Drainage equipment for grading energy dissipation of debris flow

A debris flow and equipment technology, applied in sea area engineering, construction, artificial waterways, etc., can solve the problems of unfavorable efficiency process drainage, difficult to clean, limited energy dissipation capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

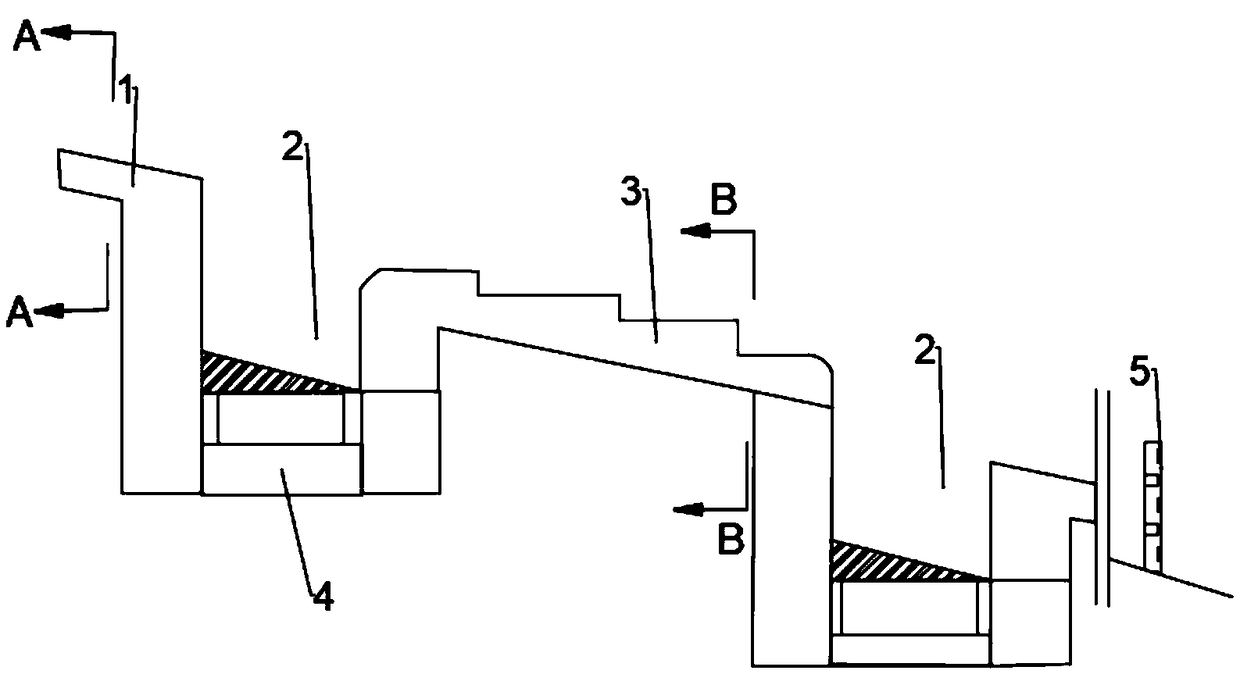

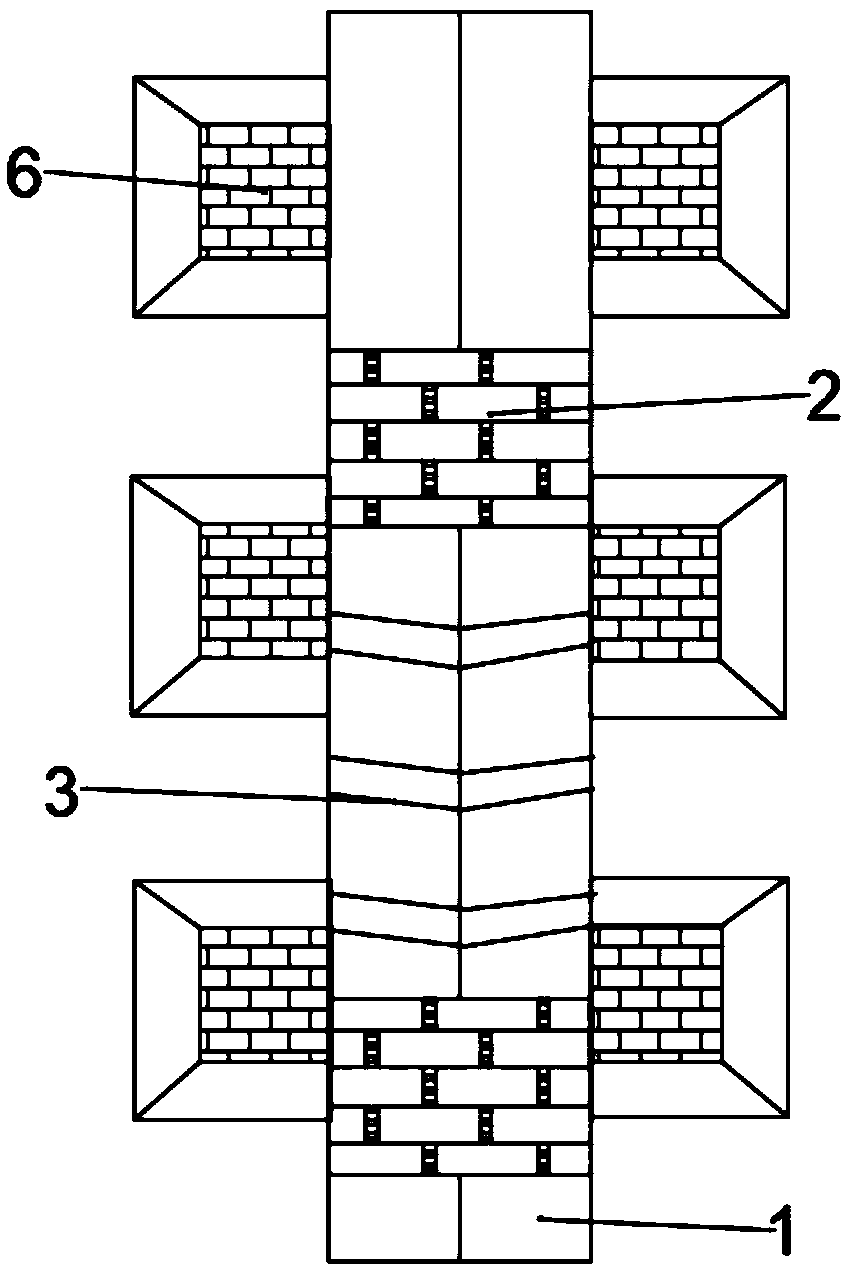

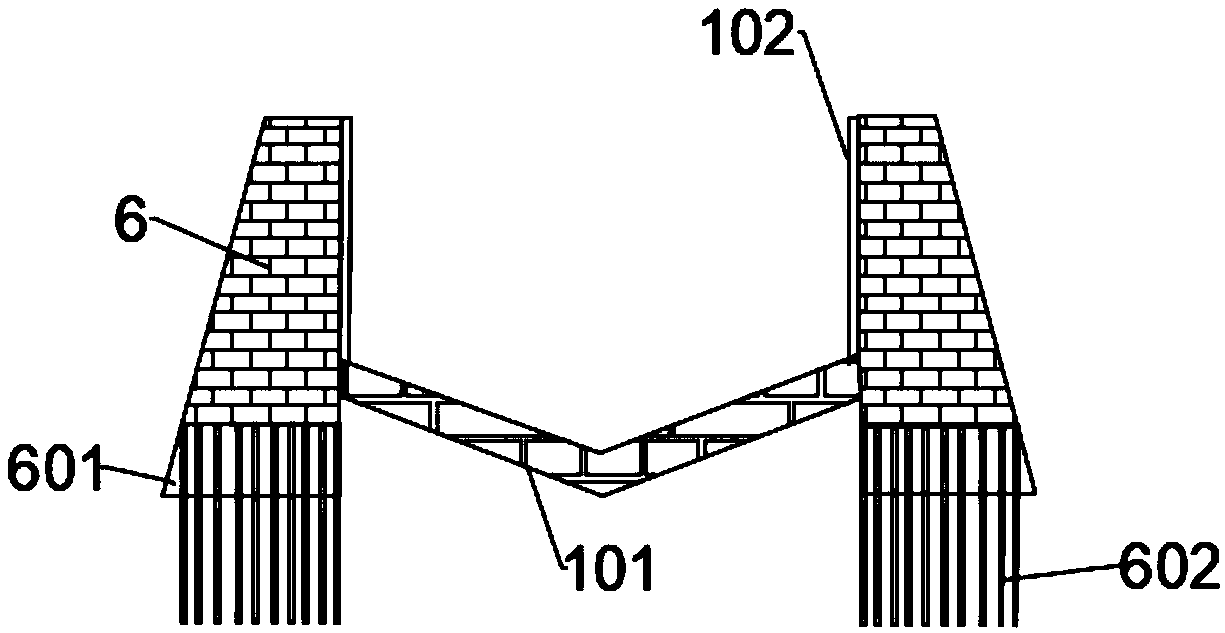

[0045] Such as figure 1 and figure 2As shown, the present invention provides a debris flow grading energy dissipation drainage device, which includes a V-shaped drainage groove 1, and an energy dissipation pool 2 is arranged on the drainage groove 1 every fixed length, and two adjacent An energy dissipation step section 3 is connected between the energy pools 2. The bottom end of the energy dissipation pool 2 is provided with a dredging hydraulic lifting device 4, and the bottom end of the discharge channel 1 is provided with a safety net 5. The left and right sides of the energy step section 3 are all provided with some prism fixing piles 6 .

[0046] The specific implementation process of the present invention and the principle of energy dissipation and drainage are as follows: firstly, it is necessary to find some terrain depressions on the mountain body that can be used for laying the ravines of the drainage groove 1, and after finding a suitable place, the ravines are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com