Patents

Literature

45results about How to "Reduce the amount of diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

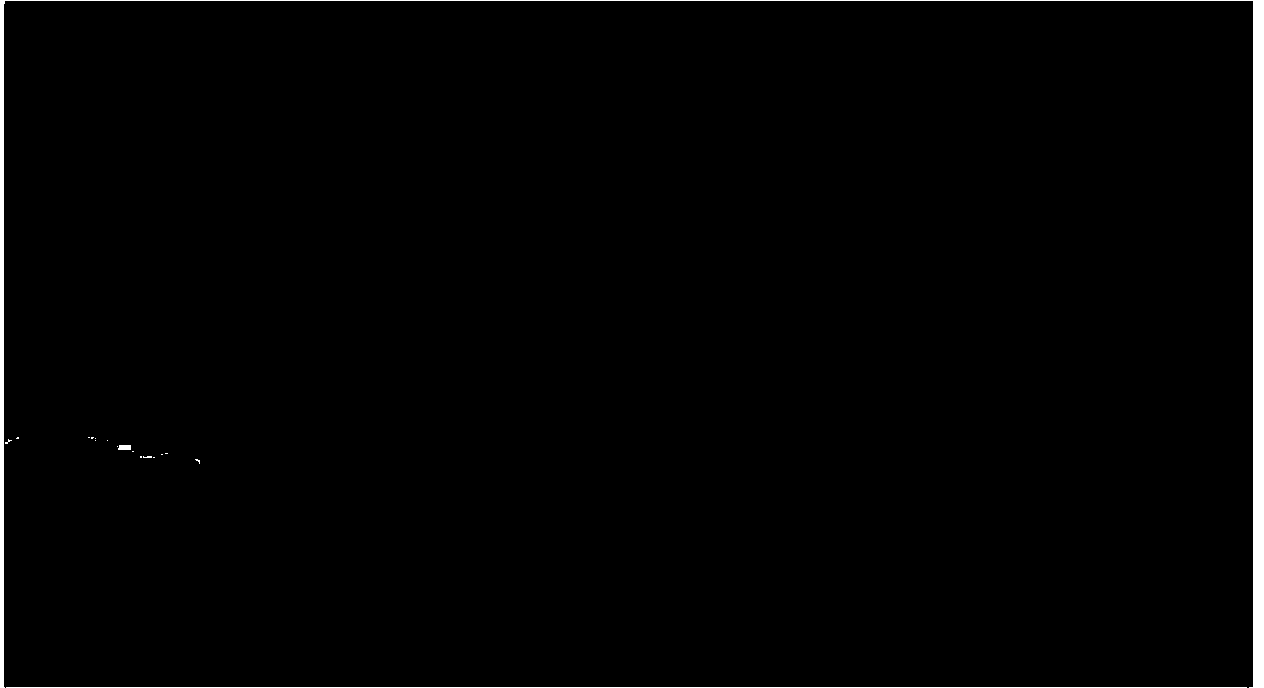

Earthquake image structure guiding noise reduction method based on regularization mixed norm filtering

ActiveCN103489163AImprove signal-to-noise ratioPreserve Texture EdgesImage enhancementDiffusionEigenvalues and eigenvectors

The invention discloses an earthquake image structure guiding noise reduction method based on regularization mixed norm filtering. The earthquake image structure guiding noise reduction method includes the following steps that a gradient structure tensor is solved for an input three-dimensional earthquake image; regularization mixed norm filtering is conducted on the gradient structure tensor; a diffusion tensor is designed according to the eigenvalue and eigenvector of the filtered gradient structure tensor; continuity factors are calculated, the continuity factors at the position of a boundary fault feather edge and the like are close to zero, and the maintain performance of the structure is achieved; a sobel operator serves as a derivation operator so that divergence can be calculated. By means of the earthquake image structure guiding noise reduction method based on regularization mixed norm filtering, the textured edge information of earthquake-related data can be reserved, Gaussian noise, ultra Gaussian noise and sub Gaussian noise can be effectively suppressed, and therefore an efficient noise reduction method is achieved.

Owner:OPTICAL SCI & TECH (CHENGDU) LTD

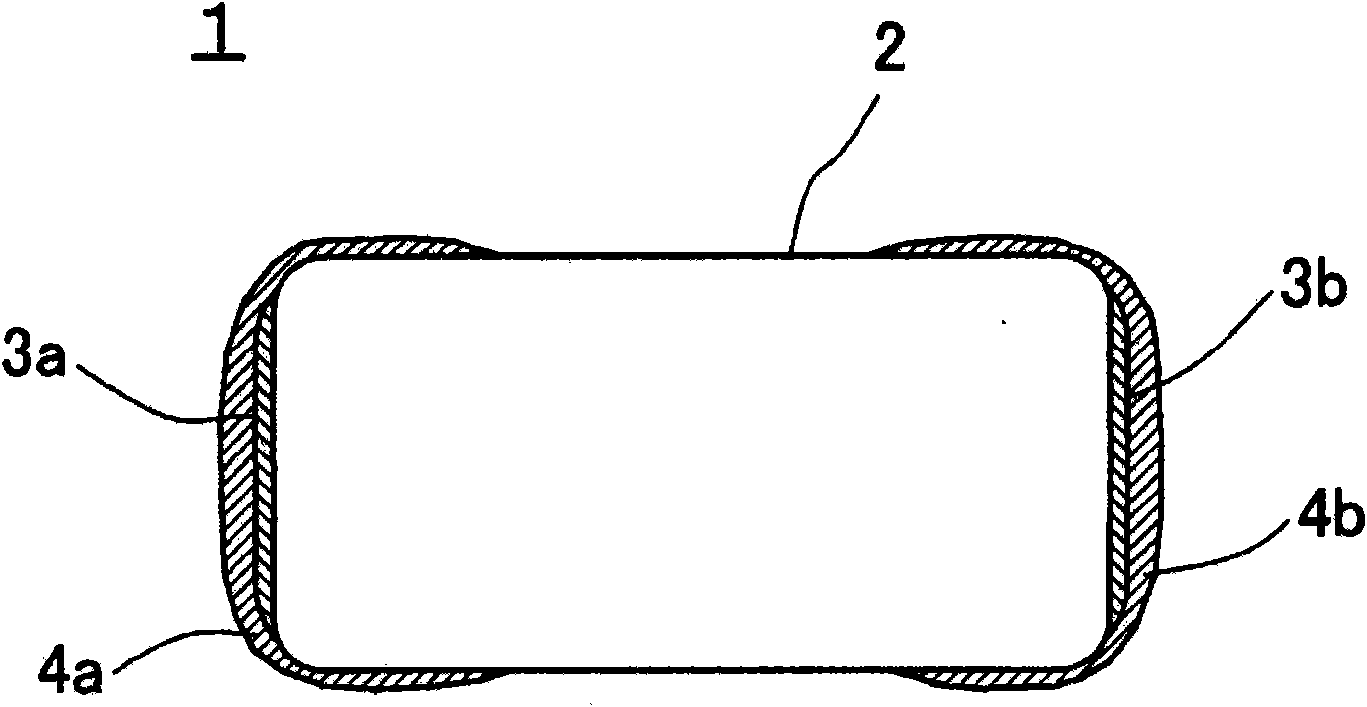

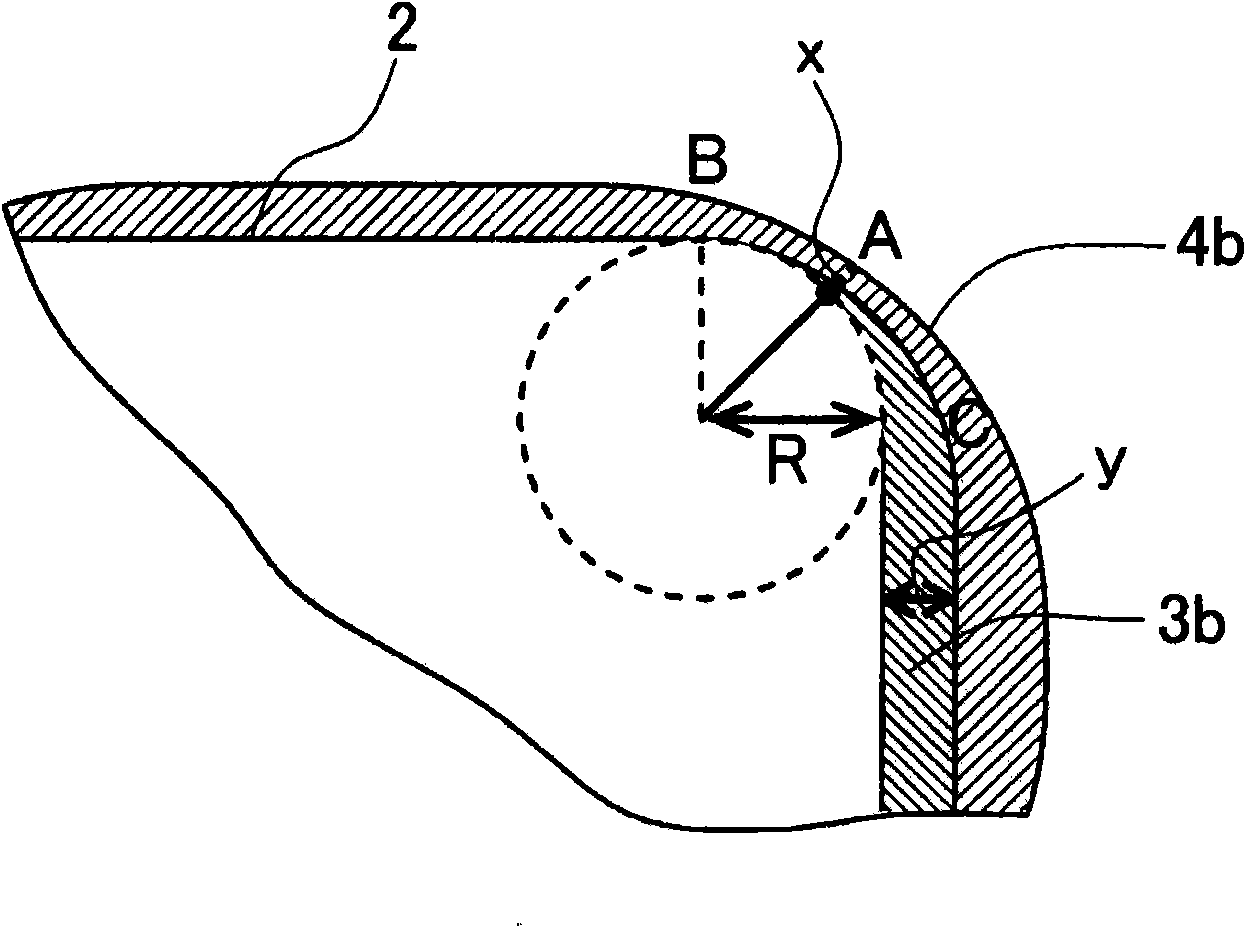

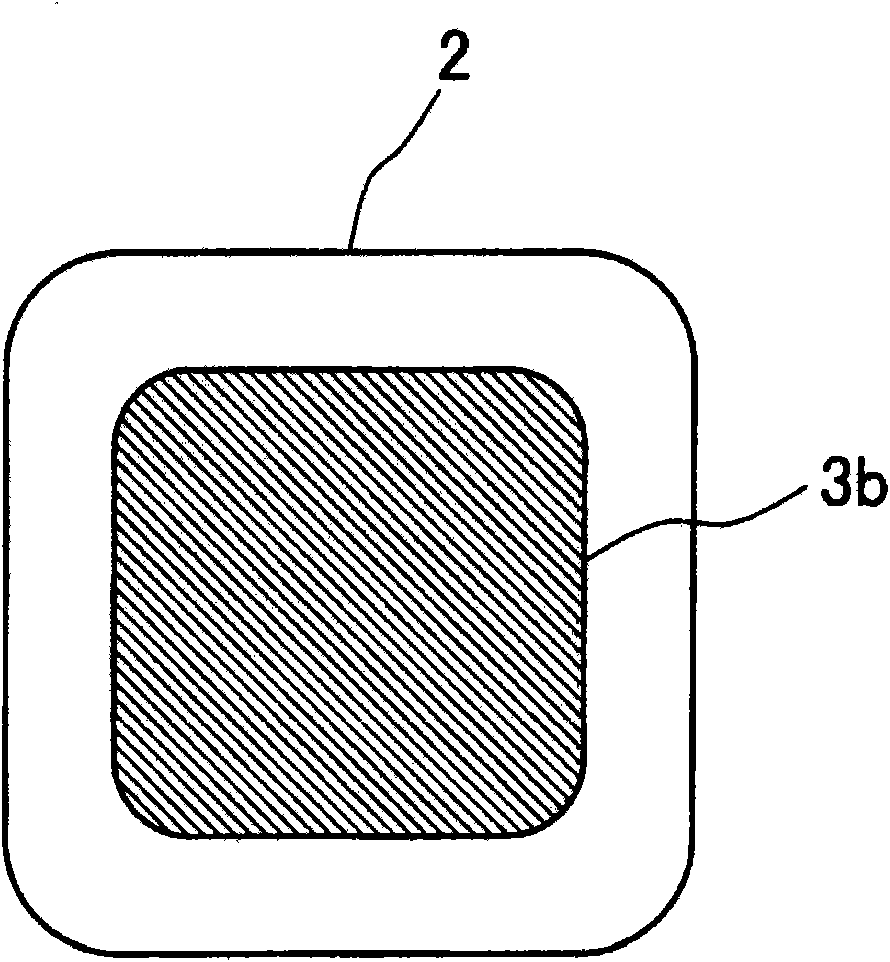

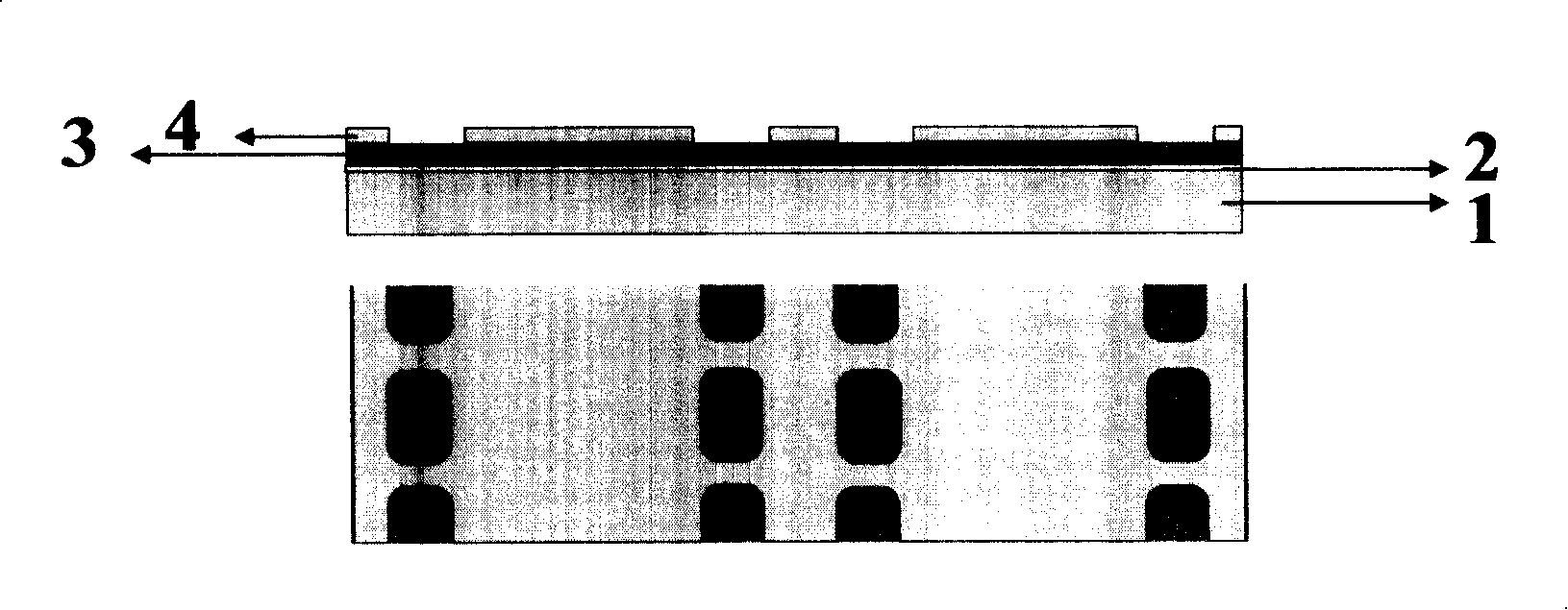

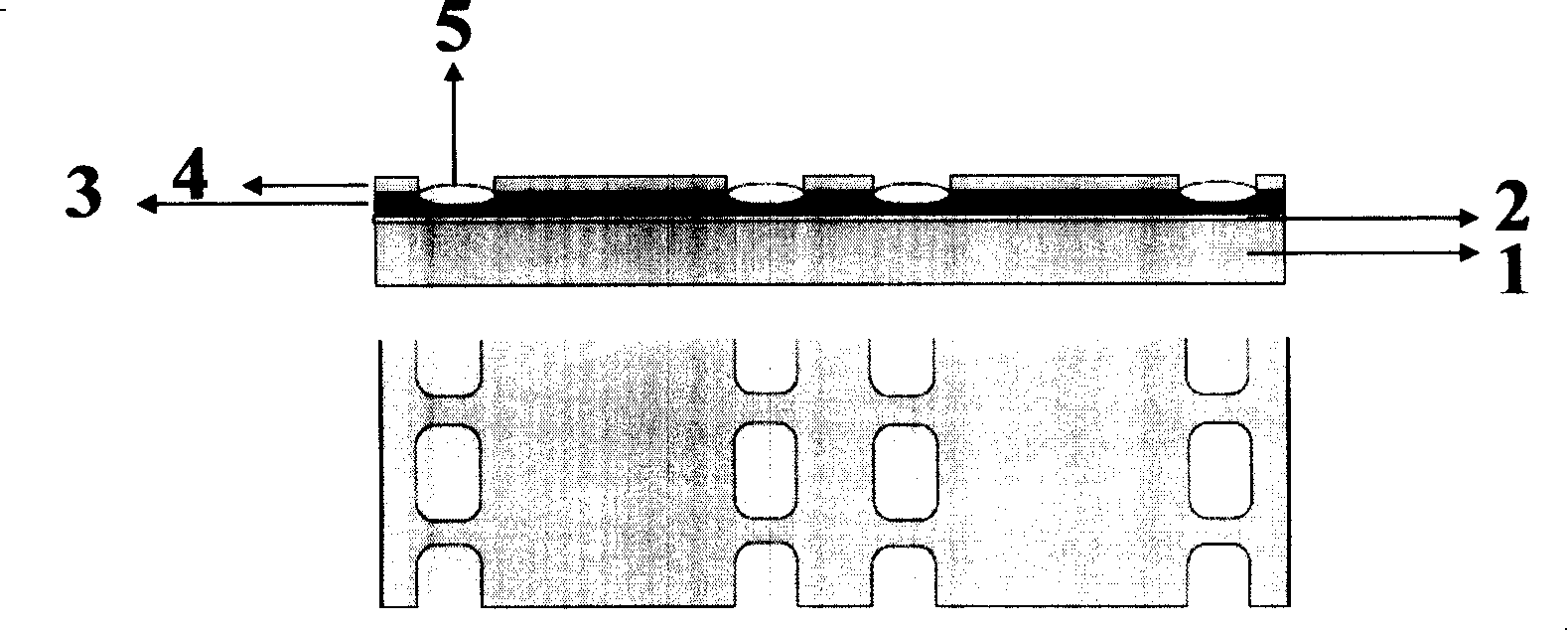

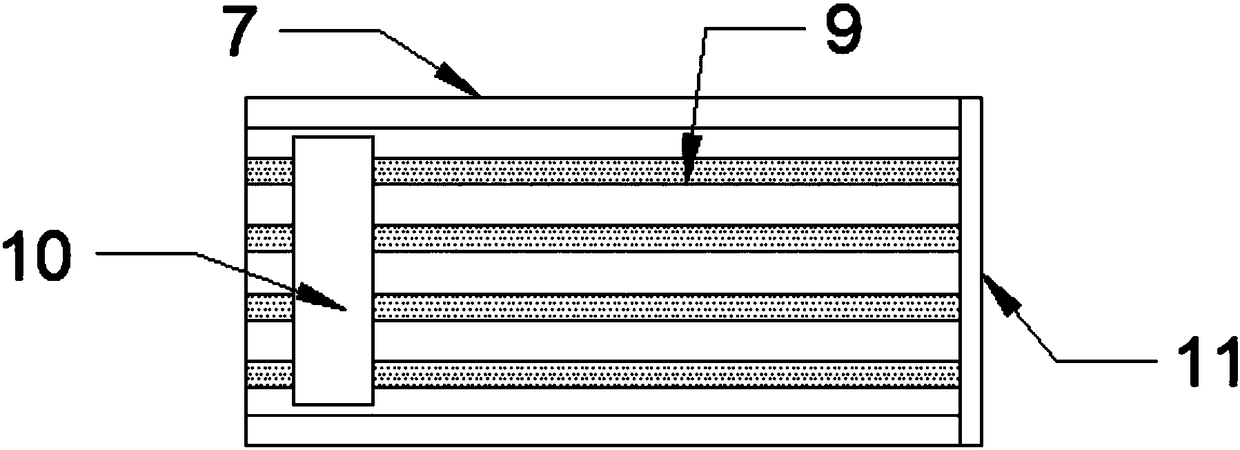

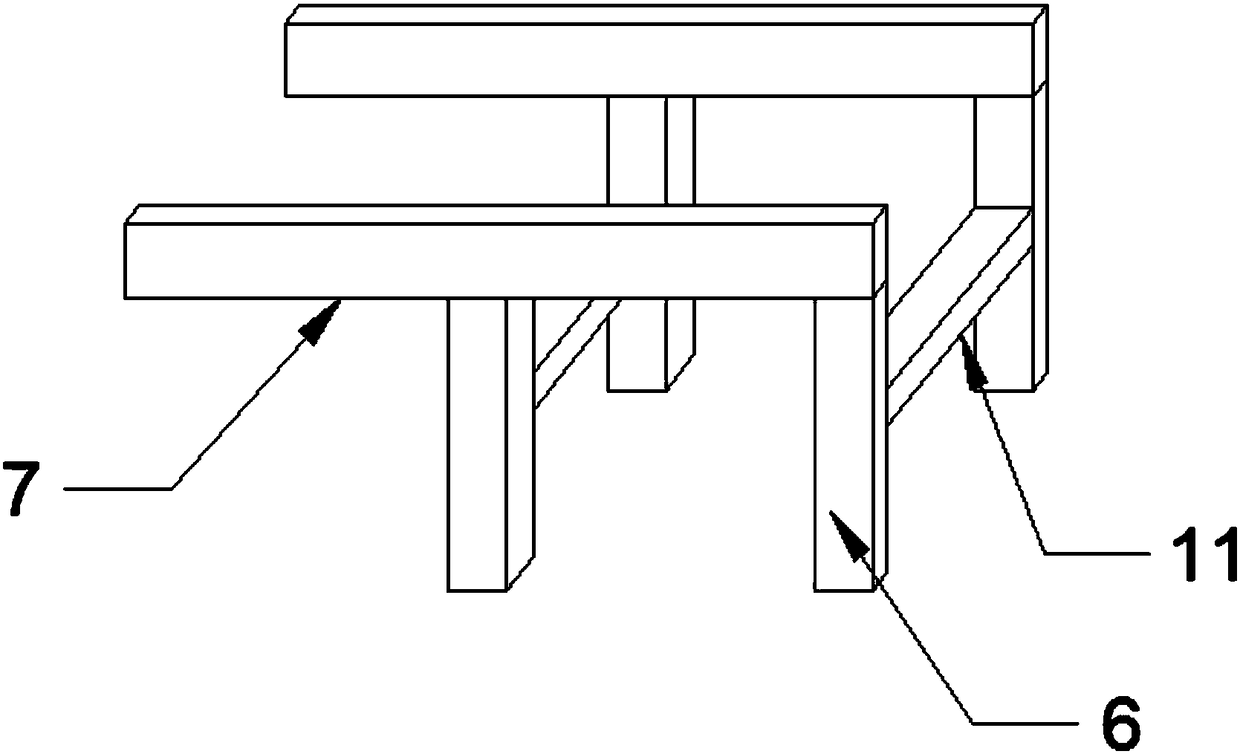

Chip-type semiconductor ceramic electronic component

ActiveCN101925968AGuaranteed functionPrevent proliferationNegative temperature coefficient thermistorsPositive temperature coefficient thermistorsElectrical resistance and conductanceElectronic component

