Vibration type grinding and polishing machine for electroplated products

A polishing machine and product technology, applied in the direction of surface polishing machine tools, grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, etc., can solve the internal product displacement, the influence of grinding and polishing uniformity, and affect product quality and other issues to achieve the effect of improving product quality and solving displacement problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

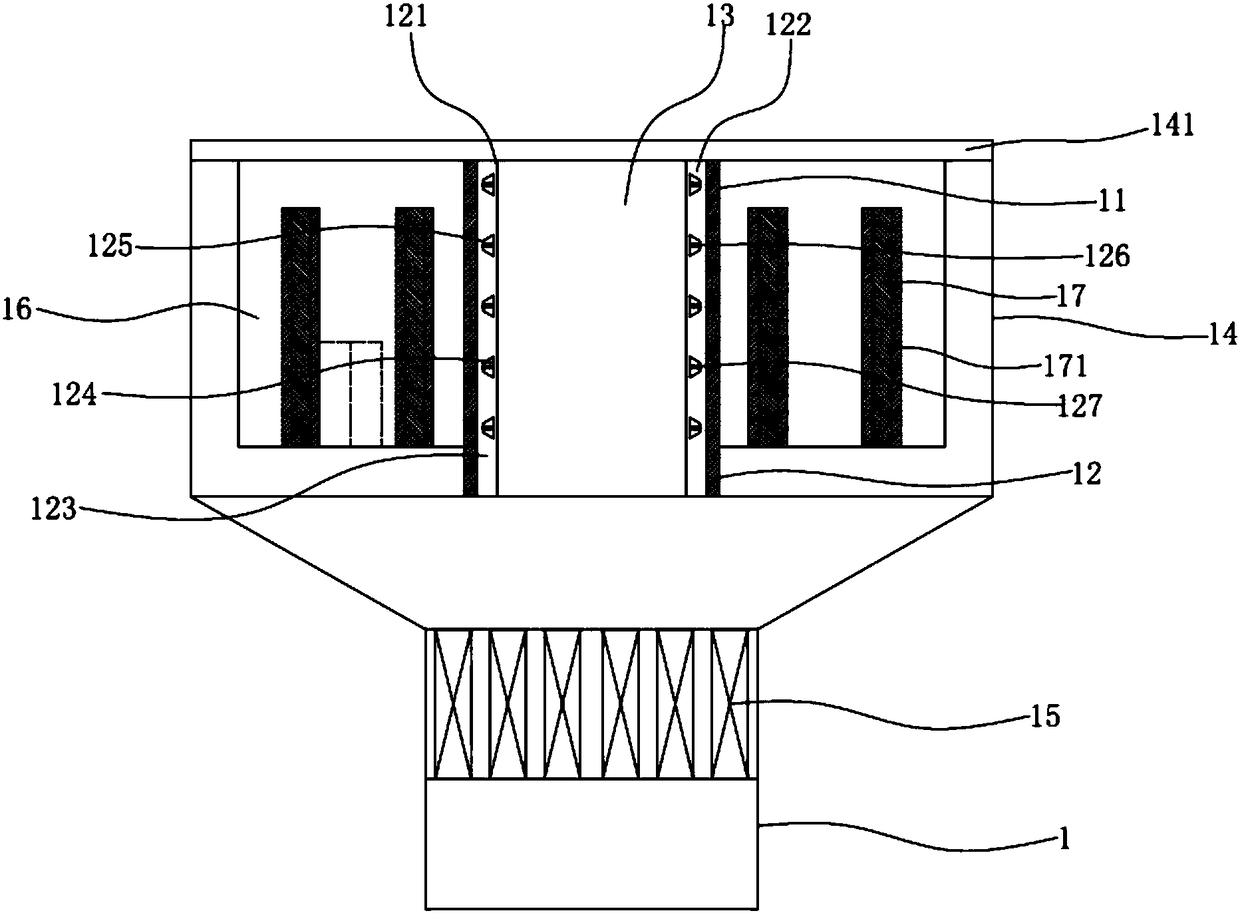

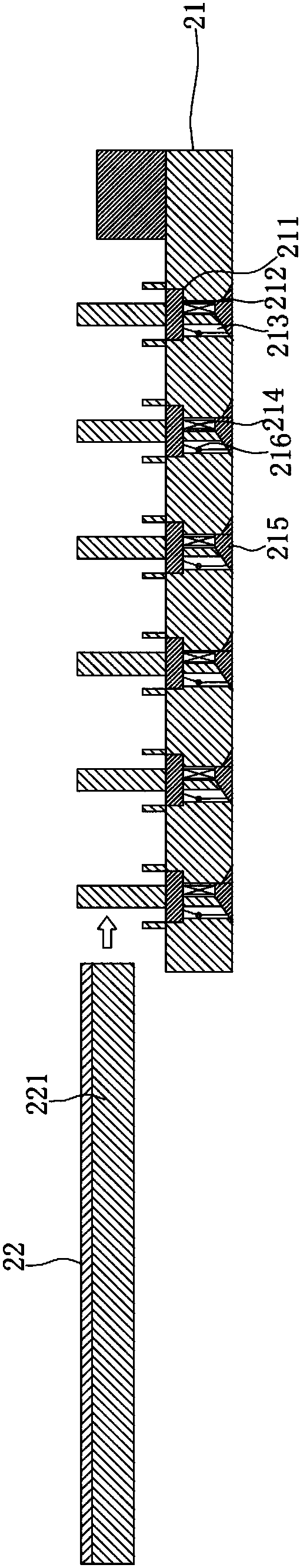

[0019] see Figure 1 to Figure 2 , the figure shows a vibratory grinding and polishing machine for electroplating products provided by an embodiment of the present invention, which includes a base 1 on which a driving mechanism 11 is installed. The driving mechanism 11 has a casing 12, and a Drive motor 13, casing 12 is set with vibration box 14, is connected with a plurality of elastic parts 15 between the bottom of vibration box 14 and base 1, and a plurality of elastic parts 15 is evenly arranged along the circumference of base 1, and casing 12 An annular vibration cavity 16 is arranged between the vibration box 14, a casing 121 is pierced in the casing 12, the driving motor 13 is arranged in the casing 121, and an inner wall of the casing 12 and an outer wall of the casing 121 are provided The annular gap 122 is provided with a backing plate 123 inside the annular gap 122 , and a plurality of deformation components 124 are arranged inside the backing plate 123 . Wherein, ...

Embodiment 2

[0022] see Figure 1 to Figure 2 , the figure shows a vibratory grinding and polishing machine for electroplating products provided by Embodiment 2 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: the filler block can be A trapezoidal filling block; a groove 126 is opened on the top of the filling block, and a spring 127 is filled in the groove 126 . Through the improvement of the above technical solution, the limiting and buffering effect of the movement of the rolling groove of the carrier in the axial direction can be further formed.

Embodiment 3

[0024] see Figure 1 to Figure 2 , the figure shows a vibration grinding and polishing machine for electroplating products provided by Embodiment 3 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: ring vibration cavity 16 is provided with a plurality of rollers 17 parallel to the axial direction of the casing 12; elastic bushings 171 are fitted on the rollers 17. Through the improvement of the above technical solution, the limiting and buffering effect of the movement of the rolling groove of the carrier in the axial direction can be further formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com