Station layout method for reducing movement energy consumption of robot

A technology of robot movement and layout method, which is applied in the direction of manipulators, manufacturing tools, program control manipulators, etc., and can solve the problems of not considering the interaction between station layout and robot trajectory planning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

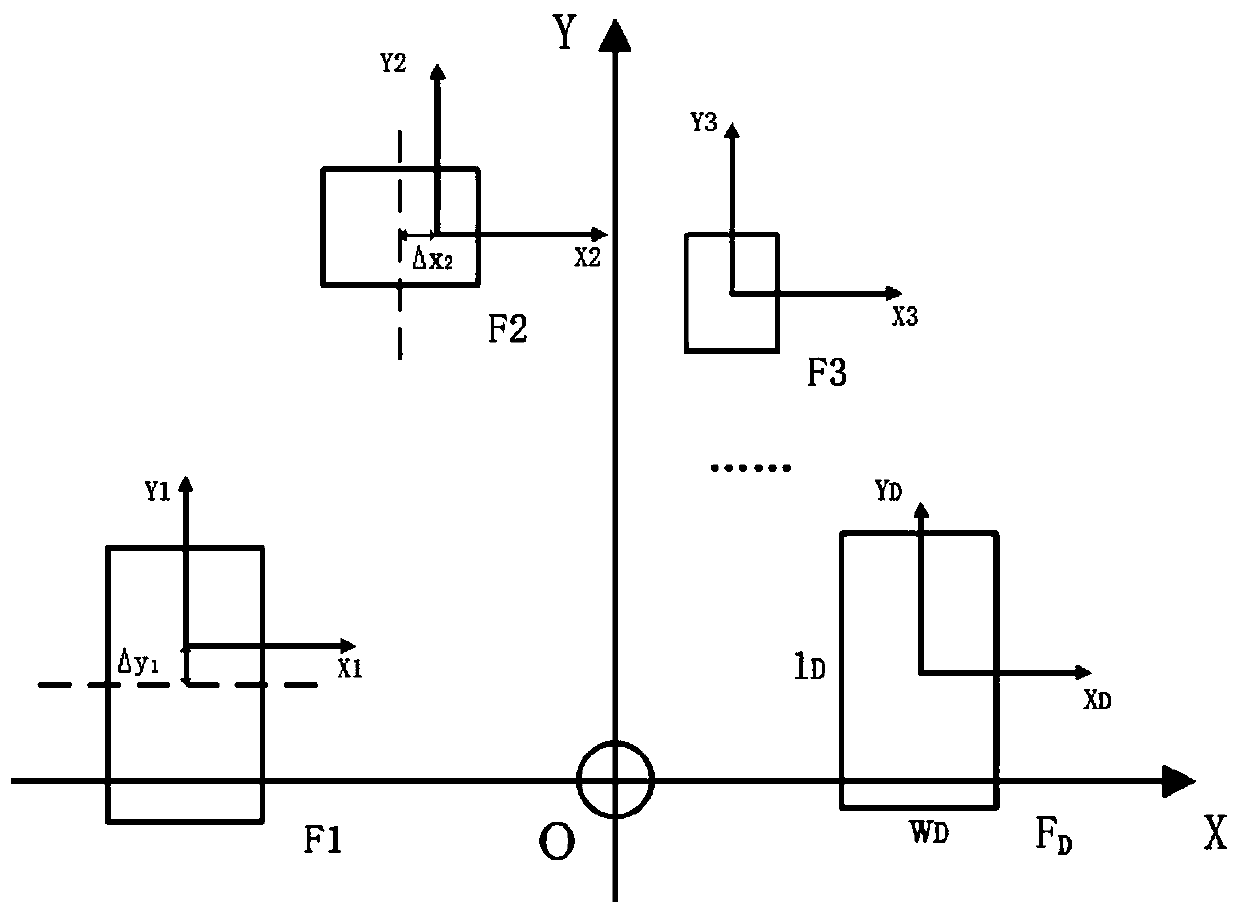

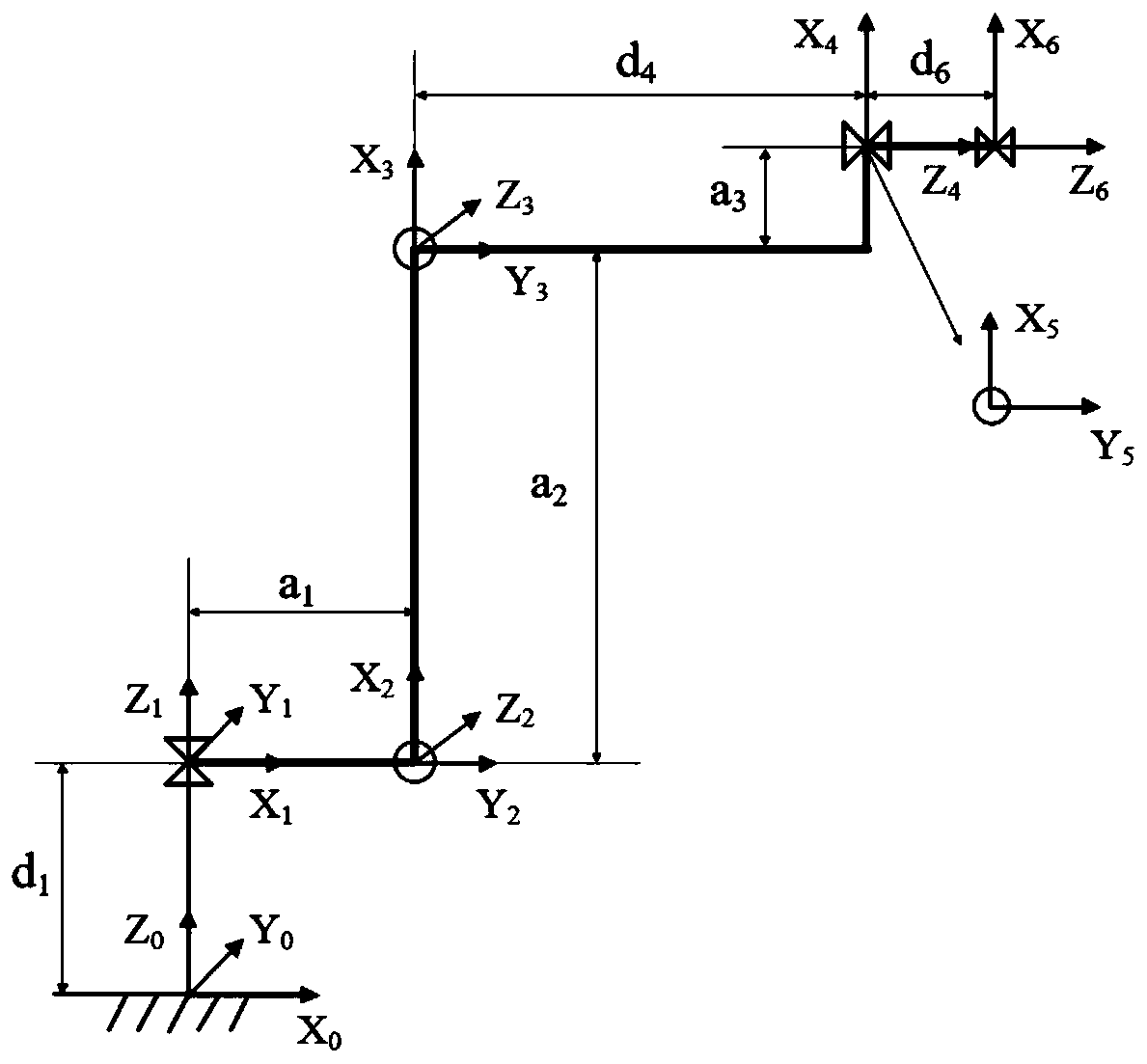

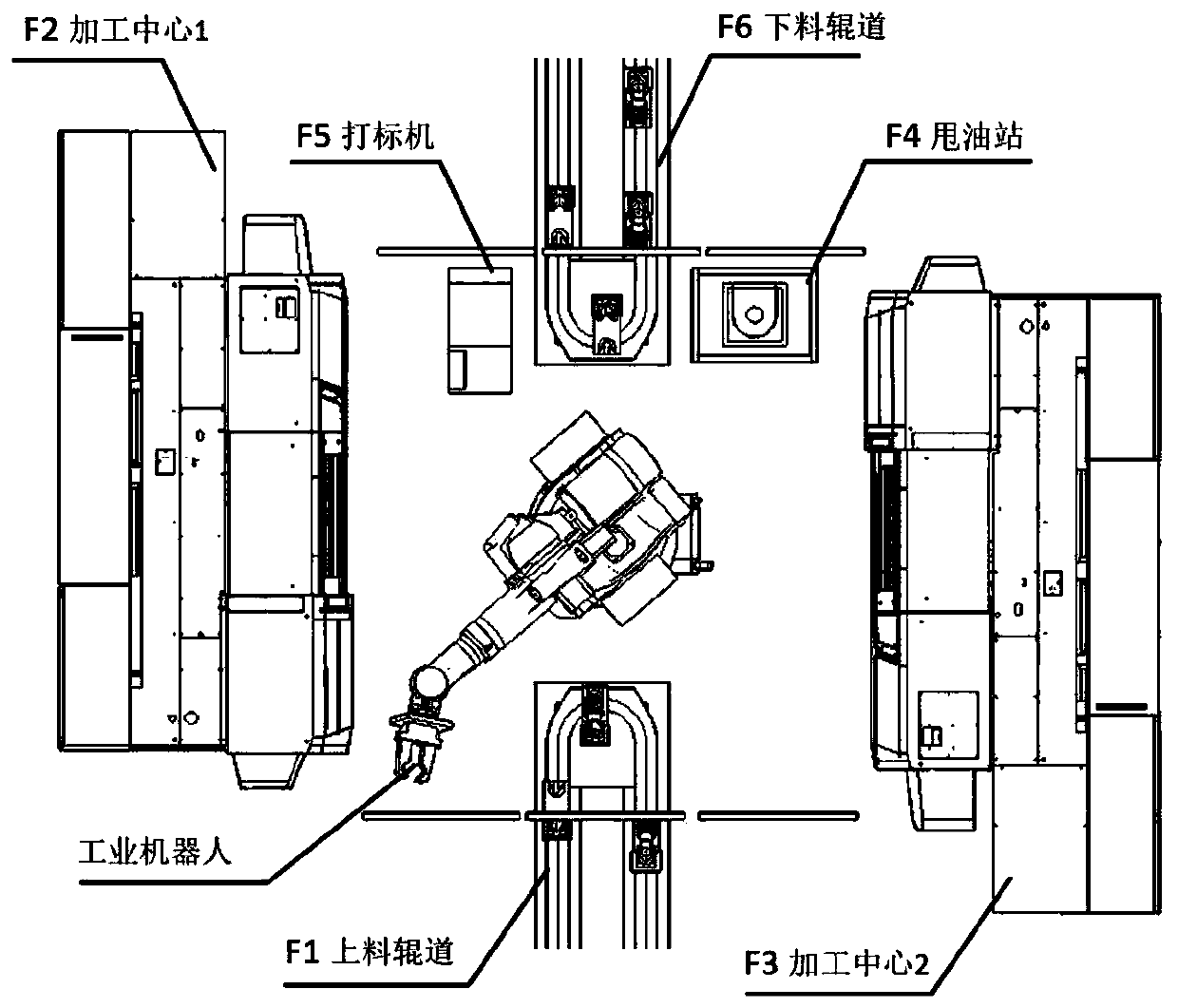

[0096] This embodiment studies the influence of station layout on robot movement energy consumption. Based on dynamic station layout, a robot movement energy consumption optimization model is established, and particle swarm algorithm is used to solve a set of optimal station layout schemes to make the robot move Minimal energy consumption.

[0097] The goal of the layout problem is to determine the location of the object. The traditional work station layout requires that on the basis of realizing the station function, combined with production experience, the equipment is as compact as possible and the floor space is reduced. This paper studies the layout problem of automated processing cells with robots, and solves the layout of workstations that minimizes the energy consumption of robots. Each processing equipment in the processing unit is continuously activated, and the industrial robot is fixed inside the unit, and performs periodic movement according to a certain law, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com