Directional yarn guide mechanism of computer flat knitting machine

A technology of yarn guide mechanism and flat knitting machine, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems that are not found in patent and non-patent literature, increase the cost of the whole machine, eliminate false alarms, Guarantee the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

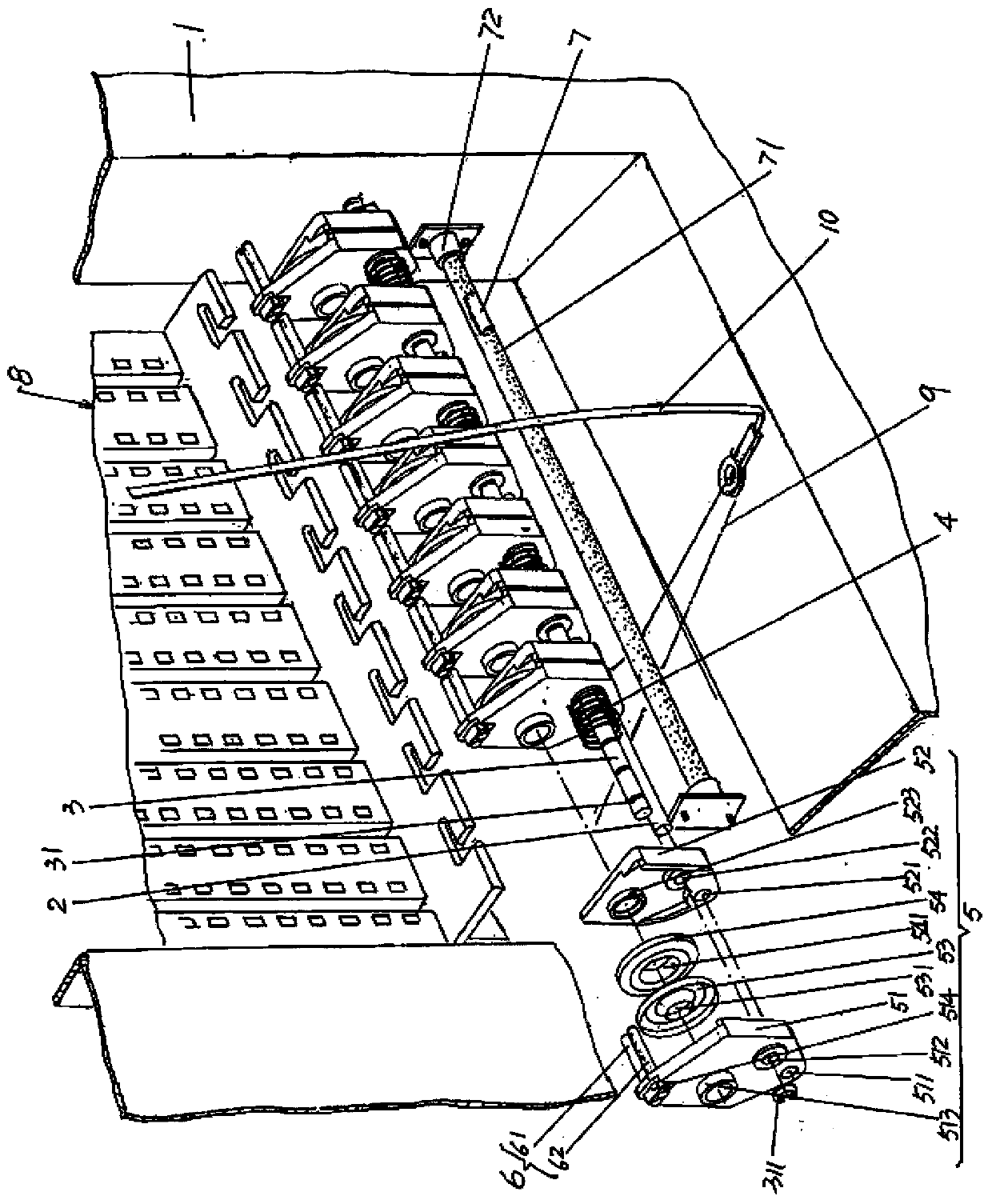

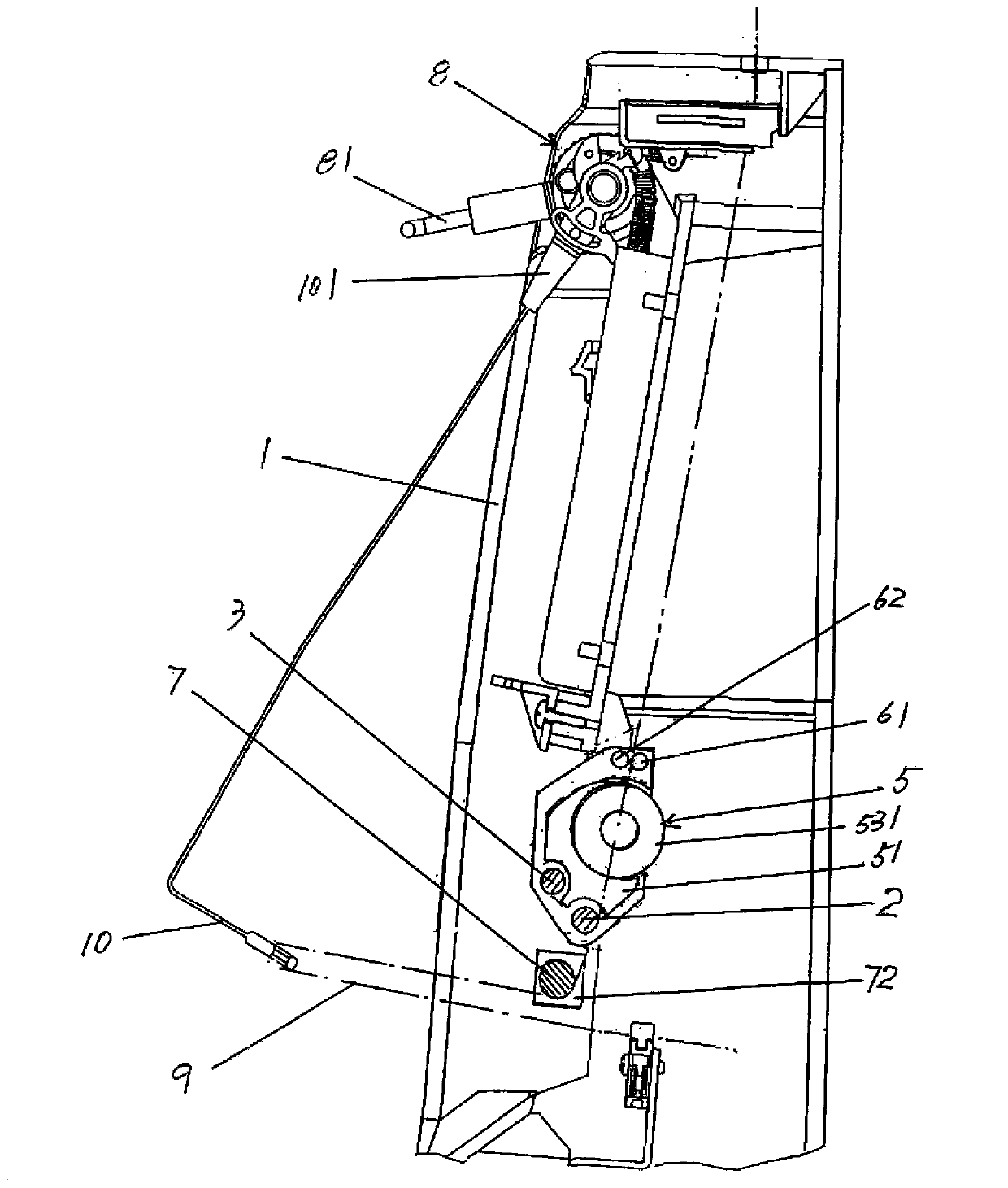

[0022] See figure 1 , provides a bedside box 1 belonging to the structural system of the computerized flat knitting machine, the bedside box 1 is located at one end of the length direction of the computerized flat knitting machine (belonging to the known technology), and the bedside box 1 The yarn pretension adjustment device 8 of the computerized flat knitting machine is arranged inside, and the yarn pretension adjustment device 8 is provided with a broken yarn alarm signal lever 81 ( figure 2 shown), because the yarn pretension adjustment device 8 belongs to the known technology, for example, you can focus on the invention patent authorization announcement number CN102191625B (yarn breakage alarm device for the yarn pretension adjustment device of the computerized The yarn break alarm device of the yarn pretension adjustment mechanism of the knitting machine), so the applicant will not repeat it. Normally, the directional yarn guiding mechanism of the present application i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com