Patents

Literature

97 results about "Plasma activated sintering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

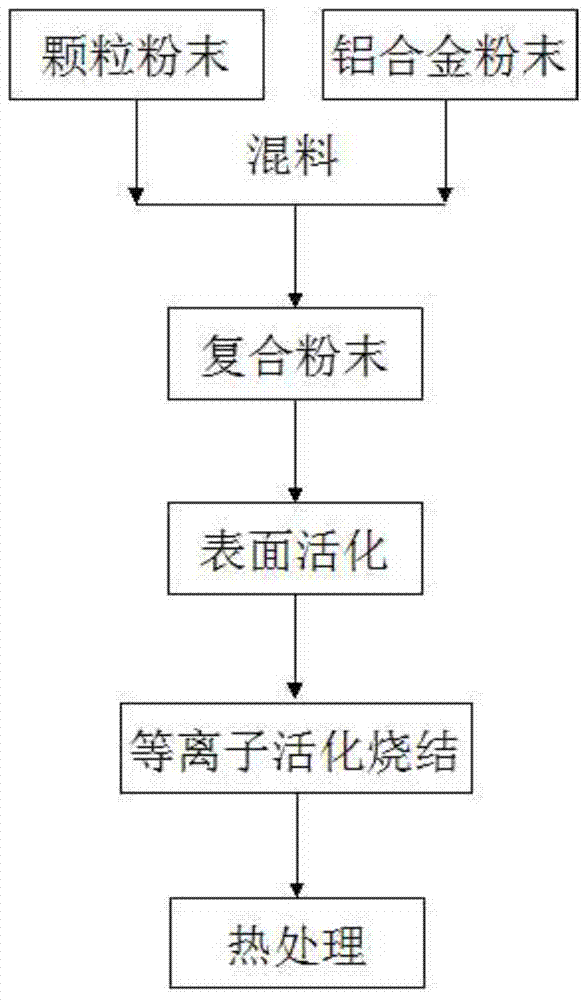

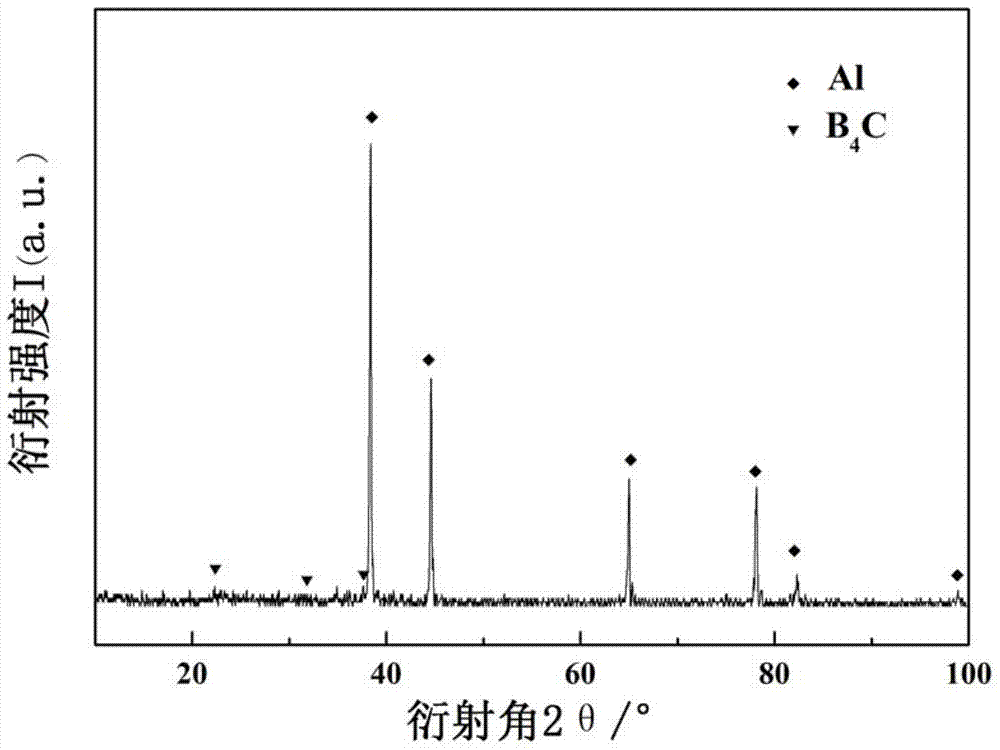

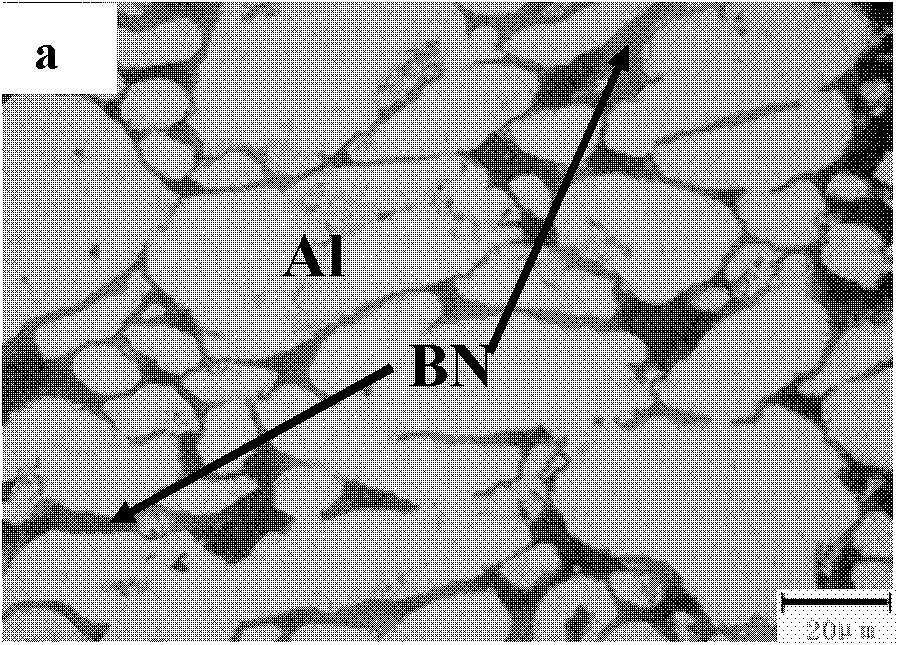

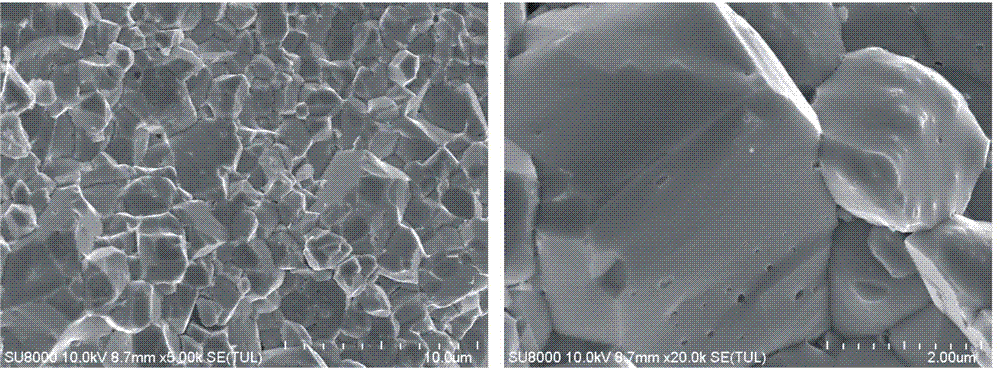

Preparation method of boron carbide particle enhanced aluminum-based composite material

