The invention provides a preparation method of desulfurized rubber modified asphalt, which comprises the following steps: adding rare earth stearate, an activator, heavy oil and stearic acid into waste tire rubber powder, uniformly stirring and mixing, and standing at 155-165 DEG C for 1 hour; carrying out melt extrusion on the mixture in a conical twin-screw extruder, and granulating the extrudate to obtain desulfurized rubber particles; the preparation method comprises the following steps: adding matrix asphalt into a reaction tank, heating to completely melt the matrix asphalt, then adding desulfurized rubber particles, controlling the mass ratio of the desulfurized rubber particles to the matrix asphalt to be (0.2-0.8): 1, stirring at a low speed, then shearing at a high speed to uniformly disperse the desulfurized rubber particles in the matrix asphalt, finally stirring at a low speed, cooling to 165 DEG C, and keeping the constant temperature for 30 minutes to obtain the desulfurized rubber modified asphalt. The desulfurized rubber modified asphalt is obtained. According to the invention, the aging resistance and shear deformation resistance of the modified asphalt can be improved, and the high-temperature stability of the desulfurized rubber asphalt is obviously improved.

Owner:TIANJIN CHENGJIAN UNIV

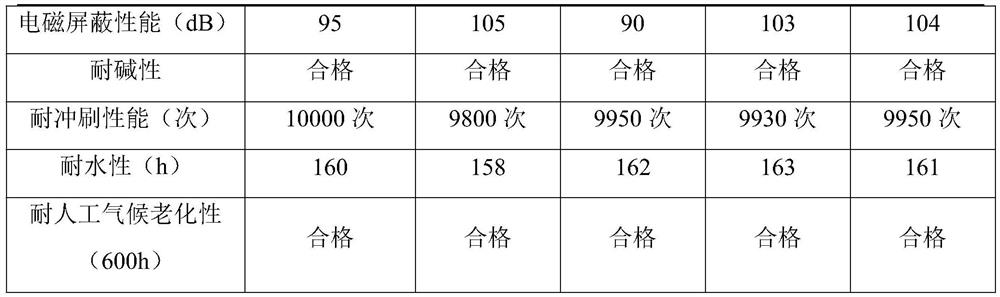

Inorganic anti-radiation building coating and preparation method thereof

ActiveCN112625477AImprove permeabilityExcellent inorganic bonding performanceFireproof paintsAlkali metal silicate coatingsWeather resistanceAluminium hydroxide

The invention discloses an inorganic anti-radiation building coating and a preparation method thereof. The inorganic anti-radiation building coating comprises the following components in parts by weight: 55-60 parts of hydrophobic silica sol, 8-10 parts of sepiolite, 10-13 parts of wollastonite, 7-10 parts of aluminum hydroxide, 5-10 parts of a microwave absorbent, 5-8 parts of an inorganic mineral pigment, 10-15 parts of a filler, 0.1-0.3 part of a dispersant and 0.5-1 part of an additive. The building coating disclosed by the invention has excellent stability, weather resistance, high temperature resistance, good adhesion to a base material and excellent electromagnetic shielding performance.

Owner:深圳力效新材料科技有限公司

Graphite-based water-based heat-conducting silicate coating and preparation method thereof

InactiveCN111378306AImprove heat resistanceImprove high temperature resistanceAlkali metal silicate coatingsPhysical chemistryGraphite

The invention relates to the technical field of coatings, and discloses a graphite-based water-based heat-conducting silicate coating and a preparation method thereof. The coating is prepared from thefollowing components in parts by weight: 60 to 80 parts of a film forming matter, 15 to 20 parts of quartz sand, 10 to 15 parts of dolomite, 5 to 10 parts of modified graphite, 1 to 3 parts of pigment, 0.5 to 1 part of a defoaming agent, 0.5 to 1 part of a dispersing agent and 30 to 50 parts of water. The brake pad is good in wear resistance and heat resistance and stable in friction coefficient;the preparation method of the coating comprises the following steps: firstly, adding a film-forming substance, quartz sand, dolomite, a defoaming agent and water into a stirring kettle and stirring for 30 to 50min at a stirring speed of 400 to 500r / min; and then adding the modified graphite, the pigment and the dispersing agent into the premix, and continuing to stir for 20-30 minutes at the stirring speed of 600-800r / min so as to obtain the high-temperature-resistant and high-pressure-resistant coating. The silicate heat-conducting coating disclosed by the invention has excellent high-temperature resistance and heat-conducting and heat-dissipating properties.

