Bidirectional belt conveyor for coal and gangue

A technology for transporting belts and belt conveyors, which is applied in the direction of conveyors, underground transportation, and conveyor objects, and can solve the problems of gangue easy to roll off and the back of the belt is not wear-resistant, so as to prevent gangue from rolling down and reduce work The effect of energy consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

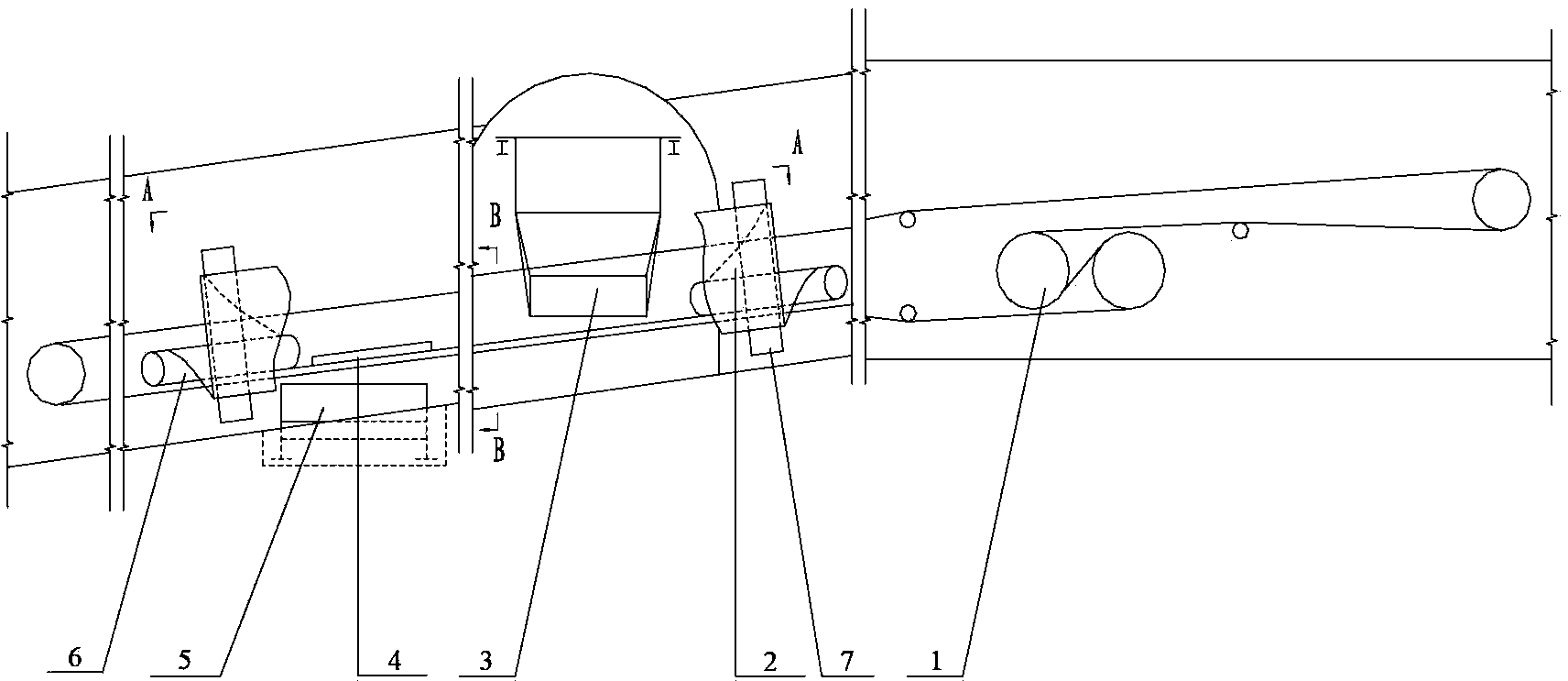

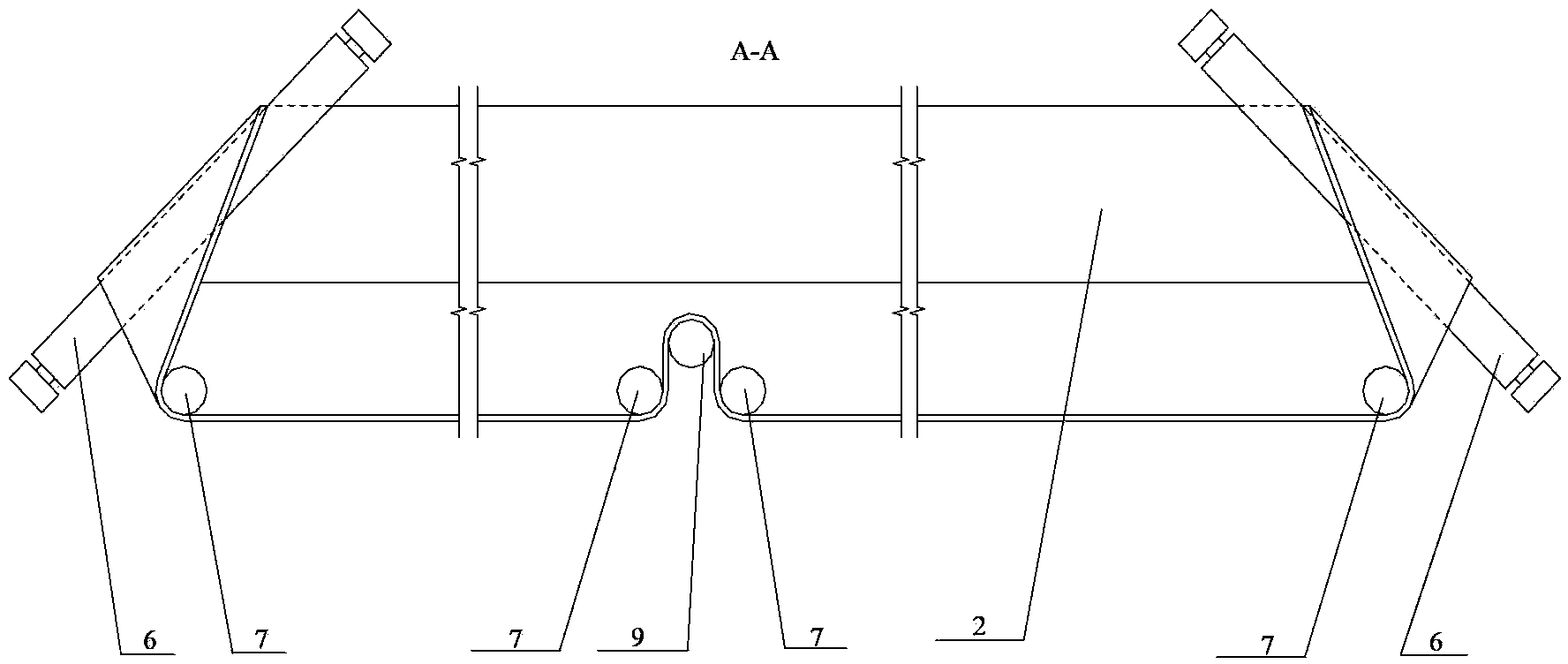

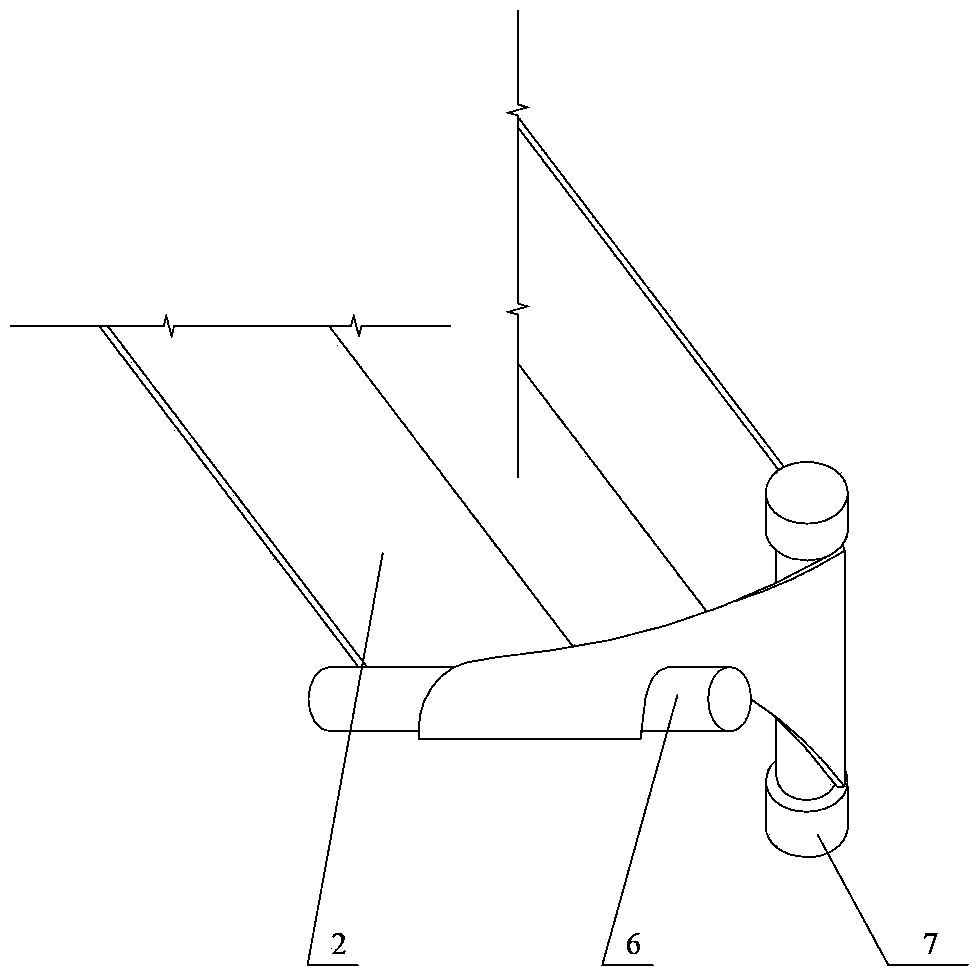

[0026] Such as figure 1 , figure 2 and image 3 As shown, the belt conveyor for two-way transportation of coal and gangue in this embodiment is equipped with a covering belt 2 for the lower belt conveying materials above the lower belt of the ordinary belt conveyor 1. The lower belt of the belt conveyor 1 contacts and runs with it under its drive. When there is no gangue load, the covering belt 2 and the lower belt are in a parallel separation state and stand still. Both ends of the cover belt 2 enter and exit the cover belt working position through a set of cover belt non-vertical entry and exit redirection rollers 6, and then return to the non-working position through a set of cover belt vertical redirection rollers 7. The gangue to be transported is loaded into the cover belt 2 by the gangue feeding device 3 located above the front end of the cover bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com