Method for preparing anode surface antioxidation protective agent used for carbon-base aluminum

An anti-oxidation, carbon-based aluminum technology, applied in the field of preparation of anti-oxidation protective agent, can solve the problems of reducing the contact area between the anode and the air, reducing the quality of primary aluminum, reducing the air reactivity, etc. Anode net consumption, effect of reducing diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

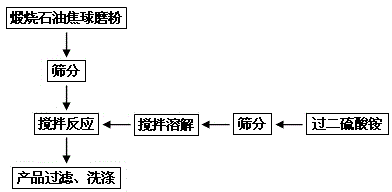

[0018] Such as figure 1 As shown, the preparation method of the carbon-based aluminum anode surface anti-oxidation protective agent of the present invention includes the following steps: screening the raw materials, selecting calcined petroleum coke ball mill powder for the carbon-based raw materials, and using ammonium peroxodisulfate as a modifier; Industrial demineralized water first dissolves ammonium peroxodisulfate to obtain a solution, and then adds pre-screened carbon-based raw materials to the solution; carries out oxidation modification reaction at 100 ℃ in an electric heating reactor with stirring; Demineralized water washes residual inorganic salt ions to obtain carbon-based antioxidant protection agent products.

[0019] The particle size of calcined petroleum coke ball mill powder is 190 mesh.

[0020] The particle size of ammonium peroxodisulfate is less than 0.48 mm.

[0021] Ammonium peroxodisulfate is fully dissolved in industrial demineralized water.

[0...

Embodiment 2

[0027] The preparation method of the anode surface anti-oxidation protective agent for carbon-based aluminum of the present invention comprises the following steps: screening the raw materials, using calcined petroleum coke ball mill powder as the carbon-based raw material, using ammonium peroxodisulfate as a modifier; using industrial demineralized water First dissolve ammonium persulfate to obtain a solution, then add pre-screened carbon-based raw materials to the solution; carry out oxidation modification reaction at 80 ℃ in an electric heating reactor with stirring; wash with industrial demineralized water after the reaction Residual inorganic salt ions are used to obtain carbon-based antioxidant protective agent products to ensure that primary aluminum will not be polluted in actual production applications. .

[0028] The particle size of calcined petroleum coke ball mill powder is 150 mesh.

[0029] The particle size of ammonium peroxodisulfate is less than 0.3 mm.

[...

Embodiment 3

[0036] The preparation method of the anode surface anti-oxidation protective agent for carbon-based aluminum of the present invention comprises the following steps: screening the raw materials, using calcined petroleum coke ball mill powder as the carbon-based raw material, using ammonium peroxodisulfate as a modifier; using industrial demineralized water First, dissolve ammonium peroxodisulfate to obtain a solution, and then add pre-screened carbon-based raw materials to the solution; carry out oxidation modification reaction at 90 ℃ in an electric heating reactor with stirring; wash with industrial demineralized water after the reaction Residual inorganic salt ions to obtain carbon-based antioxidant protective agent products.

[0037] The particle size of calcined petroleum coke ball mill powder is 100 mesh.

[0038] The particle size of ammonium peroxodisulfate is less than 0.2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com