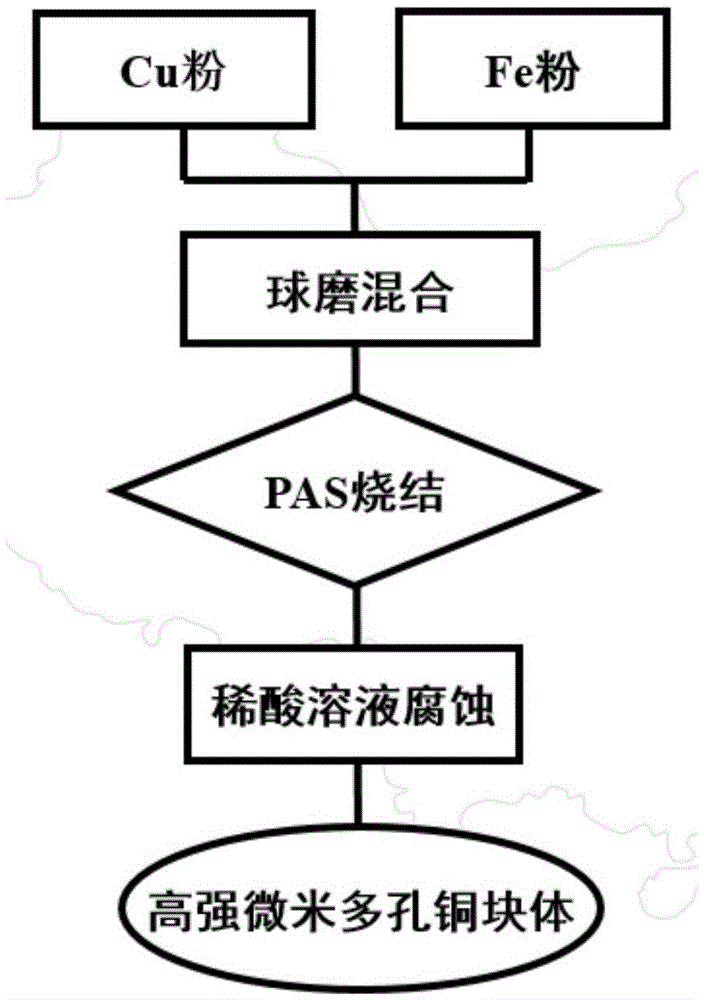

Method for preparing micrometer porous metal copper blocks by dealloying of copper-ferrum alloy

A technology of dealloying, copper-iron alloy, applied in the field of porous metal materials, can solve the problems of low strength, difficult to block nanoporous metal copper, and low specific surface area of large-pore porous metal, and achieve low cost and positive engineering application value. , the effect of controllable porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