Owner:段尚军

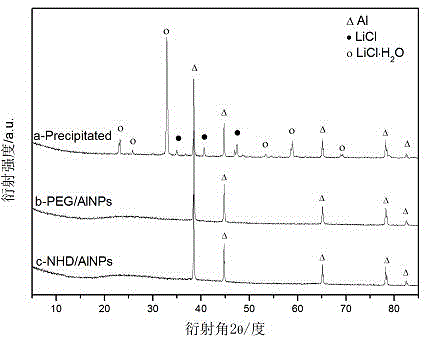

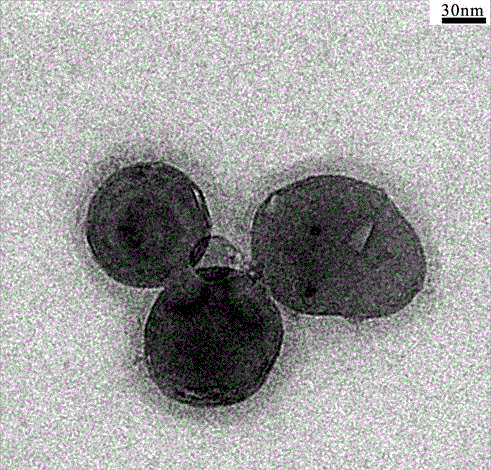

Method for preparing aluminum nanoparticles coated with dispersion stabilizers by liquid-phase chemical reduction method

InactiveCN103056388BAvoid reunionProvides antioxidant protectionNanotechnologyDispersityAluminium chloride

The invention discloses a method for preparing aluminum nanoparticles coated with dispersion stabilizers by a liquid-phase chemical reduction method. The method is characterized by including: purifying commercially available mesitylene; dispersing aluminum chloride in the mesitylene; and in the presence of nitrogen, adding polyethylene glycol or polyethylene glycol dimethyl ether serving as the dispersion stabilizer and lithium aluminum hydride in the mesitylene dispersed with the aluminum chloride according to the mass ratio of 1-2.5:0.5-1:0.5-1 among the aluminum chloride, the lithium aluminum hydride and the dispersion stabilizer, stirring for reacting 12-24 hours at the temperature of 164-166 DEG C, cooling, performing centrifugal separation, abandoning supernatant liquid, removing residual mesitylene solvents, washing by low-temperature methyl alcohol, performing ultrasonic washing and centrifugal separation, abandoning supernatant liquid and performing vacuum drying for lower materials so that the aluminum nanoparticles coated with the dispersion stabilizers are obtained. The prepared aluminum nanoparticles coated with the dispersion stabilizers are uniform in size and good in dispersity, have certain activity and are applicable to the fields of rocket propellants, explosives and powders, solar back plates and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A main power line lead-out structure of an energy storage sodium-sulfur battery module

ActiveCN103647113BOffset displacementEliminate the effects ofCurrent conducting connectionsSecondary cellsSulfurThermal expansion

