Film pasting machine

A film lamination machine and flat lamination technology, which is applied in the field of film lamination machines, can solve the problems that the protective film cannot be easily attached, waste of manpower and material resources, and difficulty in automatic film lamination operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0141] Embodiments of the present invention will be described in detail below.

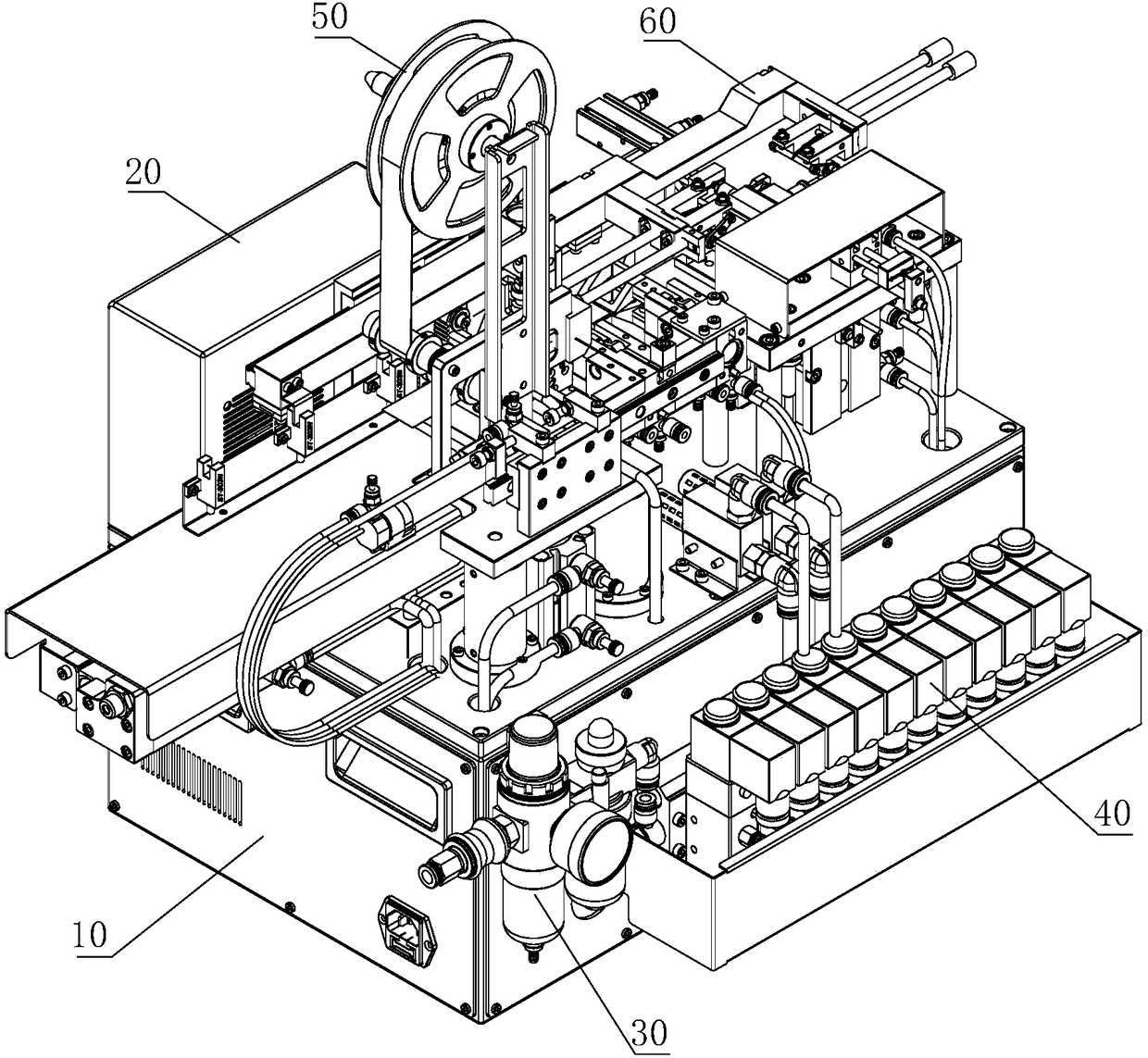

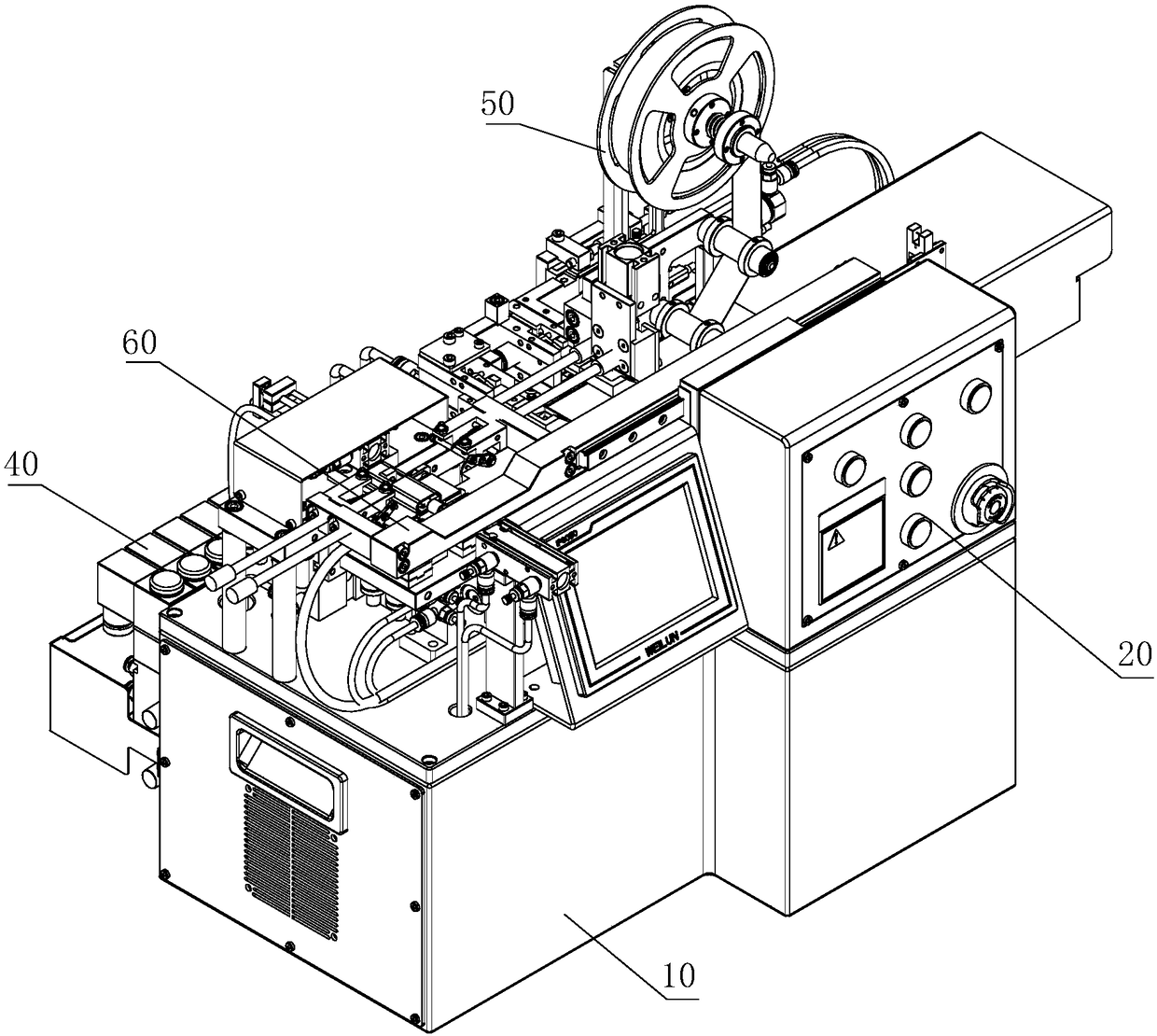

[0142] Such as Figure 1 to Figure 17 As shown, the film laminating machine includes a box body 10, an electrical control device 20, a pneumatic control device 30, a vacuum generating device 40, a cutting and retrieving device 50, a flattening and attaching device 60, a profiling attaching device 70, and an electrical control device 20, the pneumatic control device 30, and the vacuum generating device 40 are respectively installed on both sides of the box body 10, and the pneumatic control device 30 and the vacuum generating device 40 are respectively electrically connected to the electrical control device 20;

