Tool sharpening device

A sharpening and cutting tool technology, which is applied in the direction of grinding/polishing safety devices, manufacturing tools, grinding/polishing equipment, etc., can solve the problems that affect the health of workers, cannot be discharged in time, corrode the grinding wheel cover, etc., and achieve novel structure, Good effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

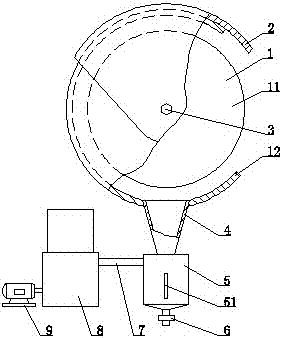

[0007] See figure 1 , The present invention includes a grinder 1, the grinder 1 includes a grinding wheel 11 and a fixed cover 12, and also includes an adjustment cover 2, a screw 3, a cone 4, a slag box 5, a manual valve 6, a wind pipe 7, a receiving The dust collector 8 and the motor 9, the panel of the slag box 5 is provided with an inspection port 51, the adjusting cover 2 is mounted on the outer surface of the fixed cover 12 by screws 3, and the cone 4 is mounted on the fixed At the lower part of the cover plate 12, the slag collecting box 5 is communicated with the cone 4, the dust collector 8 is communicated with the slag collecting box 5 through an air pipe 7, and the motor 9 is connected with the dust collector 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com