Heat-conductive type laboratory dyeing machine

A kind of dyeing machine and heat conduction technology, applied in the direction of processing textile material dyeing device, processing textile material equipment configuration, etc., can solve the problems of the service life of parts, inconsistent dyeing liquid temperature, low temperature rise and fall rate, etc., to achieve high reliability, The effect of strong anti-color flower ability and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

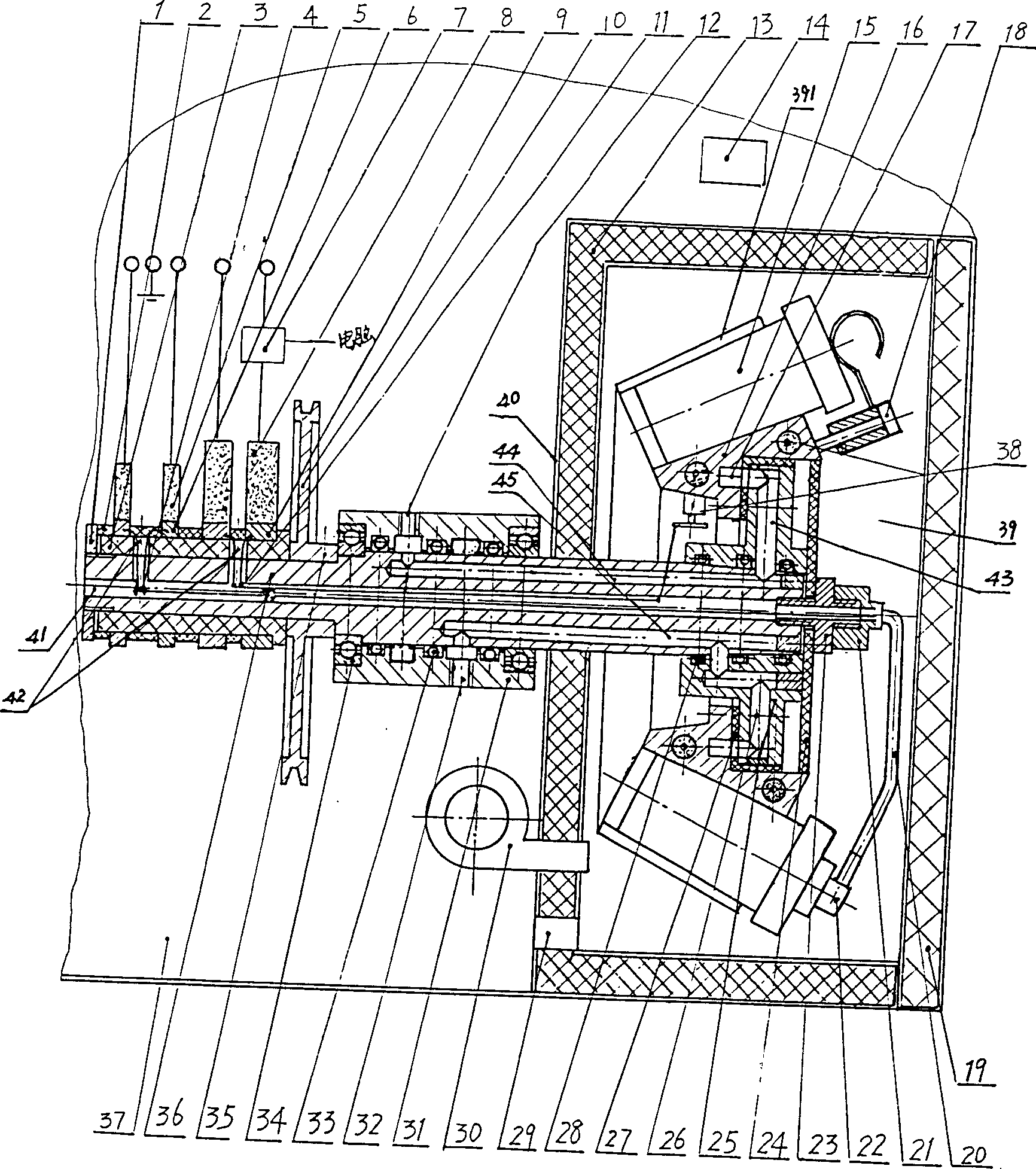

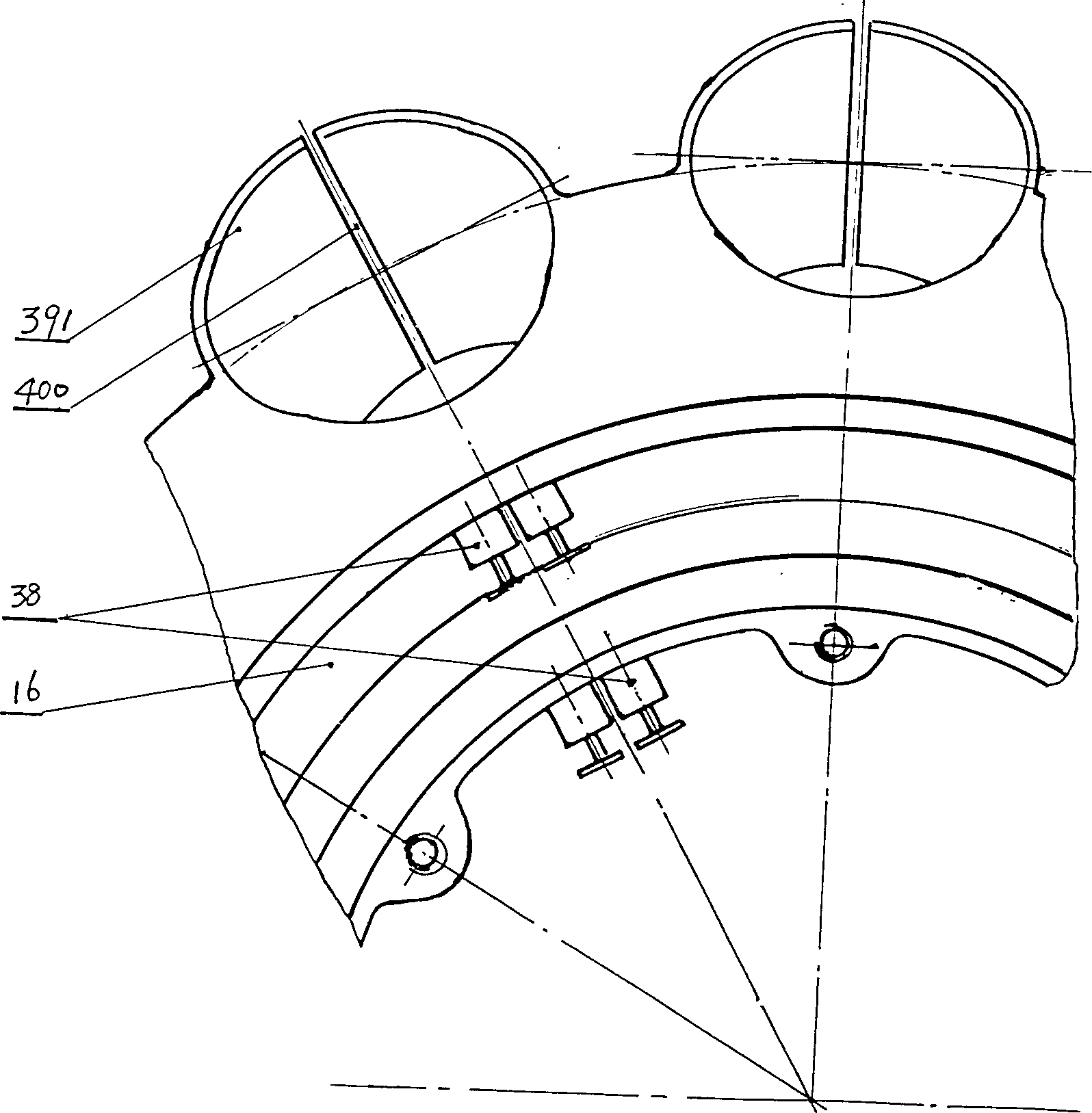

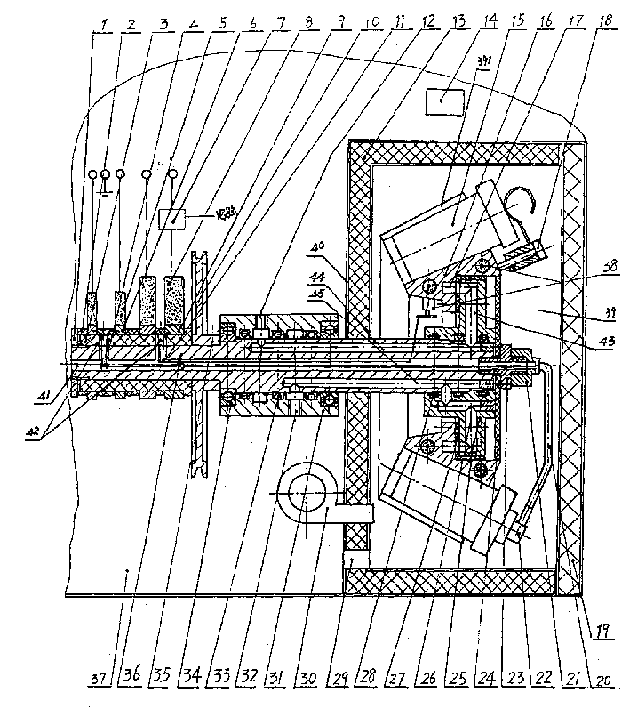

[0014] Such as figure 1 The thermal conductivity type dyeing machine shown is provided with a transmission support 31 in its body 37 for supporting the main shaft 36. The main shaft 36 is installed in the transmission support 31 through a support bearing 34 and can rotate around it. The left end of the main shaft 36 extends out of the transmission support 31, and a transmission pulley 10 is fixedly mounted on it by a fixing bolt 35, which is connected with the output pulley of the motor drive system to provide working power for the machine. The right end of the main shaft 36 also extends out of the transmission support 31, and passes through a main shaft hole opened on the left side wall 40 of the working cavity 39 fixed on the body 37 to extend into the working cavity 39. The inner part of the main shaft 36 is provided with a cavity 41 penetrating the main shaft. The left end is sleeved with an insulating bush 3 made of insulating material. In order to ensure the insulation effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com