The invention relates to the technical fields of aluminum-based composite materials and preparation thereof, in particular to a boron carbide particle enhanced aluminum-based composite material and a preparation method thereof. According to the composite material, aluminum alloy is used as a matrix; the mass percentage of boron carbide used as a wild phase is 2.5 to 30%; the boron carbide particles are distributed in the matrix uniformly. The specific preparation method comprises the following steps: mixing boron carbide powder and aluminum alloy powder; performing surface activation, plasma activated sintering and heat treatment to prepare a sintering test sample close to full density. The aluminum-based composite material prepared by the method has low sintering temperature, high density, small crystal particles and an excellent mechanical property, is simple to operate and high in controllability, and is a lightweight high-performance aluminum-based composite material.

Owner:WUHAN UNIV OF TECH

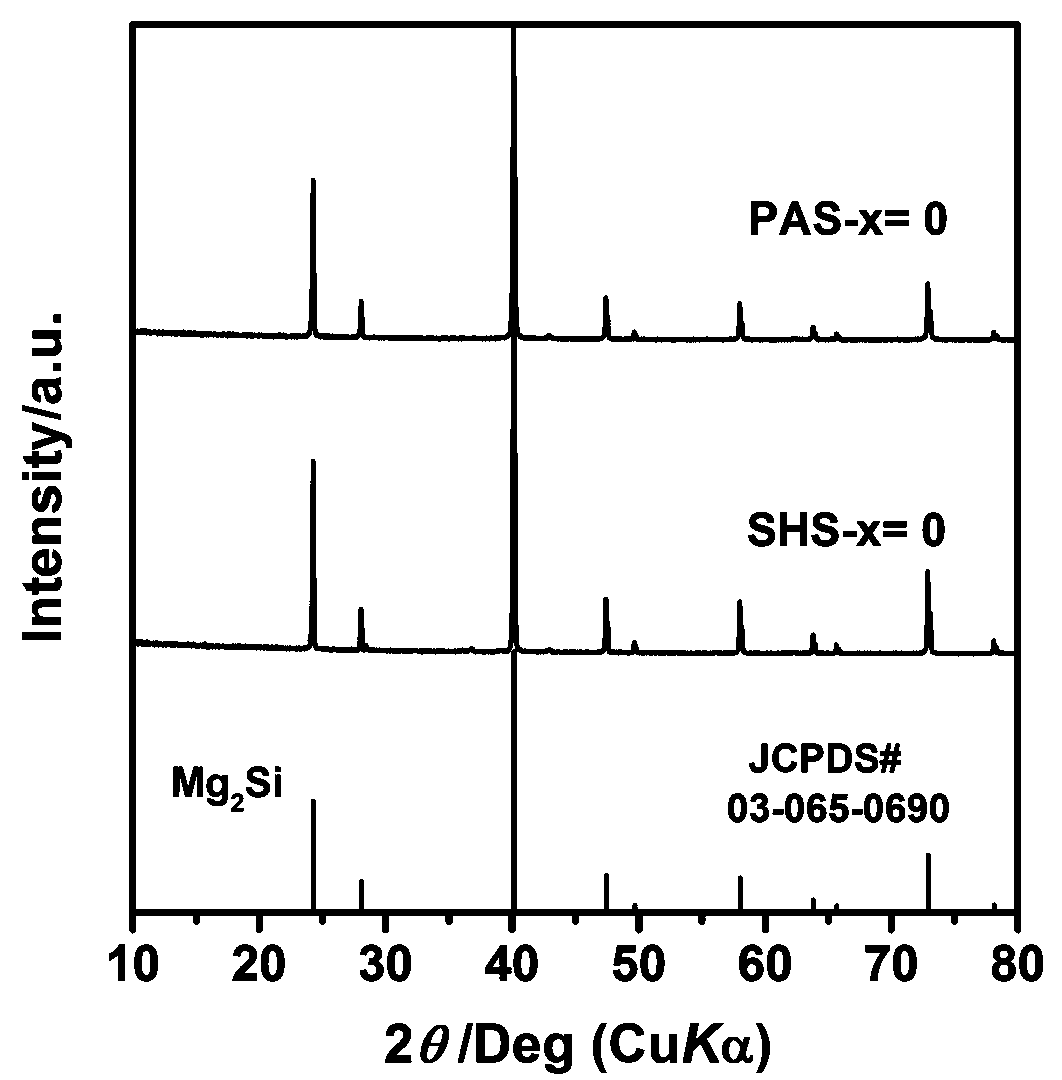

Method for quickly preparing high-performance Mg2Si-based thermoelectric material

ActiveCN103436723AQuick responseGood repeatabilityThermoelectric device junction materialsMetallurgyPlasma activated sintering

The invention relates to a method for quickly preparing a high-performance Mg2Si-based thermoelectric material. The method comprises the following steps: (1) weighing according to the stoichiometric proportion of all atoms in Mg2 (1+0.02) Si (1-x) Sbx (0<=x<=0.025), then grinding and uniformly mixing the atoms, and pressing the uniformly mixed powder into a block; (2) subjecting the block obtained in the step (1) to the self-propagating reaction, and then naturally cooling to obtain a single-phase Mg2 (1+0.02) Si (1-x) Sbx compound; (3) grinding the obtained product into powder, and performing discharge plasma activated sintering to obtain the high-performance Mg2Si-based thermoelectric material. The method provided by the invention has the advantages of quickness in reaction, simple process, high efficiency, energy saving, good repeatability and the like, the whole preparation process can be completed within 0.5 h, and the thermoelectric figure of merit ZT of the obtained block can reach 0.73 at 875K.