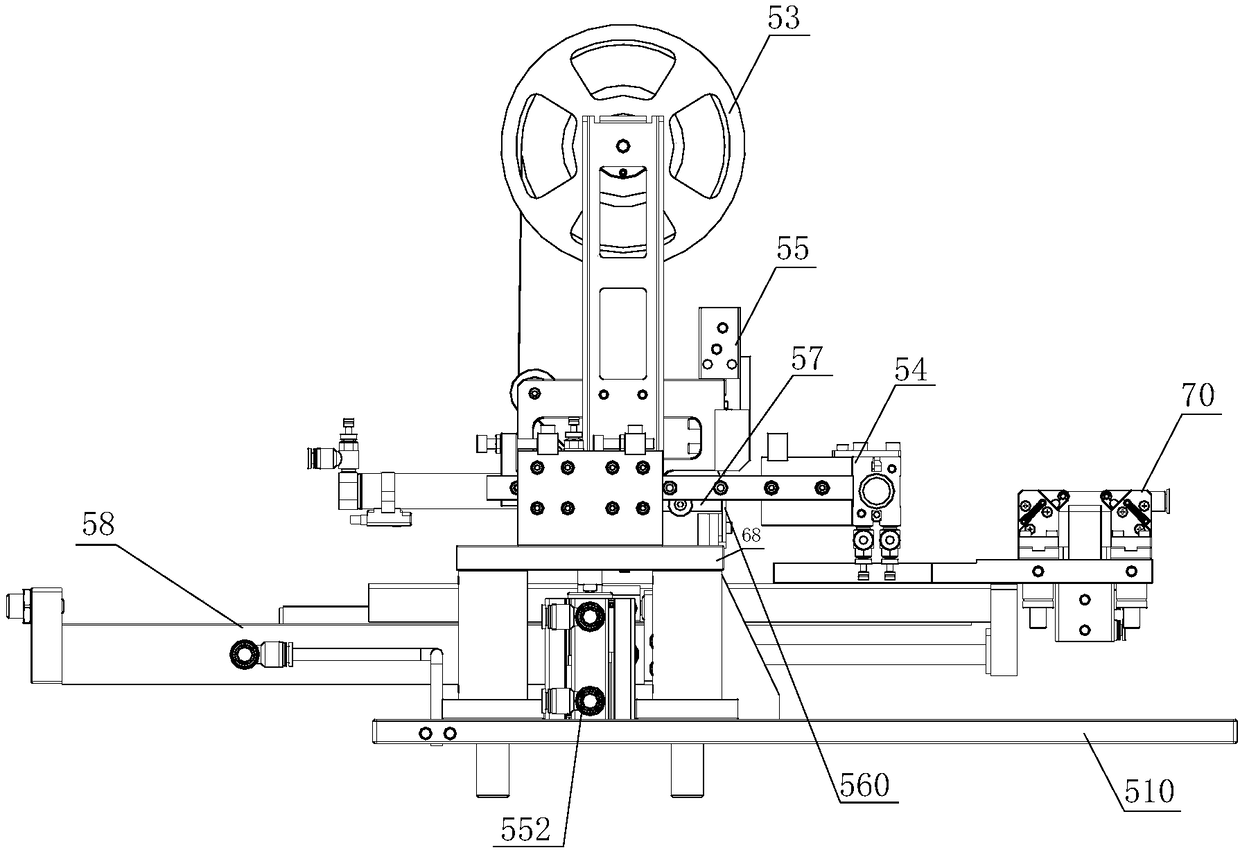

[0143] The cutting and retrieving device 50 is installed on the top surface of the box body 10. The cutting and retrieving device 50 has a base plate 51, a material retrieving slide 58, and a first vacuum suction table 57. The plane smoothing and attaching device 60 is installed on the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com