Owner:MURATA MFG CO LTD

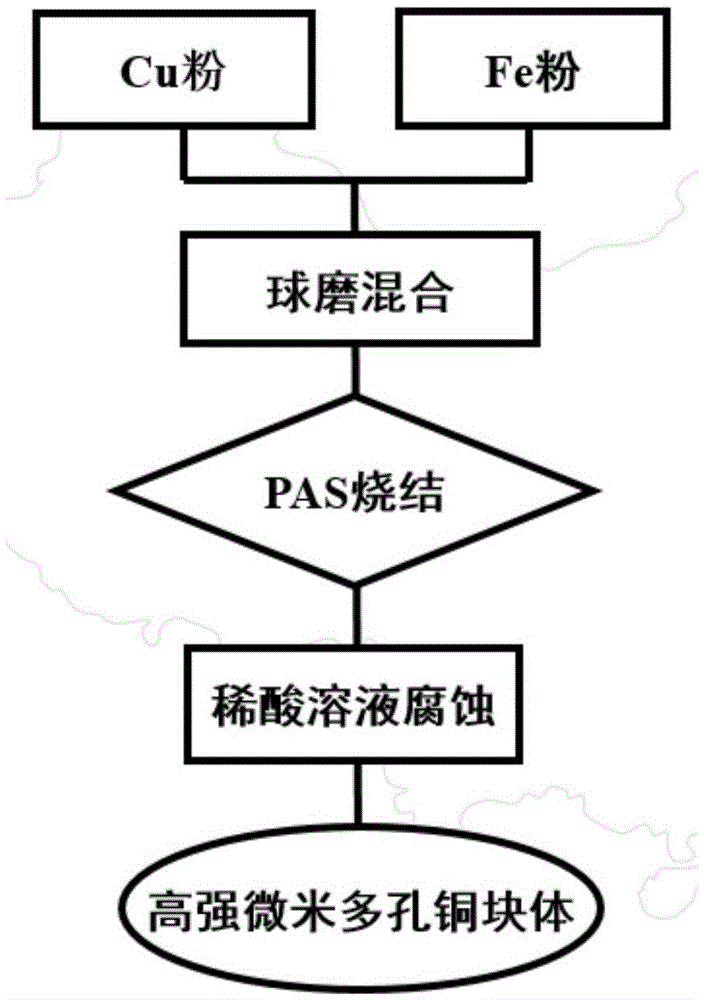

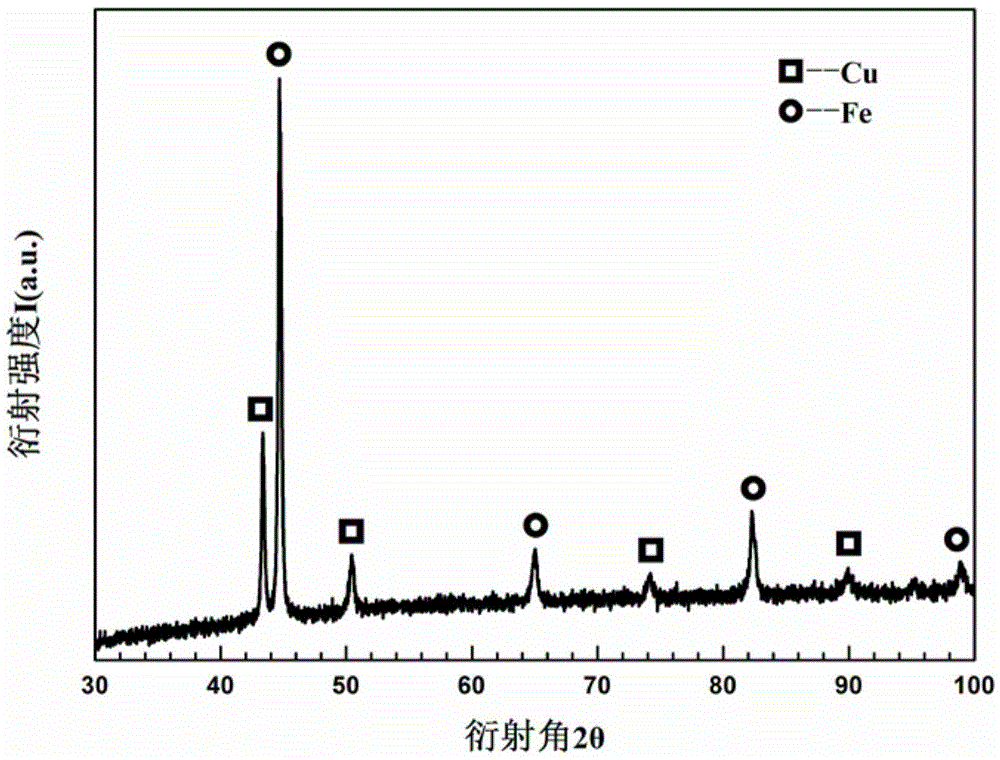

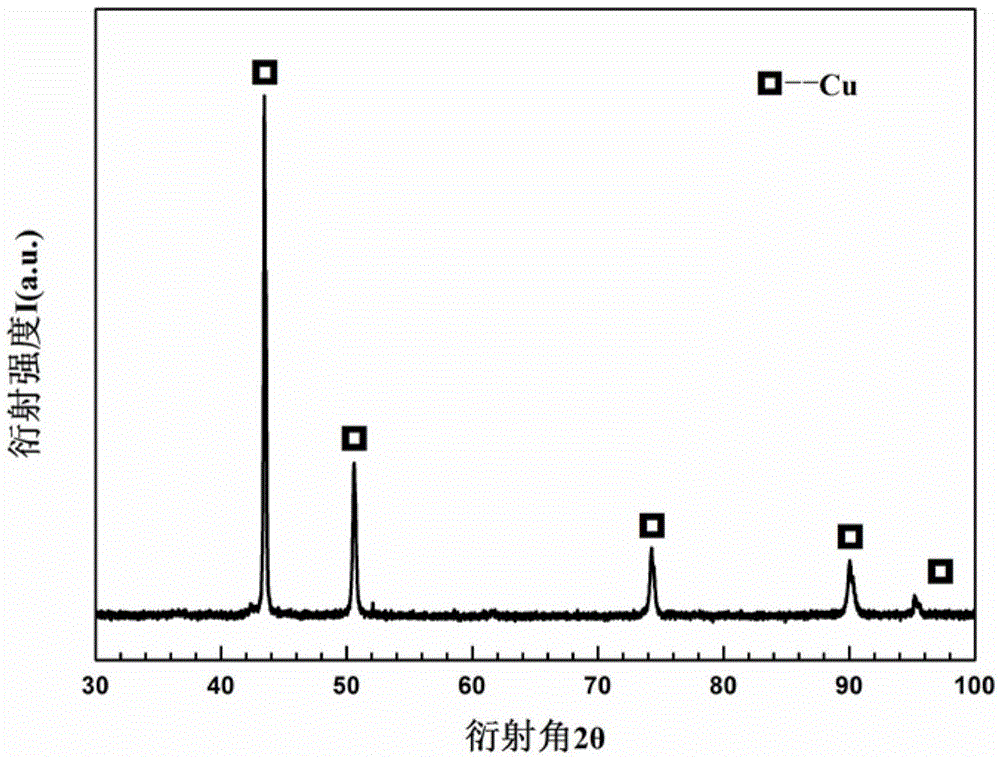

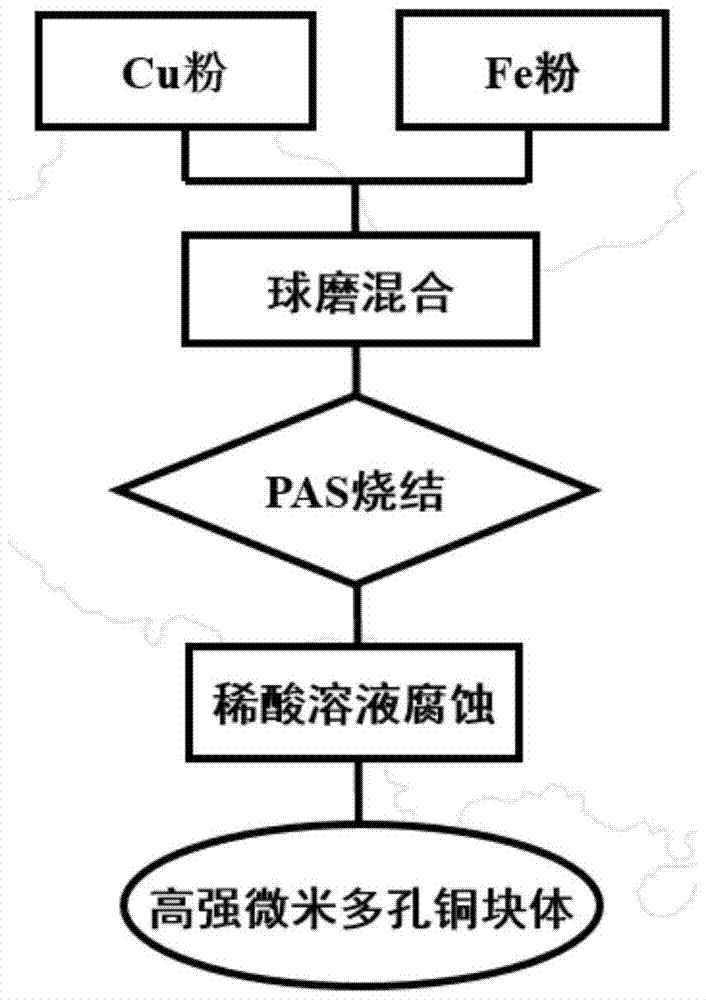

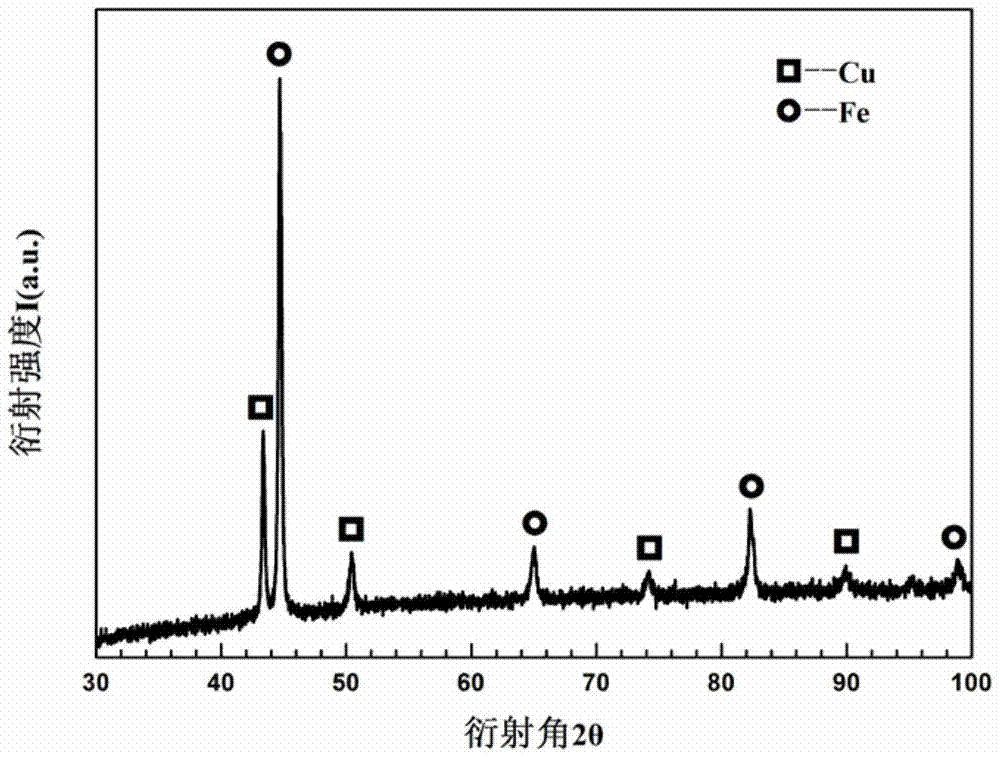

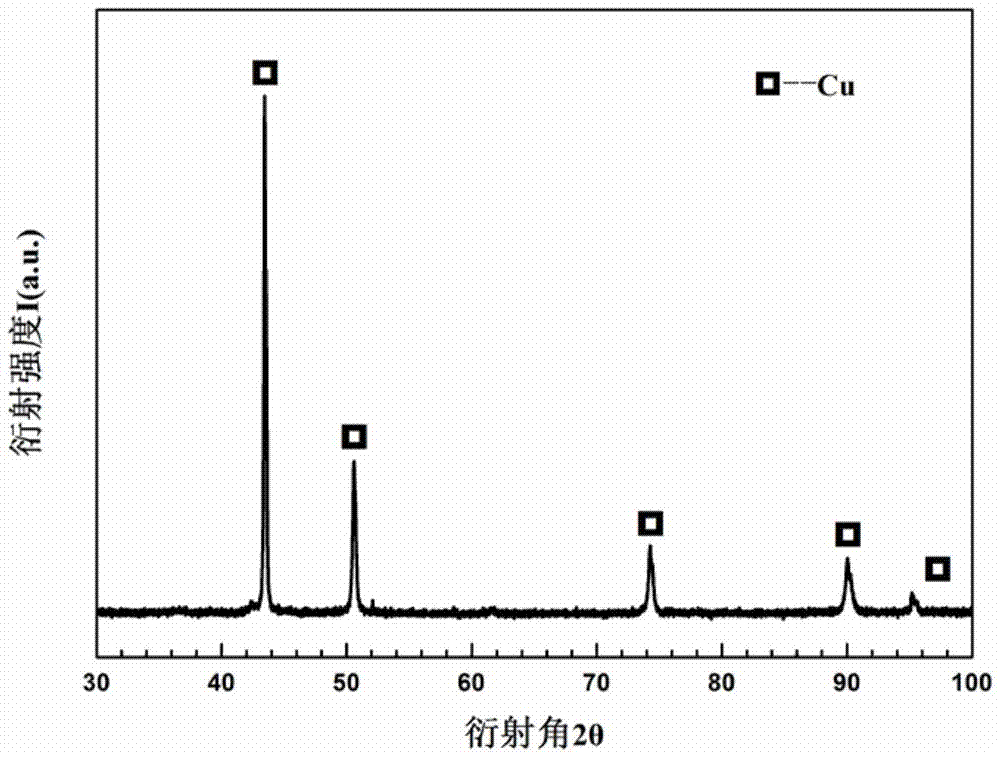

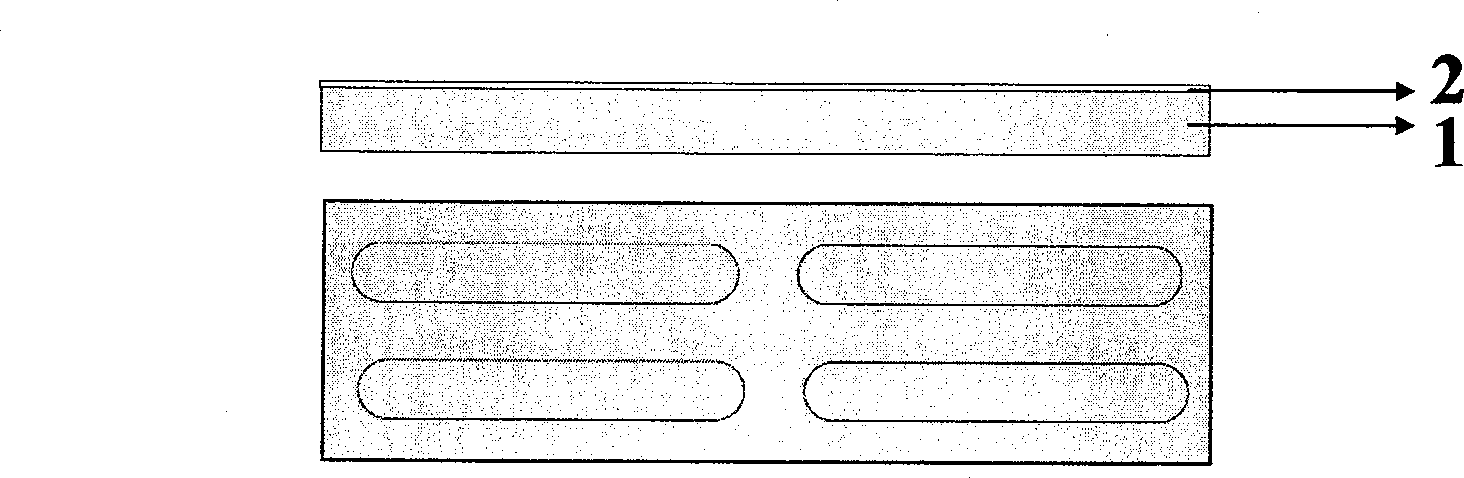

Method for preparing micrometer porous metal copper blocks by dealloying of copper-ferrum alloy

The invention relates to a method for preparing micrometer porous metal copper blocks by dealloying of copper-ferrum alloy. According to the method, plasma is adopted to activate and sinter copper-ferrum alloy, and then ferrum in the alloy is selectively corroded by utilizing a chemical dealloying method, thus obtaining porous copper blocks with high-strength micrometer apertures. According to the invention, by utilizing the characteristic that the copper-ferrum inter-atom diffusing capacity can be greatly reduced by a quick sintering process of hard miscibility of copper-ferrum alloy, which is lower than the melting point of ferrum, the dimension of a ferrous phase after sintering approaches to the particle size of micron-size material powder, so as to prepare the copper-ferrum bi-continuous three-dimensional net structured copper-ferrum alloy; the particle size of adopted copper powder is slightly smaller than that of ferrous powder, so as to form a structure that copper particles wrap ferrous particles, thus being favorable for ensuring the uniformity of aperture after corrosion; the pore structures of the porous metal copper blocks are regulated and controlled by changing the ferrous powder content and the particle size distribution; according to the process, the high-strength micrometer porous copper blocks with uniform pore distribution and adjustable pore size and porosity can be obtained; and the method has the advantages of being simple in process, low in cost and strong in practicability.

Owner:WUHAN UNIV OF TECH

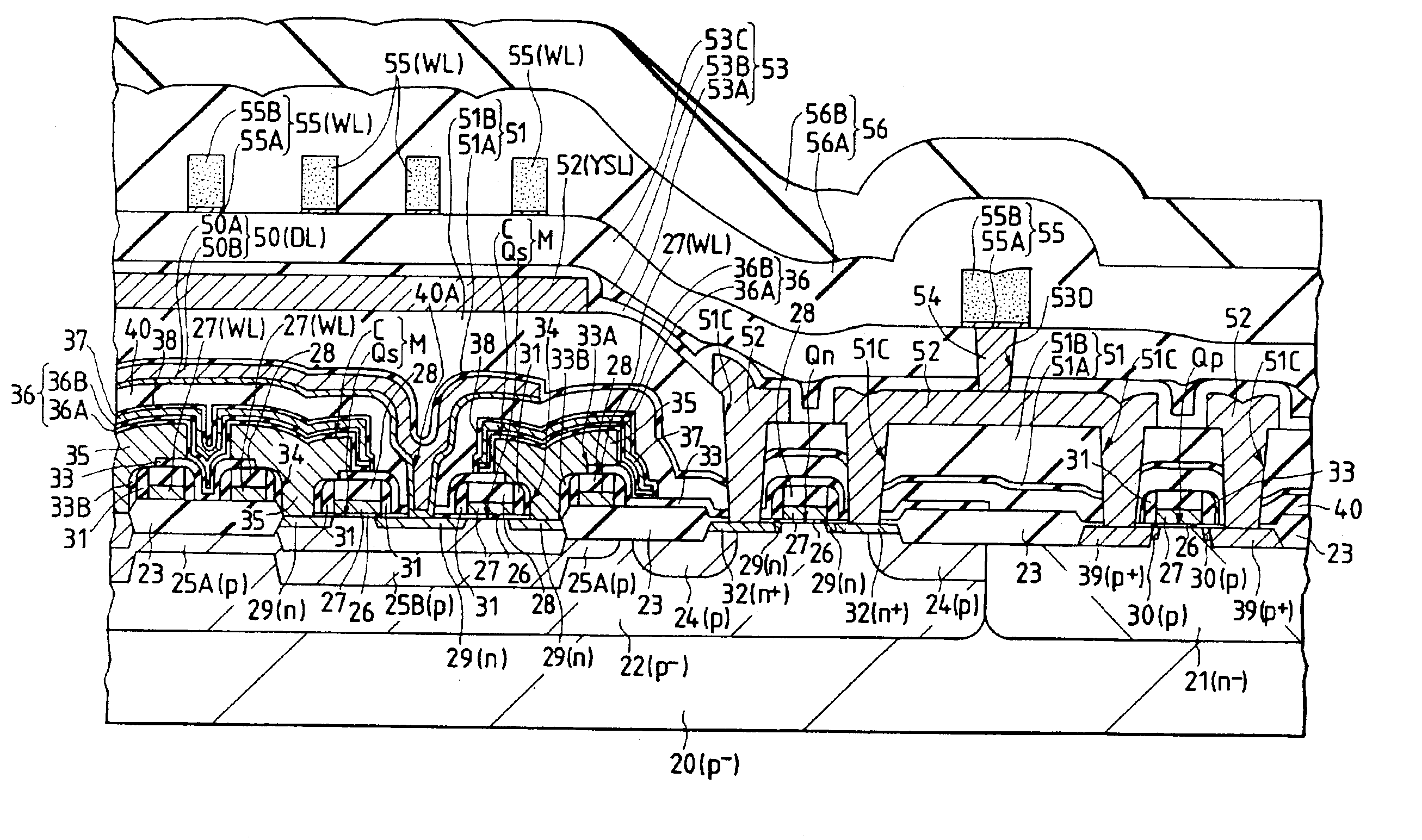

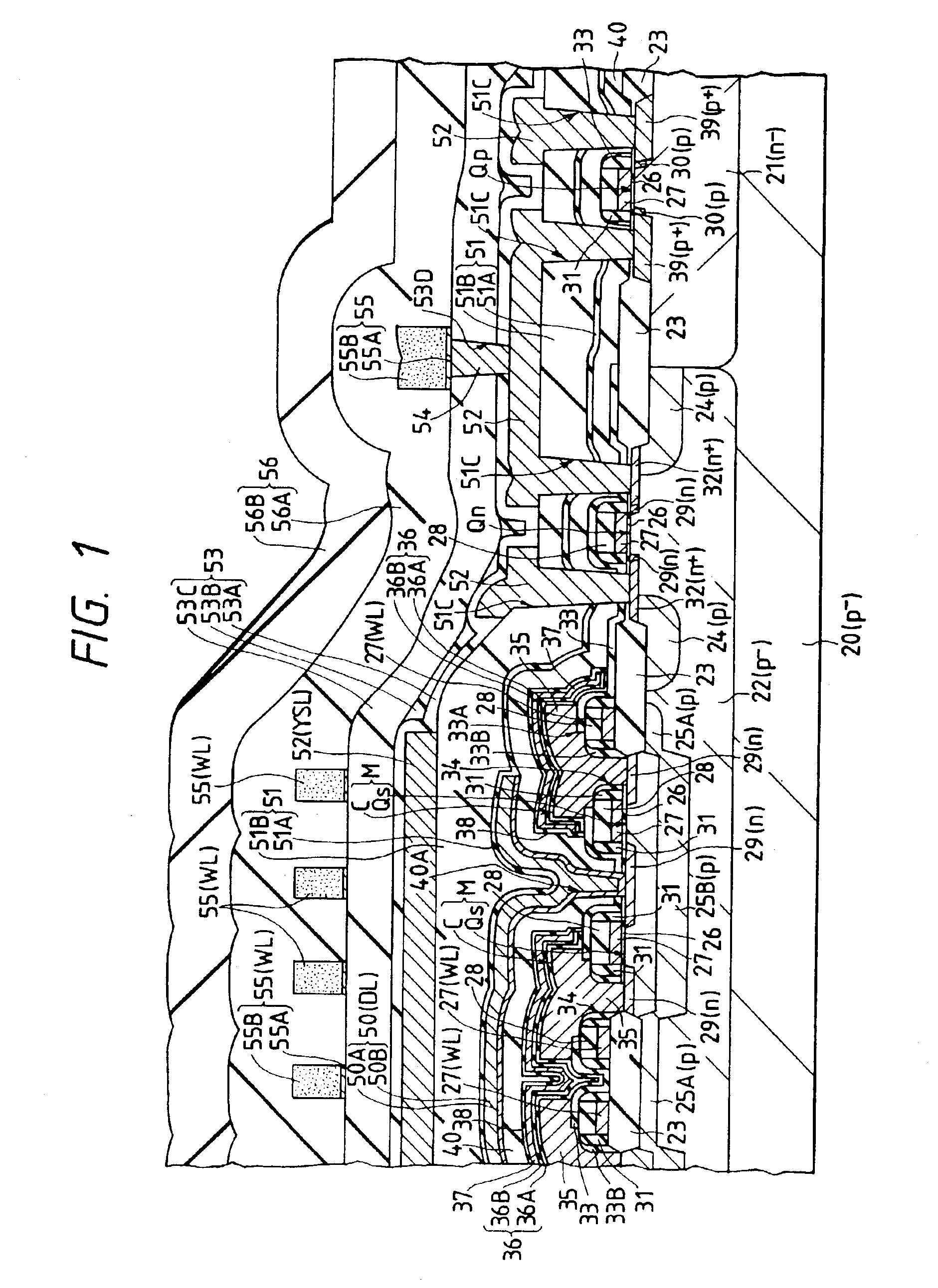

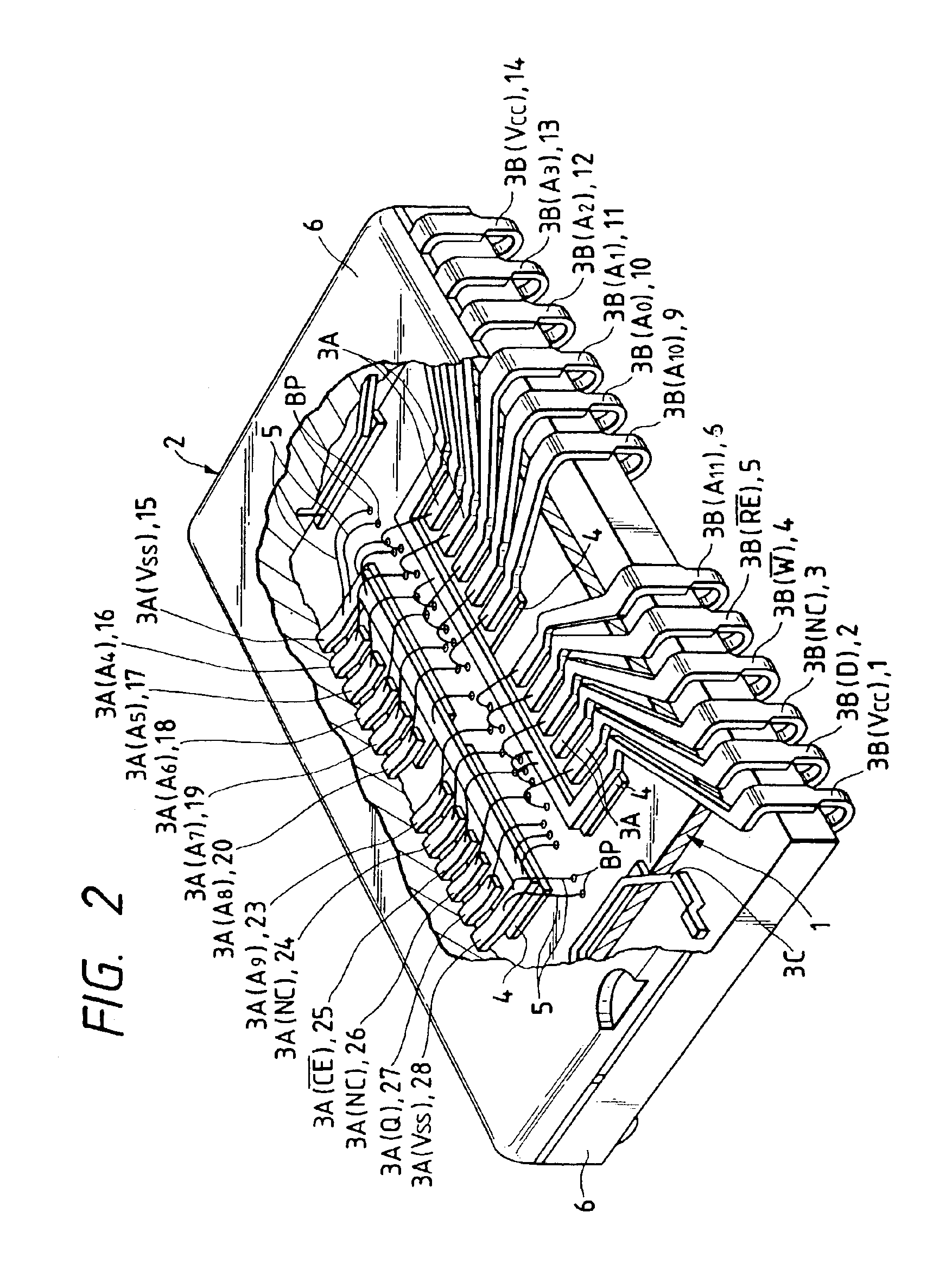

Semiconductor integrated circuit device, process for fabricating the same, and apparatus for fabricating the same

InactiveUS6894334B2Reduce narrow channel effectReduce the amount of diffusionTransistorSemiconductor/solid-state device detailsChannel-stopperEngineering

Herein disclosed is a semiconductor integrated circuit device fabricating process for forming MISFETs over the principal surface in those active regions of a substrate, which are surrounded by inactive regions formed of an element separating insulating film and channel stopper regions, comprising: the step of for forming a first mask by a non-oxidizable mask and an etching mask sequentially over the principal surface of the active regions of the substrate; the step of forming a second mask on and in self-alignment with the side walls of the first mask by a non-oxidizable mask thinner than the non-oxidizable mask of the first mask and an etching mask respectively; the step of etching the principal surface of the inactive regions of the substrate by using the first mask and the second mask; the step of forming the element separating insulating film over the principal surface of the inactive regions of the substrate by an oxidization using the first mask and the second mask; and the step of forming the channel stopper regions over the principal surface portions below the element separating insulating film of the substrate by introducing an impurity into all the surface portions including the active regions and the inactive regions of the substrate after the first mask and the second mask have been removed.

