Feeding platform emergency stop safety protection device for branch chipper

A safety protection device and shredder technology, which is applied in grain processing and other directions, can solve the problems of distortion of information collected by in-position switches, wrong signals transmitted by in-position switches, occasional false alarms or missed alarms, etc., so as to improve operation efficiency and safety The effect of improving and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments, and it should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention.

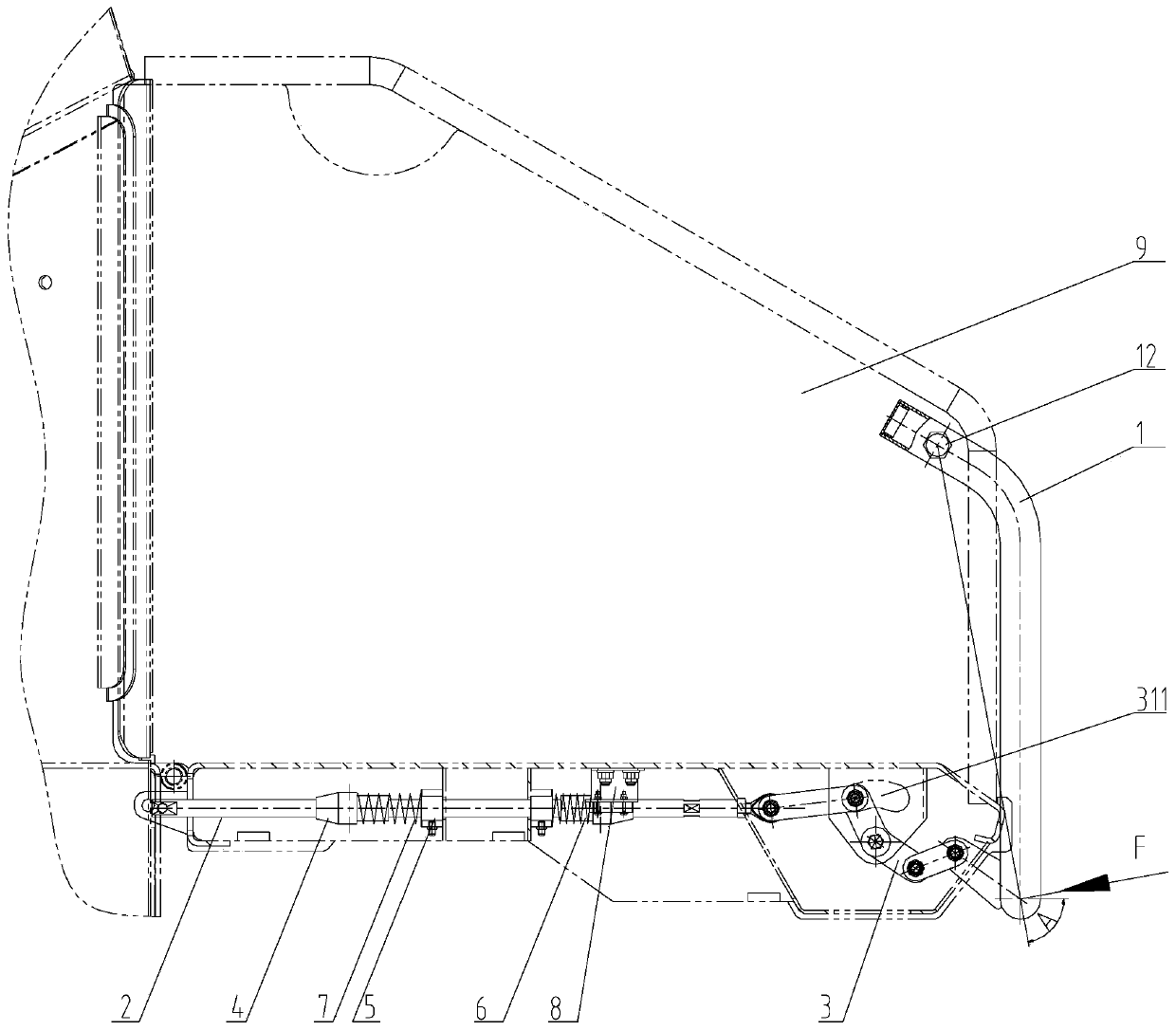

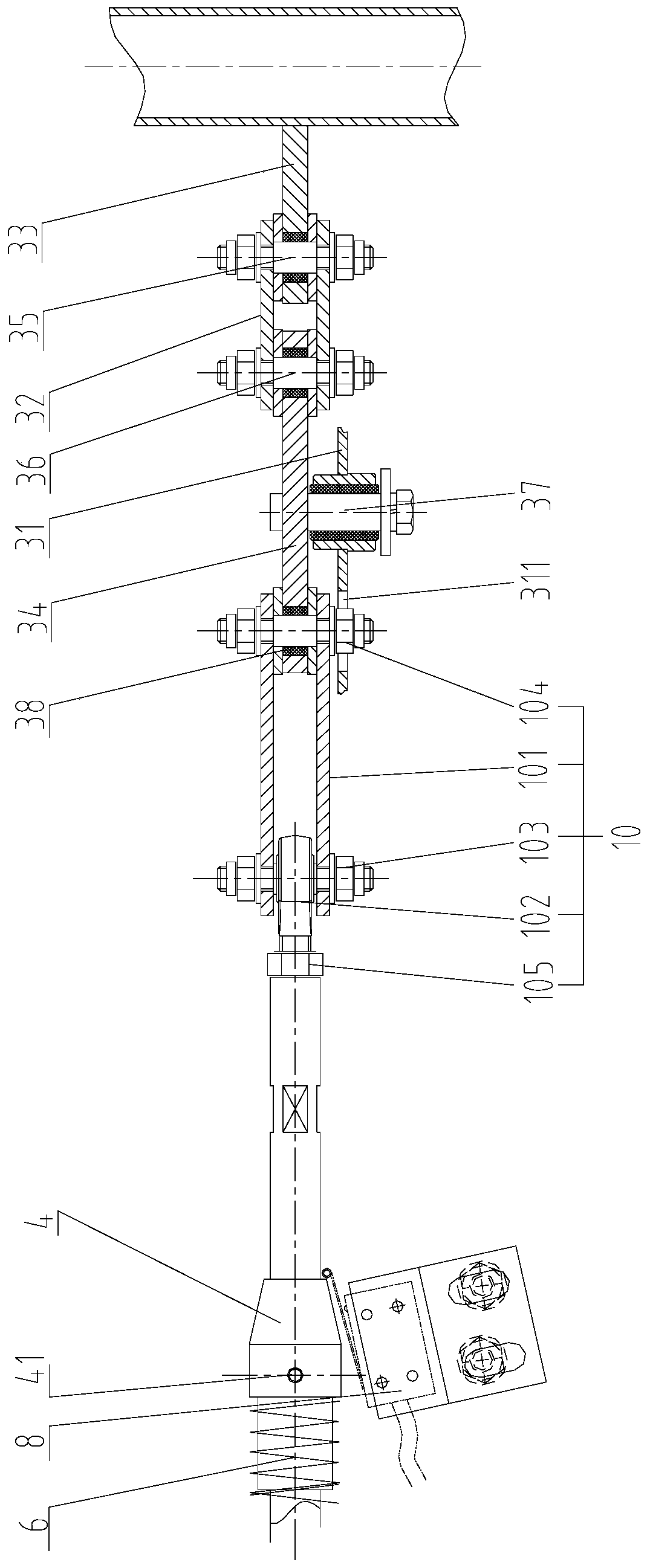

