Metering pump with constant speed and constant pressure

A technology for metering pumps and pump cylinders, which is applied in the field of metering pumps and mechanical equipment, and can solve the problems of unsustainable, constant speed, and constant pressure conveying medium, inability to feed the pump and conveying medium at the same time, and difficulty in meeting the metering requirements of the metering pump. Achieve the effects of reducing energy consumption, solving stability, and small frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

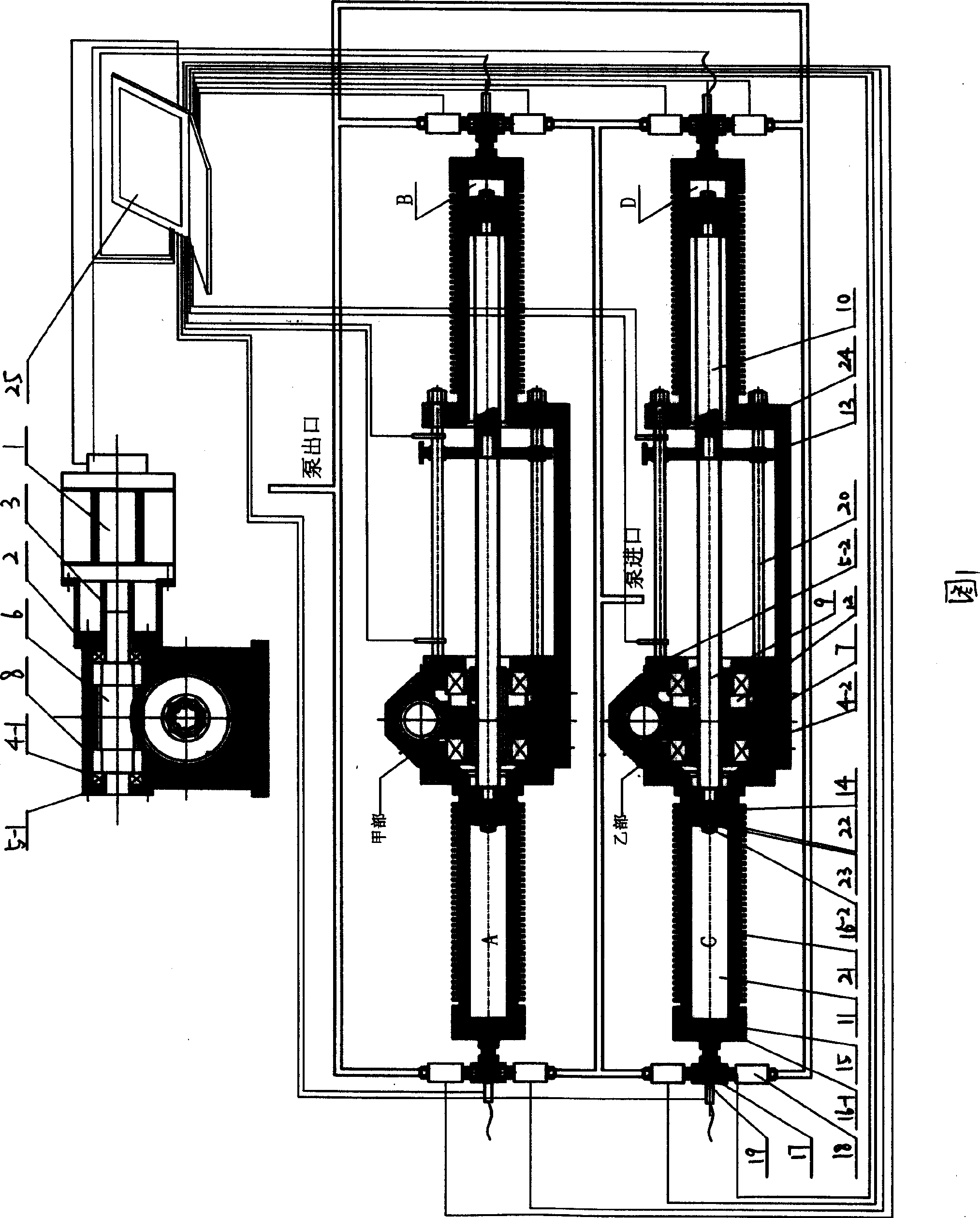

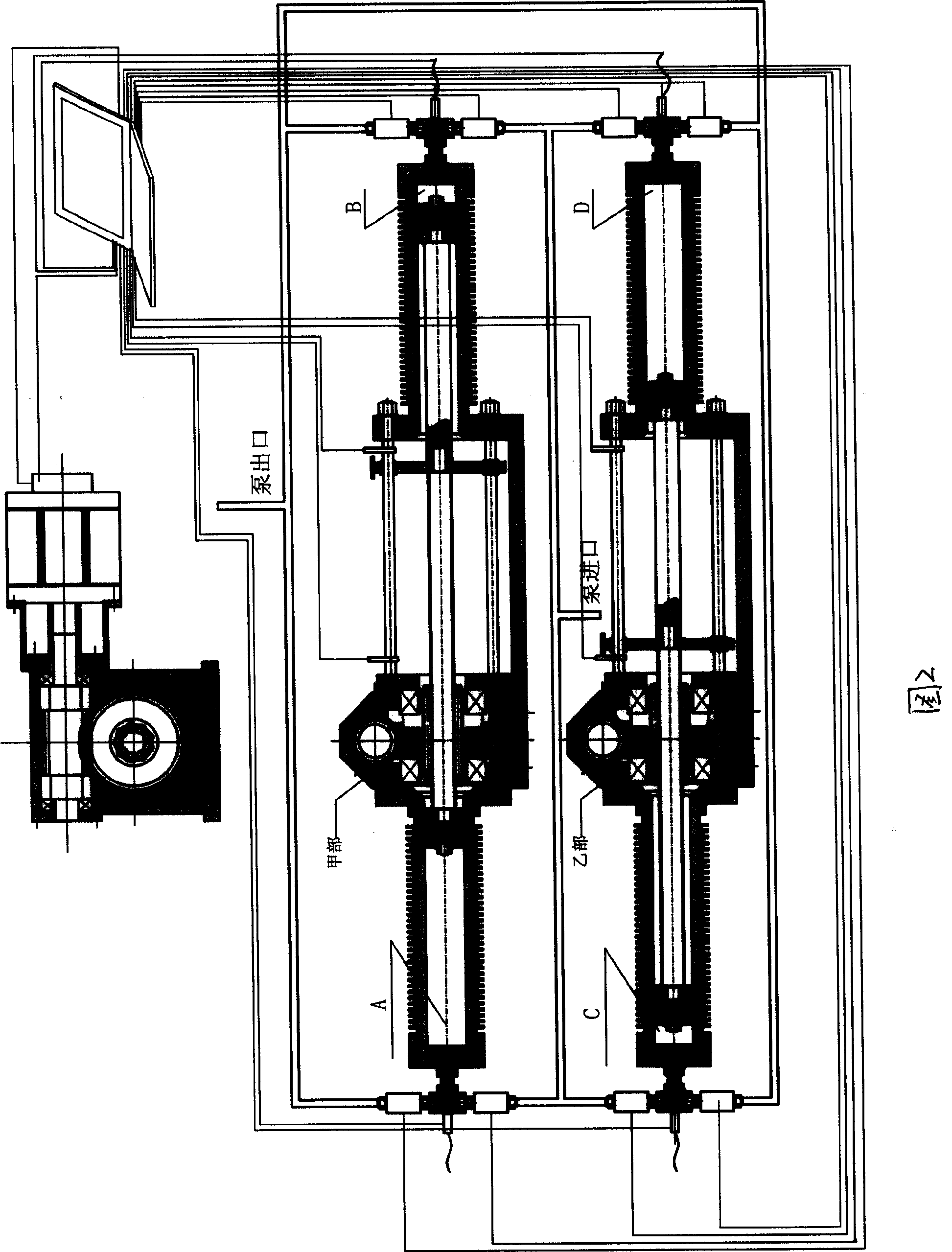

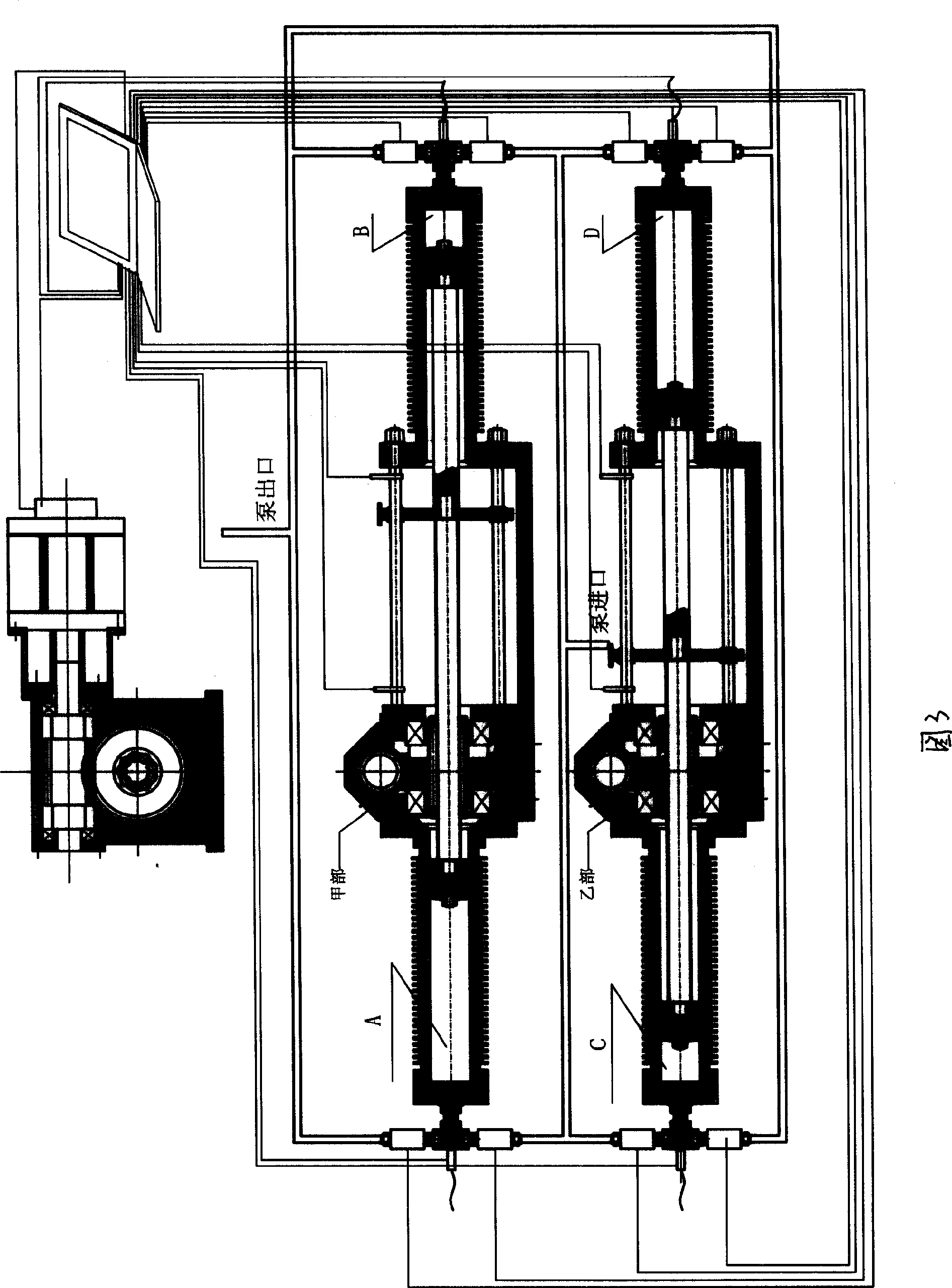

[0031] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

[0032] As shown in Figure 1, the constant speed and constant pressure metering pump of the present invention includes a power unit for power drive, a delivery device for fluid delivery, and a microcomputer 25 for regulation and control, wherein the power unit includes a servo motor 1, Motor bracket 2, shaft coupling 3, bearing 4-1, bearing cap 5-1, worm 6, worm gear and worm gear box 8, said worm 6 is connected with servo motor 1, and a pair of opposite directions are installed at both ends of worm 6 Bearing 4-1, said conveying device has two groups (Part A, Part B) with the same structure, the two are parallel and juxtaposed, and each group of conveying device is equipped with worm gear box, planetary roller screw 9, connecting rod 10 With two cylindrical pump cylinders 11 with the same structure and opposite directions, the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com