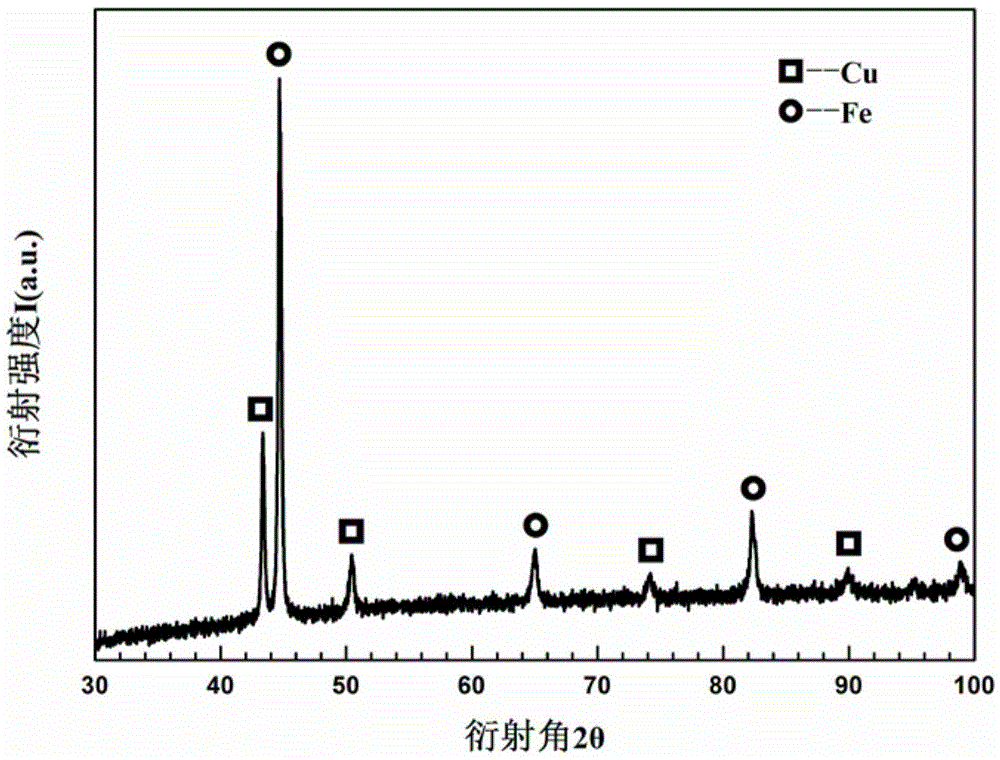

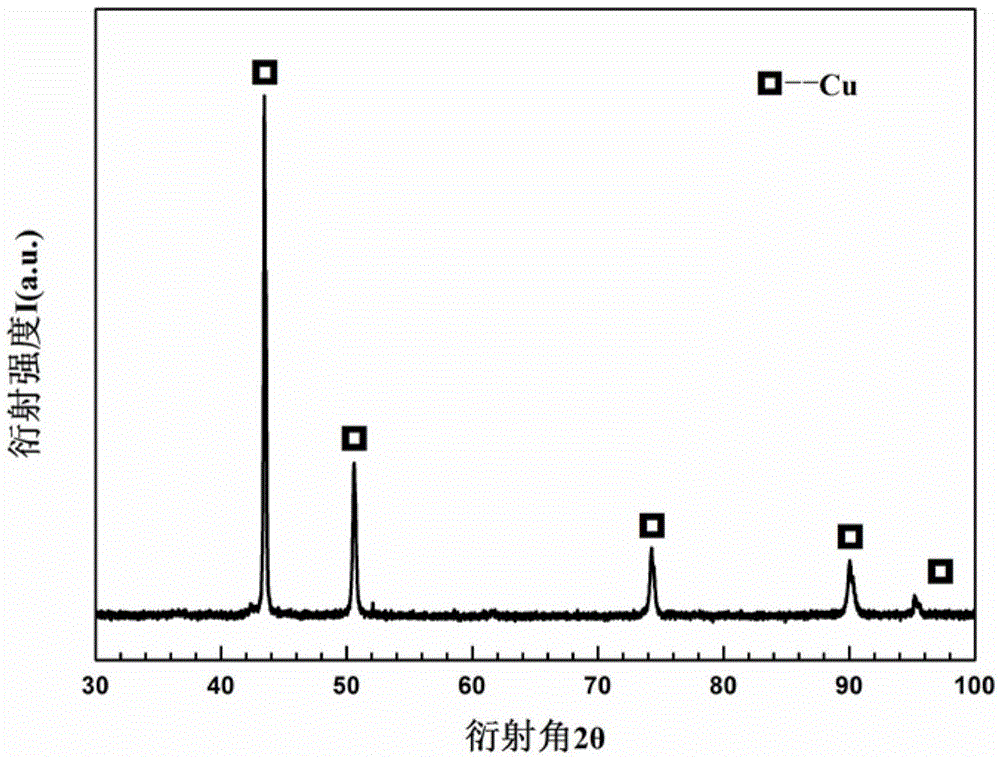

Embodiment 1

[0037] The 1 μm copper powder with a purity of ≥99.0% and the 6 μm iron powder with a purity of 99.5% are weighed at an atomic ratio of 25:75, and the element powder is ball milled on a light low-energy ball mill at a speed of 240 rpm for 24 hours to make the composite powder Mix evenly; the composite powder is sintered in PAS (plasma activated sintering) under low pressure vacuum hot pressing, the vacuum degree is ≤10Pa, the sintering temperature is 800°C, the heating rate is 50°C / min, the holding time is 5min, and the sintering pressure is 50MPa. Cu-Fe alloy bulk; the preparation concentration is 5wt% H 2 SO 4 solution, put the clean Cu-Fe alloy into H 2 SO 4 solution, and the container was placed in a water bath and heated to 90°C to keep it warm. Record time. Observe the reaction bubbles of the active metal iron and the sulfuric acid solution in the container, and find that there are no more bubbles in the solution after 15 hours, then take out the metal block and wash...

Embodiment 2

[0039] The 1 μm copper powder with a purity of ≥99.0% and the 6 μm iron powder with a purity of 99.5% are weighed at an atomic ratio of 25:75, and the element powder is ball milled on a light low-energy ball mill at a speed of 240 rpm for 24 hours to make the composite powder Mix evenly; the composite powder is sintered in PAS (plasma activated sintering) under low pressure vacuum hot pressing, the vacuum degree is ≤10Pa, the sintering temperature is 600°C, the heating rate is 50°C / min, the holding time is 5min, and the sintering pressure is 50MPa. Cu-Fe alloy bulk; the preparation concentration is 5wt% H 2 SO 4 solution, put the clean Cu-Fe alloy into H 2 SO 4 solution, and the container was placed in a water bath and heated to 90°C to keep it warm. Record time. Observe the reaction bubbles of the active metal iron and the sulfuric acid solution in the container, and find that there are no more bubbles in the solution after 15 hours, then take out the metal block and wash...

Embodiment 3

[0041] The 1 μm copper powder with a purity of ≥99.0% and the 6 μm iron powder with a purity of 99.5% are weighed at an atomic ratio of 25:75, and the element powder is ball milled on a light low-energy ball mill at a speed of 240 rpm for 24 hours to make the composite powder Mix evenly; the composite powder is sintered in PAS (plasma activated sintering) under low pressure vacuum hot pressing, the vacuum degree is ≤10Pa, the sintering temperature is 1000°C, the heating rate is 50°C / min, the holding time is 10min, and the sintering pressure is 50MPa, and the obtained Cu-Fe alloy bulk; the preparation concentration is 5wt% H 2 SO 4 solution, put the clean Cu-Fe alloy into H 2 SO 4 solution, and the container was placed in a water bath and heated to 90°C to keep it warm. Record time. Observe the reaction bubbles of active metal iron and sulfuric acid solution in the container, and find that there are no more bubbles in the solution after 24 hours, then take out the metal blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size distribution | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com