Owner:RISING SILICON

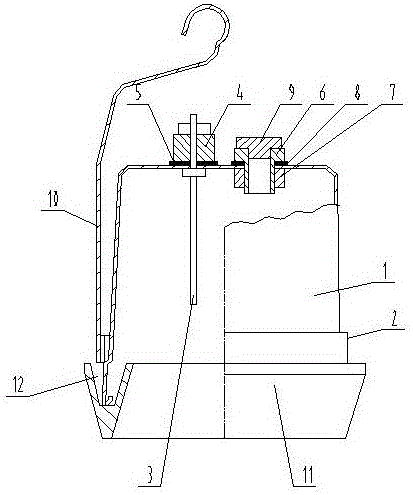

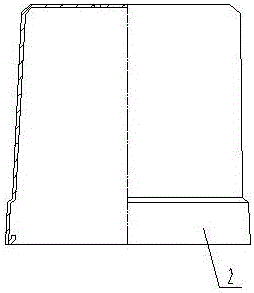

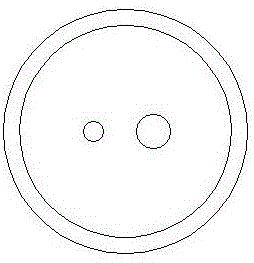

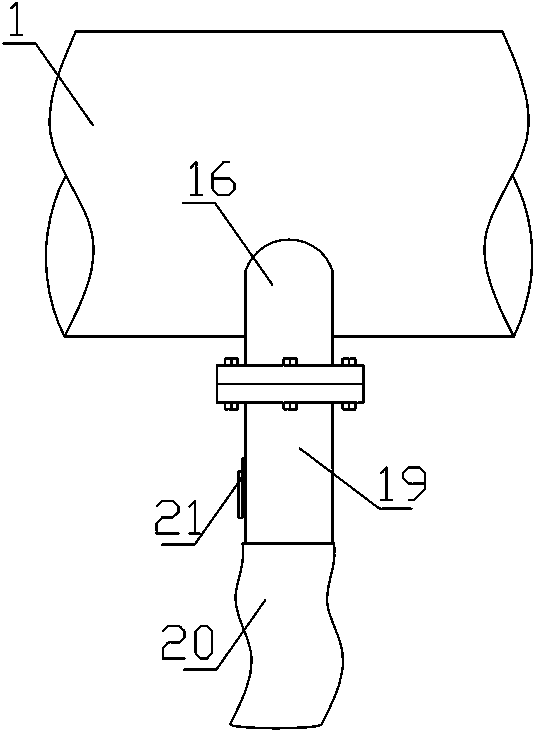

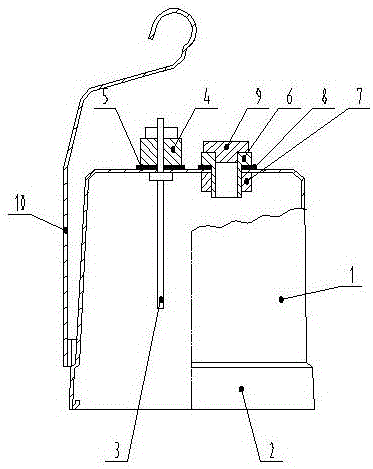

Farmland greenhouse-gas monitoring sampling device

InactiveCN106248440AInsert tightEasy to insertWithdrawing sample devicesEcological environmentEngineering

The invention belongs to the technical field of agriculture, forestry and ecological environments, and particularly relates to a farmland greenhouse-gas monitoring sampling device. The farmland greenhouse-gas monitoring sampling device comprises a box and base which are matched in shape. An air drawing hole is formed in the box, a rubber plug is arranged on the air drawing hole, the base is of a circular-ring frame structure integrating an inner layer and an outer layer, and the corresponding box is of a cylindrical structure; the cross section of the base is a wedge, and the bottom of the base is in a cutter-opening shape; an annular sealing groove higher than the base is formed in the edge of the base, and the lower portion of the box is embedded into the sealing groove in a matched mode; the base is made from nylon. The farmland greenhouse-gas monitoring sampling device is small in volume, convenient to carry and transport and high in monitoring accuracy rate.

Owner:INST OF PLANT NUTITUION & RESOURCE ENVIRONMENT HENAN ACADEMY OF AGRI SCI

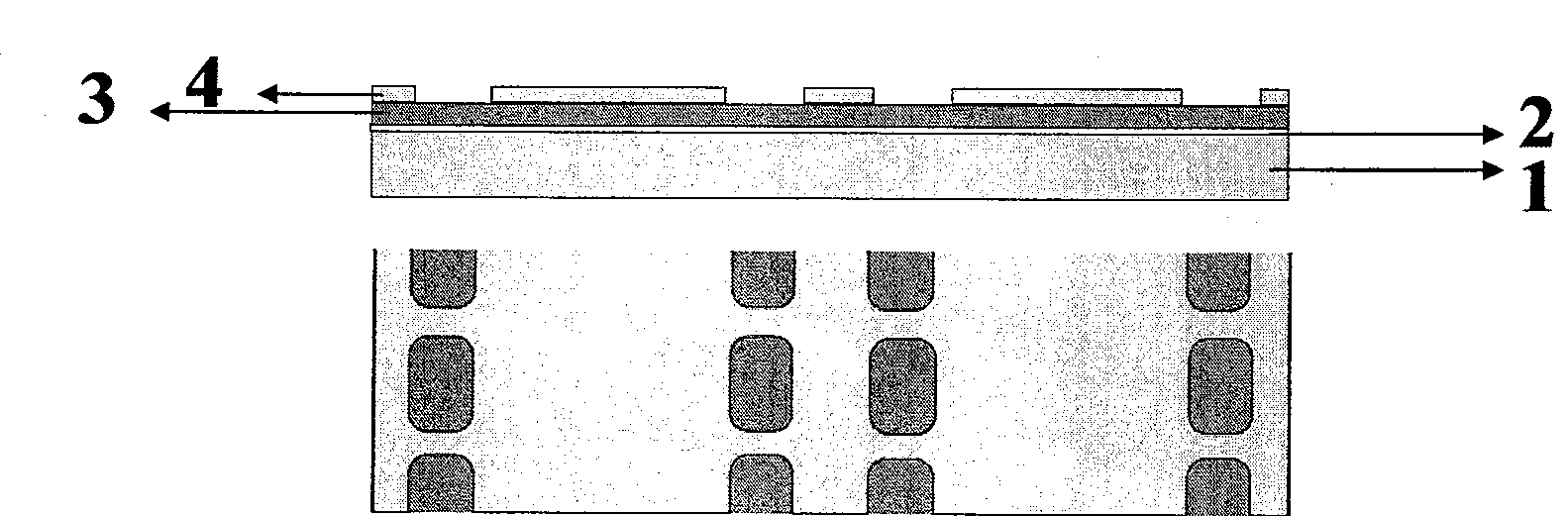

Method for making floating gate discharging sharp angle

ActiveCN101170065AGood lookingReduce the amount of diffusionSolid-state devicesSemiconductor/solid-state device manufacturingSize changeEngineering

The invention discloses a method of manufacturing a floating boom discharge sharp corner. The method comprises the steps of firstly utilizing SiH4, N2O and H2 as reaction gas and generating a layer of a SiOxNy buffer layer by the low pressure chemical vapor deposition method before silicon nitride sediment, as the buffer layer for later floating boom oxidization; in forming beak, adjusting by control technology to facilitate oxygen atoms to spread transversely toward a lateral wall underlay with certain amount. The transverse size is extended and the erasing sharp corner formed finally has a transverse extension on the upper edge, which is good for resisting the influence of subsequent floating boom etching size change on the shape of the sharp corner, improving the whole erasing performance and increasing the device stability and reliability.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP +1

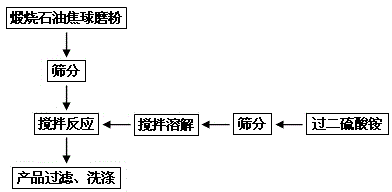

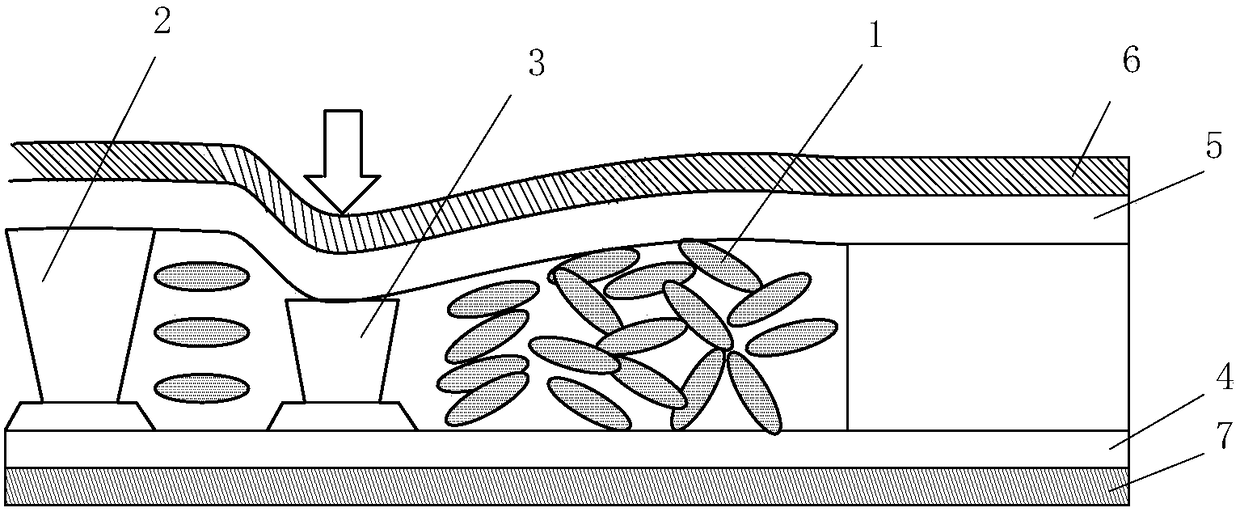

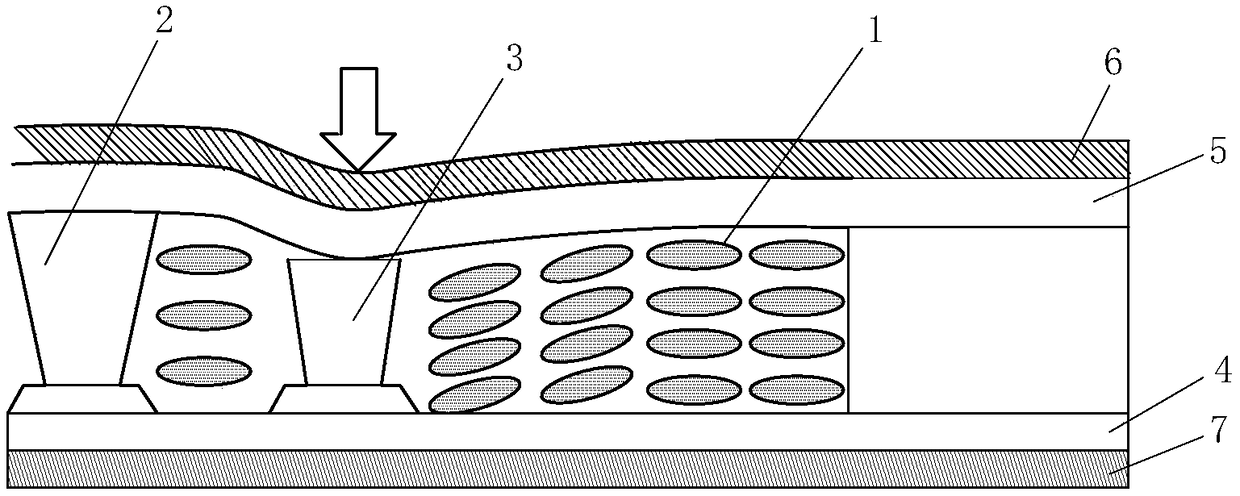

Method for preparing anode surface antioxidation protective agent used for carbon-base aluminum

ActiveCN106319570AIncreased Response Residual RateReduce the amount of diffusionInorganic saltsSoftened water

The invention relates to a method for preparing an anode surface antioxidation protective agent used for carbon-base aluminum. The method includes the steps that a raw material is screened, calcined petroleum coke ball-milled powder is selected as the carbon-base raw material, and ammonium peroxydisulfate is used as a modifying agent; industrial softened water is used for dissolving the ammonium peroxydisulfate at first so that a solution can be obtained, and then the carbon-base raw material screened in advance is added into the solution; an oxidation modified reaction is carried out in an electric heating reactor with a stirring function at the temperature of 80-100 DEG C; and the industrial softened water is used for washing residual inorganic salt ions after the reaction is completed, and thus a carbon-base antioxidation protective agent product can be obtained. The method has the advantages and effects that depositions are directly coated to be attached to the surfaces of anode carbon blocks, the air reaction residual rate of anode products can be increased by 3%-4%, and anode net consumption is effectively reduced.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

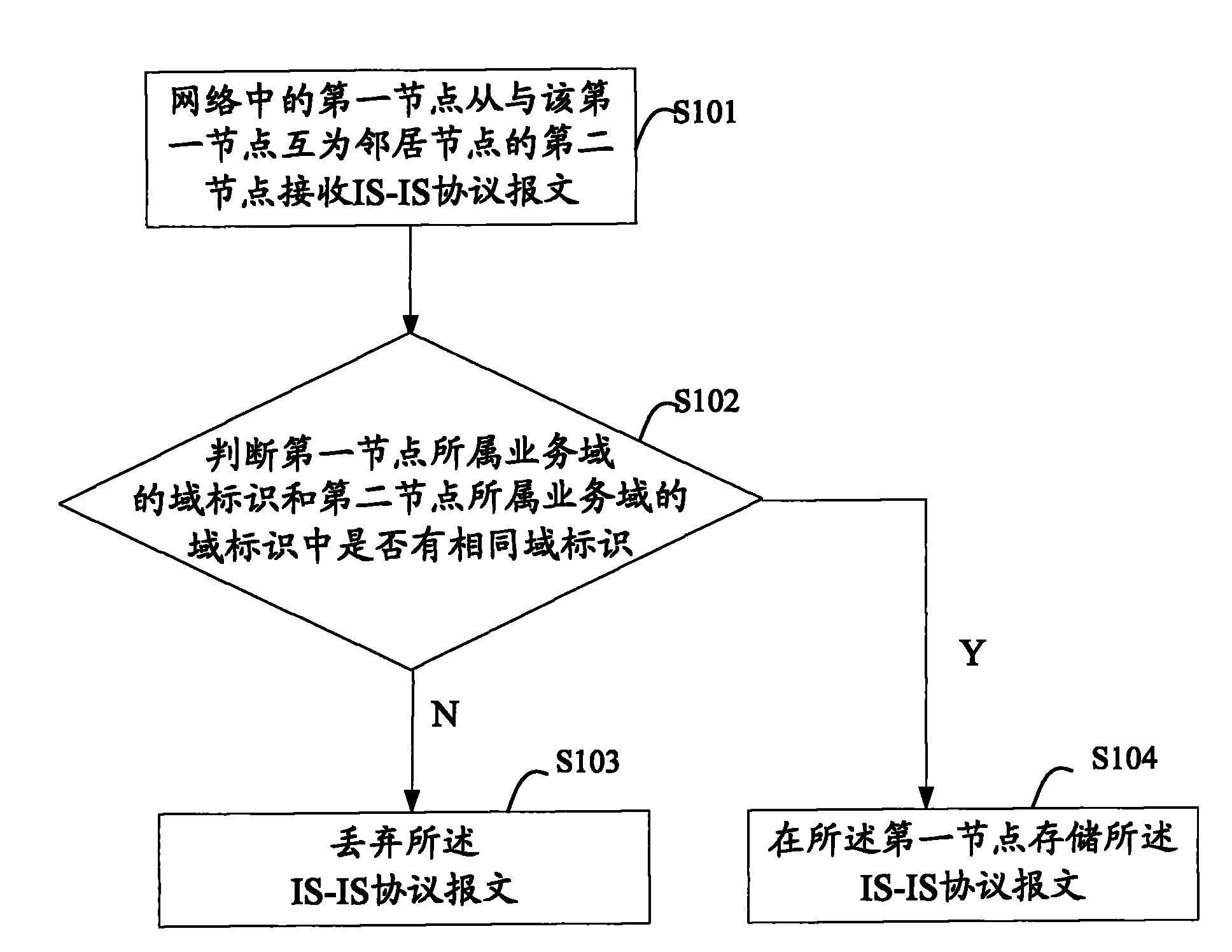

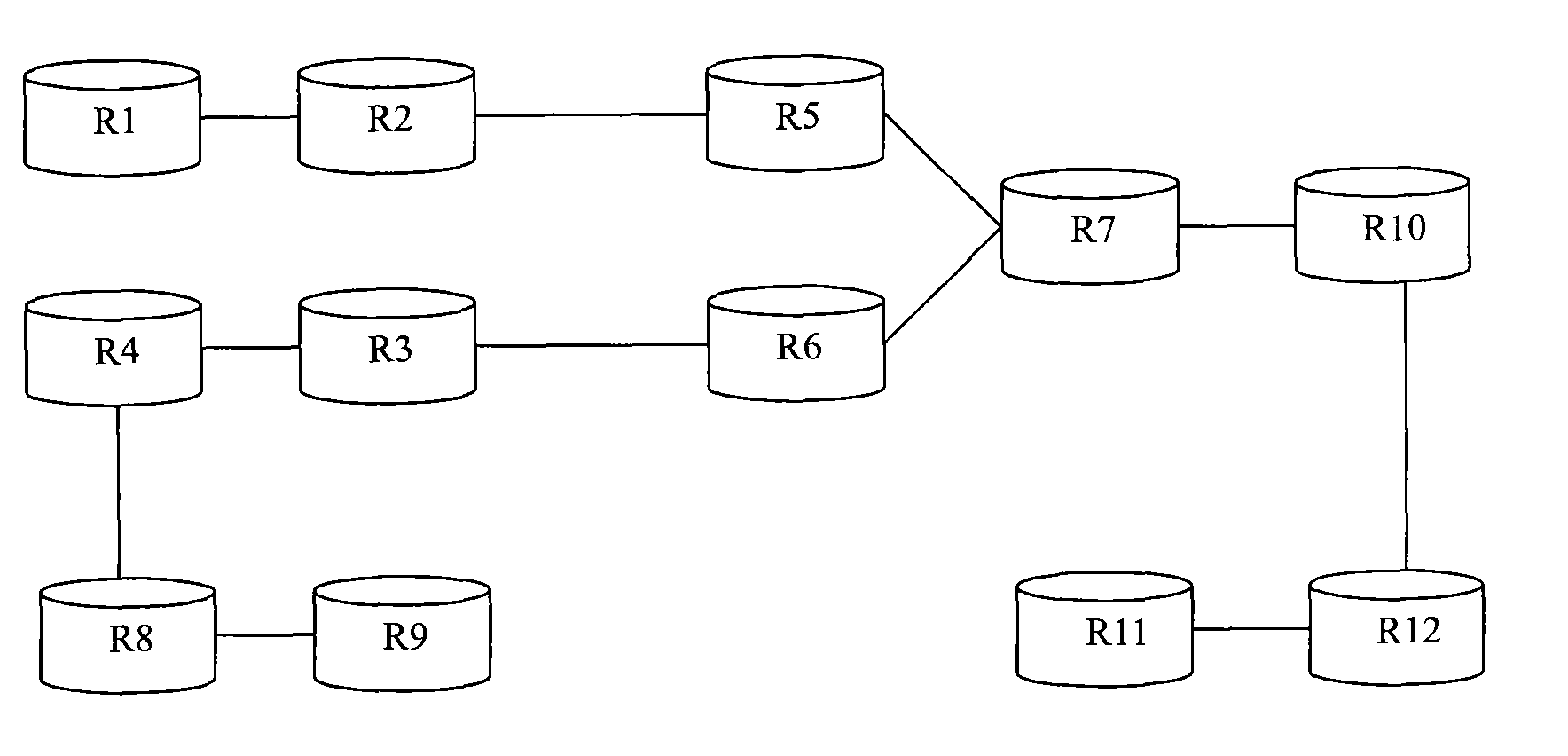

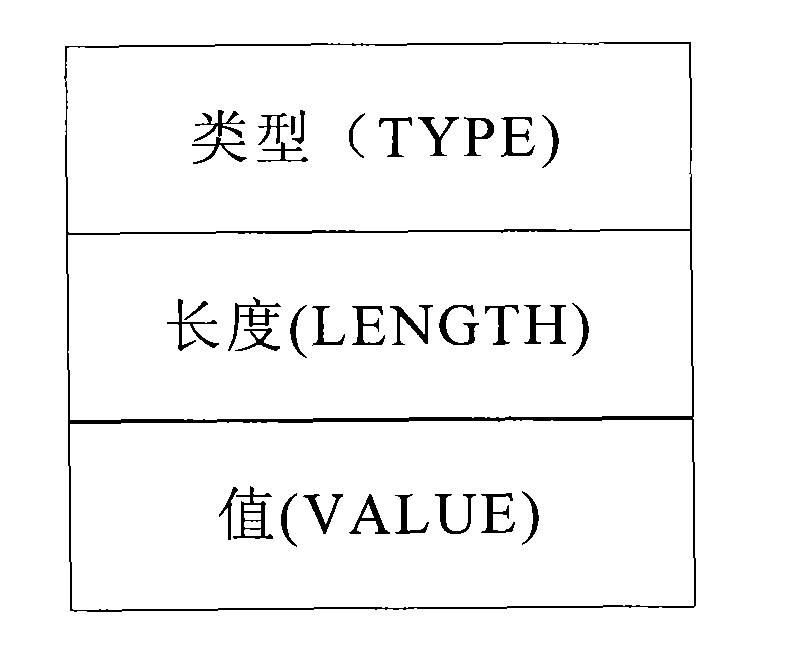

Intermediate system-intermediate system protocol message processing method, node and system

InactiveCN101771601AReduce the amount of diffusionReduce oscillationData switching networksThe InternetNetworked system

The invention discloses an intermediate system-intermediate system protocol message processing method, node and system, belonging to the communication field, which solves the problem of large information diffuse and unnecessary route oscillation in prior art. In the embodiment, the intermediate system-intermediate system protocol message processing method comprises a first node and a second node receiving IS-IS protocol message; the IS-IS protocol message carries indication according to a domain identification of the second node business domain to judge whether the domain identification of the first node business domain and the second node business domain has the same domain identification; if no identical domain identification is judged, the IS-IS protocol message is dismissed, thereby cutting down the diffusion of the protocol message in the internet and reducing the route oscillation. In the embodiment, the invention correspondingly discloses a node device and an internet system.

