Upper part seal structure of aluminium electrolytic tank

A technology of sealing structure and aluminum electrolytic cell, which is applied in the field of upper sealing structure of aluminum electrolytic cell, can solve problems such as increase of horizontal current in aluminum liquid layer, decrease of current efficiency, thickening of surrounding furnace side, etc., so as to improve work efficiency and heat preservation performance, the effect of reducing the amount of diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

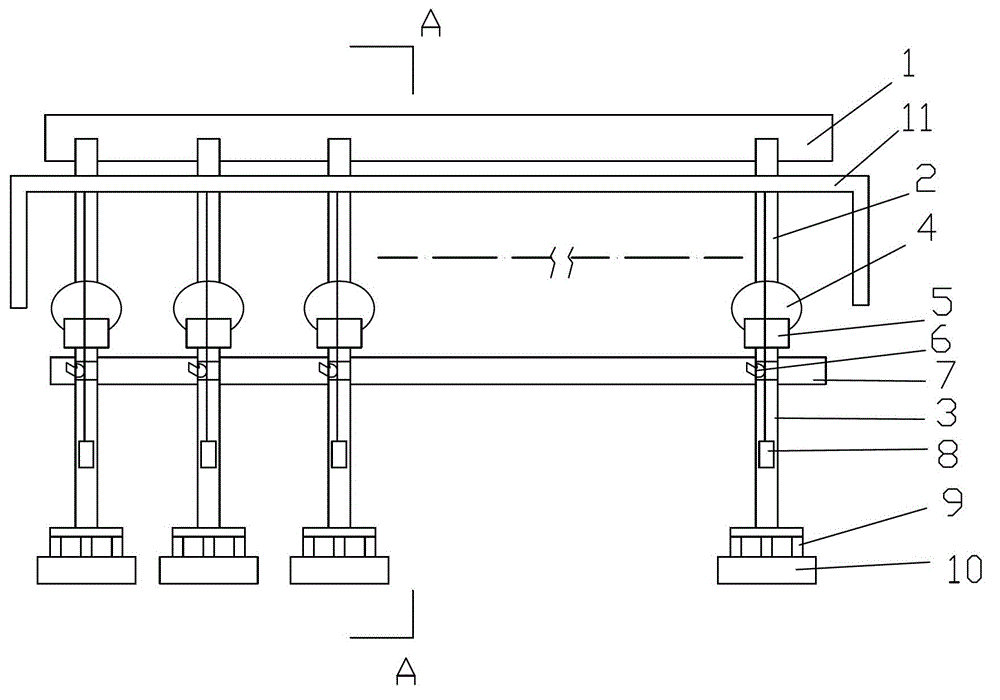

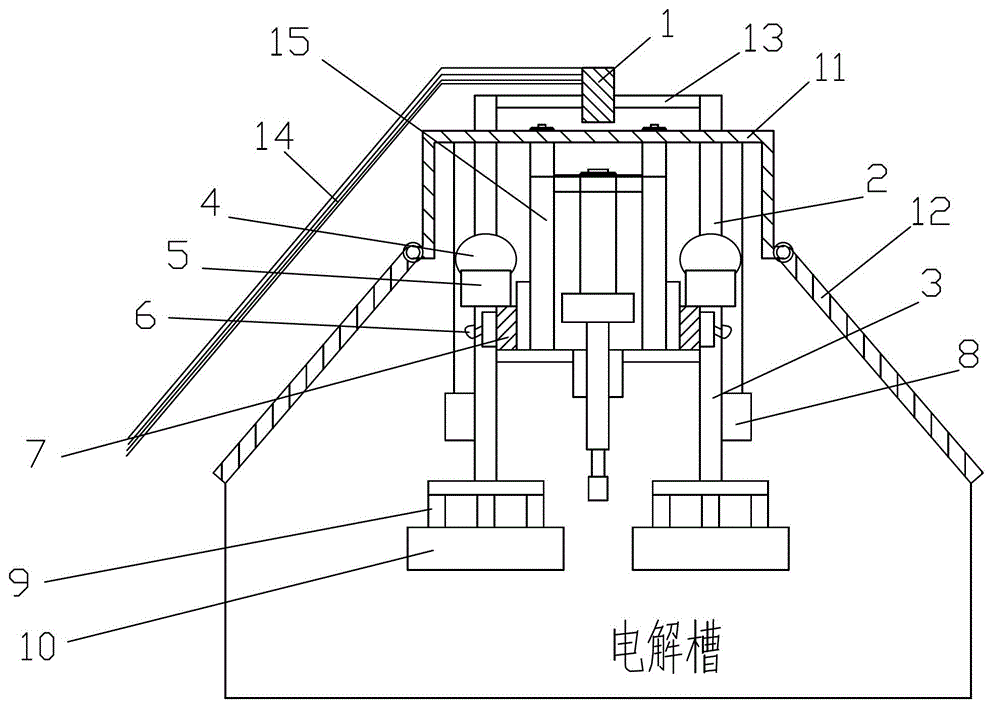

[0021] Below in conjunction with accompanying drawing, the specific implementation manner of this patent is described in further detail.

[0022] Such as Figures 1 to 2 As shown, an upper sealing structure of an aluminum electrolytic cell, the outer cover 11 is a steel outer cover, the outer cover 11 is installed on the door-shaped column 15 of the load-bearing truss of the electrolytic cell and is arranged on the upper side of the electrolytic cell, and the two sides of the outer cover 11 are covered by the tank The plate 12 is closed, and the upper side of the tank cover plate 12 is hinged on the outer cover 11, and the tank cover plate 12 is controlled to rotate by the rotating device. When the tank cover plate 12 is closed, the lower side of the tank cover plate 12 contacts and seals with the upper part of the edge of the electrolytic cell. When the tank cover plate 12 is opened, it can be automatically opened by a rotating device, so as to facilitate the replacement of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com