Multi-size full-automatic glass feeding device and working method thereof

A fully automatic technology on glass, applied in transportation and packaging, conveyor objects, furnaces, etc., can solve the problem of large demand for difficult glass, achieve automatic control, improve utilization rate, and ensure the effect of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

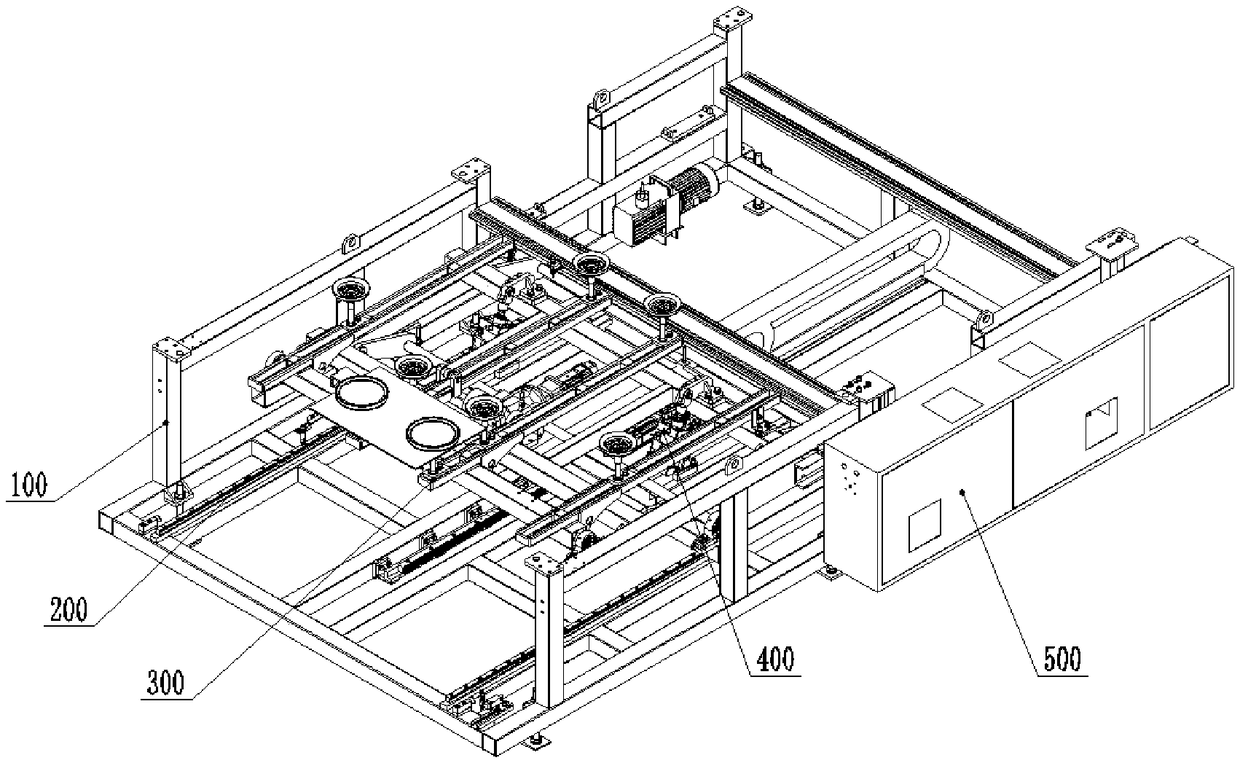

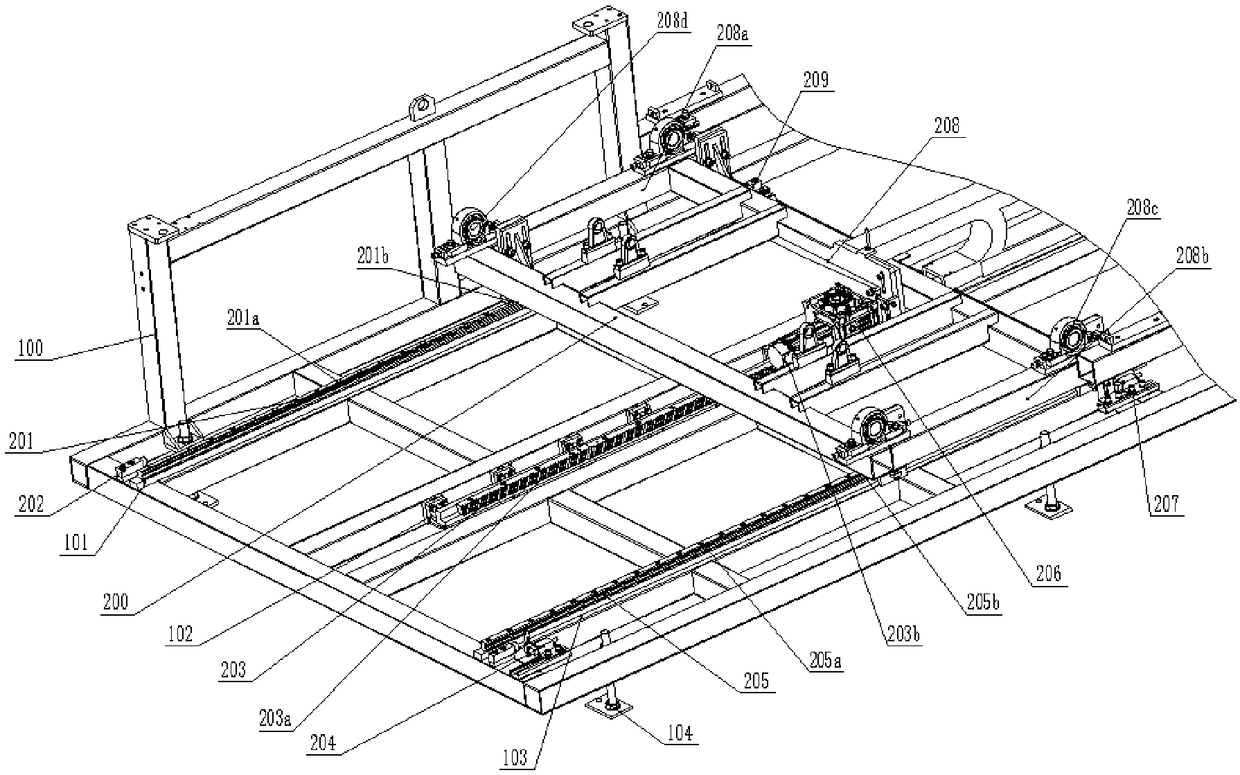

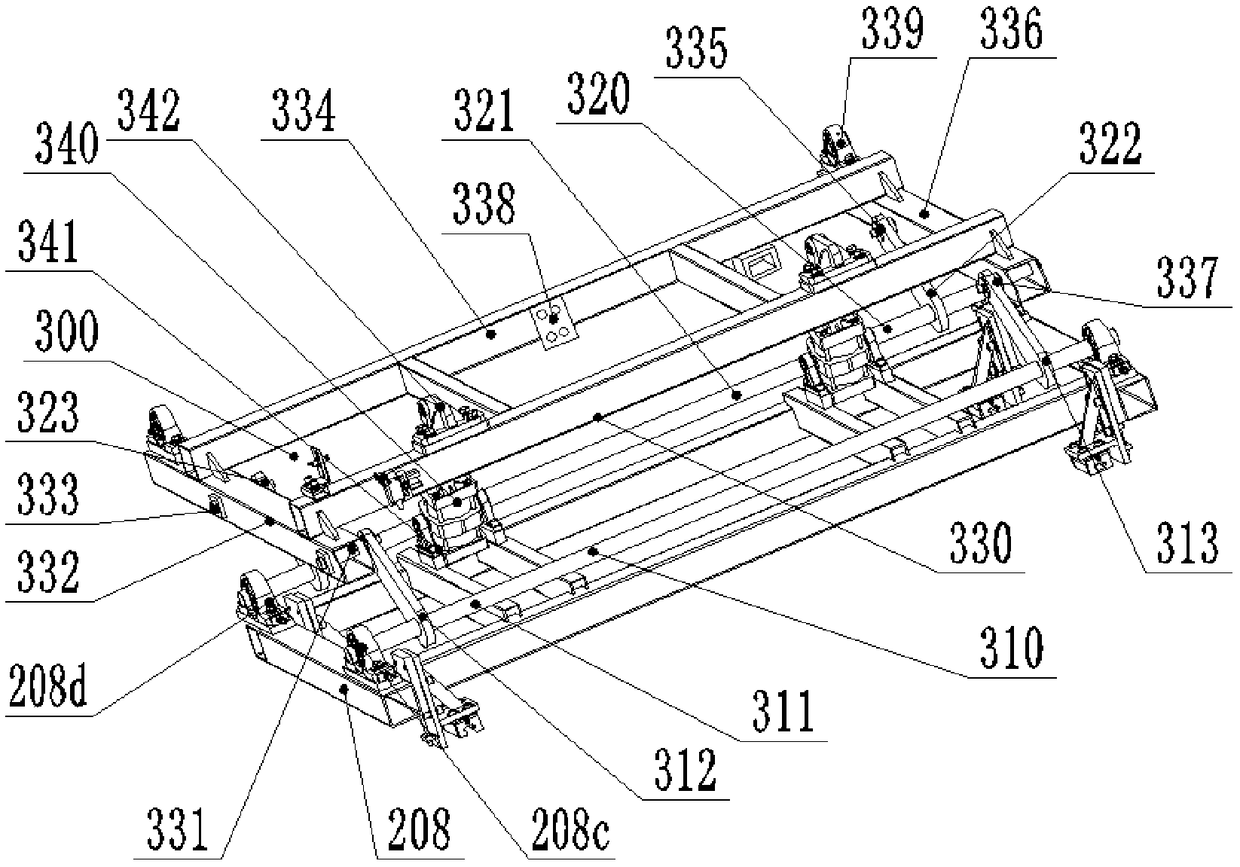

[0047] A kind of multi-size fully automatic glass feeding device of this embodiment, as attached figure 1 As shown, it includes a frame 100 , a sliding platform 200 , a lifting platform 300 , an overturning grabbing arm 400 and a control system 500 . The sliding platform 200 is arranged on the frame 100 , and the sliding platform 200 moves horizontally on the frame 100 . The lifting platform 300 is arranged on the sliding platform 200 , and the lifting platform 300 moves vertically under the action of the lifting cylinder 340 . The turning and grabbing arm 400 is provided on the lifting platform 300, and the turning and grabbing arm 400 is provided with a plurality of suction cup assemblies 420 for absorbing glass. The overturn grabbing arm 400 performs a rotational movement relative to the frame 100 under the action of the crank assembly. The control system 500 is used for receiving and processing signals during the working process of the grabbing device.

[0048] Furtherm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com