Owner:HUAWEI TECH CO LTD

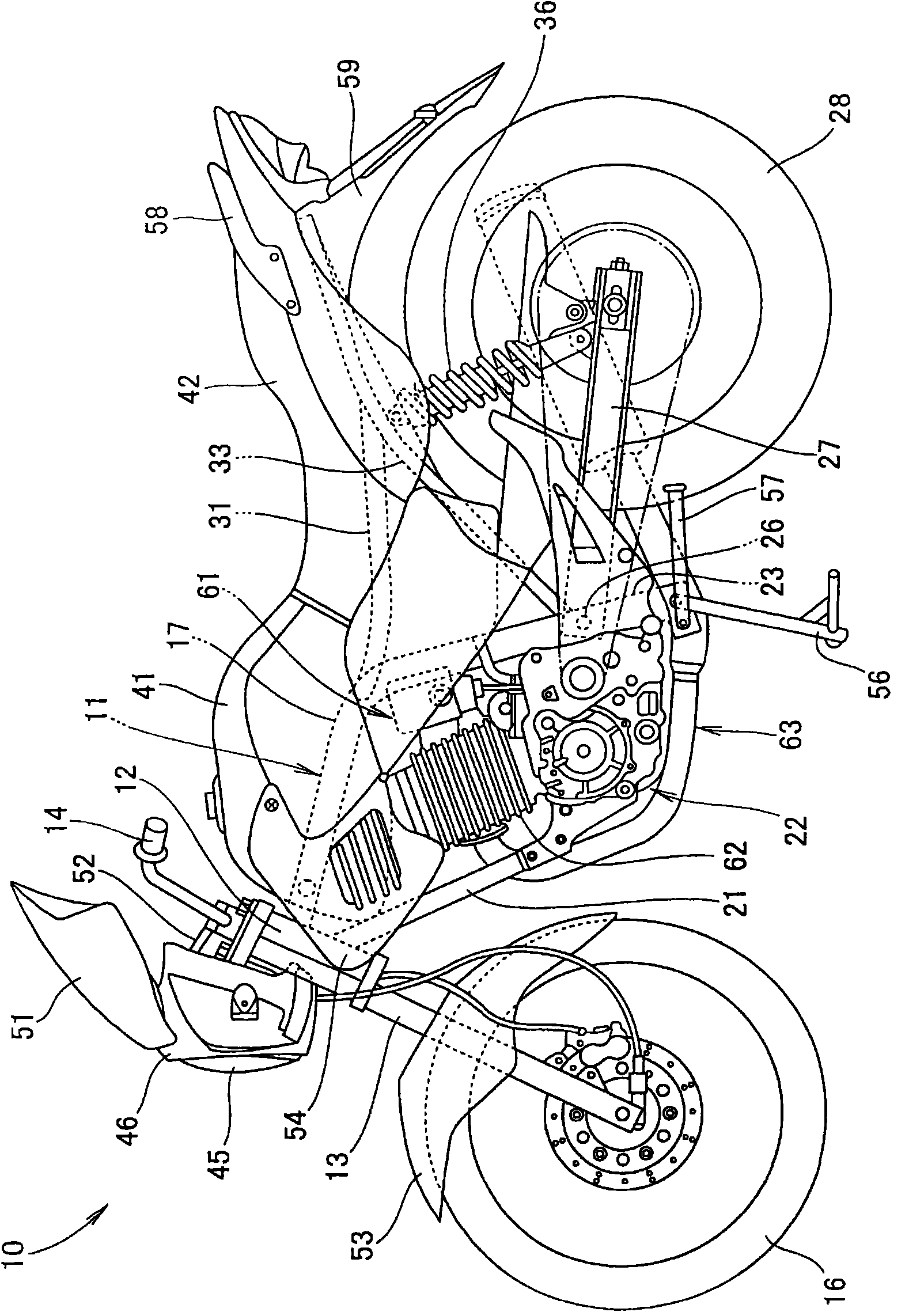

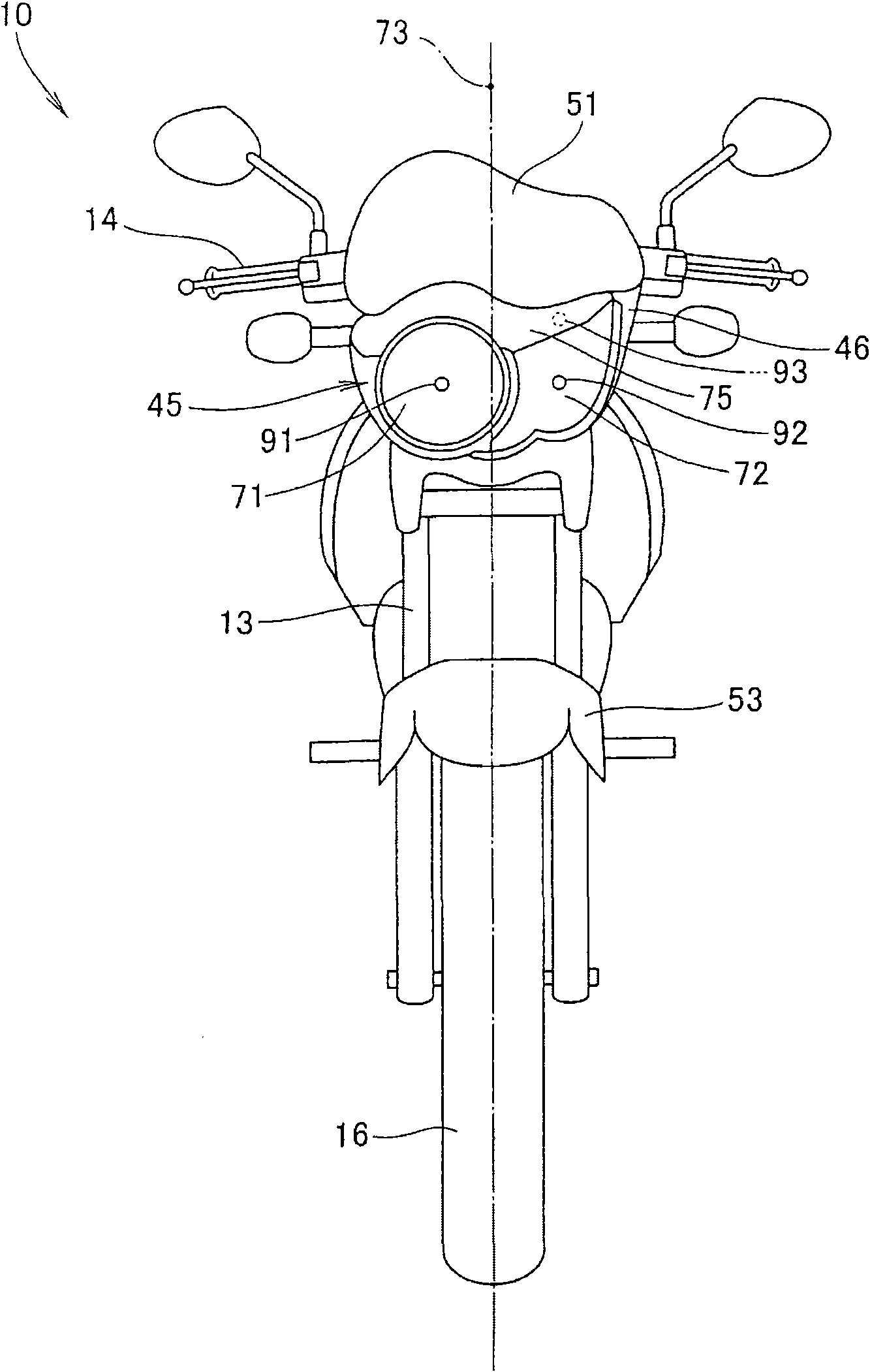

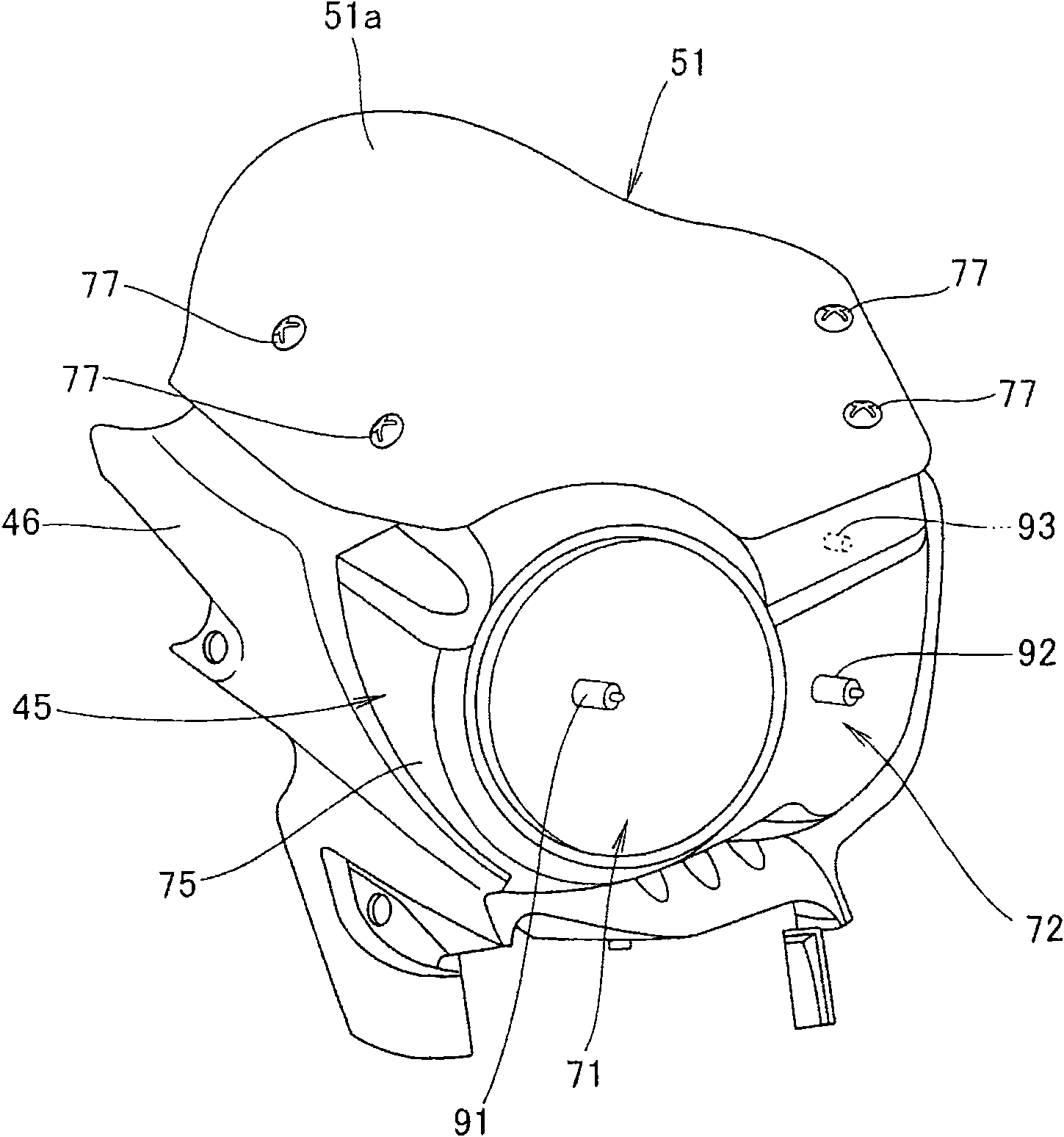

Head-light structure of motive bicycle

The present invention provides a head-light structure of a motive bicycle, capable of trying for improvement of design and functional properties. When viewing from the frontispiece, the head-light structure of the motive bicycle is provided with at least a near light special lamp (71) and a distance light special lamp (72) on right and left separately, and the right and left near light special lamp (71), distance light special lamp (72) are non symmetrical, wherein a top-to-bottom width (H1) of the near light special lamp (71) is larger than a top-to-bottom width (H2) of the distance light special lamp (72) through a first plumb line (101) of a near light bulb (91) of the near light special lamp (71) and a second plumb line (102) of a distance light bulb (92) of the distance light speciallamp (72), the shapes of the right and left near light special lamp (71) and distance light special lamp (72) form a roundness, and the other is a rectilinear shape.

Owner:HONDA MOTOR CO LTD

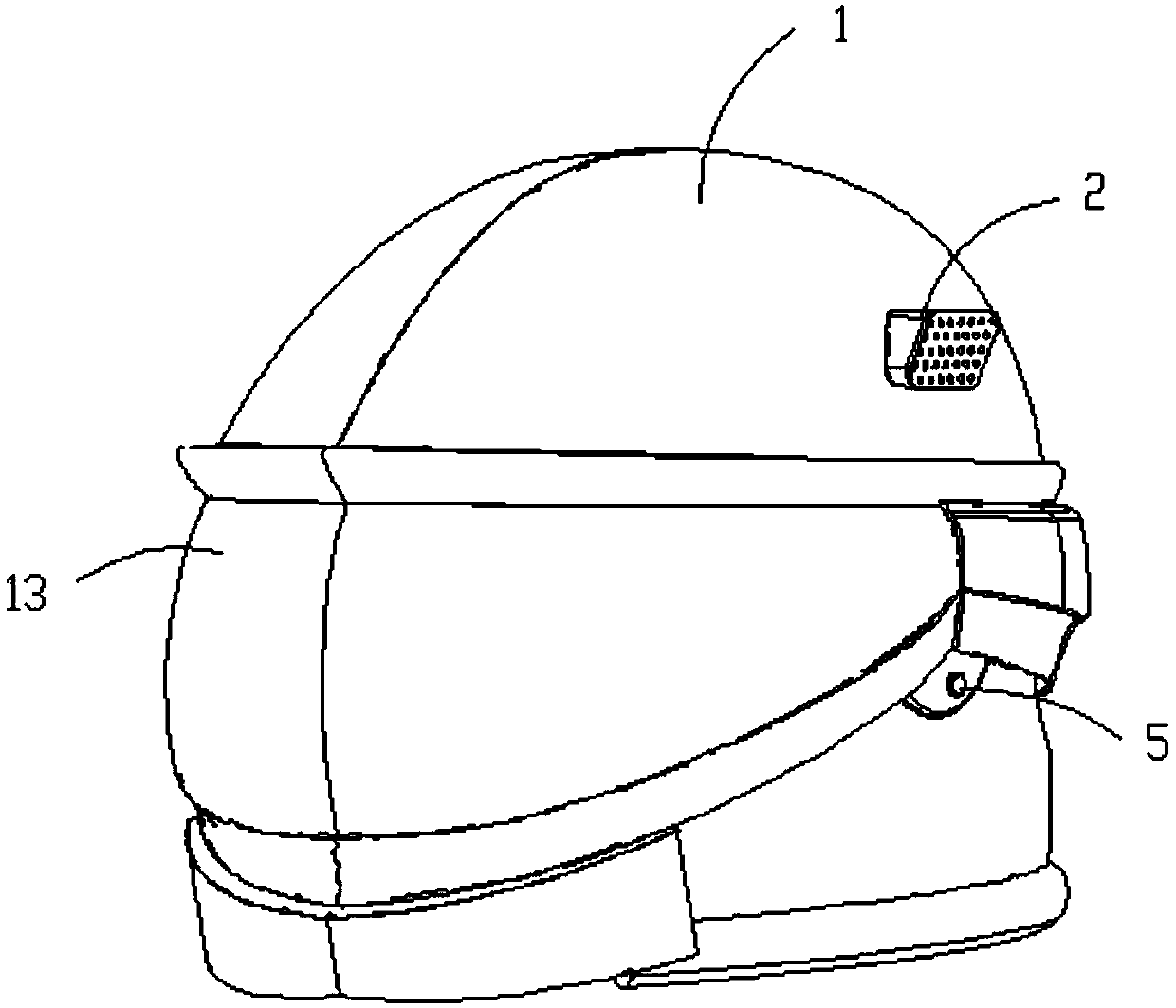

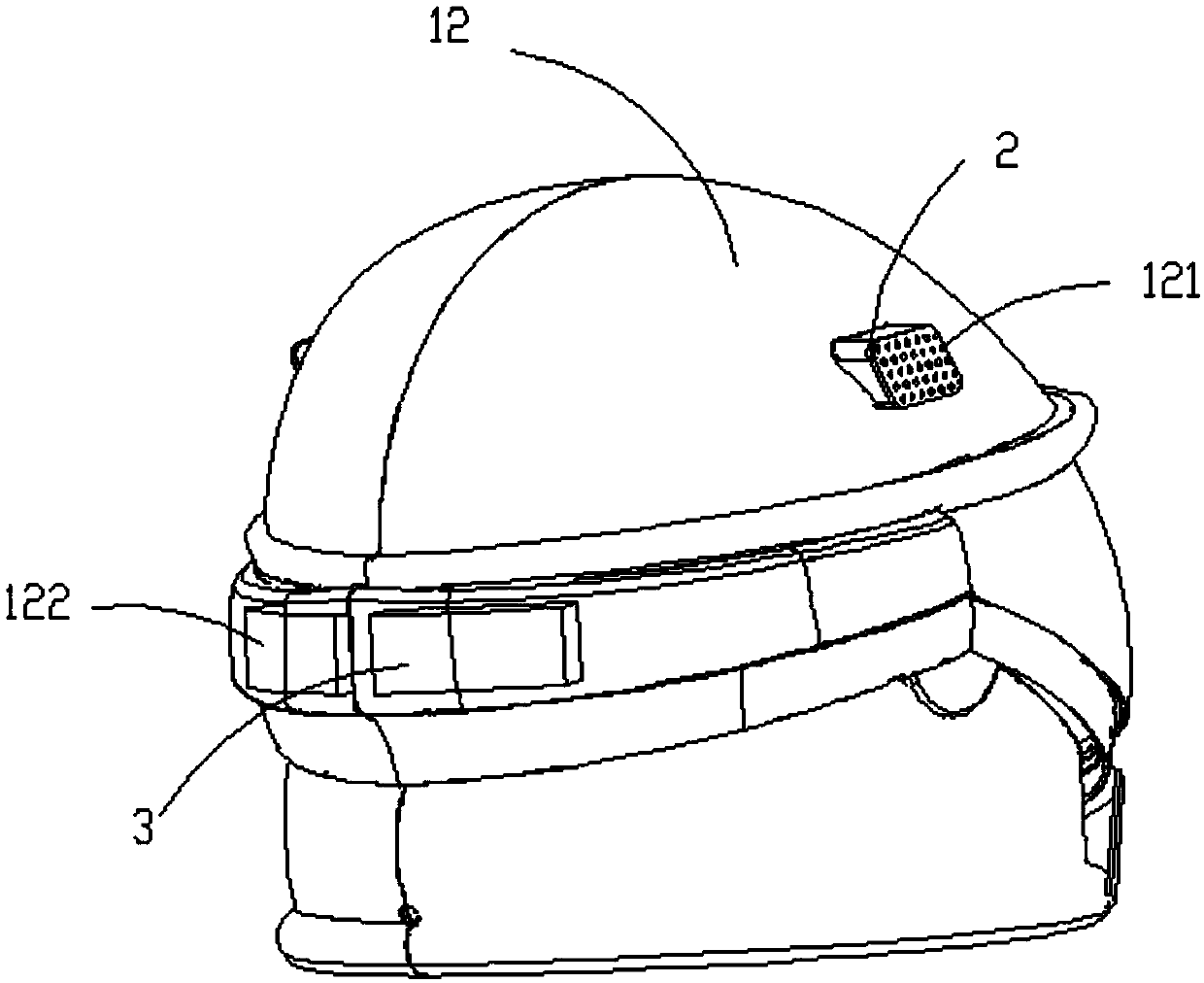

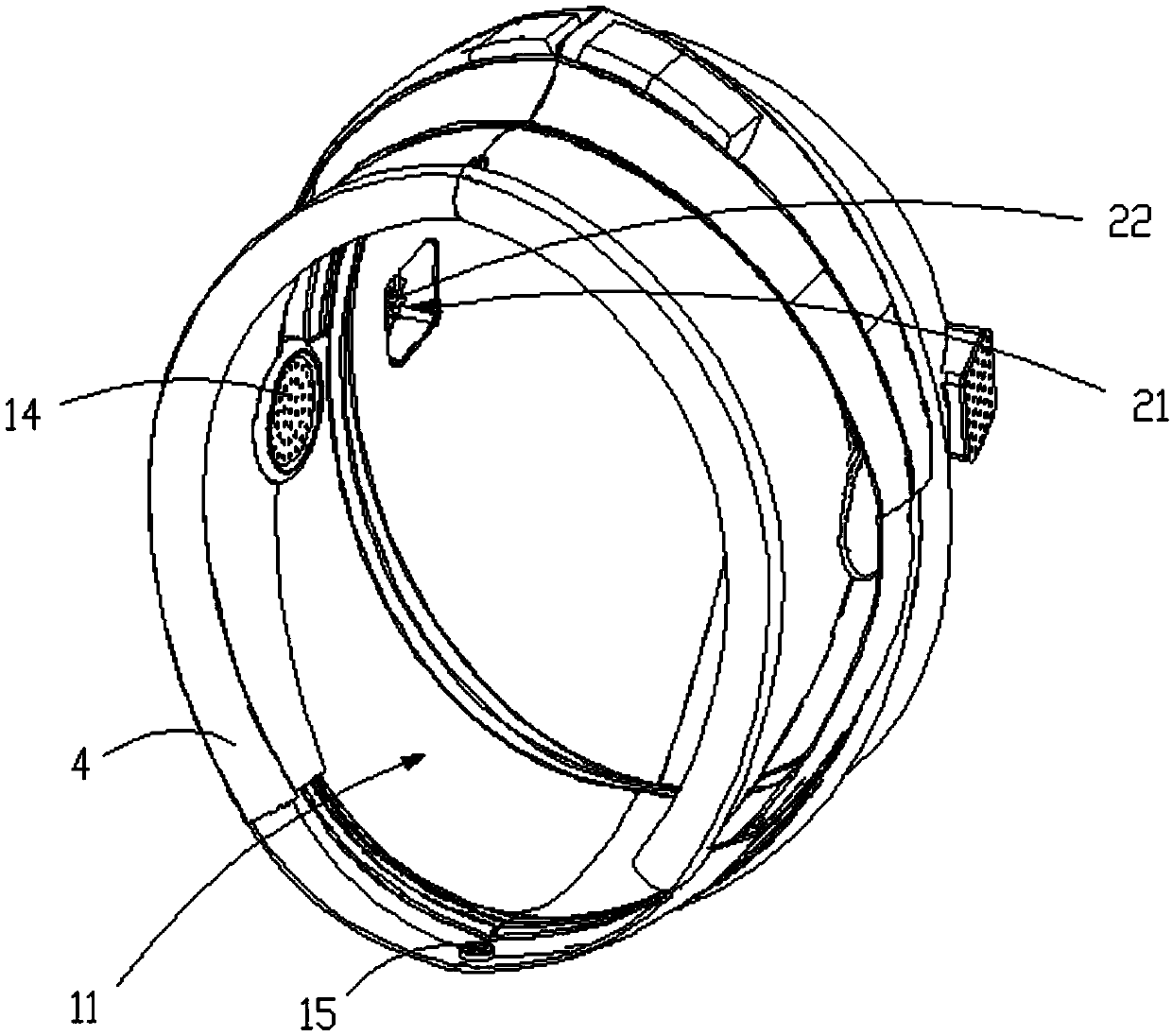

Sound insulation helmet with KTV function

PendingCN110934371AReduce the amount of diffusionLower the volumeHelmetsHelmet coversEngineeringHeadphones

The invention belongs to the technical field of sound insulation helmets, and discloses a sound insulation helmet with a KTV function. The helmet comprises a helmet main body with a head accommodatingspace, and the helmet main body comprises a main body shell and a sound insulation lining arranged in the main body shell; the helmet main body is provided with a sound insulation eyepiece, an earphone and a microphone; the helmet also comprises a ventilation assembly, and the ventilation assembly comprises a fan accommodating groove formed in the main body shell or formed between the main body shell and the sound insulation lining, and a plurality of ventilation holes are formed in the main body shell; and the fan accommodating groove is communicated with the head accommodating space. The sound insulation helmet with the KTV function further comprises an electrical assembly. Compared with the prior art, the helmet has the KVT function; after a user wears the helmet, the head accommodating space is a relatively closed space, and the sound insulation part is arranged in the helmet body, so sound diffusion can be reduced, and the requirements of the user for reading and singing wheneverand wherever possible are met.