The invention discloses a main power supply wire extraction structure of an energy-storage sodium-sulfur battery module. The main power supply wire extraction structure comprises a linear aluminum bar, a convex-concave button, a flexible conducting wire and an F-shaped aluminum bar which is formed by stamping an aluminum plate in one step and bending the aluminum plate on multiple positions, wherein the tail end of the F-shaped aluminum bar is also bent, and the extension end of all bending positions including the bending position on the tail end are respectively connected with lugs of sodium-sulfur batteries one by one; the first end of the linear aluminum bar is connected with the bending position on the tail end of the F-shaped aluminum bar, the second end of the linear aluminum bar penetrates through a heat preserving box to be led out of a heat preserving box body and is connected with a fuse through the flexible conducting wire; the second end of the linear aluminum bar penetrates through the convex-concave button and fixed on a shell of the heat preserving box body through the convex-concave button. By adopting the main power supply wire extraction structure, the safety passing of large current can be guaranteed, the influence of the hot expansion and cold shrinkage of the metal in a temperature variation process on the internal battery and external devices can be reduced, and the loss of the internal heat can be prevented to a certain extent.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

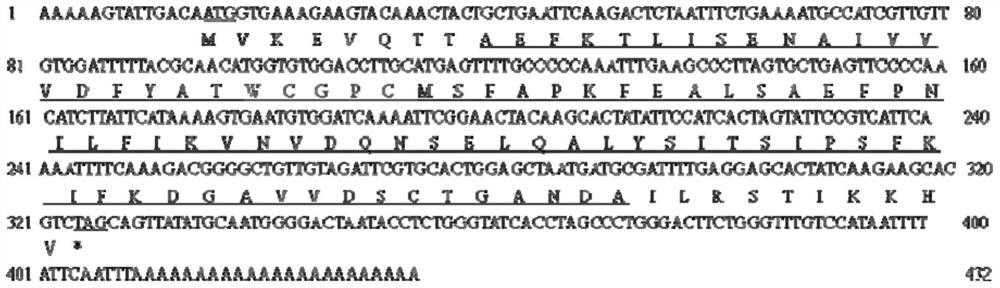

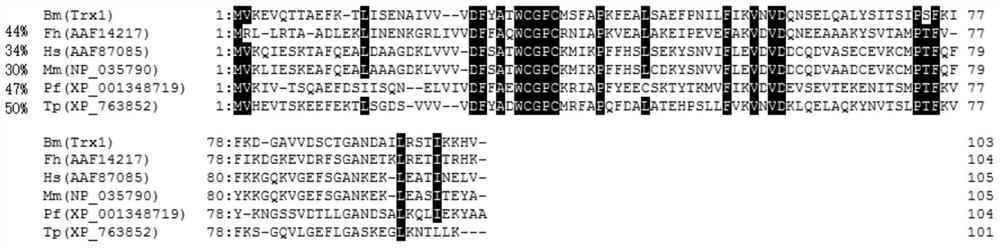

Babesia microti thioredoxin molecule and its gene and application

ActiveCN107602684BProvides antioxidant protectionPeptide/protein ingredientsSerum immunoglobulinsBABESIA MICROTIPharmaceutical drug

The invention discloses an amino acid sequence of a Babesia microti thioredoxin molecule. The invention also discloses a Babesia microti thioredoxin molecule gene which comprises a nucleotide sequencefor coding an amino acid sequence as shown in SEQ ID NO.1. The Babesia microti thioredoxin molecule disclosed by the invention has an oxidation-resistant protective action on cells, and is suitable for screening thioredoxin inhibitor drugs for treating Babesia.

Owner:SHANGHAI VETERINARY RES INST CHINESE ACAD OF AGRI SCI

Preparation method of liquid antibacterial mask

InactiveCN110179713ASolve the problem of poor anti-inflammatory effectProvides antioxidant protectionCosmetic preparationsToilet preparationsBLACK TEA EXTRACTInjury prevention

The invention belongs to the field of cosmetics, and particularly relates to a preparation method of a liquid antibacterial mask. The mask comprises the following raw materials in parts by mass: 10-20parts of hyaluronic acid, 10-15 parts of red juice orange extract, 5-10 parts of black tea extract, 5-7 parts of chitosan, 1-4 parts of fulvic acid, 4-6 parts of gellan gum, 10-12 parts of plant essential oil and 10-14 parts of distilled water. The mask solves the problem of a poor anti-inflammation effect of the existing mask and achieves a free radical removal effect to achieve an antioxidationprotection effect using the characteristics of repairability and injury prevention of hyaluronic acid, and the black tea extract and fulvic acid.

