A metal pipe stretching device

A technology of metal pipes and stretching devices, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve problems such as low efficiency and inconvenient operation, and achieve the effect of preventing damage and offsetting displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

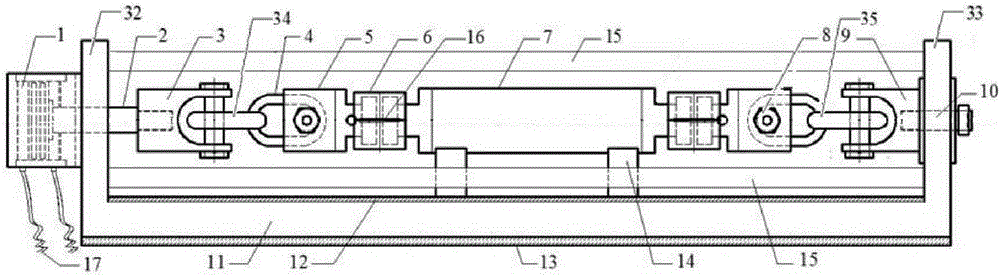

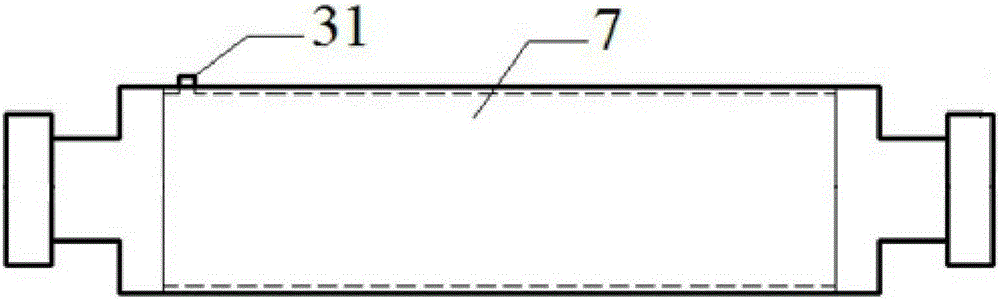

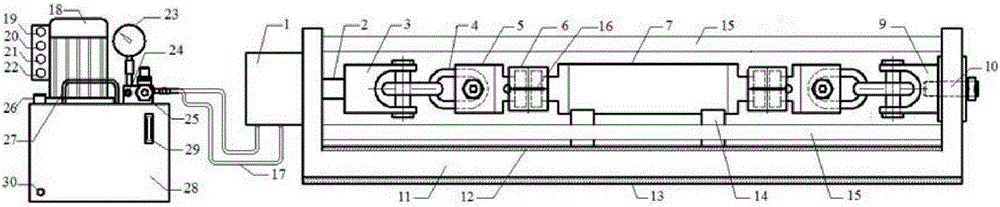

[0038] The metal pipe stretching device described in this embodiment includes: an assembly bracket 11 and a stretching structure, wherein: the assembly bracket 11 is formed with a first support plate 32 and a second support plate 33 arranged parallel to each other;

[0039] The tensile structure is arranged between the first support plate 32 and the second support plate 33, and includes a first connecting rod 34, a second connecting rod 35, a first buffer member and a second buffer member, wherein the first A connecting rod 34 is connected to the first support plate 32, and the second connecting rod 35 is connected to the second support plate 33. At the same time, the first connecting rod 34 is also connected to the hydraulic system, which is suitable for Under the action of the hydraulic system, the hydraulic system reciprocates in the axial direction. The hydraulic system in this embodiment includes a hydraulic cylinder 1 and a hydraulic connecting rod 2. The hydraulic cylind...

Embodiment 2

[0050] For the metal pipe stretching device described in this embodiment, see figure 1 ( figure 1 It is a schematic cross-sectional structure diagram of the metal pipe stretching device according to the present invention), including: an assembly bracket 11 and a stretching structure, wherein: the assembly bracket 11 is formed with a rectangular first support plate 32 and a second rectangular support plate arranged parallel to each other. Two support plates 33;

[0051] The tensile structure is arranged between the first support plate 32 and the second support plate 33, including: a first connecting rod 34, a second connecting rod 35, a first buffer member and a second buffer member, wherein the The first connecting rod 34 is connected to the first support plate 32, the second connecting rod 35 is connected to the second support plate 33, and the first connecting rod 34 is also connected to the hydraulic system. The hydraulic system reciprocates axially under the action of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com