Closed mixing plant

A mixing station and closed technology, which is applied in mixing plants, clay preparation devices, mixing operation control devices, etc., can solve problems such as endangering the health of workers, affecting the air quality of mixing stations, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

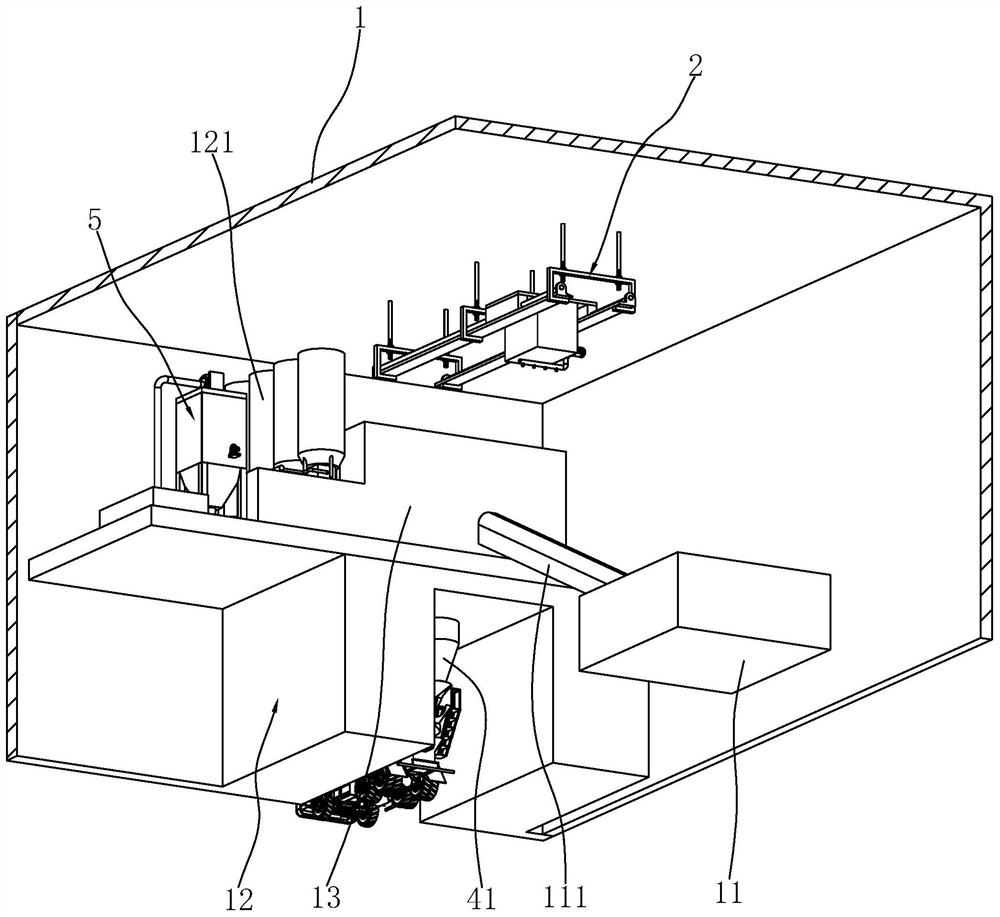

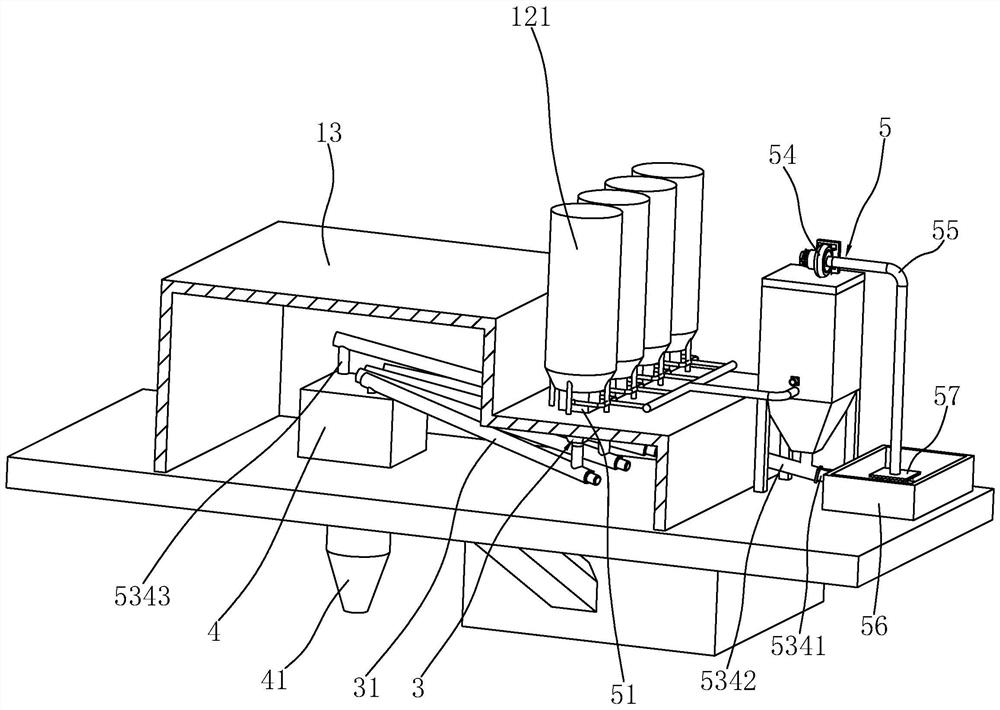

[0039] refer to figure 2 and image 3 , is a kind of closed mixing plant disclosed by the present invention, including a room body 1, and the room body 1 includes a raw material area 11 and a mixing area 12; the raw material area 11 is used to place sand aggregates for mixing, and the upper side of the raw material area 11 A dedusting assembly 2 for dedusting the raw material area 11 is provided; a mixing building 13 is set in the mixing area 12, and four silos 121 are erected on the top of the mixing building 13 through installation brackets, and the silos 121 are used to store cement and pulverized coal powdery materials such as ash and additives; the underside of the silo 121 is provided with a powder scale 3 , and the powder scale 3 is arranged at the bottom of the silo 121 and installed on the mixing building 13 . The lower side of the powder scale 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com