Owner:绍兴市高砚智生物科技有限公司

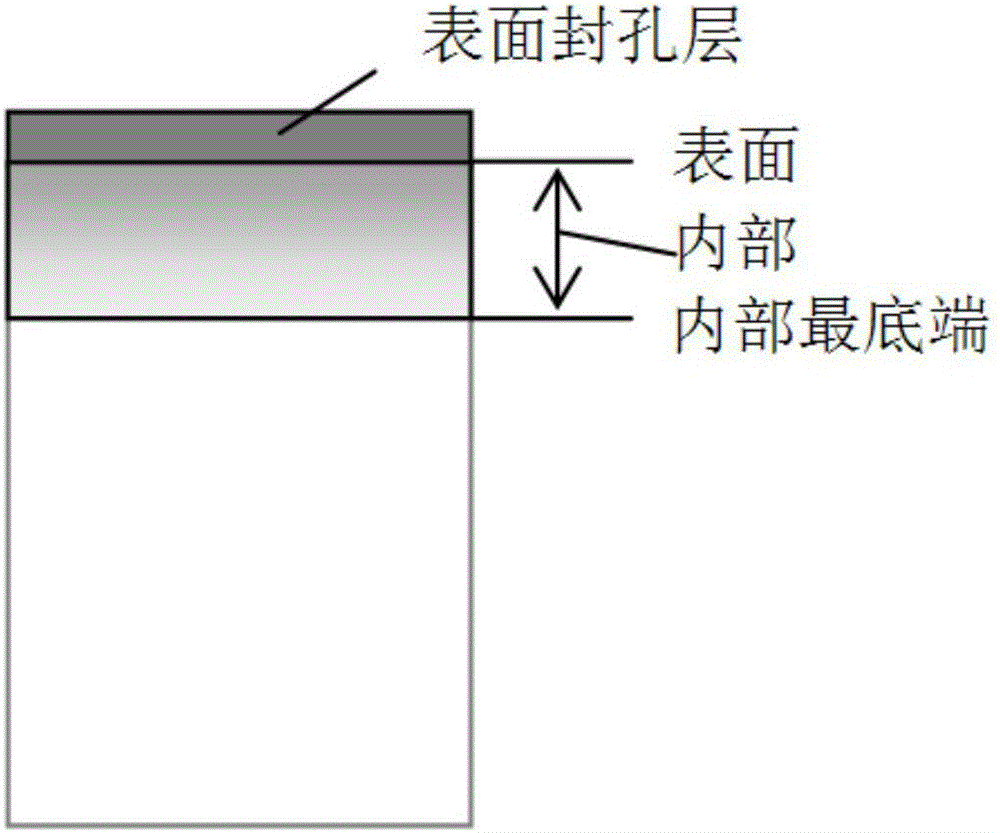

Multi-element alloy coating, zirconium alloy cladding and fuel assembly

ActiveCN108588532BProvides antioxidant protectionSolve the problem of thermal expansion mismatchOptical rangefindersNuclear energy generationOxidation resistantThermal expansion

A multi-element alloy coating, a zirconium alloy cladding, and a fuel assembly. The multi-element alloy coating comprises the following elements in percentage by mass: 65%-90% of Cr, 3%-13% of Al, 0.5%-8% of N, 5%-20% of Fe, and 1.5%-12% of Zr. The multi-element alloy coating can be applied to the zirconium alloy cladding, so that the problem of thermal expansion mismatch between the coating and a matrix is solved. The thermal stress is reduced. The hardness and the abrasion resistance performance of a conventional Cr coating are further promoted. By means of regulation and control of multi-element components, the anti-oxidation performance is enhanced, and the anti-oxidation protection effect of the coating under high-temperature steam environment of 1200°C is implemented.