Owner:WUHAN UNIV OF TECH

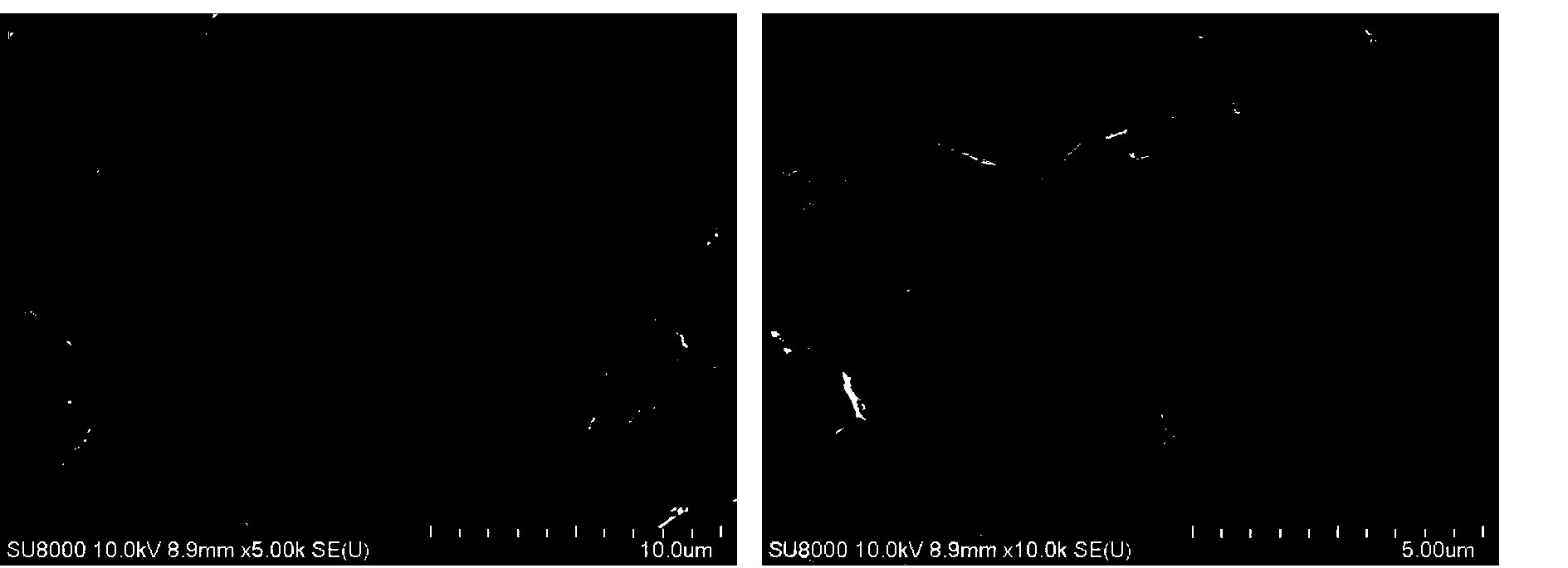

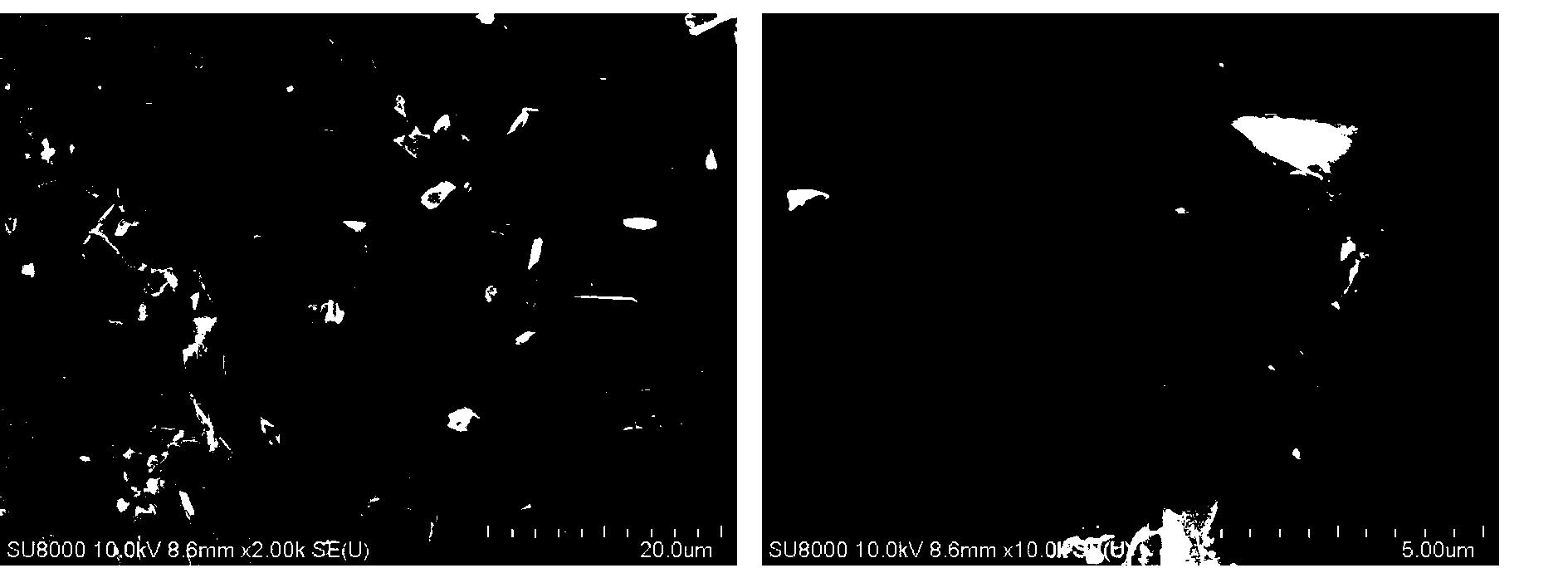

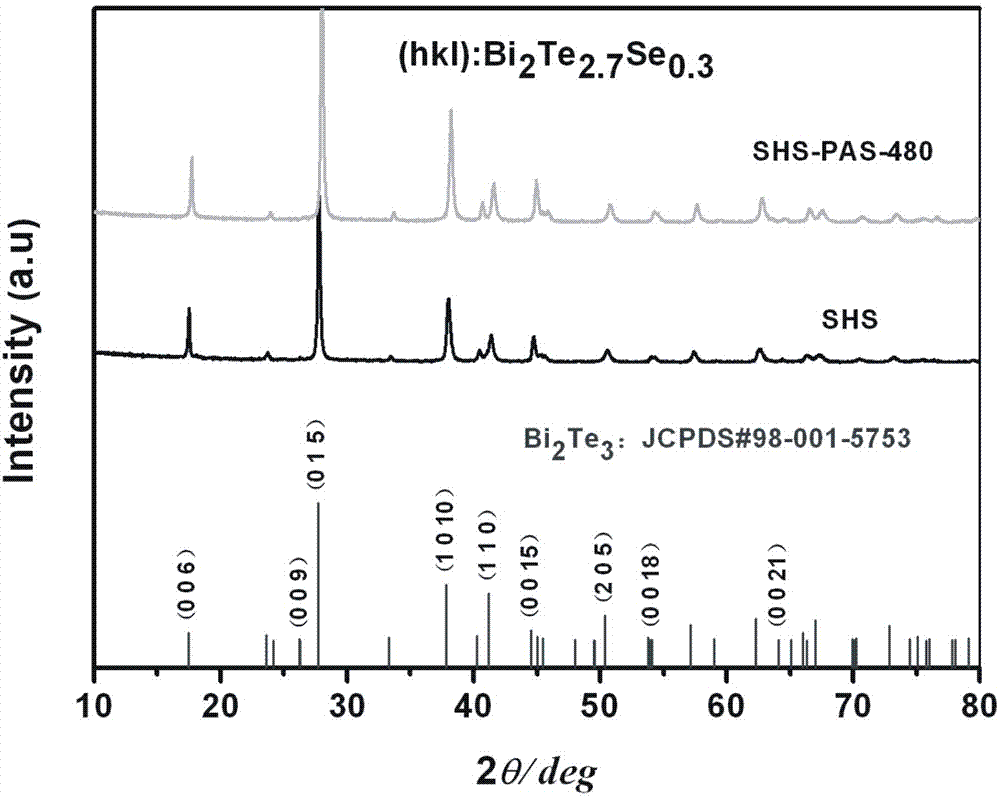

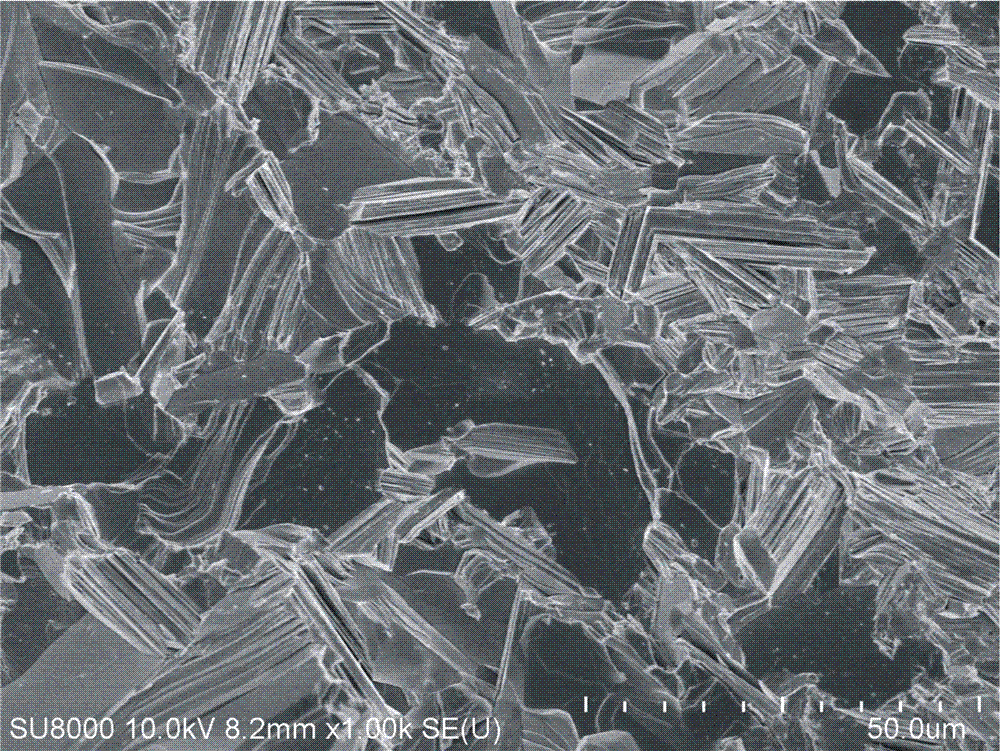

