Production process of high-purity spray-free crucible

A production process, spray-free technology, applied in the direction of coating, etc., can solve the problems of sagging, sticking to the pot, waste of silicon raw materials, etc., to reduce the probability of adhesion and shedding, reduce the content of silicon nitride, and reduce the amount of diffusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

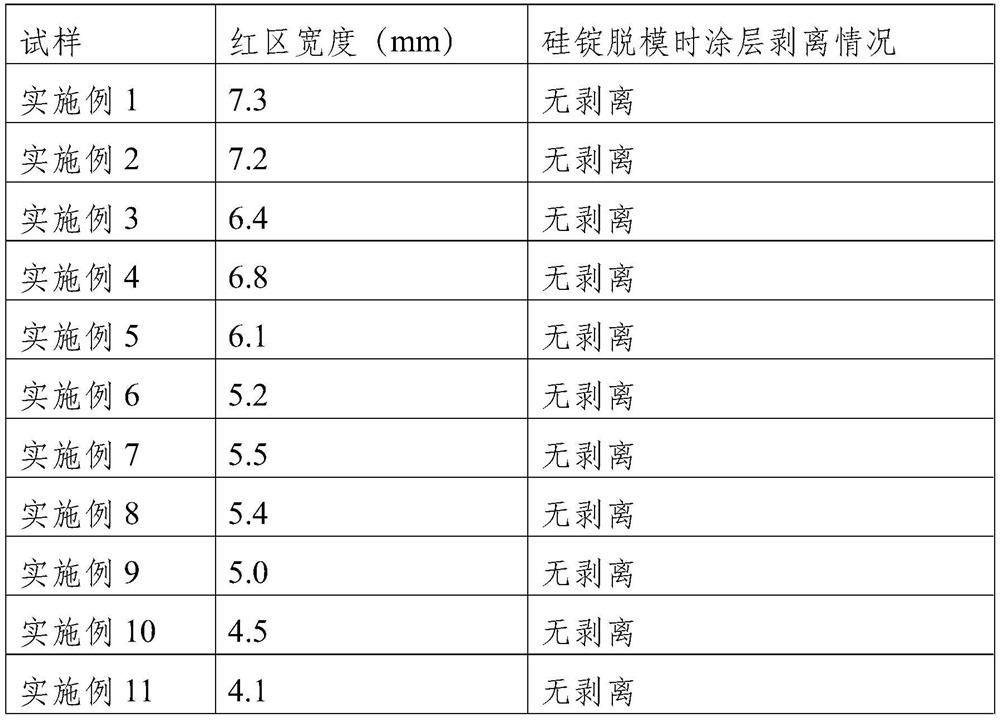

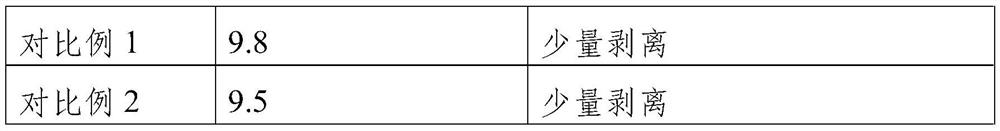

Examples

Embodiment 1

[0021] The production technology of embodiment 1 high-purity spray-free crucible comprises the following steps:

[0022] Ⅰ. Configure the silicon nitride slurry, and brush the silicon nitride slurry on the inner surface of the ordinary quartz crucible;

[0023] Ⅱ. Dry the painted crucible at 130°C to obtain a high-purity spray-free crucible with a silicon nitride coating on the inner surface;

[0024] Wherein, by weight percentage, the composition of the silicon nitride slurry includes: 30% of silicon nitride powder with α-phase content ≥ 90%, 22% of silica sol and 48% of deionized water. The solid content of the silica sol is 30%; the thickness of the silicon nitride coating is 70 microns.

[0025] The silicon nitride of embodiment 1 adopts the silicon nitride fine powder of 100-200 mesh.

Embodiment 2

[0027] The difference between Example 2 and Example 1 is that the drying temperature is 165° C., and the composition of the silicon nitride slurry includes: 44% silicon nitride powder with an α-phase content ≥ 90%, 15% silicon nitride powder sol and 41% deionized water.

Embodiment 3

[0029] The difference between Example 3 and Example 2 is that the drying temperature is 200° C., and the composition of the silicon nitride slurry includes: 37% of silicon nitride powder with α-phase content ≥ 90%, and 18% of silicon nitride powder. sol and 45% deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com