Owner:GUANGDONG NUCLEAR POWER JOINT VENTURE +3

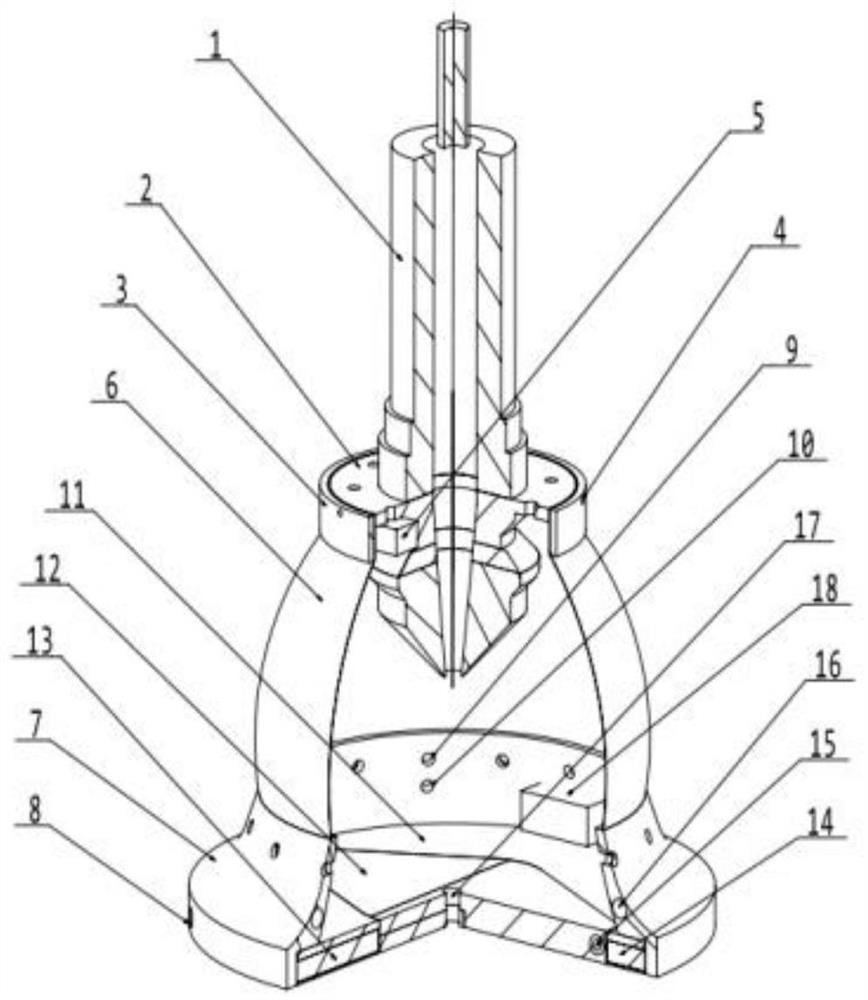

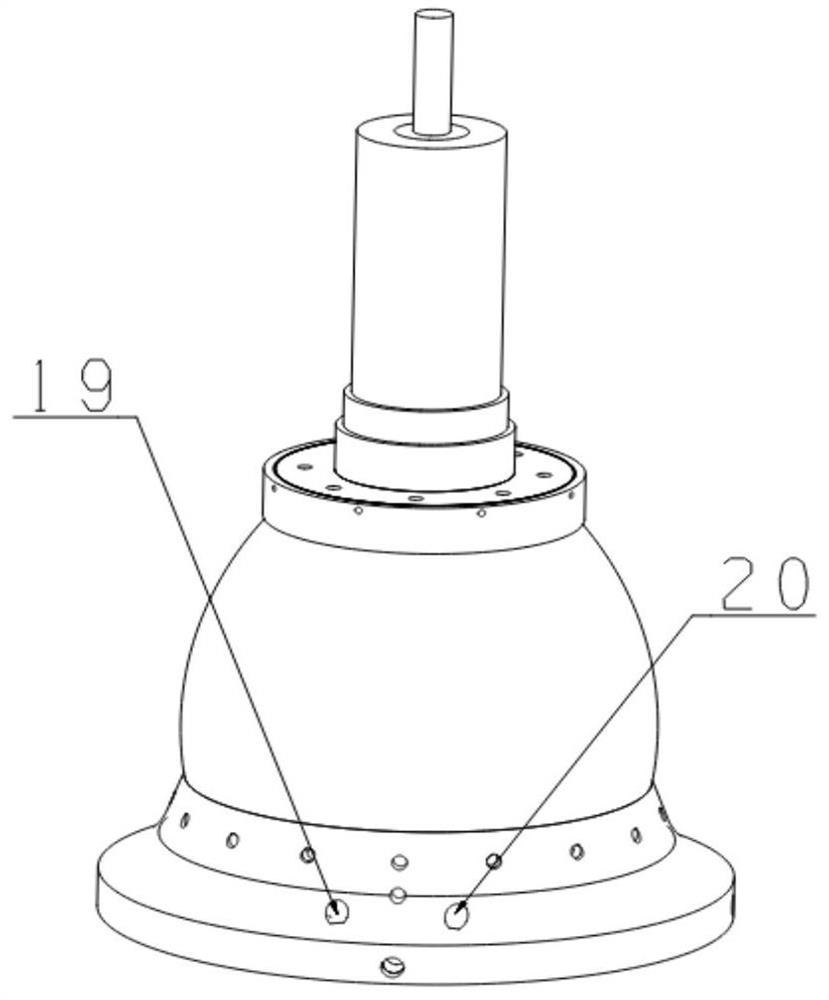

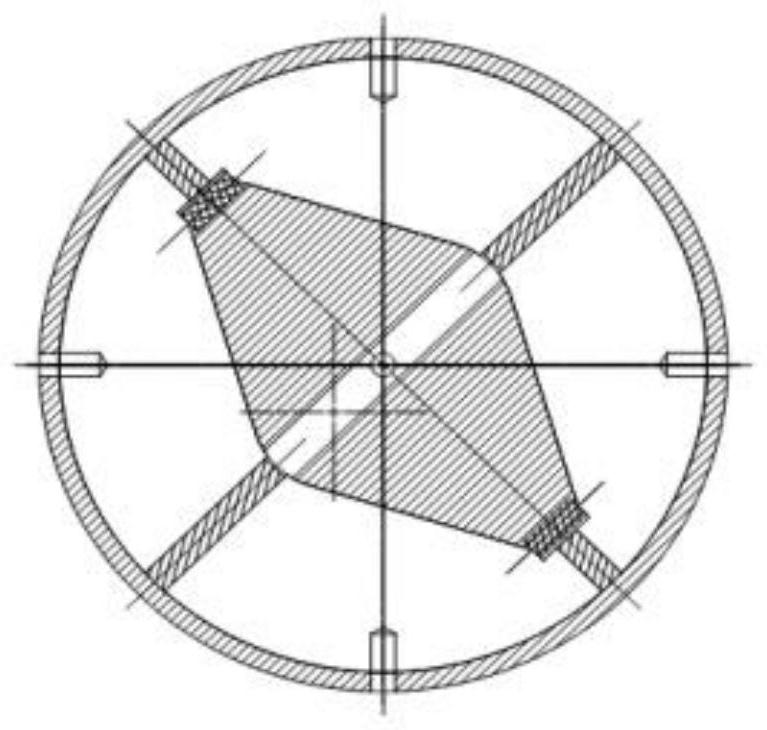

High-adaptability anti-oxidation laser cladding device

PendingCN113930758ALow costIncrease flexibilityMetallic material coating processesRotational axisEngineering

The invention relates to a high-adaptability anti-oxidation laser cladding device. The high-adaptability anti-oxidation laser cladding device comprises a protective cover and a laser spray head at least partially arranged in the protective cover, wherein the protective cover is provided with a cover body and a bottom plate sealing the bottom of the cover body, and a laser inlet allowing the laser spray head to stretch into the cover body is formed in the top of the cover body; and the bottom plate is connected with the cover body through a connecting piece, and the bottom plate can rotate relative to the cover body in the axis direction of the cover body with the connecting piece as the rotating axis so as to open the bottom of the cover body. The high-adaptability anti-oxidation laser cladding device can adapt to the sizes of different parts, so that an expensive large-size fixed inert gas cabin does not need to be purchased, and much cost is saved; and the high-adaptability anti-oxidation laser cladding device is high in flexibility and adaptability, and capable of achieving a better anti-oxidation protection effect.

