Treatment agent of acidic components used for mixed gas

A technology of acidic components and mixed gases, which is applied in the field of amide compositions or aqueous solutions, treatment agents, and alcohol amines, which can solve the problems of high cost and achieve the effects of low energy consumption, large processing capacity, and low desorption temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

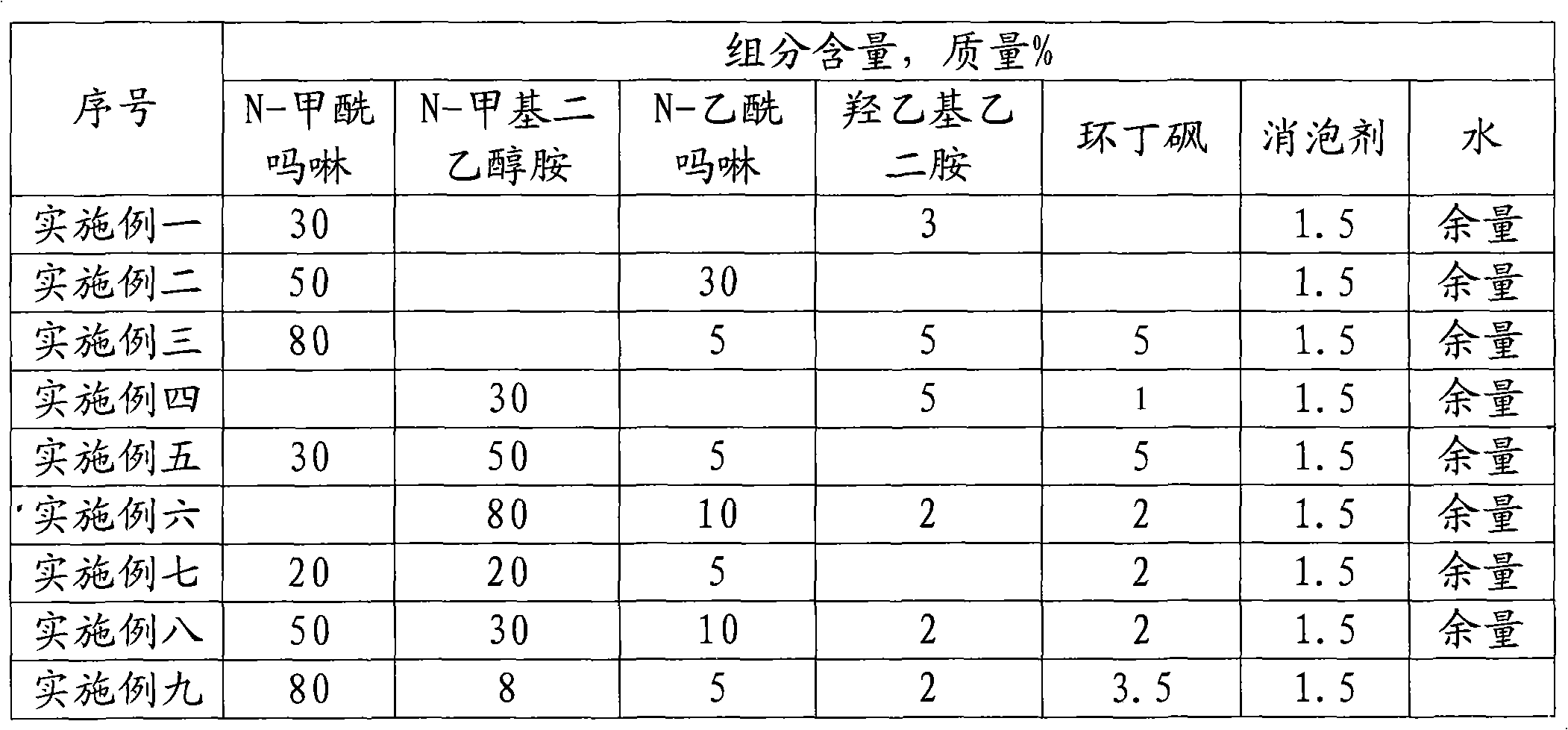

Examples

Embodiment Construction

[0017] The present invention can be implemented according to the following typical process flow.

[0018] The raw material gas containing acidic gas components enters the absorption tower equipped with packing or trays from the lower part, the absorption treatment agent drips from the top of the tower, and absorbs countercurrently with the raw material gas, and the purified net gas is drawn out from the top of the absorption tower. The absorption treatment agent containing acidic components is discharged from the bottom of the absorption tower, heated by a heat exchanger, and then enters a separator to separate part of the acidic components, and the acidic gas components are sent for further treatment.

[0019] The absorption treatment agent flowing out of the separator is further removed from the acid gas components in the desorption tower. After being cooled and condensed, the acid-rich gas stream from the top of the tower is separated into gas and liquid in the separator, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com