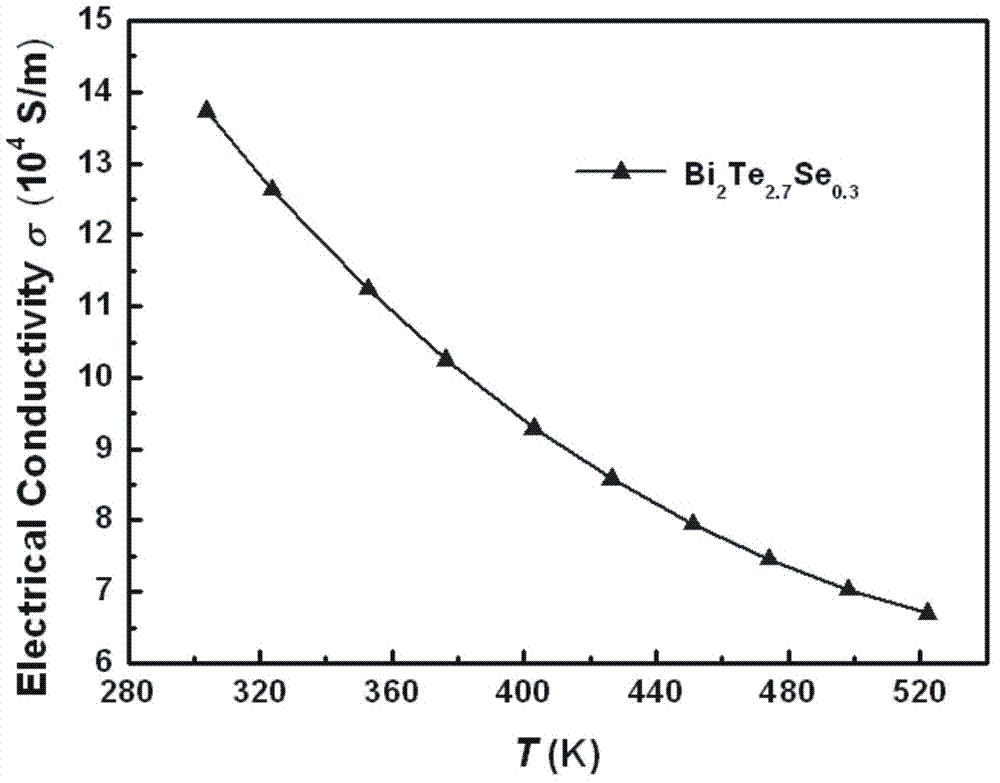

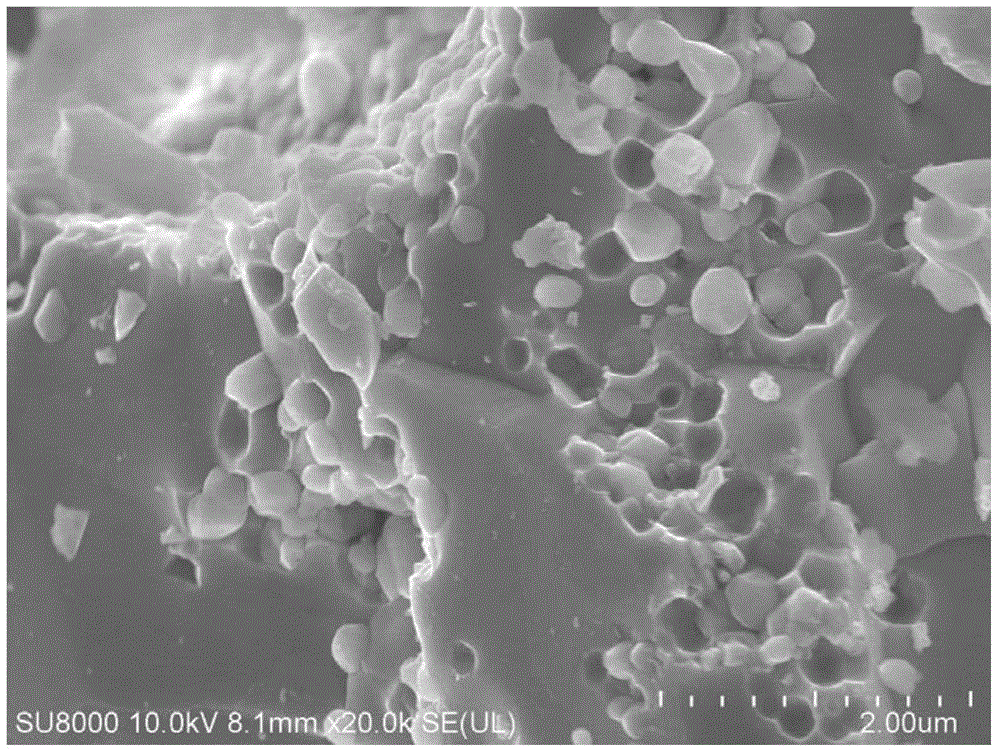

Method for fast manufacturing n-type bismuth telluride based high-performance thermoelectric materials

