Carbon fiber electric heating device

An electric heating device and carbon fiber technology, applied in water heaters, fluid heaters, heating element materials, etc., can solve the problems of flat uniform heating, long heating time, large power consumption, etc., and achieve uniform heating and stable product performance. , the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

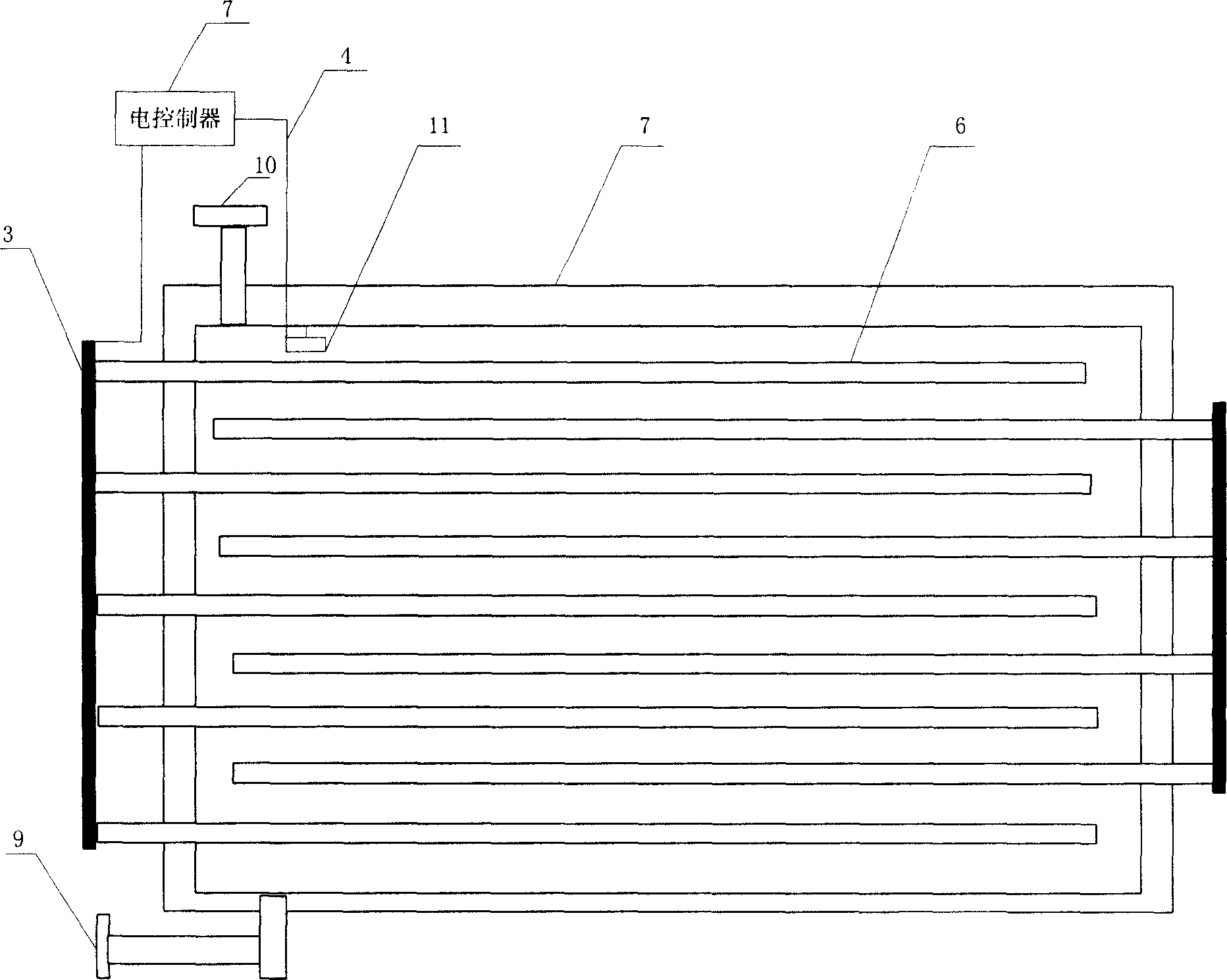

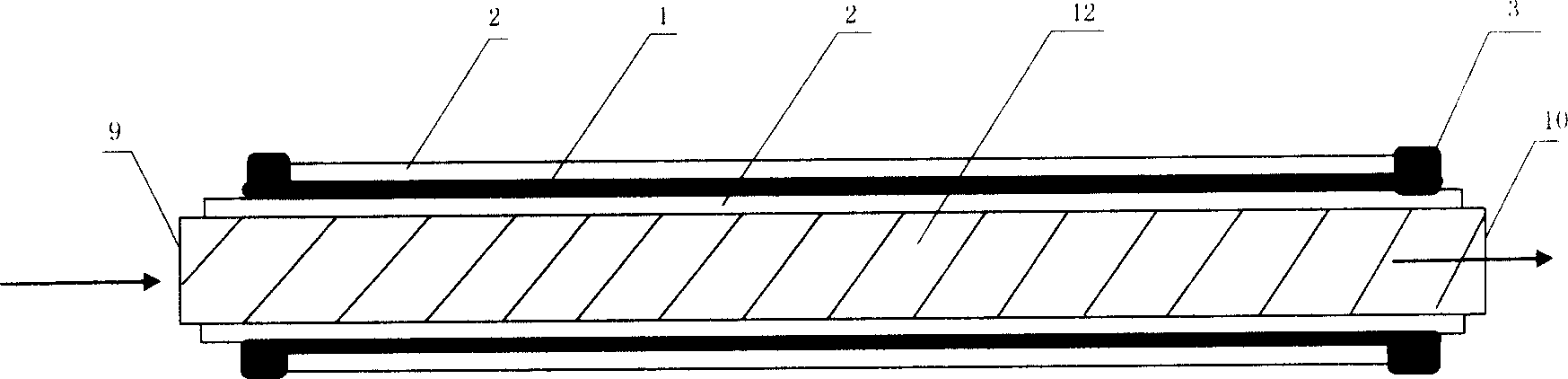

[0028] The production of carbon fiber electric heating devices is divided into plate carbon fiber electric heating devices and tubular carbon fiber electric heating devices according to the shape of carbon fiber electric heating elements; the carbon fiber electric heating elements are divided into two types: heating resin and heating (felt) cloth according to the shape of heating materials.

