A main power line lead-out structure of an energy storage sodium-sulfur battery module

A sodium-sulfur battery, lead-out structure technology, applied in the direction of secondary battery, structural parts, electrical connector introduction, etc., can solve problems such as use risk, and achieve the effect of eliminating influence, reducing leakage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

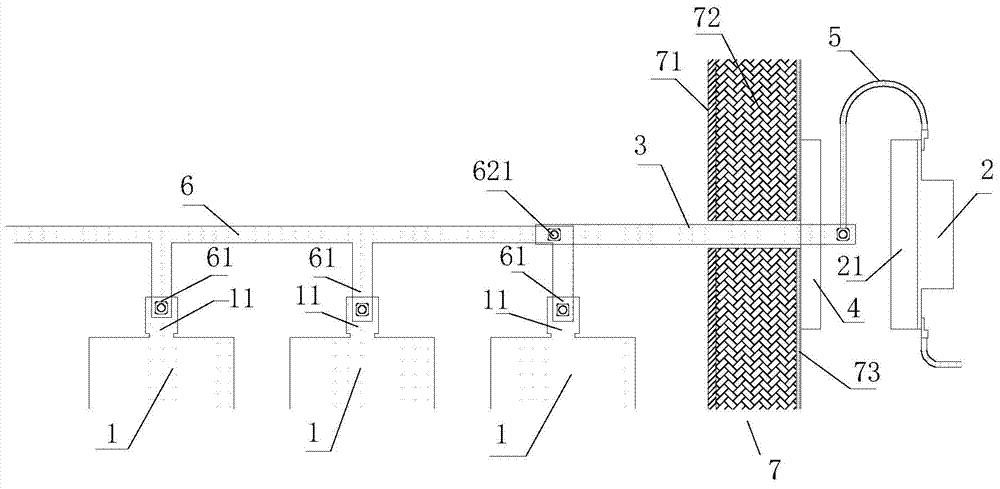

[0018] see figure 1 , the energy storage sodium-sulfur battery module includes a number of sodium-sulfur batteries 1, placed in the incubator; the main power line lead-out structure of the present invention is used to lead the main power line of the energy storage sodium-sulfur battery module out of the incubator, and the external fuse 2 connected. The lead-out structure of the main power line includes a straight aluminum row 3, a concave-convex buckle 4, a soft wire 5 and an F-shaped aluminum row 6, of which:

[0019] The F-shaped aluminum row 6 is formed by punching and bending multiple places of an aluminum plate at one time, extending from each bend to form an extension end 61, and the intervals between each adjacent two bends are equal. In this implementation, each bend is 90-degree bending; in particular, the tail end of the F-type aluminum row 6 is also bent, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com