ActiveCN103928604AShort preparation timeSimple processThermoelectric device manufacture/treatmentThermoelectric device junction materialsMetallurgyBismuth telluride

The invention provides a method for fast manufacturing n-type bismuth telluride based high-performance thermoelectric materials. The method specifically comprises the steps that 1), Bi powder, Te powder and Se powder are weighed according to the stoichiometric ratio of all elements in Bi2Te3-xSex, 0=<x<=3, and the Bi powder, the Te powder and the Se powder are evenly mixed and pressed to be blocks; 2), a self-propagating reaction is generated on the blocks in the step 1), cooling is carried out after the reaction is completed, and a single-phase Bi2Te3-xSex compound is obtained; 3), the single-phase Bi2Te3-xSex compound obtained in the step 2) is ground to be powder, then plasma activation sintering is carried out, and the high-performance Bi2Te3-xSex thermoelectric materials are obtained. The technology with self-propagating combustion synthesis combined with plasma activation sintering is adopted, the n-type bismuth telluride block thermoelectric materials with the thermoelectric optimal value zT reaching 0.95 within 426 K are manufactured within 20 min, and the advantages of being short in manufacturing time, simple in technology, high in thermoelectric performance of the materials and the like are achieved.

Owner:武汉新赛尔科技有限公司

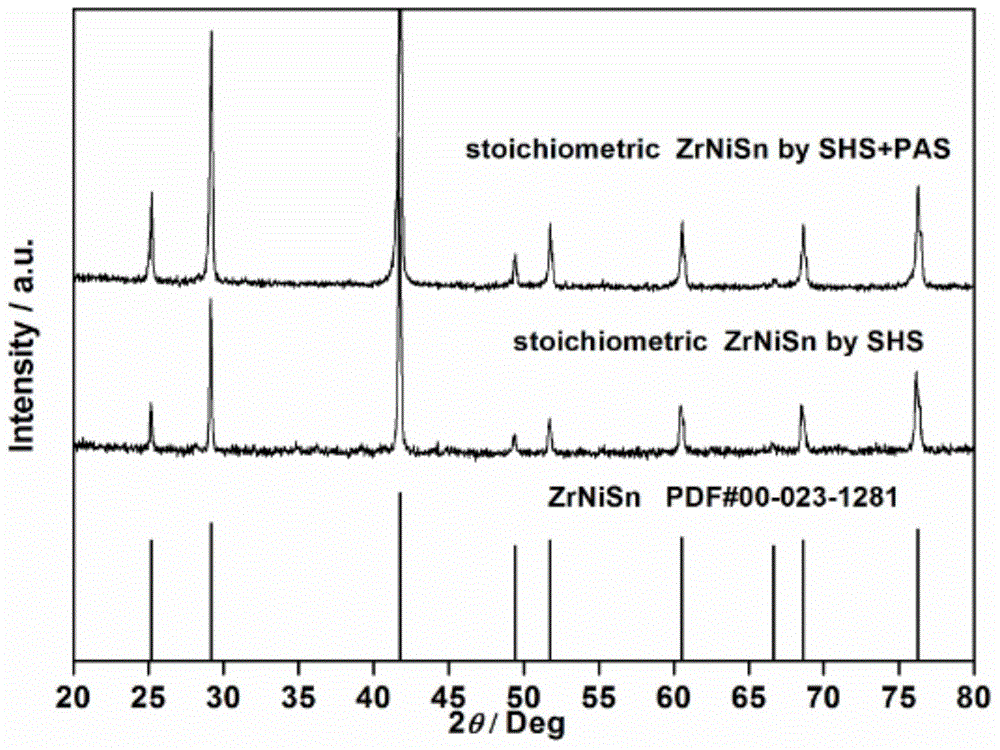

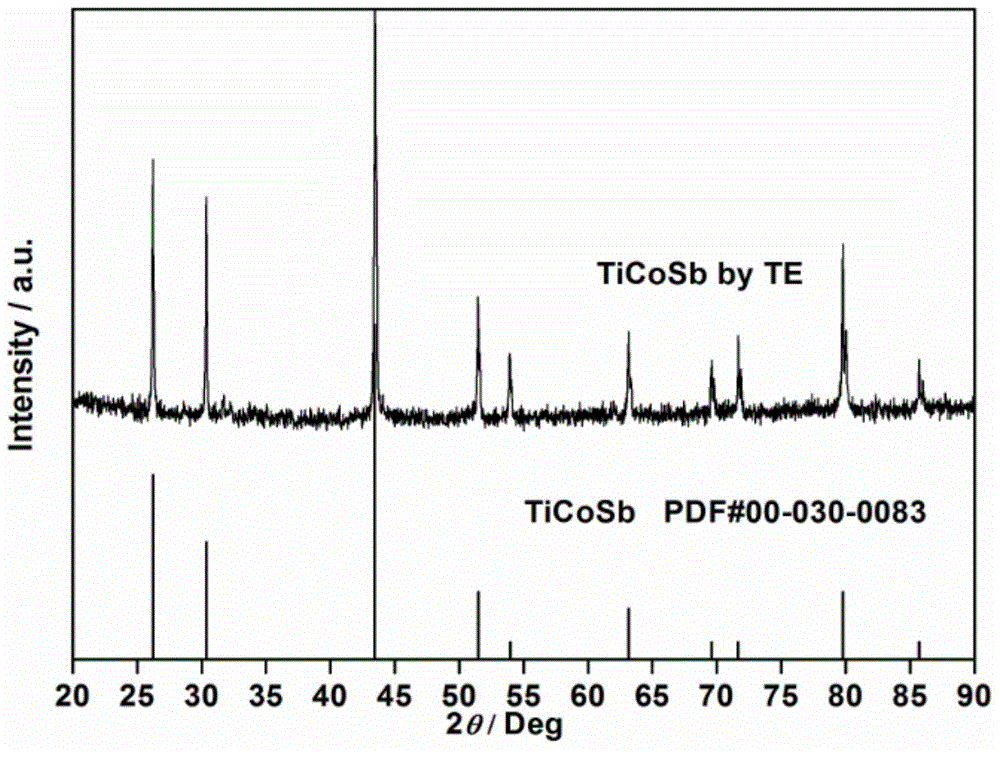

Method for preparing high-performance Half-Heusler block thermoelectric materials at ultrahigh speed and low cost

ActiveCN103934459AImprove performanceShort preparation timeThermoelectric device junction materialsThermoelectric materialsCombustion

The invention provides a method for preparing high-performance Half-Heusler block thermoelectric materials at ultrahigh speed and low cost. The method particularly includes the steps that firstly, according to the general formula ABX of Half-Heusler compounds, powder A, powder B and powder X are weighed at the chemical stoichiometric ratio of 1:1:1, used as raw materials and uniformly mixed, and then an reactant is acquired; secondly, the reactant generates a combustion synthesis reaction, and cooling or quenching is conducted after the reaction is finished; thirdly, a product acquired through the second step is ground into fine powder, then PAS is conducted, and then the high-performance Half-Heusler block thermoelectric materials are acquired. According to the method, by the combination of the combustion synthesis reaction with the PAS process, the high-performance Half-Heusler block thermoelectric materials can be prepared within 15 min, and the method has the advantages that preparation time is short, energy consumption is low, the process is simple, the requirement for equipment is low, repeatability is good, and the method is suitable for large-scale production.

