Modified carbon aerogel and its preparation method and application

A carbon aerogel and aerogel technology, applied in the field of aerogel, can solve the problems of limiting the application of carbon aerogel, loss of carbon aerogel quality, and reduction of mechanical properties, and achieve macroscopic morphology and microstructure. Controlling, improving anti-oxidation performance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

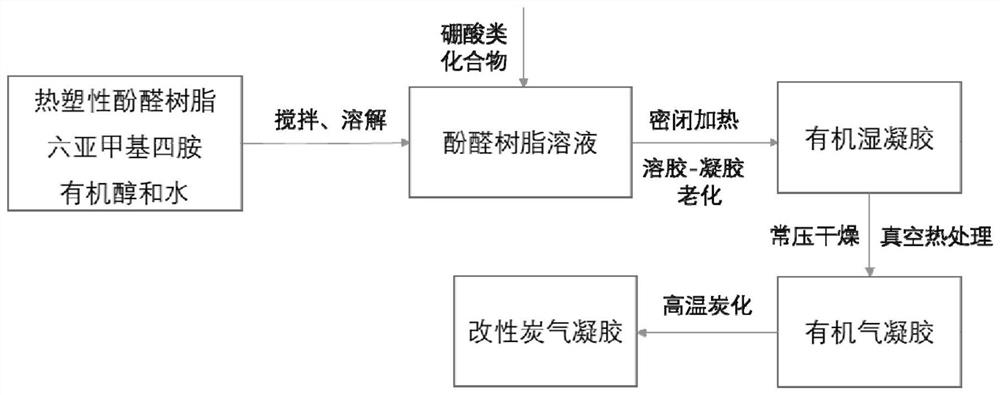

[0083] In a second aspect, a method for preparing a modified carbon aerogel is provided in at least one embodiment, comprising the following steps:

[0084] The modified carbon aerogel is obtained by mixing formula amounts of thermoplastic phenolic resin, curing agent, solvent and boron-containing compound, and undergoing sol-gel reaction and post-treatment.

[0085] Preferably, the above-mentioned modified carbon aerogel with excellent anti-oxidation performance uses thermoplastic phenolic resin as the reaction precursor, hexamethylenetetramine as the curing agent, organic alcohols as the main solvent, and water as the auxiliary solvent, Boric acid compounds are modifiers, which are prepared by sol-gel reaction, aging, drying at normal pressure, vacuum heat treatment and carbonization at high temperature.

[0086] It should be noted that the term "sol-gel" refers to a sol and a gel, and may also be referred to as a sol-gel. The sol can be converted to a gel by, for example, ...

Embodiment 1

[0122] 1. Modified carbon aerogel

[0123] It is mainly prepared from raw materials with the following mass ratios:

[0124] 10.0 g of thermoplastic phenol resin, 2.0 g of hexamethylenetetramine, 90.0 g of ethanol, 1.0 g of water, and 3.0 g of boric acid.

[0125] 2. Preparation of modified carbon aerogels

[0126] Include the following steps:

[0127] According to the ratio, weigh a certain amount of thermoplastic phenolic resin and curing agent hexamethylenetetramine respectively, add them to a reaction kettle containing a small amount of water and a certain amount of ethanol, and stir until the thermoplastic phenolic resin and curing agent are stirred under mechanical stirring. Completely dissolve to obtain a phenolic resin solution; then add a certain amount of boric acid, continue stirring to dissolve.

[0128] Pour the dissolved phenolic resin solution from the reactor into a plastic bottle or a stainless steel mold, then seal the mold, and place it in a constant temp...

Embodiment 2

[0130] 1. Modified carbon aerogel

[0131] It is mainly prepared from raw materials with the following mass ratios:

[0132] 15.0 g of thermoplastic phenolic resin, 4.0 g of hexamethylenetetramine, 85.0 g of isopropanol, 1.0 g of water, and 3.0 g of boric acid.

[0133] 2. Preparation of modified carbon aerogels

[0134] Include the following steps:

[0135] According to the proportion, weigh a certain amount of thermoplastic phenolic resin and curing agent hexamethylenetetramine respectively, add them to a reaction kettle containing a small amount of water and a certain amount of isopropanol, and under mechanical stirring until the thermoplastic phenolic resin and The curing agent is completely dissolved to obtain a phenolic resin solution; then a certain amount of boric acid is added, and the stirring is continued to dissolve;

[0136] The rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com