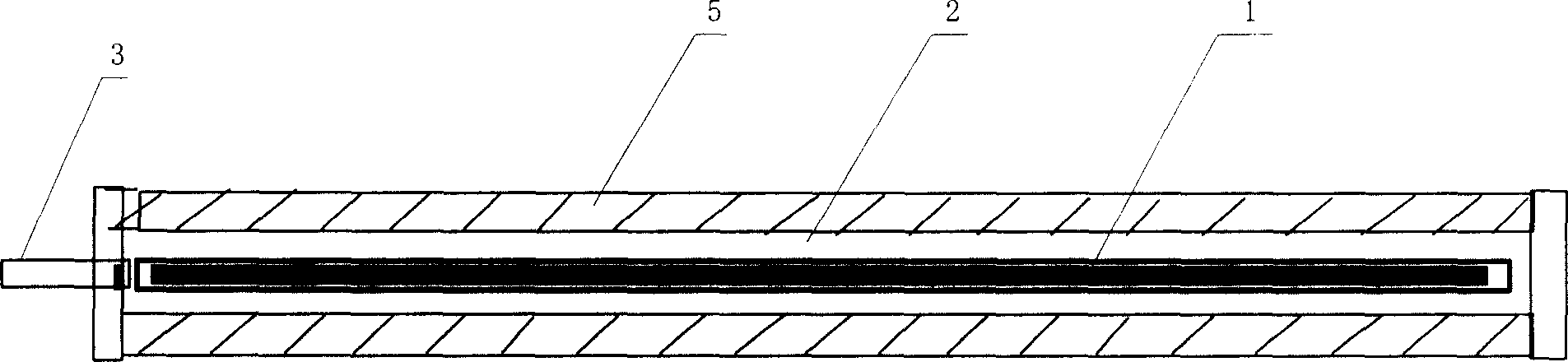

[0029] figure 1 It is a structural schematic diagram of the heating resin carbon fiber electric heating body of the present invention. Such as figure 1 As shown, the carbon fiber electric heating layer 1 prepared by a certain ratio of chopped carbon fiber (or a mixture with graphite) and high-temperature adhesive resin is evenly coated on the insulating layer 2 (mica board, insulating fiber cloth or high-temperature insulating paint) etc.) in the middle; and fix the electrode 3 with high-temperature conductive glue at both ends, and lead out the power cable at the same time. )-like resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com