Owner:WUHAN UNIV OF TECH

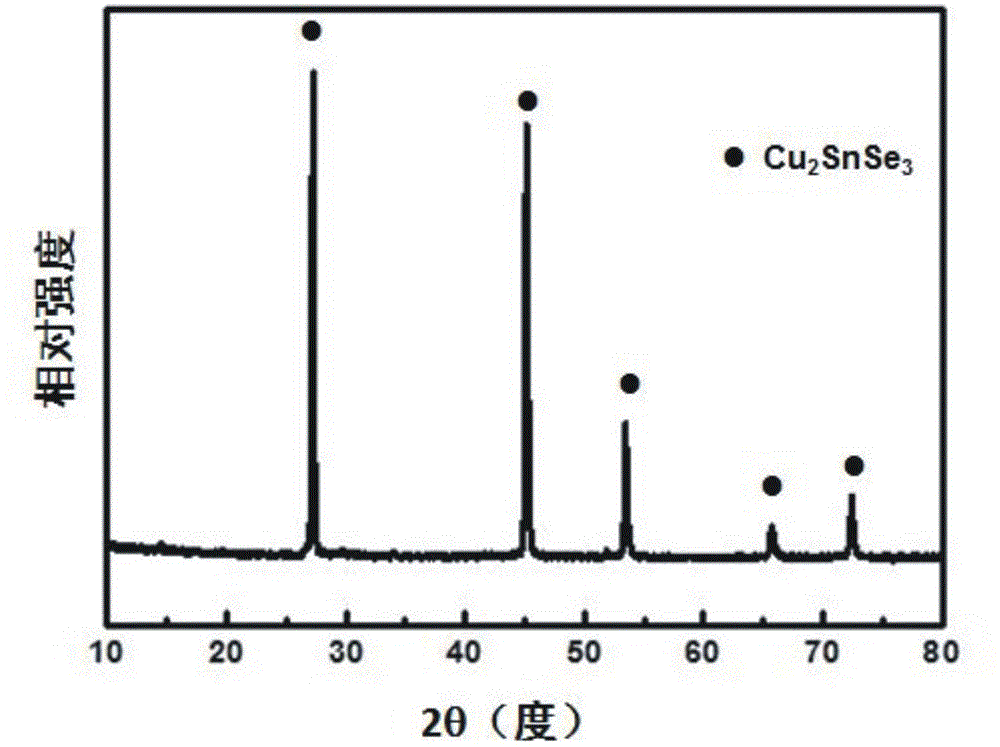

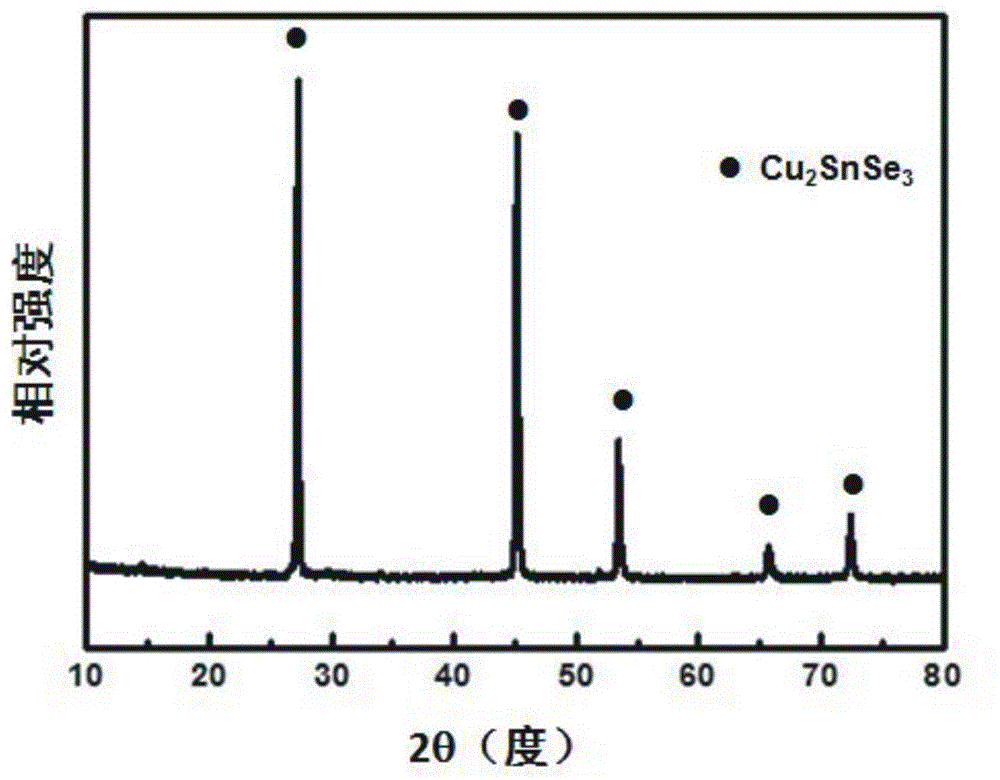

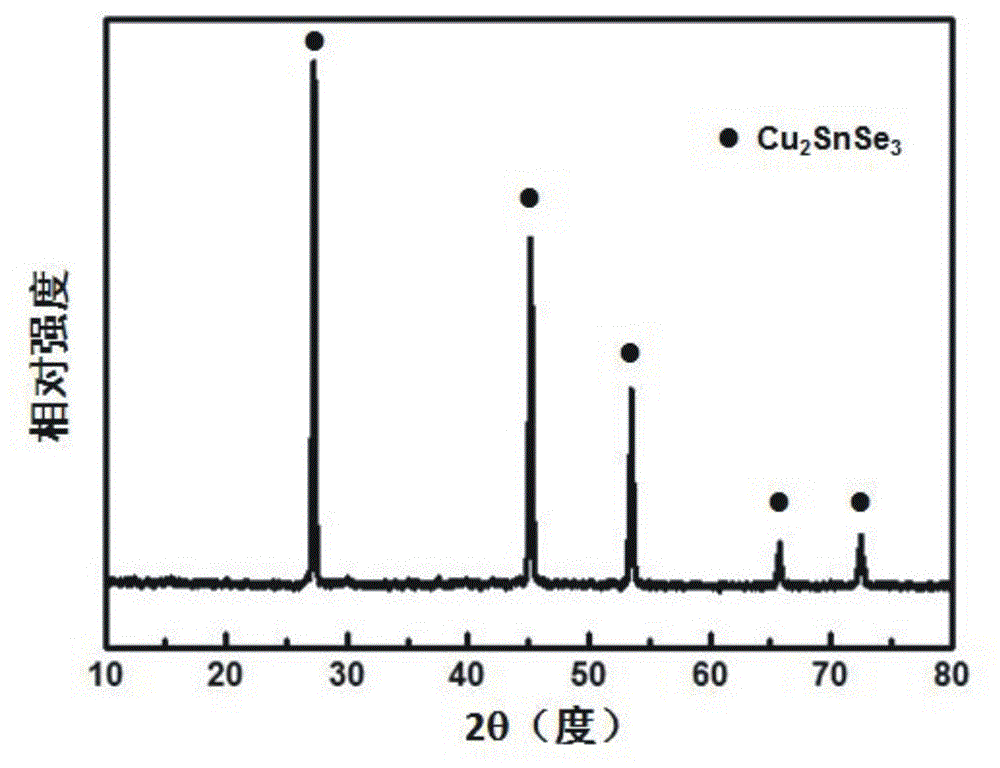

High-performance Cu2SnSe3 thermoelectric material and rapid preparing method thereof