Owner:黄子辉

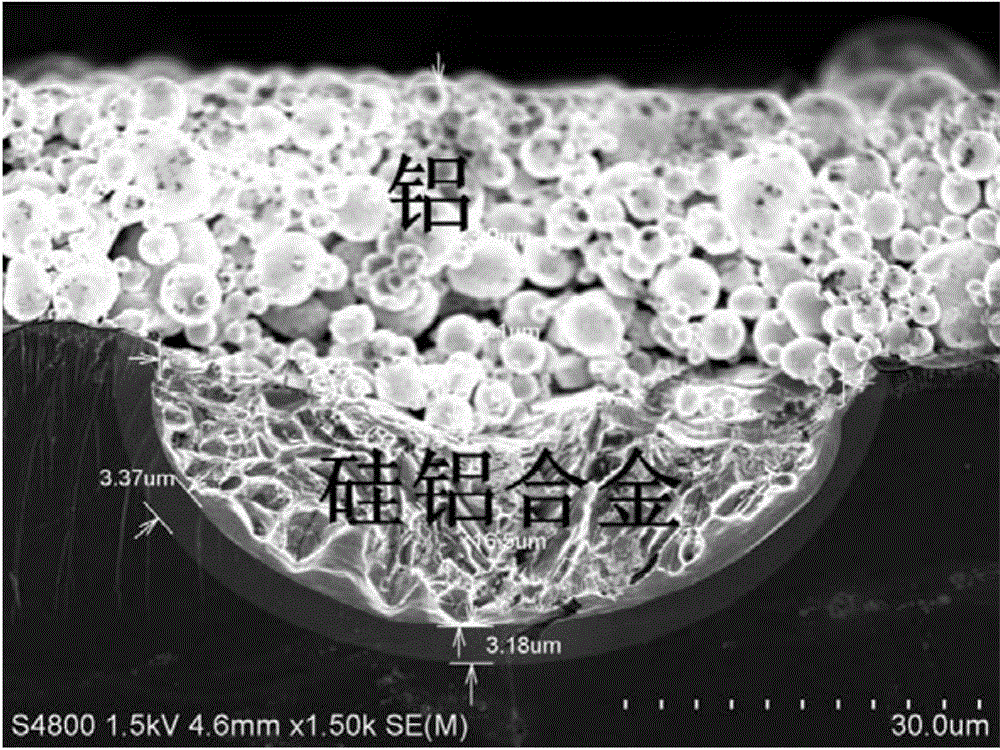

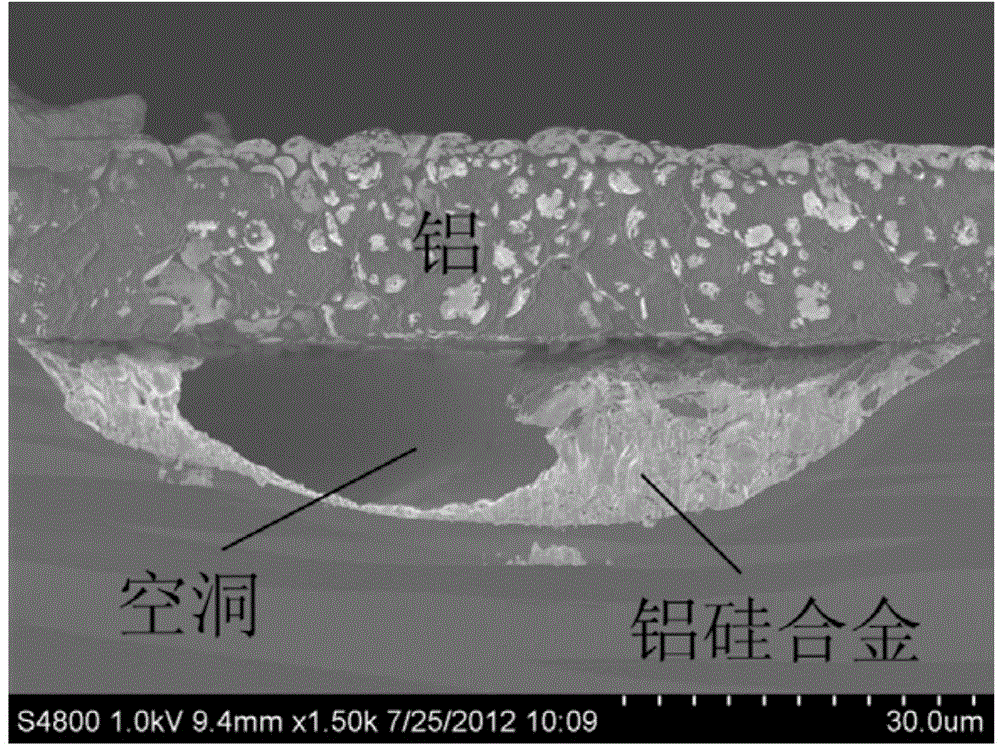

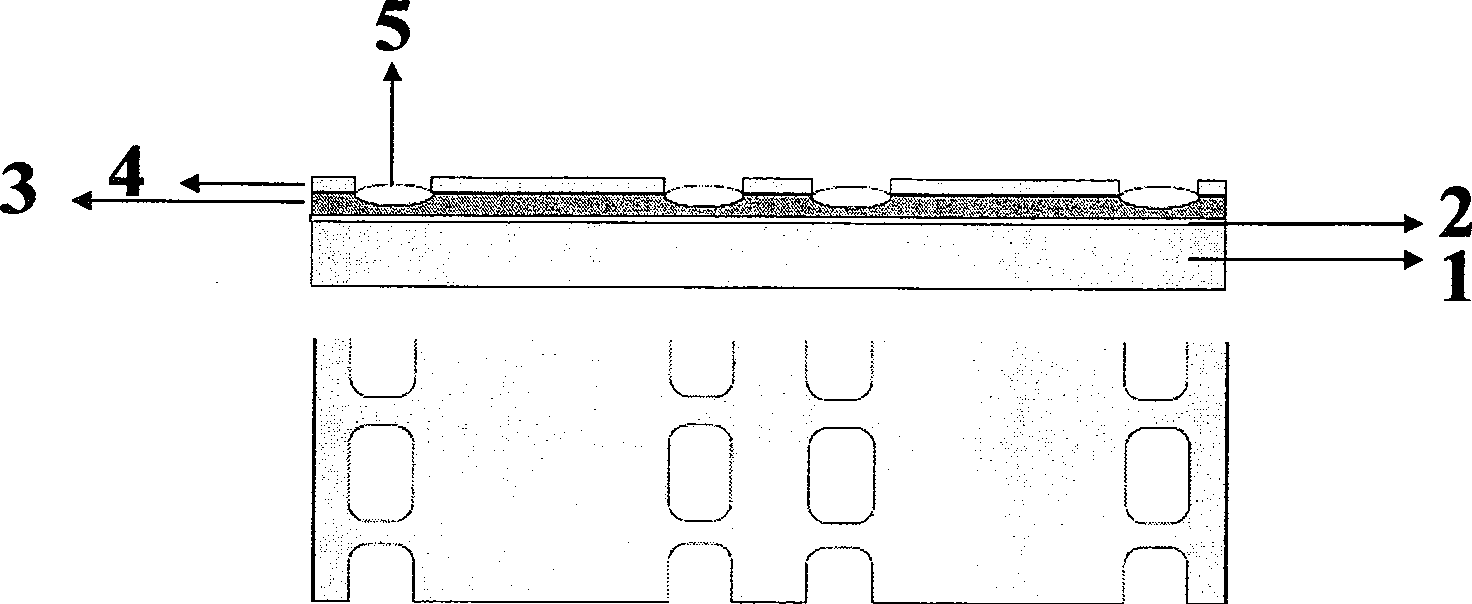

PERC solar cell sintering method

InactiveCN104882515AThe proportion of Al-Si voids is reducedIncrease the open circuit voltageFinal product manufacturePhotovoltaic energy generationRise rateAluminium

The invention discloses a PERC solar cell sintering method. The method includes a warming step and a cooling step. In the warming step, temperature is raised to 600 DEG C from 300 DEG C at a temperature rise rate of 30-90 DEG C / s. According to the invention, a comparatively high temperature rise rate is adopted, so that Al-Si balance is achieved quickly and diffusing amount and depth of Si to Al are reduced, and thus Al-Si cavity proportion is reduced. As the experiments prove, compared with the prior art, the Al-Si cavity proportion of a solar cell obtained by utilizing the method provided by the invention is reduced by over 60 percents and the battery efficiency is improved by 0.14-0.30 percent. An extraordinary technical effect is achieved.

Owner:CSI CELLS CO LTD +1

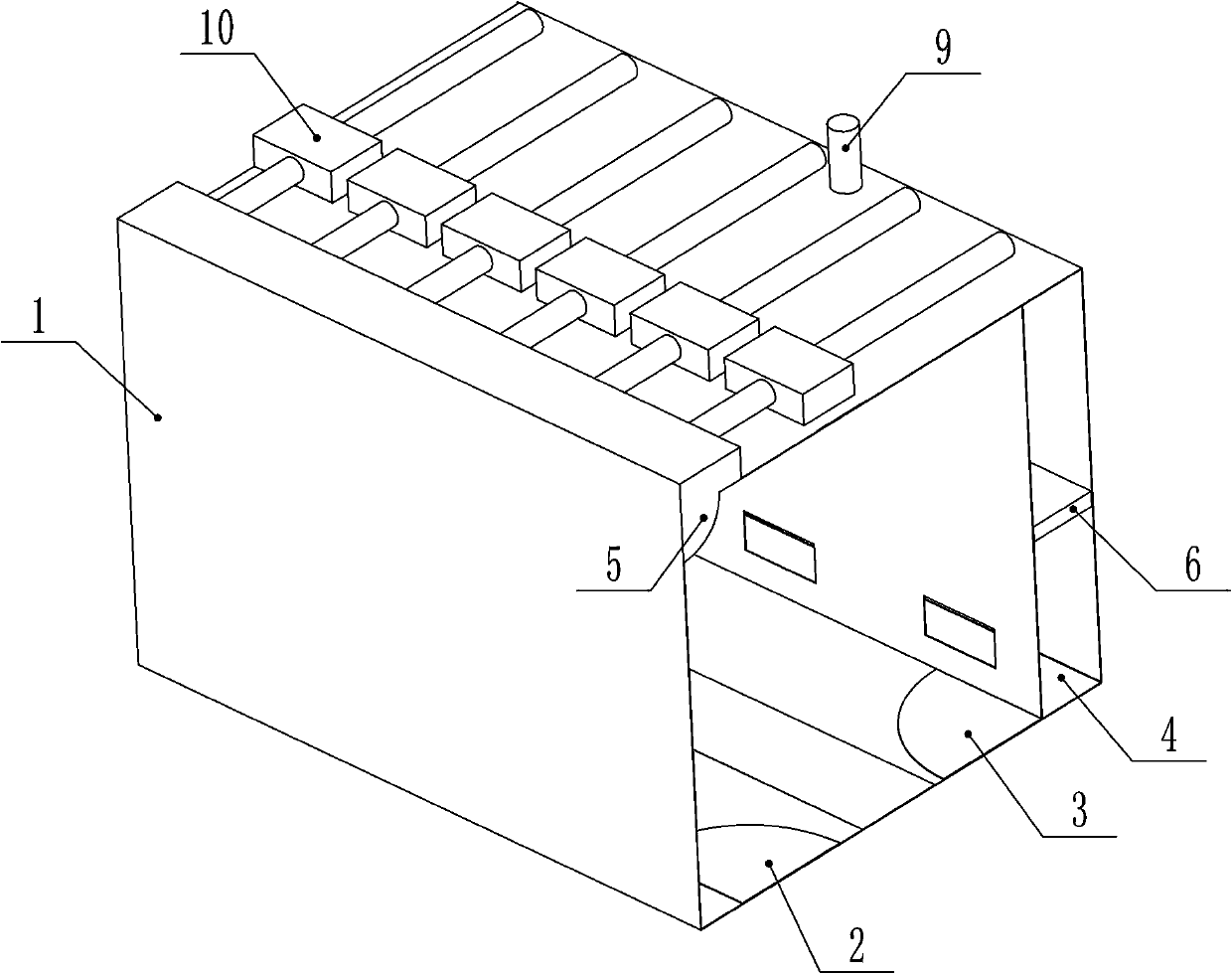

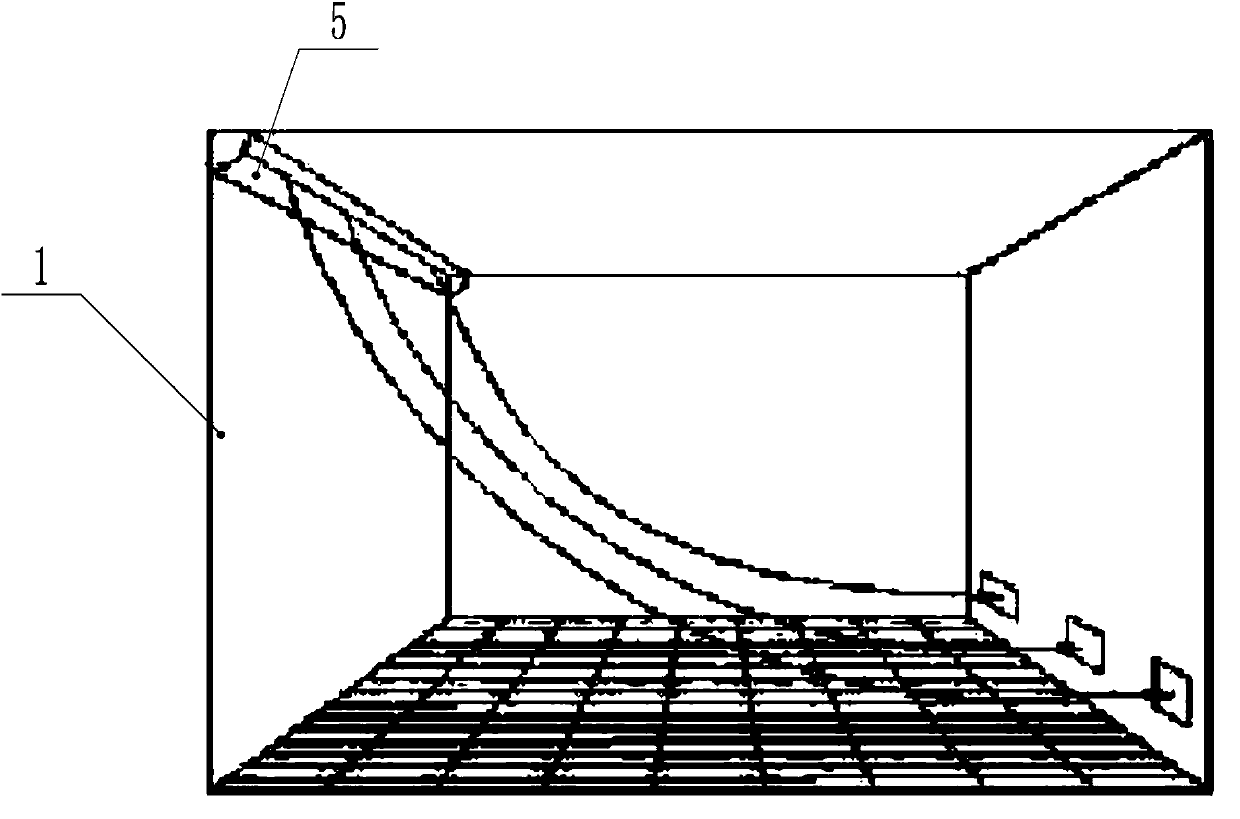

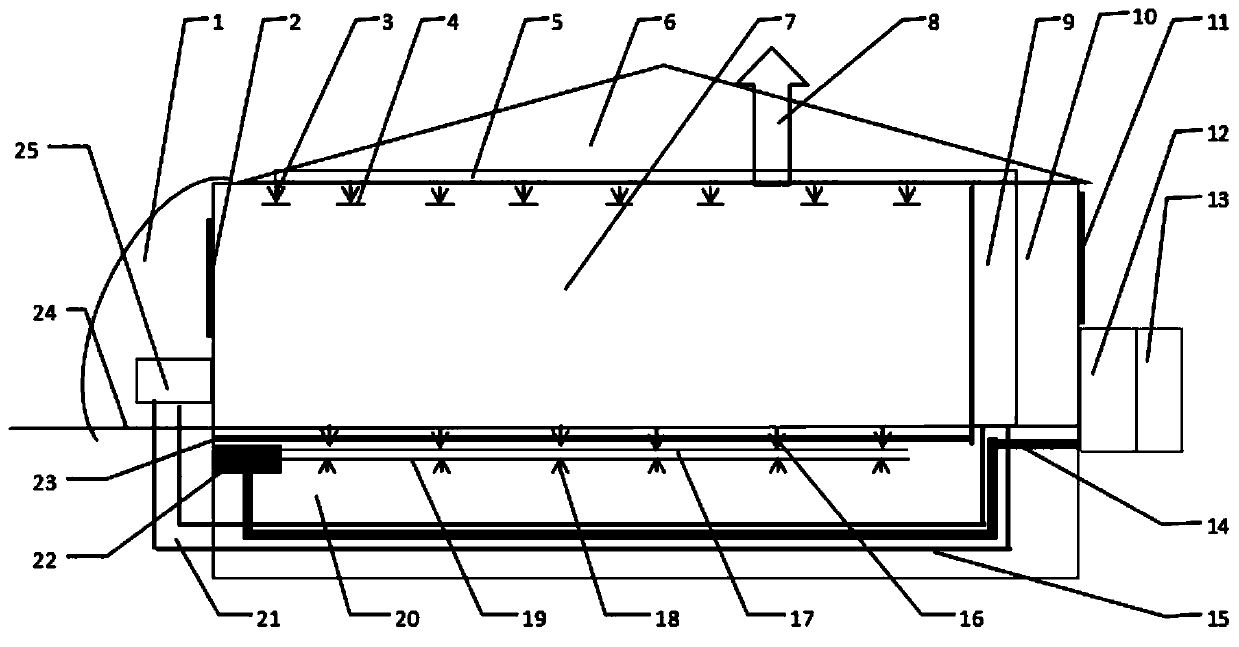

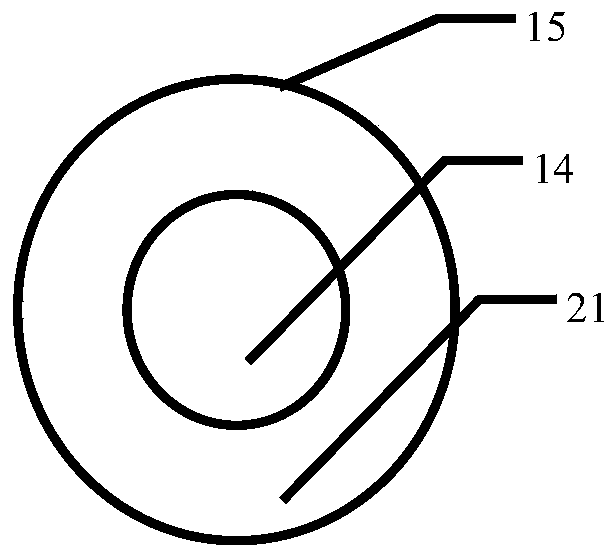

Steady state replacement flow medical diagnosis cabin

ActiveCN111594948AEnsure safetyProtection dischargeBreathing protectionDucting arrangementsAir cycleAir filter

The invention discloses a steady state replacement flow medical diagnosis cabin and relates to the technical field of medical air cleaning, in particular to a cross infection preventing medical diagnosis cabin. The steady state flow replacement medical diagnosis cabin comprises a diagnosis cabin, an air supply tail end, a fresh air supply unit, an air discharging unit, an air circulation unit andan intelligent control unit. The diagnosis cabin is provided with a medical staff channel and a patient channel, and cross infection between doctors and patients is avoided. A steady state replacementflow air supply tail end device is adopted as a diagnosis cabin air outlet so that air can be pushed out in a radial manner, and air flow in the diagnosis cabin is not crossed. The fresh air supply unit is provided with a low-resistance anti-bacterium efficient air filter, a static electric field disinfecting device and an air supply draught fan. The draught fan is controlled by the air change capacity, the air discharging unit is provided with a low-resistance anti-bacterium efficient air filter, a static electric field disinfecting device and an air discharging draught fan. Air in the diagnosis cabin is subjected to harmless treatment and then is discharged into the atmosphere, and an air secondary circulation unit is provided with an air three-level filtering system. The intelligent control unit can be used for adjusting the pressure difference inside the cabin and outside the cabin.

Owner:SHIJIAZHUANG AOXIANG MEDICAL ENG

A method for preparing micro-porous metal copper blocks by dealloying copper-iron alloys

The invention relates to a method for preparing micrometer porous metal copper blocks by dealloying of copper-ferrum alloy. According to the method, plasma is adopted to activate and sinter copper-ferrum alloy, and then ferrum in the alloy is selectively corroded by utilizing a chemical dealloying method, thus obtaining porous copper blocks with high-strength micrometer apertures. According to the invention, by utilizing the characteristic that the copper-ferrum inter-atom diffusing capacity can be greatly reduced by a quick sintering process of hard miscibility of copper-ferrum alloy, which is lower than the melting point of ferrum, the dimension of a ferrous phase after sintering approaches to the particle size of micron-size material powder, so as to prepare the copper-ferrum bi-continuous three-dimensional net structured copper-ferrum alloy; the particle size of adopted copper powder is slightly smaller than that of ferrous powder, so as to form a structure that copper particles wrap ferrous particles, thus being favorable for ensuring the uniformity of aperture after corrosion; the pore structures of the porous metal copper blocks are regulated and controlled by changing the ferrous powder content and the particle size distribution; according to the process, the high-strength micrometer porous copper blocks with uniform pore distribution and adjustable pore size and porosity can be obtained; and the method has the advantages of being simple in process, low in cost and strong in practicability.

