PERC solar cell sintering method

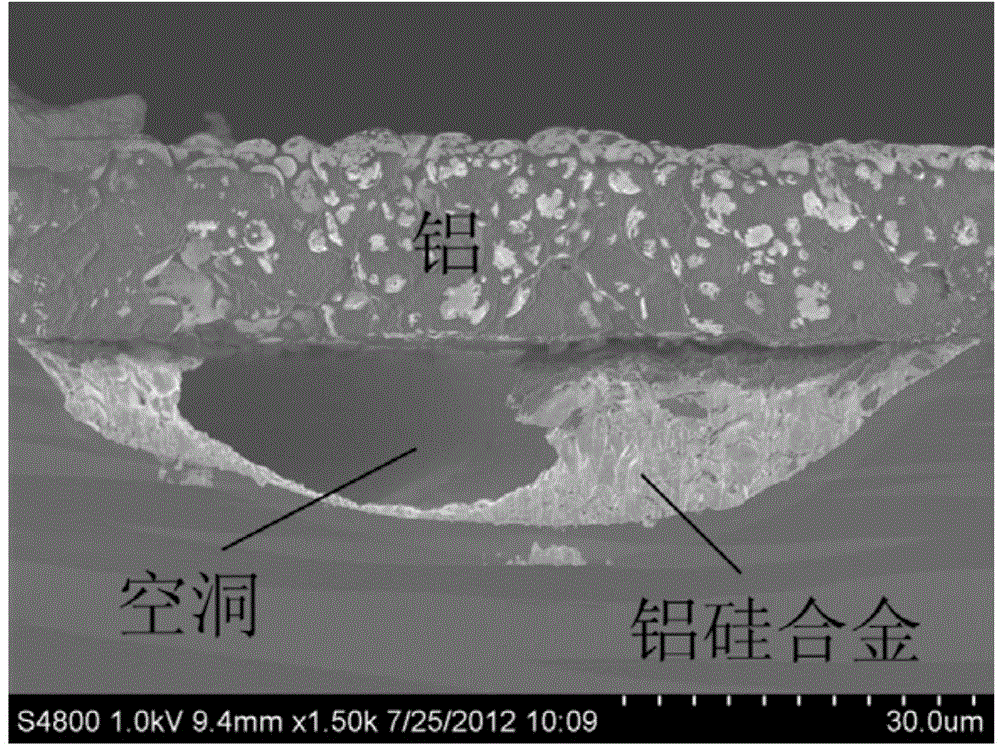

A technology of solar cells and sintering methods, applied in the field of solar cells, can solve problems such as the formation of voids in the area of silicon-aluminum alloys, and achieve the effects of reducing the proportion of aluminum-silicon voids, being easy to implement, and the method is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A PERC solar cell, the preparation method mainly includes the following steps: texturing, diffusion, back polishing, etching and impurity removal glass, depositing aluminum oxide or silicon oxide film on the back, depositing a silicon nitride protective film, and depositing silicon nitride on the front The solar cell can be obtained by antireflection layer, partial opening on the back, screen printing the metal paste on the front and back, and sintering.

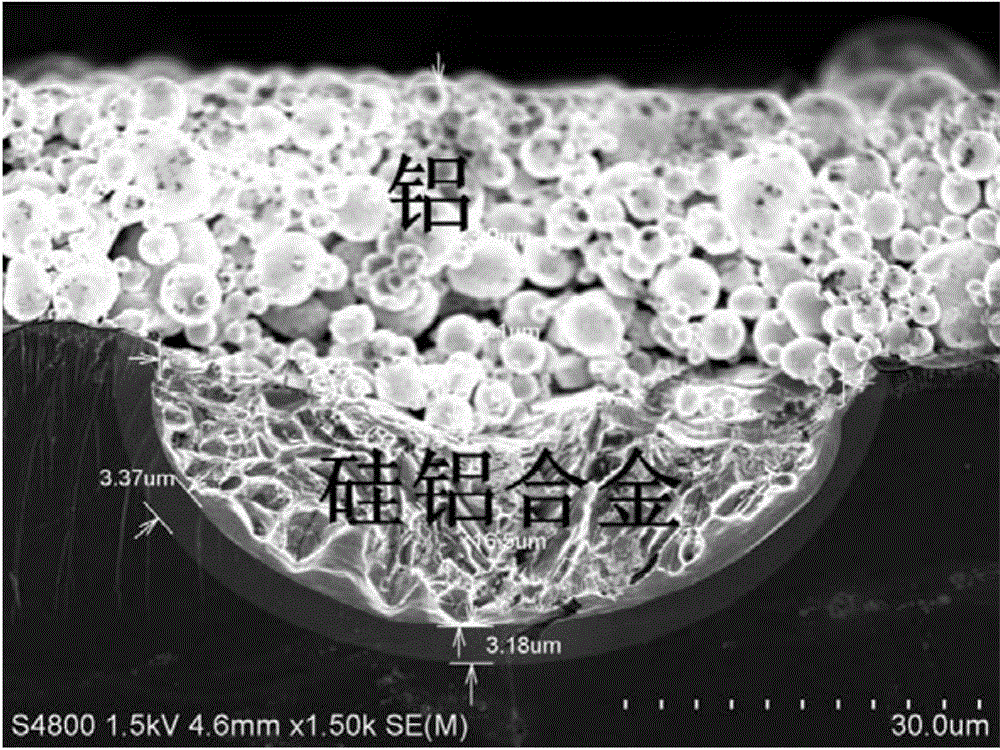

[0027] Among them, screen printing front and back metal paste refers to printing metal electrodes (such as silver paste) and aluminum paste on the back, printing metal electrodes (such as silver paste) on the front and back, and then sintering. The sintering method is as follows: including heating and cooling Two steps, in which the heating step is generally divided into three stages: the first stage, from room temperature to about 300 ° C, its main function is to dry and drive the volatile organic compounds in the slu...

Embodiment 2

[0030] A PERC solar cell, its preparation method is the same as that of the first embodiment; its sintering method is also the same as that of the first embodiment. The difference is that in the sintering process, the heating steps are:

[0031] In the first stage, the heating rate during the process from room temperature to 300°C is 10°C / s;

[0032] In the second stage, the heating rate from about 300°C to about 670°C is 60°C / s;

[0033] In the third stage, the heating rate from about 670°C to the highest temperature (about 800°C) is 10°C / s.

[0034] Experiments have proved that the local contact area between aluminum and silicon should be the silicon aluminum alloy area without forming voids.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com