Owner:SUZHOU UNIV

Health powder containing kudzu root, and preparation method of health powder

InactiveCN109315727APromote body absorptionImprove immunityFood ingredient functionsMedicineRaw material

The invention relates to health powder containing kudzu root. The health powder is prepared from the following raw materials by a weight ratio: 40-60 wide kudzu root, 10-30 big red dates and 10-30 carrot. The invention also relates to a preparation method of the health powder containing the kudzu root.

Owner:李武

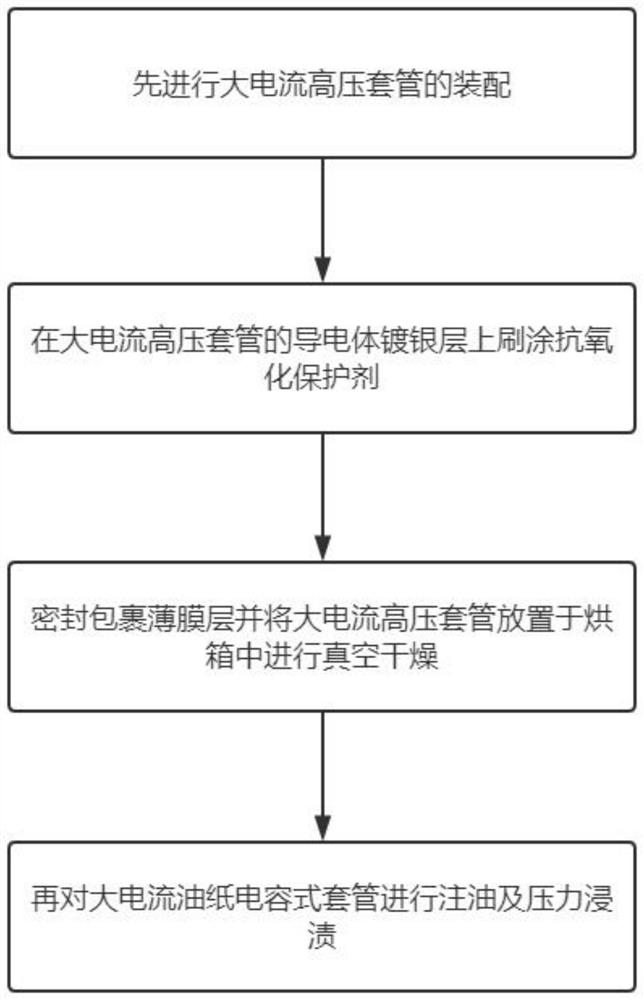

Method for reducing dielectric loss of large-current high-voltage bushing

PendingCN112825285ASmall dielectric lossReduce manufacturing costTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionDielectric lossHigh pressure

The invention discloses a method for reducing the dielectric loss of a large-current high-voltage bushing, and belongs to the technical field of transformer equipment. The method for reducing dielectric loss of a large-current high-voltage bushing comprises the following steps: firstly, assembling the large-current high-voltage bushing; brushing an anti-oxidation protective agent on a silver-plated layer of a conductor of the large-current high-voltage bushing; sealing and wrapping a thin film layer, and putting the large-current high-voltage bushing into a drying oven for vacuum drying; and carrying out oiling and pressure impregnation on the large-current oiled paper condenser bushing and the like. Oxidation discoloration or falling of the silver-plated layer of the conductor on the large-current high-voltage bushing can be avoided in the vacuum drying process, so that the large-current high-voltage bushing can be integrally subjected to vacuum drying and insulation treatment after being assembled, and the dielectric loss of the large-current high-voltage bushing is effectively reduced; and the anti-oxidation protective agent is a carbon-based anti-oxidation protective agent, and the anti-oxidation protective agent can permeate into the conductor silver-plated layer, so that the surface of the conductor silver-plated layer is compact, and the anti-oxidation protection effect on the conductor silver-plated layer is achieved.