Owner:WUHAN UNIV OF TECH

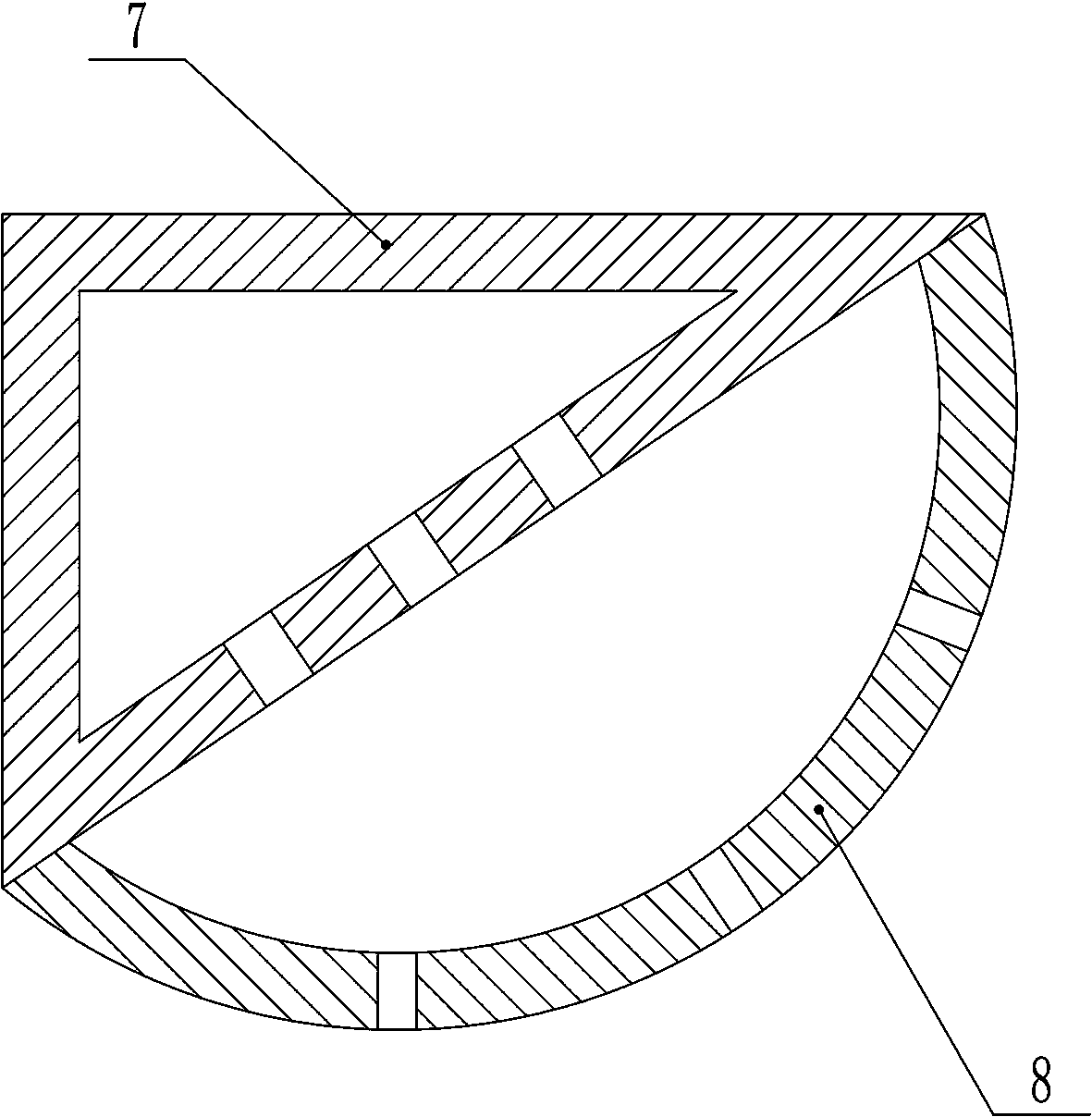

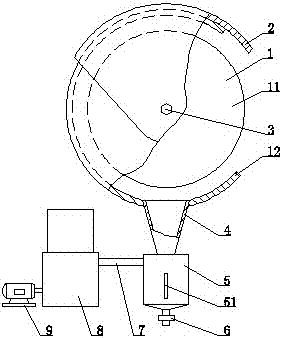

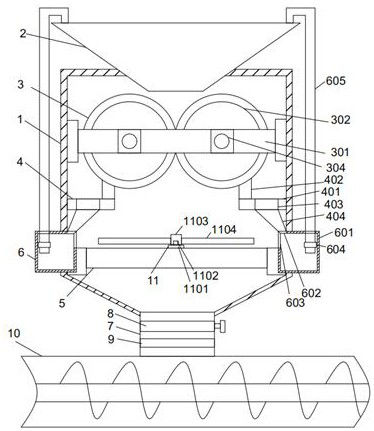

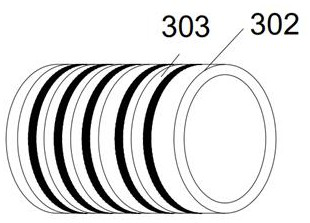

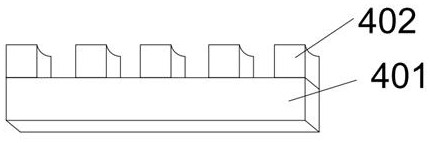

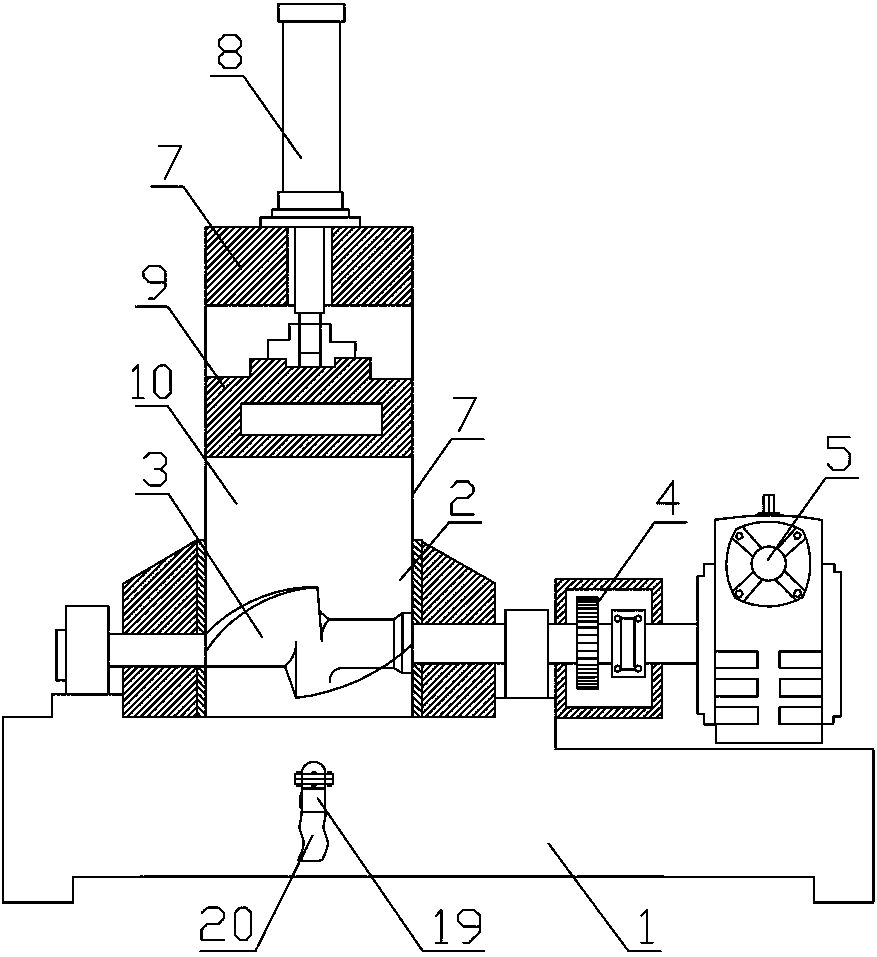

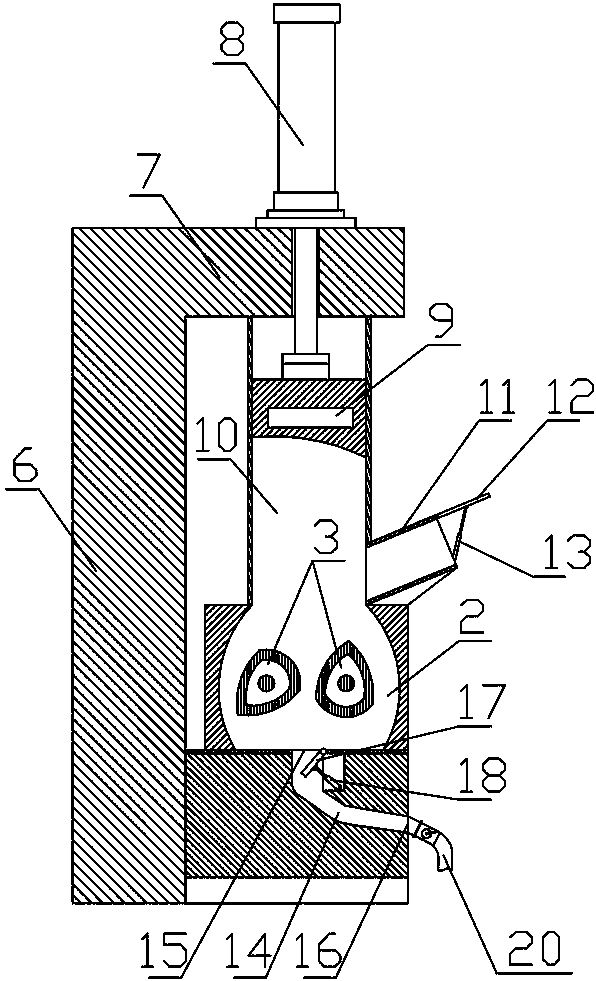

Tool sharpening device

InactiveCN107225442AReduce the amount of diffusionImprove dust collection effectOther manufacturing equipments/toolsGrinding/polishing safety devicesSlagBench grinder

The invention discloses a tool sharpening device, comprising a grinder (1), the grinder (1) comprising a grinding wheel (11) and a fixed cover (12), characterized in that it also includes an adjustment cover (2) , screw (3), cone bucket (4), slag collection box (5), manual valve (6), air duct (7), dust collector (8) and motor (9), the slag collection box (5 ) is provided with an inspection port (51), the adjusting cover (2) is mounted on the outer surface of the fixed cover (12) through screws (3), and the cone bucket (4) is mounted on the fixed cover (12), the slag collection box (5) communicates with the cone bucket (4), the dust collector (8) communicates with the slag collection box (5) through the air duct (7), and the motor (9 ) is connected with the dust collector (8). The invention has novel structure, good slag collection and dust collection effect, environmental protection and safety, and long service life.

Owner:HUANGSHI ZHIYUN ELECTROMECHANICAL TECH INST

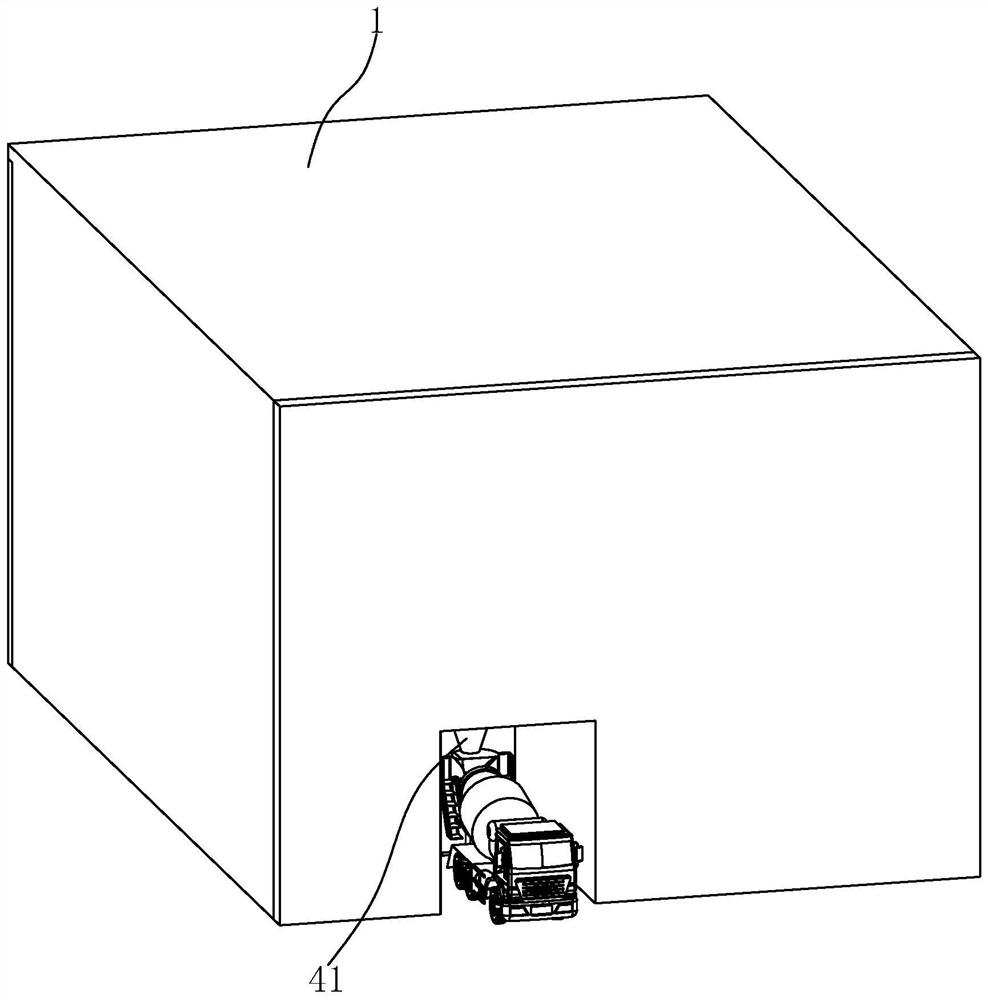

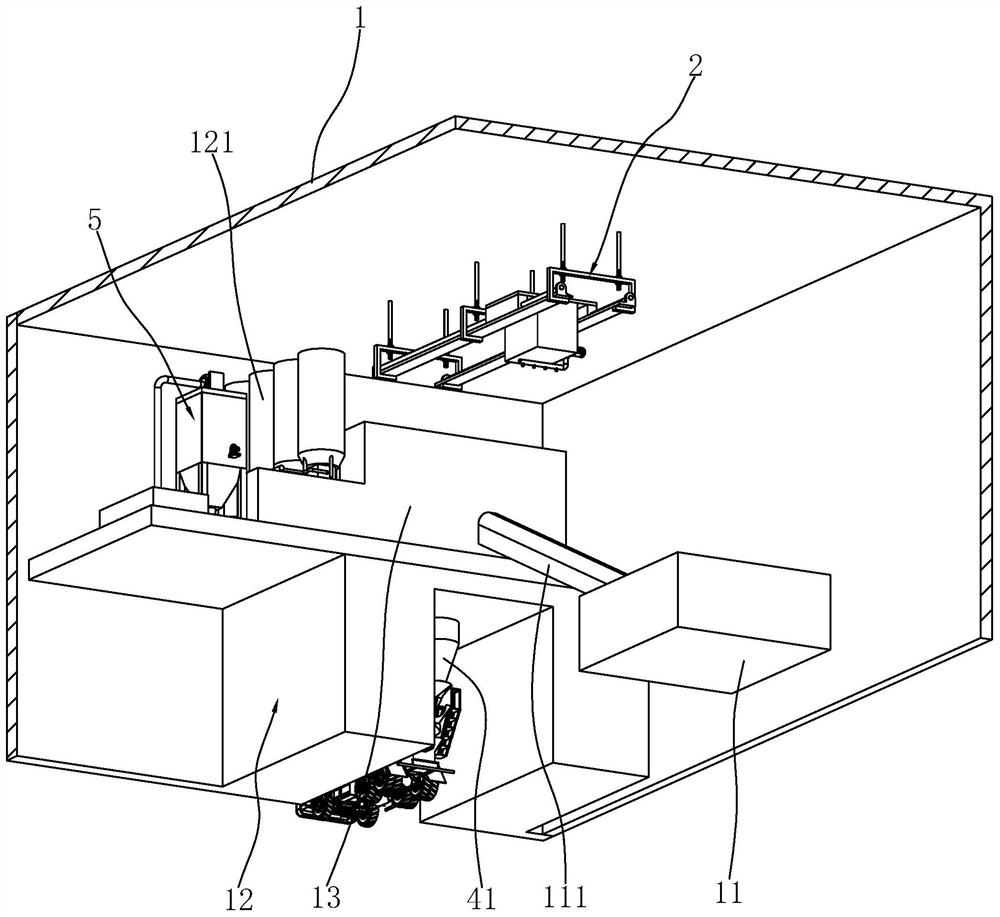

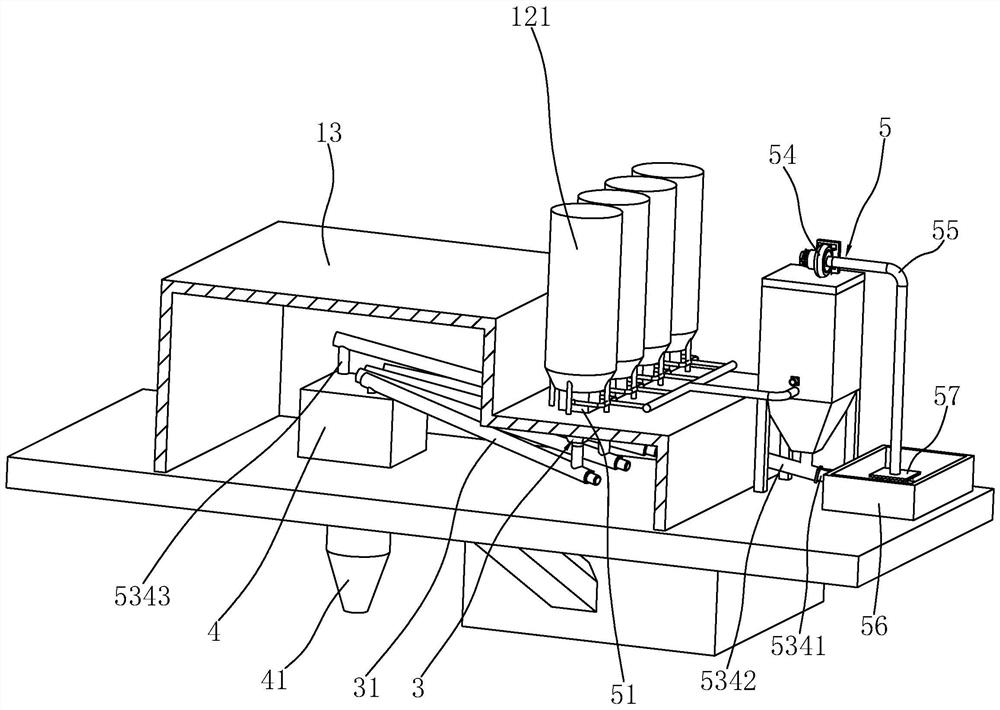

Closed mixing plant

InactiveCN111804099AImprove pollutionReduce the amount of diffusionCombination devicesMixing operation control apparatusBLENDER/MIXERThermodynamics

The invention relates to a closed mixing plant which comprises a room body, and the room body comprises a raw material area and a stirring area; a plurality of silos are arranged in the stirring area;a powder weigher is arranged on the lower side of each silo; a dust collection device is arranged between thesilos and the powder weigher; the lower side of each powder weigher is connected with a stirring machine through a spiral conveyor; the lower side of the stirring machine is provided with a discharge port, the raw material area is connected with the stirring machines through a belt conveyor, the dust collection device comprises a surrounding plate arranged at the bottom of the silo, the surrounding plate is communicated with a dust suction pipe, the other end of the dust suction pipe is communicated with a dust falling box, and the other side of the dust falling box is communicated with a negative pressure fan. The closed mixing plant has the advantages that the mixing plant can becompletely sealed, and flying dust emission of the mixing plant is reduced.

Owner:北京中实上庄混凝土有限责任公司

Anti-blocking polyethylene granulating and discharging device

The invention discloses an anti-blocking polyethylene granulating and discharging device which comprises a discharging machine shell, wherein a discharging hopper is fixedly connected to the top of the discharging machine shell, a smashing device is fixedly mounted in the discharging machine shell, a scraping device is fixedly mounted at the position, located at the bottom of the smashing device,in the discharging machine shell, and a filtering device is fixedly mounted at the bottom end in the discharging machine shell. Large-particle polyethylene particles are cut and crushed into small-particle polyethylene through the crushing device, the large-particle polyethylene particles which are completely crushed are filtered out through the filtering device, material returning and re-crushingare conducted through the material returning device, so that it is guaranteed that the discharged raw materials are all small-particle polyethylene particles and are easier to melt in a hot melting extrusion process; and the probability of blockage is reduced. The blanking speed is controlled through the speed control device, and heat in a screw extruder is prevented from being transferred into aconnecting pipe through a heat extraction device, so that materials in the connecting pipe are prevented from being molten by hot air to cause adhesion.

Owner:闫金明

Manufacturing method of sonos device

ActiveCN105047670BSmall sizeReduce leakageSolid-state devicesSemiconductor/solid-state device manufacturingDevice typeIndium

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Dust-raising-resistant type rubber internal mixer

The invention relates to the field of internal mixer equipment, in particular to a dust-raising-resistant type rubber internal mixer. The mixer is provided with a base, wherein an internal mixing chamber is arranged on the base, two internal mixing rotors which rotate relative to each other are installed in the internal mixing chamber side by side, a cantilever is arranged on one side of the base,a floating hammer is vertically installed on the cantilever, the floating hammer extends downwards into the internal mixing chamber under pushing of a hydraulic push cylinder, a sealing cabin is arranged between the internal mixing chamber and the cantilever, a feeding opening communicates with the cabin wall of one side of the sealing cabin, a feeding opening door capable of being kept open is installed on the opening edge of the feeding opening, a discharging cabin is formed in the base, one end of the discharging cabin is connected to a discharging door in a hinged mode, the other end of the discharging cabin is connected with a rectangular discharging barrel, a dust removing cloth bag is installed at the bottom of the rectangular discharging barrel, and a control valve used for controlling the discharging speed is installed on the rectangular discharging barrel. According to the mixer, the diffusion of material dust to the periphery in the feeding and discharging processes is effectively blocked, so that the outward diffusion amount of the dust is greatly reduced, and the working environment of a production workshop is effectively improved.

Owner:黄石市东兴橡胶制品有限公司

Method for making floating gate discharging sharp angle

ActiveCN100490099CGood lookingReduce the amount of diffusionSolid-state devicesSemiconductor/solid-state device manufacturingSize changeEngineering

The invention discloses a method of manufacturing a floating boom discharge sharp corner. The method comprises the steps of firstly utilizing SiH4, N2O and H2 as reaction gas and generating a layer of a SiOxNy buffer layer by the low pressure chemical vapor deposition method before silicon nitride sediment, as the buffer layer for later floating boom oxidization; in forming beak, adjusting by control technology to facilitate oxygen atoms to spread transversely toward a lateral wall underlay with certain amount. The transverse size is extended and the erasing sharp corner formed finally has a transverse extension on the upper edge, which is good for resisting the influence of subsequent floating boom etching size change on the shape of the sharp corner, improving the whole erasing performance and increasing the device stability and reliability.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP +1

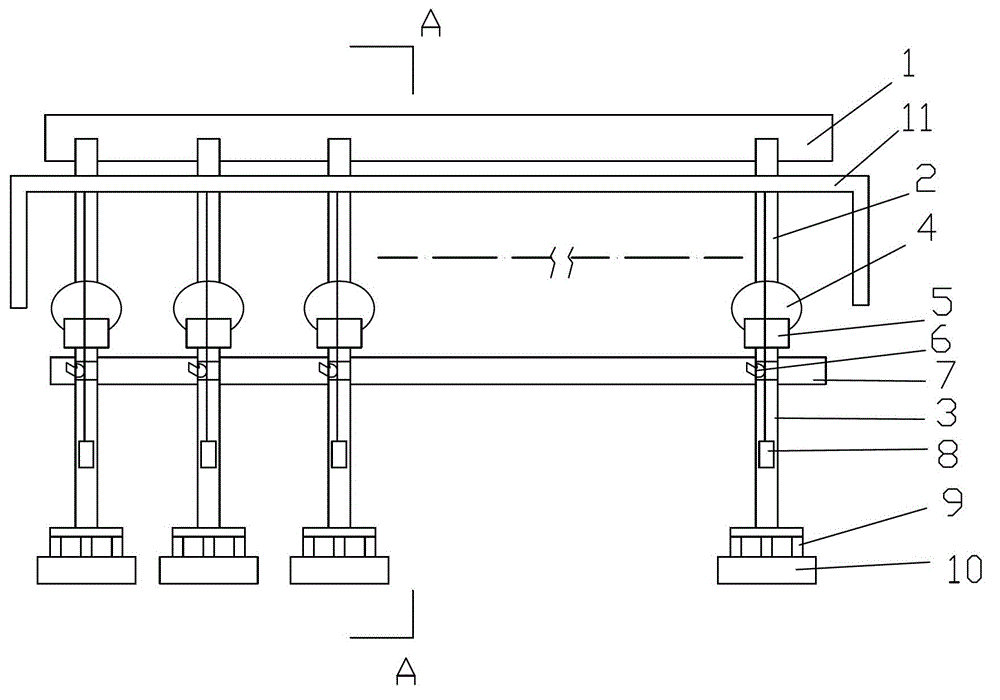

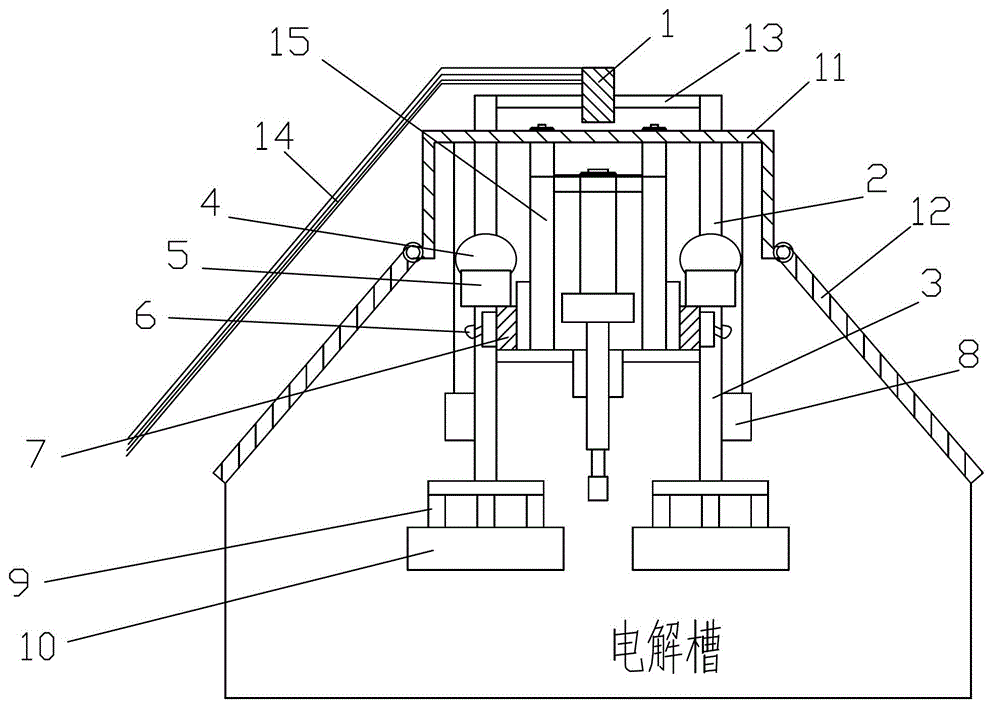

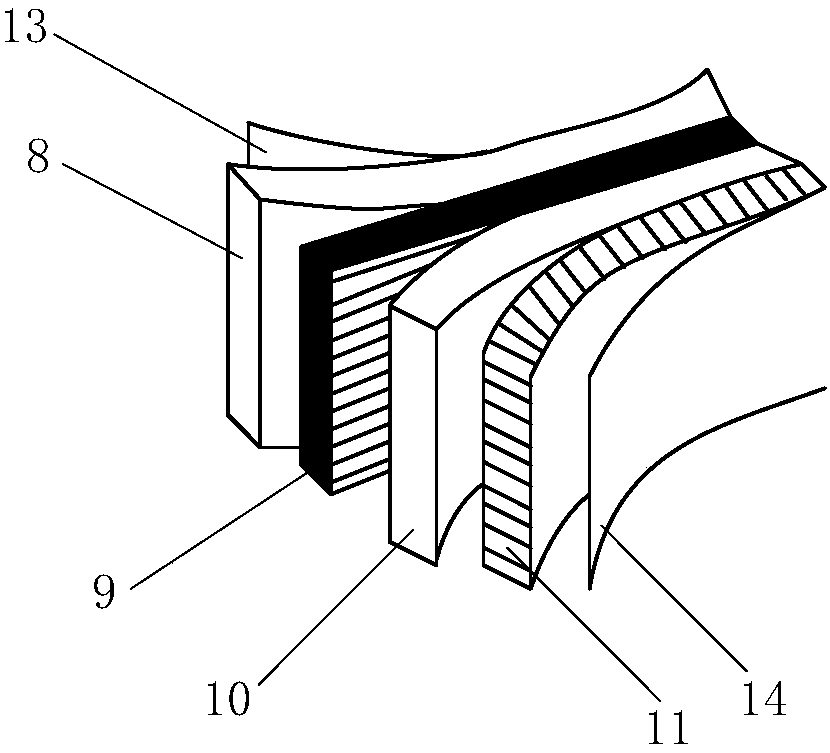

Upper part seal structure of aluminium electrolytic tank

The invention discloses an upper part seal structure of an aluminium electrolytic tank. The seal structure comprises an anode guide rod, a beam bus and a vertical column bus. An anode carbon block is arranged at the end of the anode guide rod. An outer cover is arranged above the electrolytic tank. The outer cover is connected with a tank cover plate of the electrolytic tank, and an opening of the whole electrolytic tank is packed by a structure formed by the outer cover and the tank cover plate of the electrolytic tank. The device favorably improves the whole thermal insulation properties of the aluminium electrolytic tank, and also reduces the diffusing capacity of flue gas produced in the aluminium electrolytic tank around factories, so that the heat dissipation loss of the upper part of the aluminium electrolytic tank can be greatly reduced, heat balance when a low voltage is normally operated is maintained, and the thermal insulation requirement of a future low temperature aluminium electrolytic tank is met.