[0021] An emergency stop safety protection device for a chipper feeding platform, such as Figure 1~3 As shown, it includes protective rod welding 1, linkage rod 2, swing arm 3, positioning sleeve 4, shaft sleeve 5, elastic member 1 6, elastic member 2 7, position switch 8 and connection assembly 10.

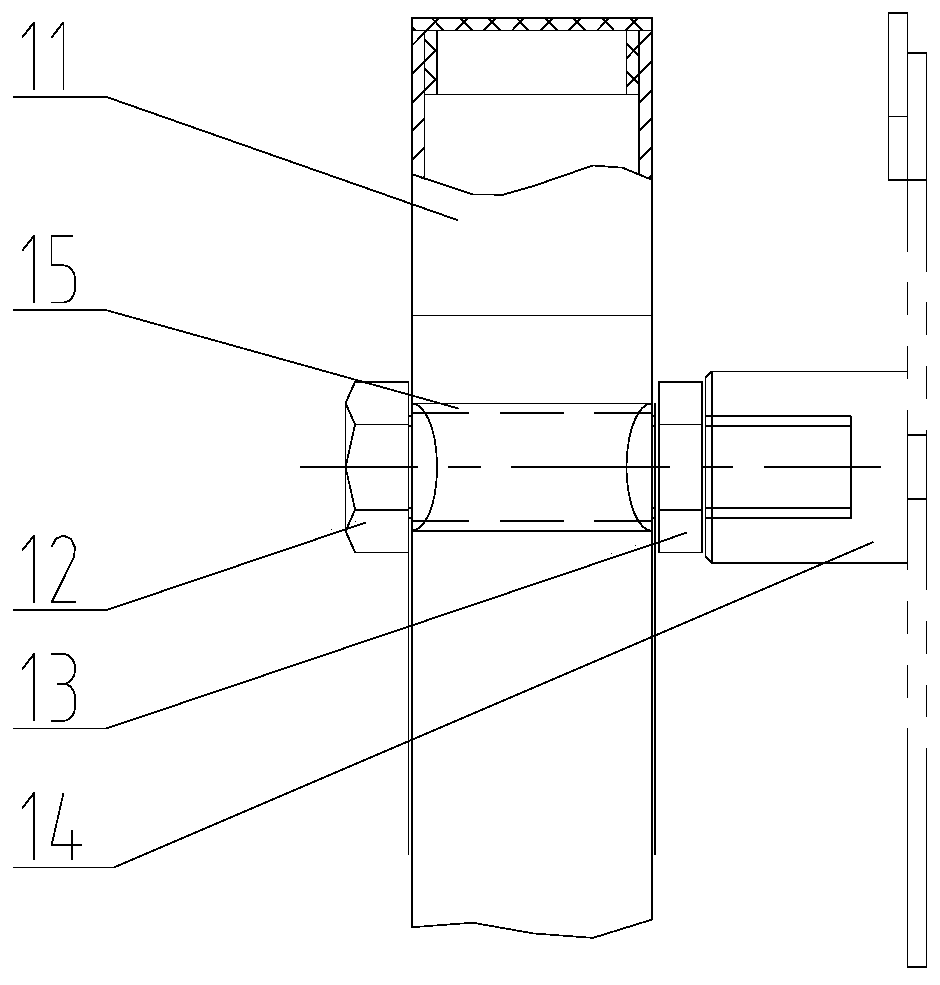

[0022] The protective rod welding 1 is arranged on the feeding chute 9 of the shredder, and the notch of the feeding chute 9 is located at the middle and lower part of one side thereof. The protective rod welding 1 includes a protective rod 11, a fastening bolt 12, and a fastening nut 13 , the connecting seat 14, the bushing 15, the protective rod 11 is a rod-shaped structure with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com