Owner:GUIYANG BUREAU OF CHINA SOUTHERN POWER GRID CO LTD EHV TRANSMISSION CO

Preparation method of anodic surface anti-oxidation protective agent for carbon-based aluminum

ActiveCN106319570BIncreased Response Residual RateReduce the amount of diffusionInorganic saltsSoftened water

The invention relates to a method for preparing an anode surface antioxidation protective agent used for carbon-base aluminum. The method includes the steps that a raw material is screened, calcined petroleum coke ball-milled powder is selected as the carbon-base raw material, and ammonium peroxydisulfate is used as a modifying agent; industrial softened water is used for dissolving the ammonium peroxydisulfate at first so that a solution can be obtained, and then the carbon-base raw material screened in advance is added into the solution; an oxidation modified reaction is carried out in an electric heating reactor with a stirring function at the temperature of 80-100 DEG C; and the industrial softened water is used for washing residual inorganic salt ions after the reaction is completed, and thus a carbon-base antioxidation protective agent product can be obtained. The method has the advantages and effects that depositions are directly coated to be attached to the surfaces of anode carbon blocks, the air reaction residual rate of anode products can be increased by 3%-4%, and anode net consumption is effectively reduced.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Method and device for preparing carbon-coated copper nanoparticles by wire electric explosion method

ActiveCN110116215BProvides antioxidant protectionImprove performanceMaterial nanotechnologyTransportation and packagingCarbon coatingCopper wire

The invention discloses a method and a device for preparing carbon-coated copper nanoparticles by using a metal wire electric explosion method. A copper wire with a certain length and diameter is evenly wound on a carbon rod, and the metal wire is passed through in an argon atmosphere. High voltage and high current make the wire explode electrically, and the carbon-coated copper nanoparticles can be collected. The copper wire undergoes phase transformation during heating during the electric explosion, and undergoes melting, gasification, plasma and other processes successively, and produces copper atoms under the high temperature heating of the plasma, and a part of carbon atoms will also be formed after the carbon rod is passed through a high current. , and then the two spontaneously and uniformly nucleate and condense into atomic clusters from the gas phase, forming an initial small droplet, which grows continuously, and then forms a carbon coating layer through two mechanisms of internal carbon atom precipitation and external carbon atom deposition, and finally passes through Cooling forms carbon-coated copper nanoparticles. This method proposes a new method for preparing carbon-coated copper nanoparticles, which has great application value for industrial production and scientific research.

Owner:XI AN JIAOTONG UNIV

An anti-oxidation coating on the surface of a low-density carbon tile resistant to 1300-1500 ° C and its preparation method

ActiveCN106242643BExcellent high temperature heat insulation performanceSimple preparation processHeat inorganic powder coatingMetallurgyProtection system

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Method for surface treatment of Cr-steel

InactiveCN101328532BImprove antioxidant capacityLess weight gainBlade accessoriesMachines/enginesMartensiteSolid particle erosion

A method for the surface treatment of ferritic / martensitic 9-12% Cr steels and of austenitic Cr steels for the purpose of achieving increased resistance to oxidation and solid particle erosion at application temperatures of above 500° C., in particular of approximately 650° C., in steam, includes that the surface of the steel is shot-peened with particles of aluminum or of an aluminum alloy; optionally, in a subsequent step, the surface of the steel is smoothed to a roughness of <0.5 mum, preferably <0.3 mum. Following additional heat treatment is not necessary, and the parts thus treated may be employed, for example, as blades in steam turbines.

Owner:GENERAL ELECTRIC TECH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com