Owner:CENT SOUTH UNIV

A kind of polarizer and its preparation method, liquid crystal display device

ActiveCN105807343BReduce deformationReduce the amount of diffusionPolarising elementsNon-linear opticsLiquid-crystal displayPolarizer

The invention discloses a polarizer, a production method thereof and a liquid crystal display device, relates to the technical field of display, and aims to avoid the ripples of images displayed by a liquid crystal display device. The polarizer comprises a first protecting layer, a polarizing layer, a second protecting layer and an adhering layer which are sequentially stacked, wherein elastic particles capable of absorbing pressure are arranged in the adhering layer. The liquid crystal display device comprises a display panel, an upper polarizer and a lower polarizer, wherein each of the upper polarizer and the lower polarizer is the polarizer mentioned above. The polarizer is used for converting light penetrating the polarizer into linearly polarized light with a specific polarization direction.

Owner:BOE TECH GRP CO LTD +1

Small static chamber for farmland greenhouse gas monitoring and sampling

InactiveCN106053155AReduce disturbanceWell mixedWithdrawing sample devicesEcological environmentGreenhouse

The invention belongs to the technical field of agriculture, forestry and ecological environment and particularly relates to a small static chamber for farmland greenhouse monitoring and sampling. The small static chamber comprises a chamber body, an extractor vent with a rubber plug is arranged in the chamber body, and an atmosphere equalizing valve which is of a vent pipe 3-4mm in diameter and inserted in the chamber body is fixedly mounted on the chamber body; the chamber body is 1.10-1.28L in size; in the small static chamber, the vent pipe is vertically arranged at the top of the chamber body, a clamp platform is arranged between the insert end of the vent pipe and the top of the chamber body, and a pressure head is fixedly connected between the external extension end of the vent pipe and the top of the chamber body in a threaded manner. The small static chamber is small in size, convenient in carrying and transportation and high in monitoring accuracy.

Owner:INST OF PLANT NUTITUION & RESOURCE ENVIRONMENT HENAN ACADEMY OF AGRI SCI

A kind of cold-wet sandy grassland restoration vegetation building material and its application method

ActiveCN107360889BEffective coverageConvenient for later diggingGrowth substratesCulture mediaVegetationSoil science

The invention relates to the technical field of agricultural ecology, in particular to an establishment material for recovering vegetation of cold-dampness type desertified grassland and a use method thereof. The vegetation establishment material is prepared from, by weight, 200-400 parts of cow dung, 100-200 parts of sheep manure, 500-1,000 parts of meadow soil, 100-200 parts of peat soil and 100-200 parts of bentonite, and is particularly suitable for recovering planting of the vegetation of the cold-dampness type desertified n grassland. As for plateau regions, yak dung can be directly used as one local raw material of the vegetation establishment material. The vegetation establishment material is added with water to ensure that during blending, the raw materials can be bonded to one another, and therefore the desertified grassland can be effectively covered, and meanwhile, more convenience is brought to excavation work in the later period. The establishment material for recovering the vegetation of the cold-dampness type desertified grassland and the use method thereof relate to the following approaches, steps and tools, and the steps consist of investigating a desertification diffusion direction in a desertified grassland region to determine the main movement orientation of a desert and then determine windward sides and leesides of fixed dunes, semi-fixed dunes and traveling dunes in an area where governance work is conducted, applying the vegetation establishment materials to the desert according to a usable area, and conducting monitoring and testing.

Owner:LANZHOU UNIVERSITY

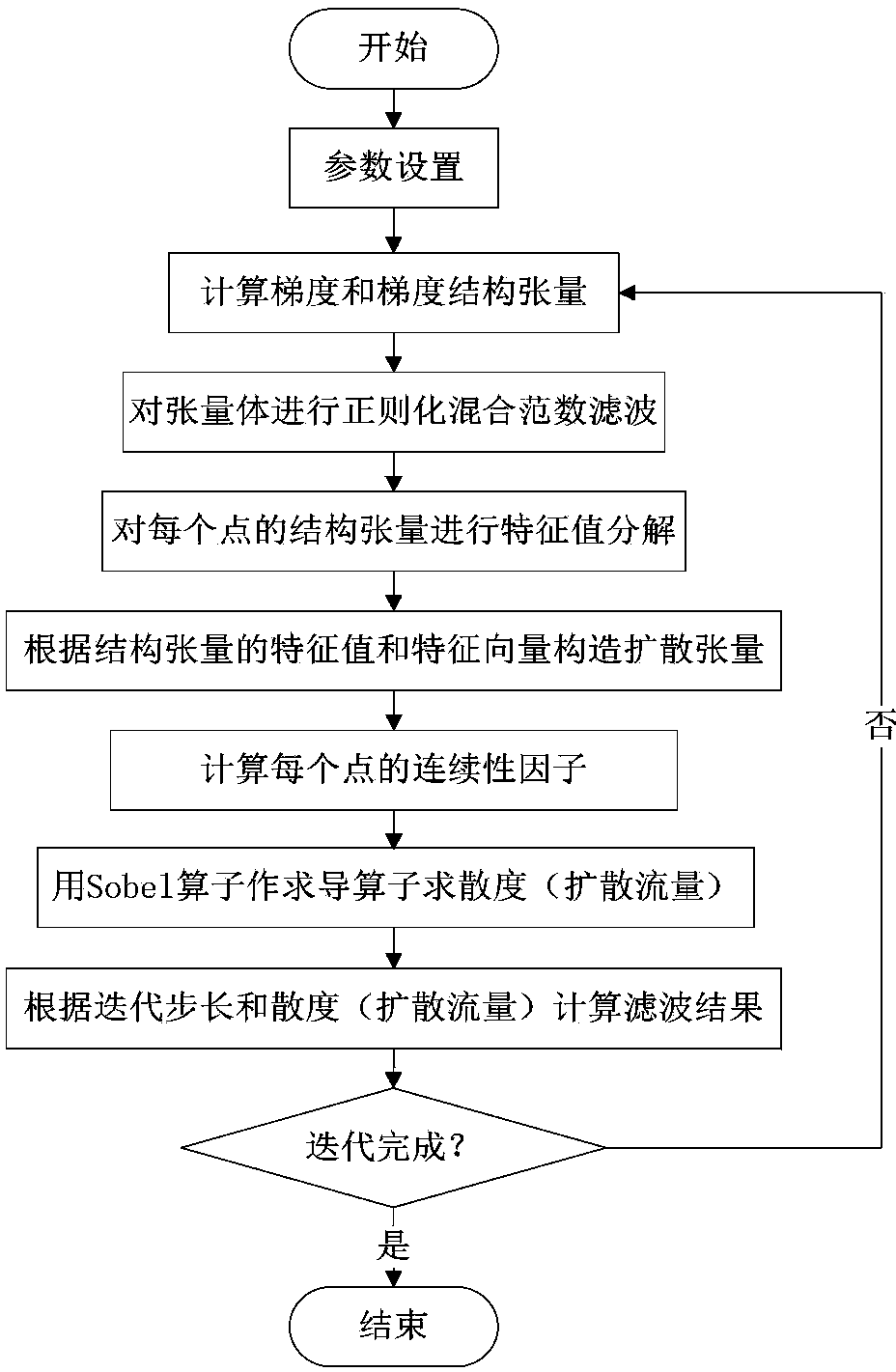

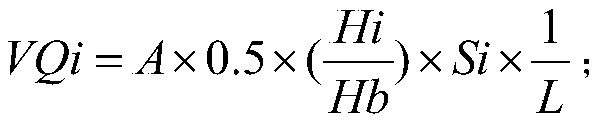

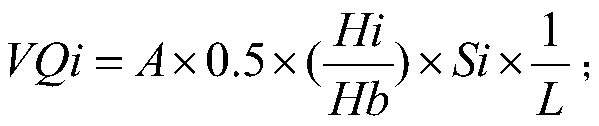

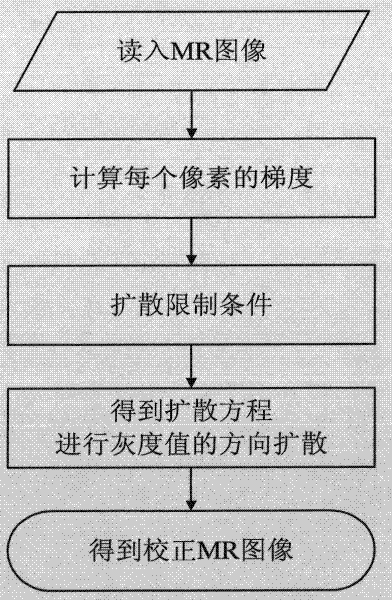

Inverse diffusion method for eliminating Gibbs annular artifact of magnetic resonance image

InactiveCN101908204BQuality improvementReduce the amount of diffusionImage enhancementDiffusion methodsResonance

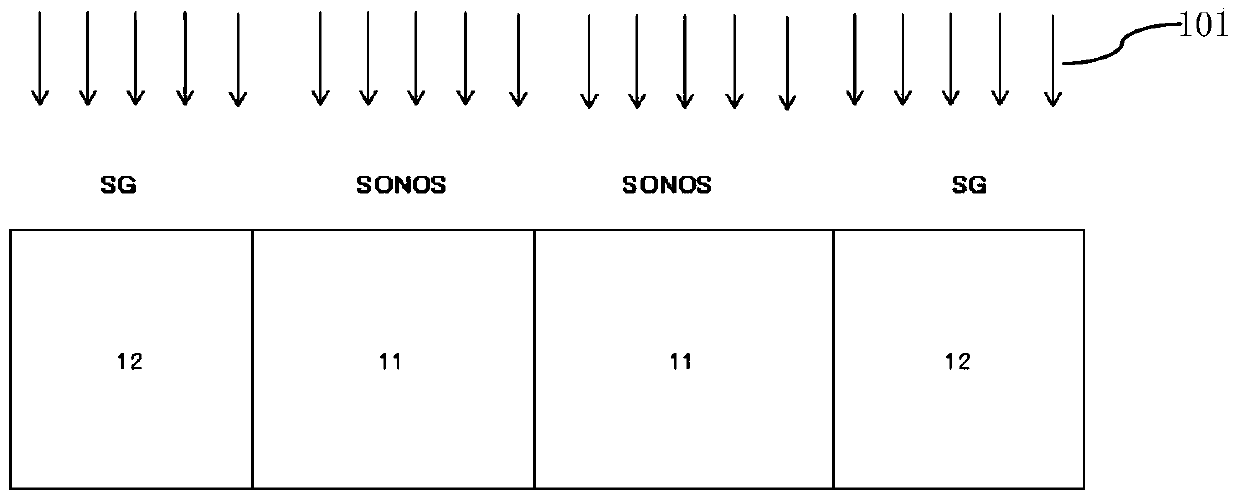

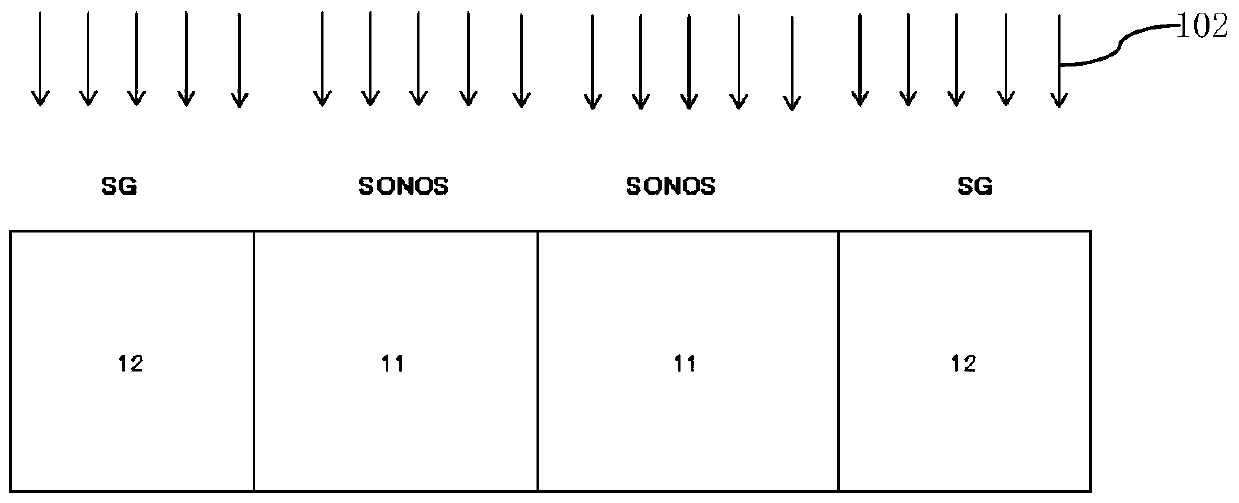

The invention discloses an inverse dispersion method for eliminating a Gibbs annular artifact of a magnetic resonance image. The method comprises the following steps of: reading an MR artifact image acquired through magnetic resonance imaging; calculating the gradient of each pixel from the image data and inversely diffusing the grey values of all pixels along the gradient direction; forming limiting conditions of grey value diffusion so as to make the whole diffusion process capable of adaptively adjusting the diffusion speed and to guarantee the stability of the whole diffusion process; obtaining the directional diffuseness of a diffusion equation which progresses the grey value; and updating the grey values of the pixels to acquire the corrected MR image. A high-quality image can be acquired by performing data correction on the artifact generated by cutting of the k space data.

Owner:SOUTHERN MEDICAL UNIVERSITY

Plating method for preventing hydrogen bubbles of copper-tin alloy plating layer

InactiveCN101649475BPrevent hydrogen bubblingHydrogen Bubble EliminationSquare waveformAverage current

The invention provides a plating method for preventing hydrogen bubbles of a copper-tin alloy plating layer. A plating anode material is a high-purity copper plate with purity of 99.9 percent, a cathode material is a 27 SiMn steel plate which is processed by oil-removing treatment, copper-tin alloy plating liquid is industrial low-tin bronze electrolyte, and pH is 8-9. The plating method comprises plating parameters: the plating adopts a square-wave impulse plating technology, the impulse average current density is 1-5 A / dm<2>, the frequency is 500Hz-2500Hz, the duty ratio is 25-40 percent, aspace between a cathode and an anode is 5-10cm, the area ratio of the cathode to the anode is from 1:1.5 to 1:5, and the electrolyte temperature is from 25 DEG C to 35 DEG C. Compared with the traditional DC plating copper-tin alloy technology, the plating method introduces impulse current and effectively inhibits hydrogen generation in a planting process, and optimal technological parameters of the impulse plating technology are sieved, thereby the hydrogen bubbles of the copper-tin alloy plating layer can be prevented. The plating method for preventing hydrogen bubbles of a copper-tin alloyplating layer has simple technology, low cost, strong applicability, and the like.

Owner:HARBIN ENG UNIV

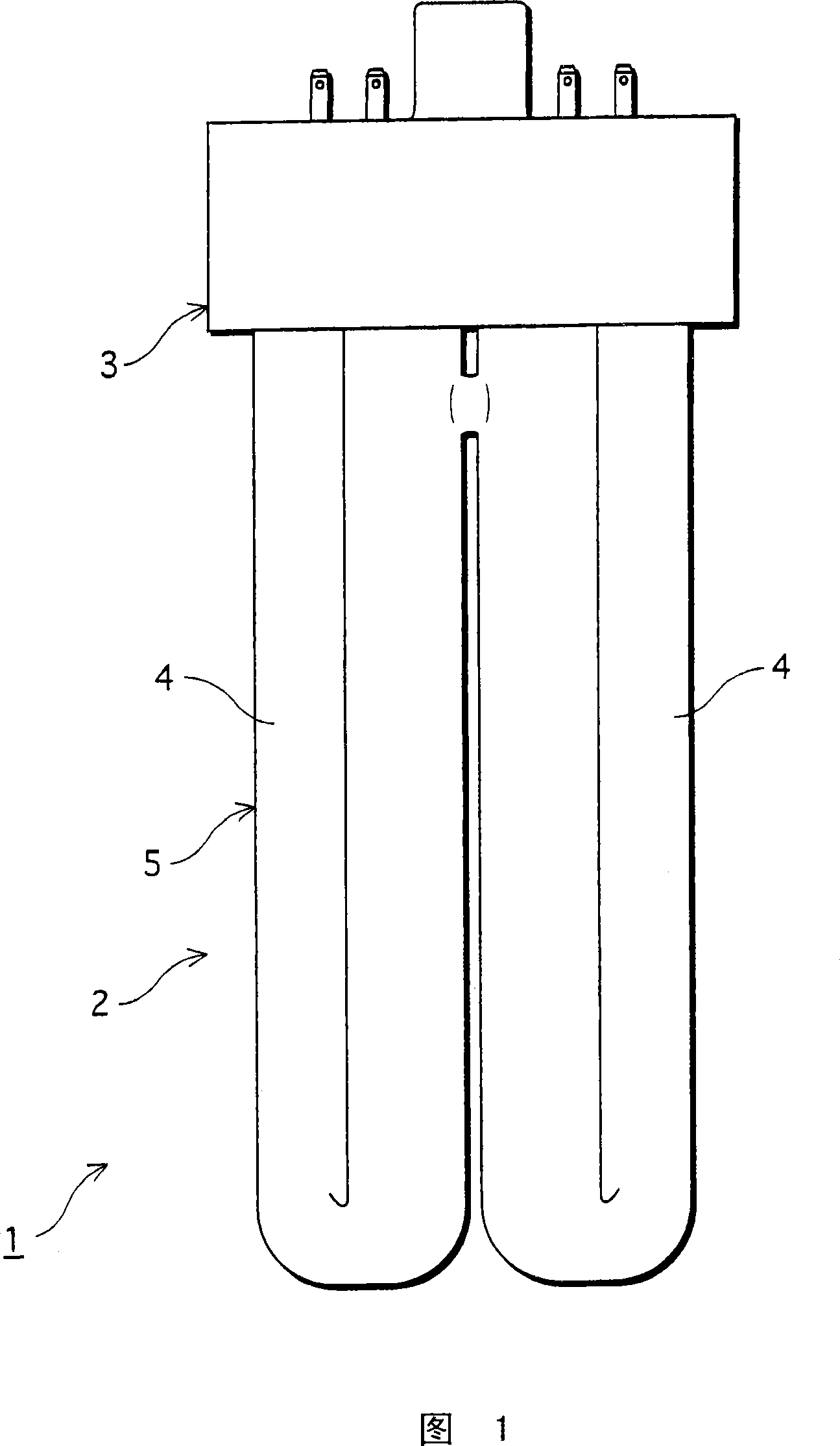

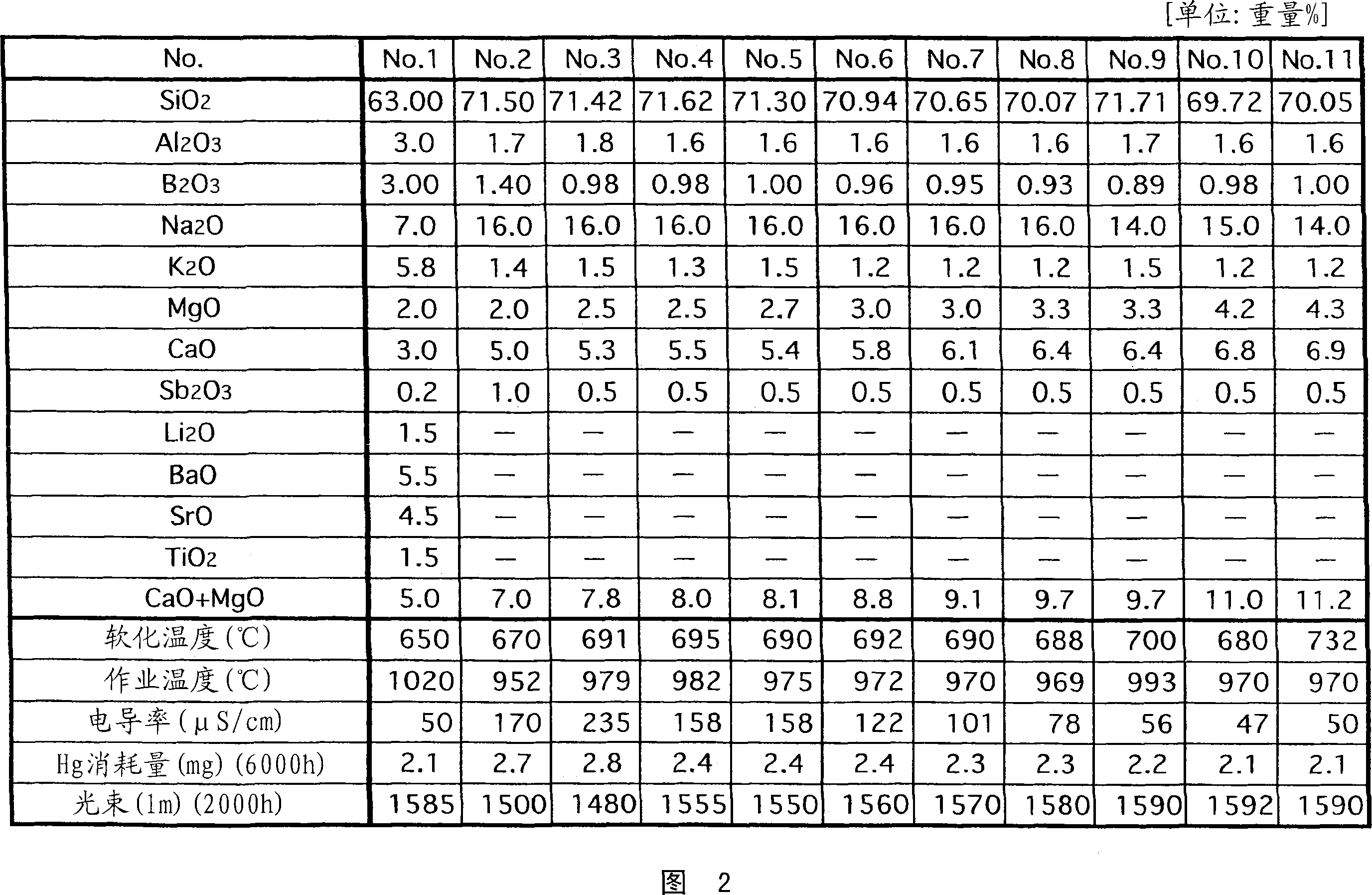

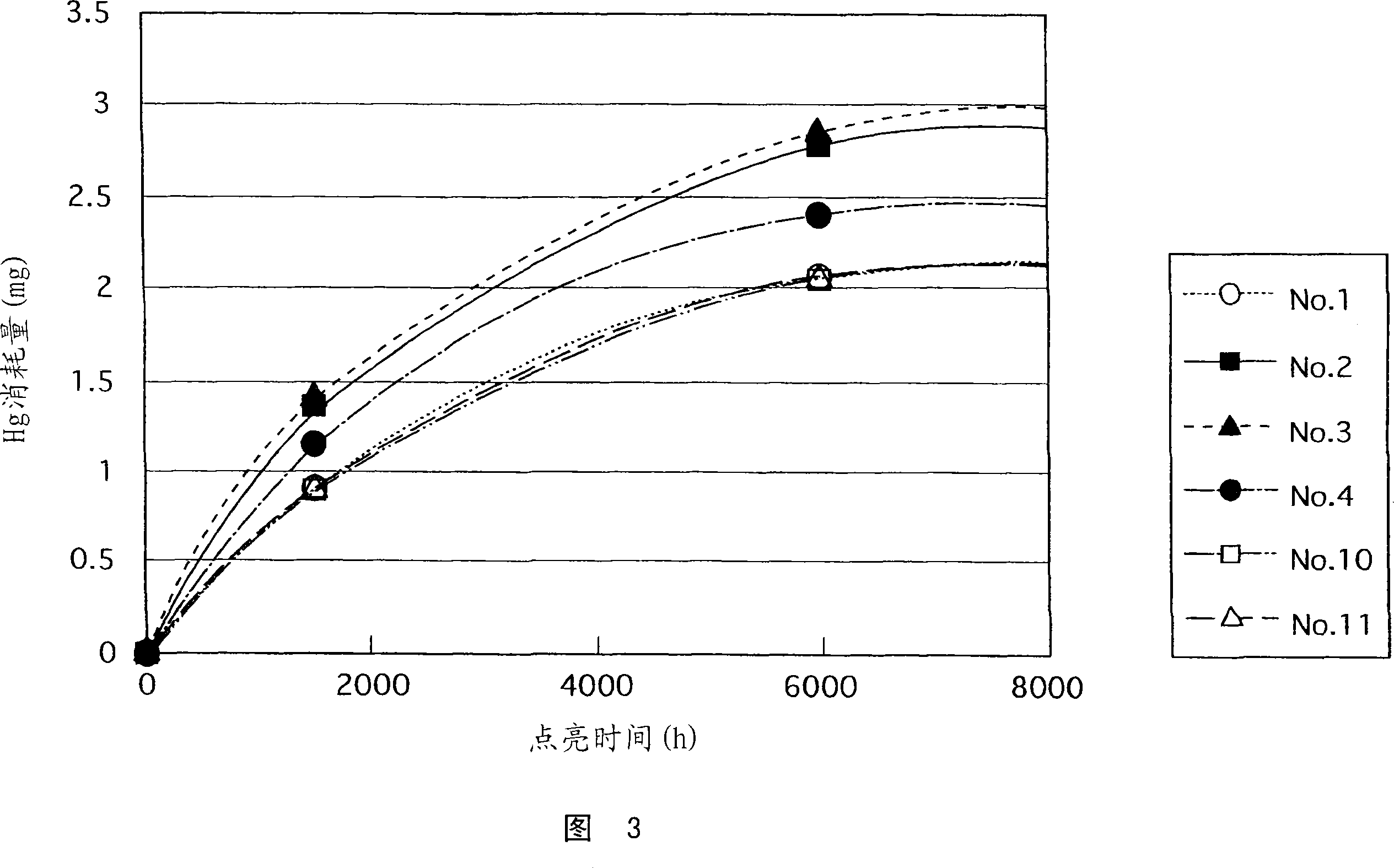

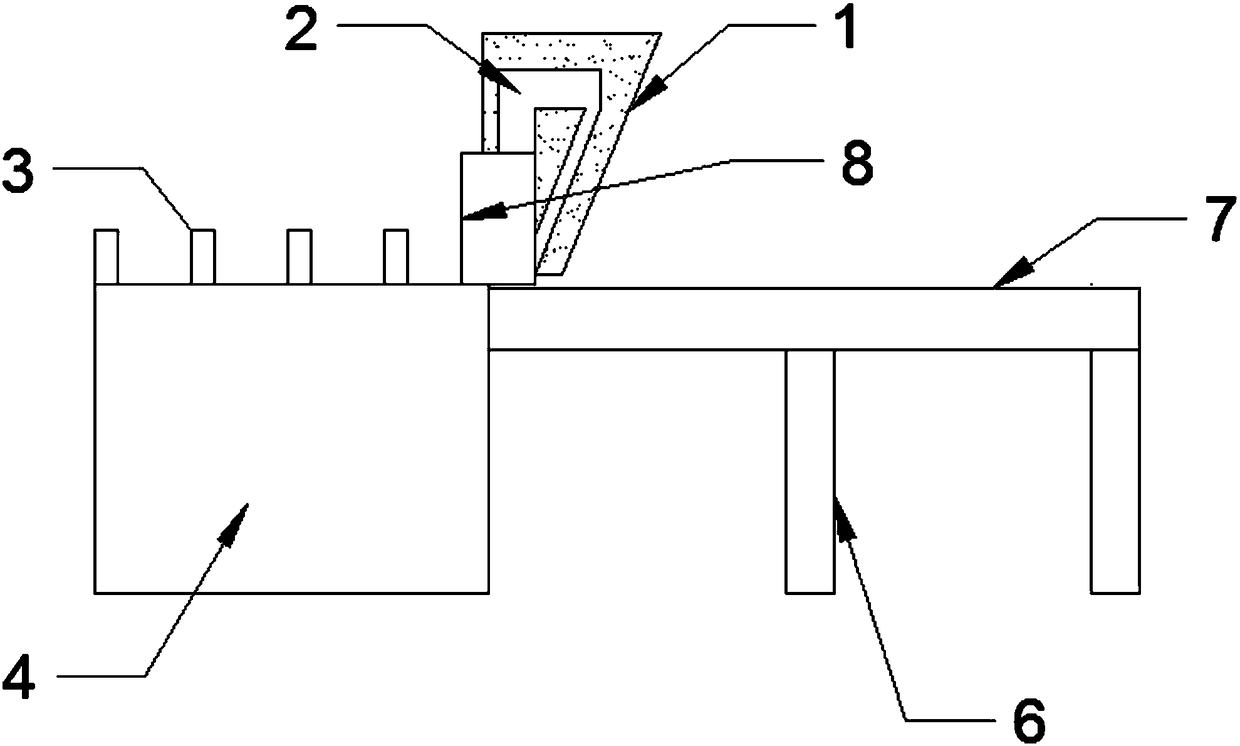

Glass composition for lamp and lamp using same

InactiveCN1964925AIncrease contentEasy to processGas discharge lamp detailsPhysical chemistryEngineering

Disclosed is a glass composition for lamps mainly containing SiO2 (silicon dioxide) and further containing 12-17 wt% of Na2O (sodium oxide), 2.5-4 wt% of MgO (magnesium oxide) and 5.3-7.3 wt% of CaO (calcium oxide) with MgO and CaO being 8-11 wt% in total. With this constitution, the glass composition can be obtained at low cost while having excellent strength and workability. Furthermore, this glass composition does not erode a melting furnace and only a small amount of alkali is dissolved therefrom.

Owner:PANASONIC CORP

Ribbed steel bar six-line rolling device and production method thereof

PendingCN108581290AEasy to installEasy to disassembleWelding/cutting auxillary devicesAuxillary welding devicesSteel barMechanical engineering

The invention discloses a ribbed steel bar six-line rolling device. The ribbed steel bar six-line rolling device comprises a welding machine case; correcting devices are arranged at the top of the welding machine case; an electric welding machine is arranged on one side of the correcting devices; a fixed set square is arranged at the top end of the electric welding machine; a bracket is arranged on the rear surface of the fixed set square; an electric supporting transverse rod is arranged on the right side of the welding machine case; fixed upright rods are arranged at the bottom of the electric supporting transverse rod; the arrangement of a sound absorbing plate can reduce the noises produced by the electric welding machine in a using process, the diffusion amount of the noises is reduced, and the comfort degree of employees in a working process is improved; the arrangement of an intelligent switch can control the elongating or shortening of an electric telescopic rod according to whether a machine starts or not so as to control whether the sound absorbing plate enters the welding machine case or not, so that the sound absorbing plate is prevented from dust falling in a daily placement process; and therefore, a sound absorbing effect of the sound absorbing plate is prevented from being affected adversely.

Owner:江阴市建鑫金属有限公司

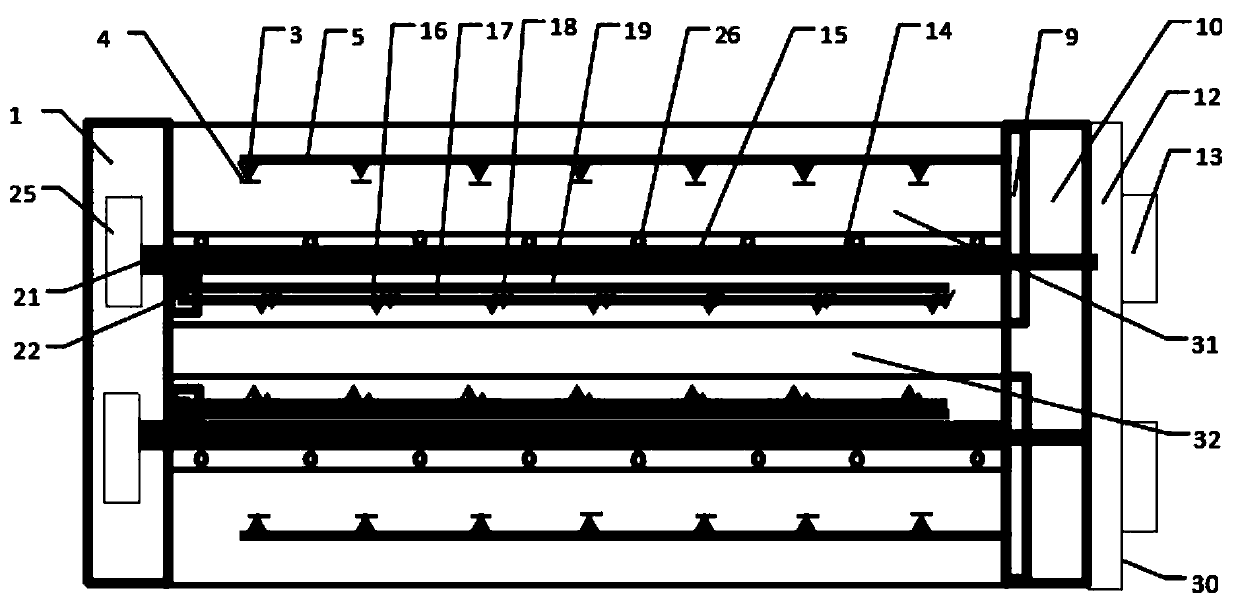

A ventilation system for pig houses in cold regions

ActiveCN107912305BImprove insulation effectImprove ventilationAnimal housingTemperature controlExhaust fumes

The invention discloses a pigsty ventilation system for cold regions. The pigsty ventilation system for the cold regions comprises a pigsty and a ventilation system. The ventilation system comprises an air inlet pipeline and an exhaust pipeline, and the air inlet pipeline sequentially comprises a fresh air fan, a heat conversion device, a temperature control room, an air inlet pipe, fresh air openings and protective plates; the exhaust pipeline sequentially comprises first exhaust outlets, second exhaust outlets, a first exhaust pipe, a second exhaust pipe, a guide valve, the heat conversion device, a waste gas treatment room and an exhaust fan. The pigsty ventilation system has the advantages that lost heat of the pigsty can be effectively recycled, the pigsty is good in heat insulation and high in waste gas removal efficiency and can be uniformly ventilated, energy can be saved, survival environments for pigs can be obviously improved, environmental pollution can be abated, and the like.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

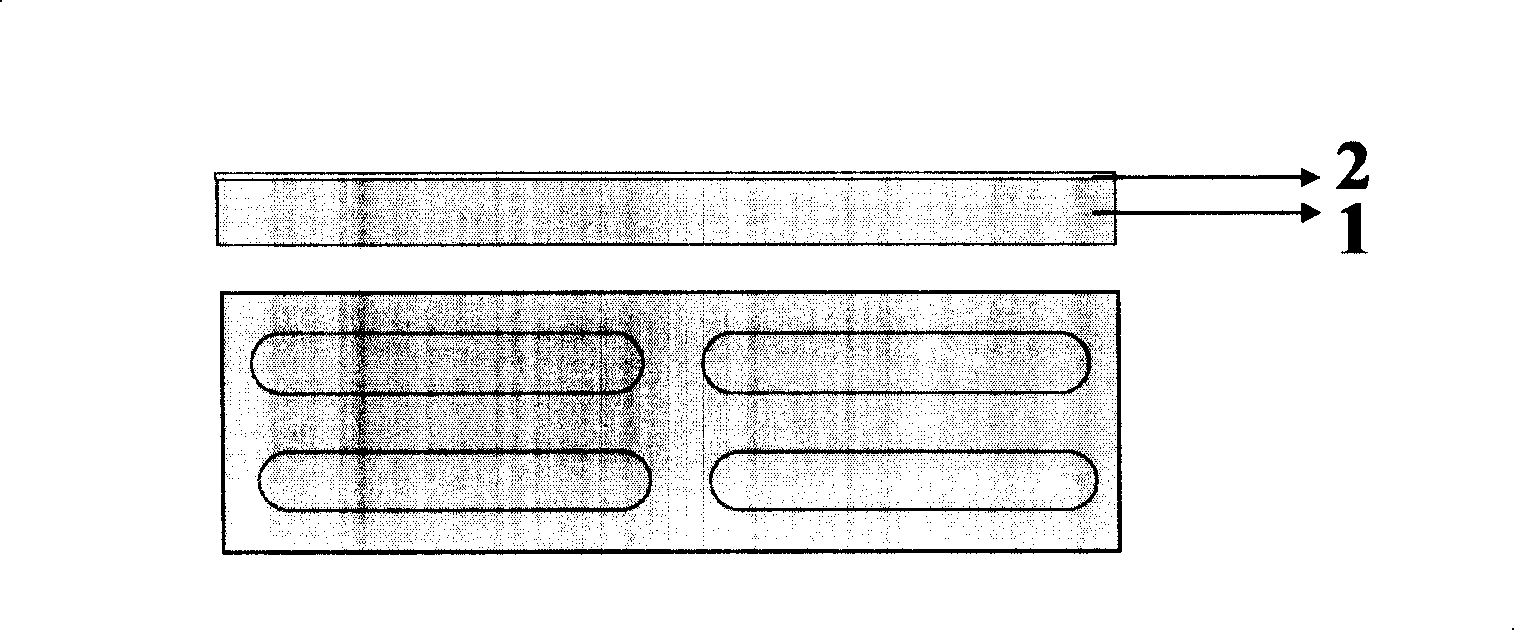

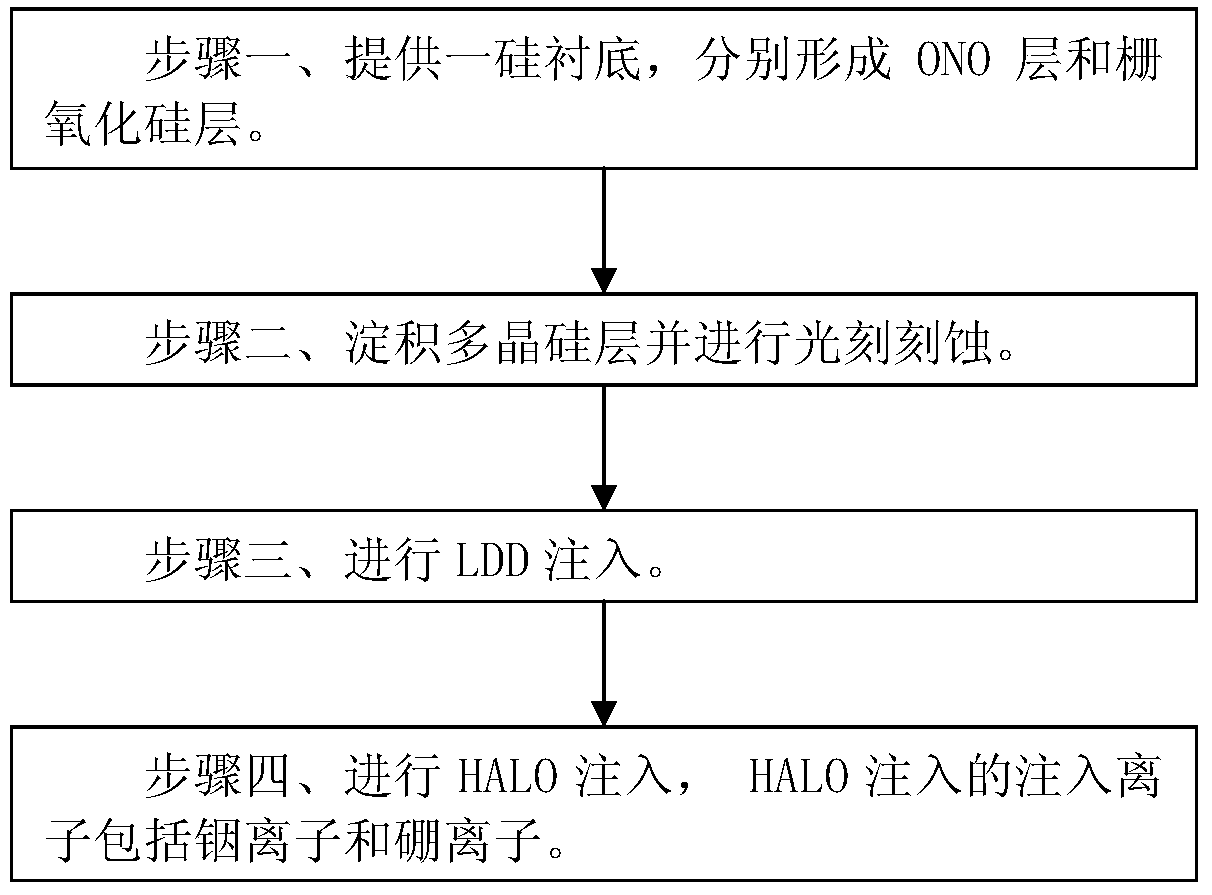

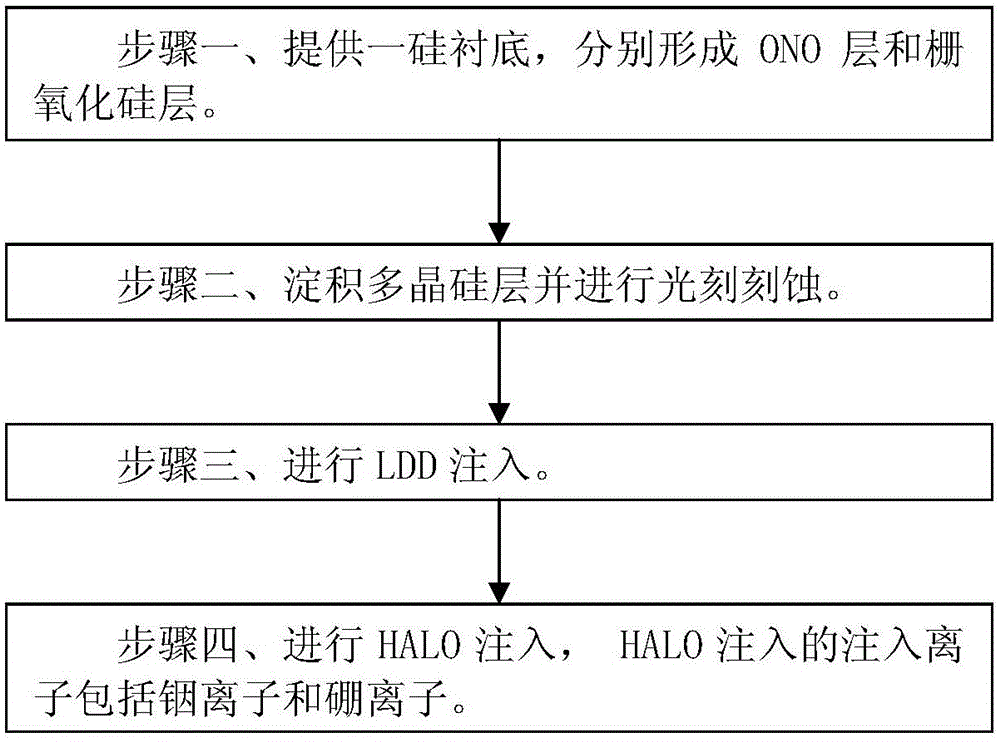

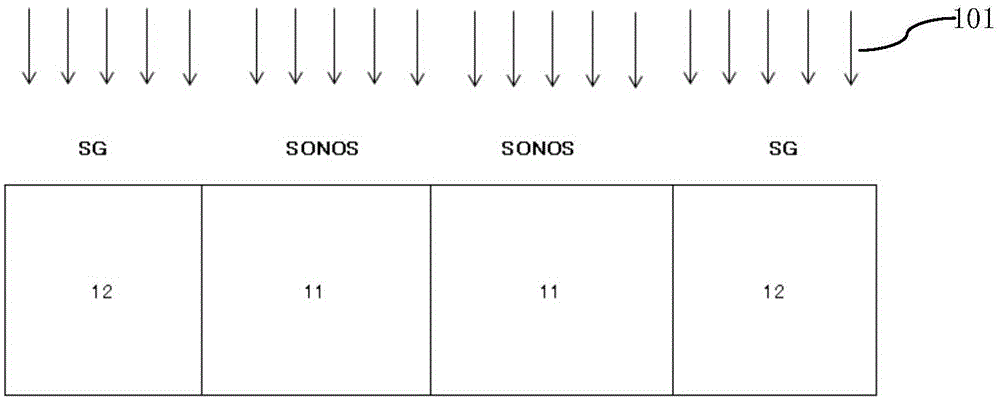

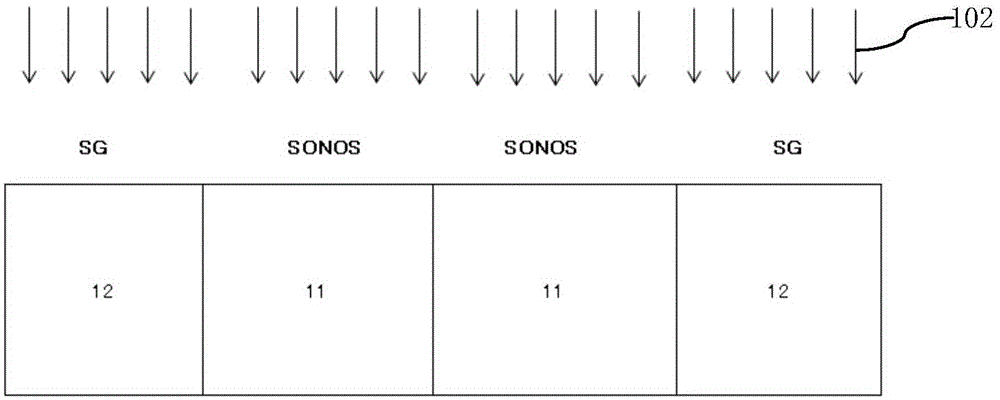

Manufacturing method of SONOS device

ActiveCN105047670ASmall sizeReduce leakageSolid-state devicesSemiconductor/solid-state device manufacturingIndiumIon distribution

The present invention discloses a manufacturing method of an SONOS device. A manufacturing method of a unit structure of the SONOS device comprises the following steps of providing a silicon substrate, and forming an ONO layer and a gate silicon oxide layer separately; depositing a polysilicon layer and carrying out the photoetching; carrying out the LDD injection; carrying out the HALO injection, wherein the injected ions comprise indium ions and boron ions. According to the present invention, by utilizing the characteristics that the indium ions are larger than the mass of the boron ions, are distributed shallowly after being injected, and are smaller in diffusion amount along with a heat process, and by adding the indium ion injection, the ion distribution of the HALO injection is adjusted, when the size of the SONOS device is reduced continuously, the ions of the HALO injection are distributed and concentrated at the bottom of a polysilicon gate by adding the indium ion injection, thereby being able to reduce the electric leakage of the SONOS device and the gate-induced drain electric leakage, facilitating reducing the size of the SONOS device, and being able to improve the reliability of the device.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

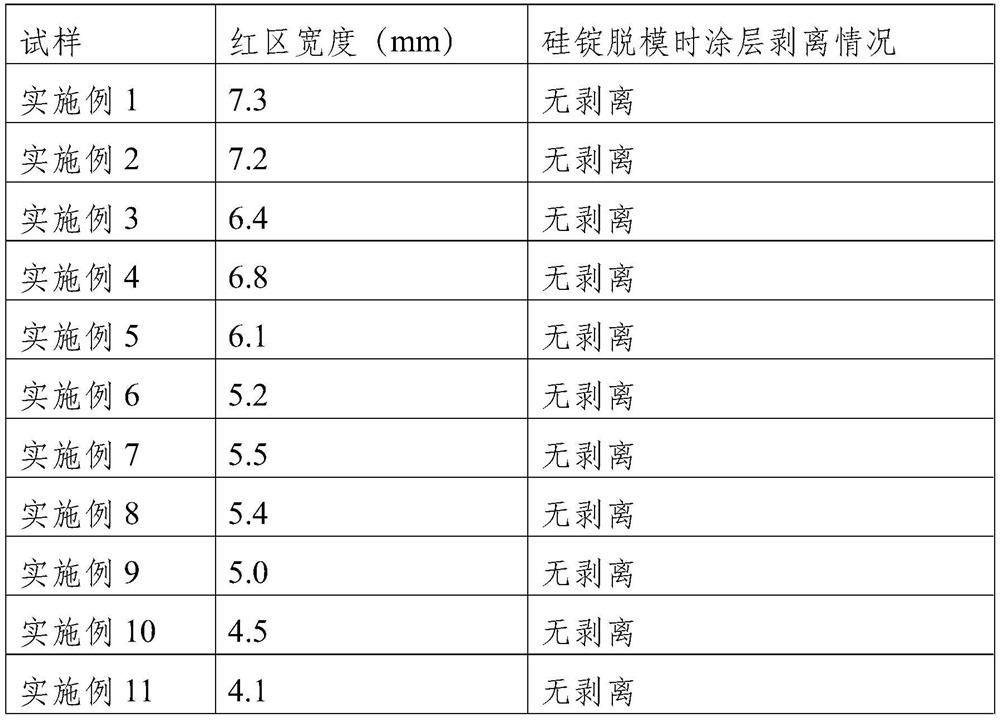

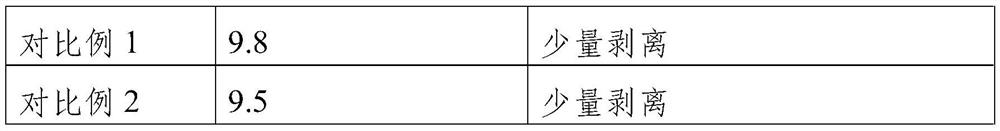

Production process of high-purity spray-free crucible

The invention discloses a production process of a high-purity free-spraying crucible. The production process comprises the following steps of: (1) preparing silicon nitride slurry, and painting the silicon nitride slurry on the inner surface of a common quartz crucible; and (2) drying the painted crucible at 130-200 DEG C so as to obtain the high-purity free-spraying crucible which has a silicon nitride coating on the inner surface, wherein the silicon nitride slurry comprises, in percent by weight, 30-44% of silicon oxide powder with an alpha phase content of 90% or above, 15-22% of silica sol and 41-48% of deionized water. By introducing the silica sol with high-temperature viscosity into the silicon nitride slurry, the content of silicon nitride in the silicon nitride coating is reduced, and the diffusion amount of nitrogen to the surface of silicon melt is reduced; and meanwhile, the strength and density of the silicon nitride coating and adhesion of the silicon nitride coating tothe surface of the common quartz crucible are increased, and probability of adhesion and falling off of the silicon nitride coating on the surface of a silicon ingot is reduced after demoulding is conducted.

Owner:WUXI SHUNYANG NEW ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com