ActiveCN103909262APrecise control of stoichiometric ratioQuick responseThermoelectric device manufacture/treatmentSelenium/tellurium compundsThermoelectric materialsMetallurgy

The invention relates to a high-performance Cu2SnSe3 thermoelectric material and a rapid preparing method thereof. The method includes the following steps that (1) Cu powders, Se powders and Sn powders are prepared as raw materials according to a stoichiometric ratio of 2.02: 3.03: 1, and then the Cu powders, the Se powders and the Sn powders are uniformly mixed to form a reactant; (2) self-propagating reaction of the reactant which is obtained in the step (1) is initiated, and naturally cooling is performed after the reaction is finished to obtain Cu2SnSe3 product; (3) the Cu2SnSe3 product obtained in the step (2) is ground to form fine powders, and then plasma activated sintering is performed to obtain the high-performance Cu2SnSe3 thermoelectric material. The high-performance Cu2SnSe3 thermoelectric material and the rapid preparing method thereof have the advantages that the reaction time is short, operation is simple and convenient, large devices are not required, noises are absent, and the performances of the product are 37.8% higher than those of products by traditional methods.

Owner:WUHAN UNIV OF TECH

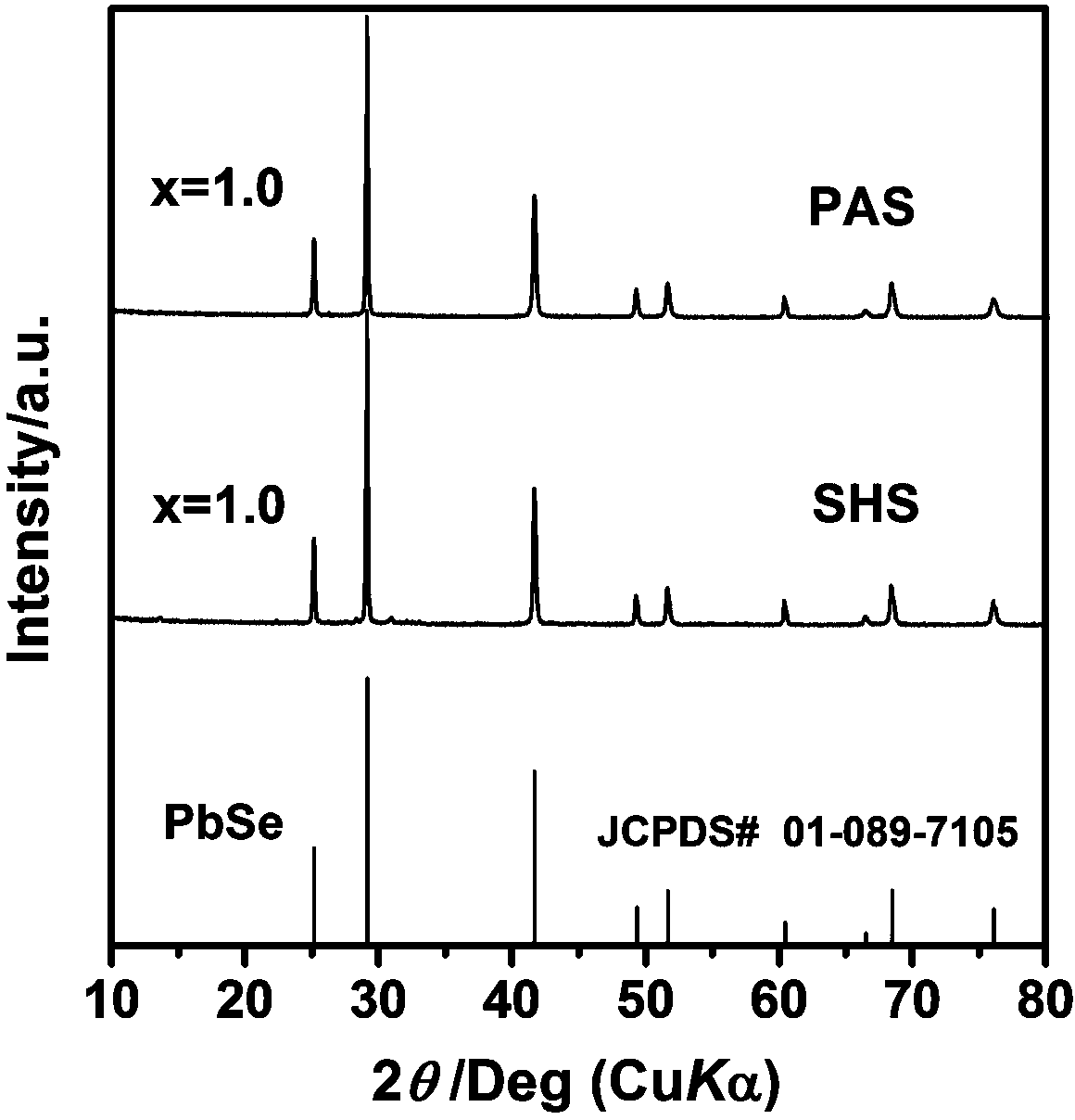

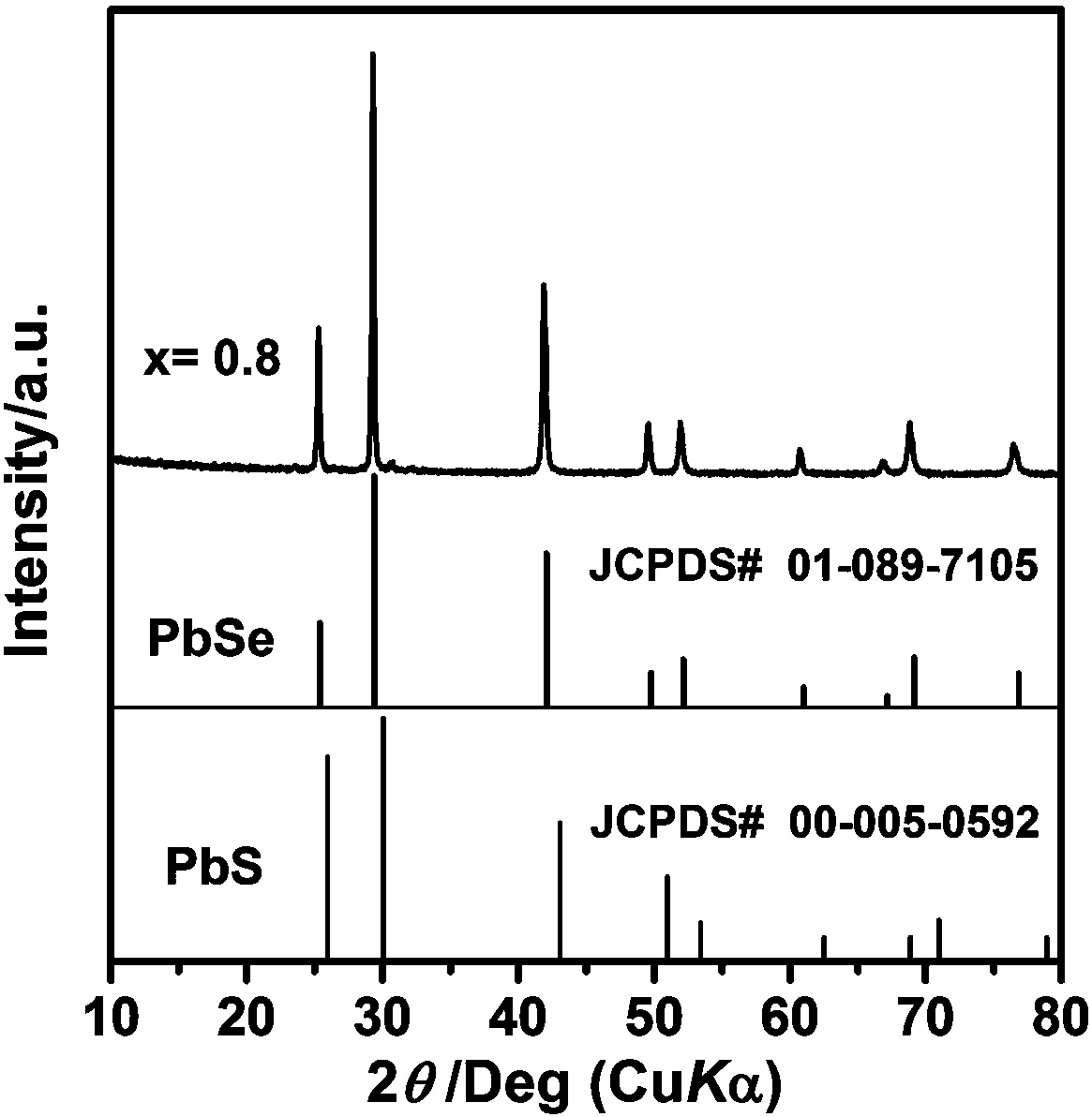

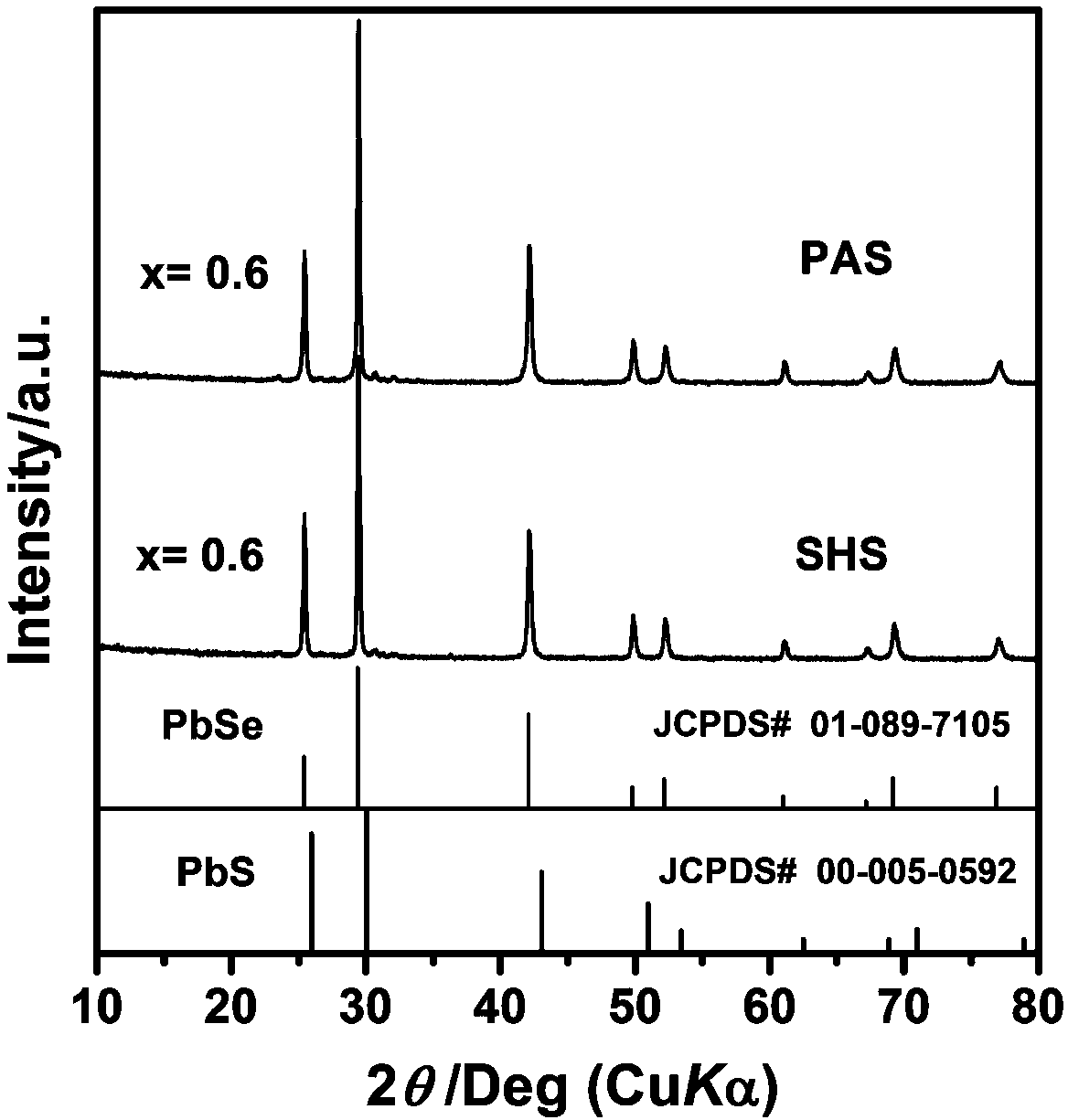

New method for quickly preparing high-performance PbS(1-x)Sex based thermoelectric material

The invention relates to a new method for quickly preparing a high-performance PbS(1-x)Sex based thermoelectric material. The new method comprises the following steps of: 1) weighing Pb powder, S powder and Se powder as raw materials according to the stoichiometric ratio of all the atoms in PbS(1-x+y)Se(x+z), wherein x is greater than or equal to 0 and less than 1.0, y is equal to 0.02 and z is equal to 0; and when x is equal to 1.0, y is equal to 0 and z is equal to 0.02; next, grinding the powdery raw materials and mixing evenly, and then pressing into blocks; 2) arousing the self-propagating reaction of the blocks obtained in the step 1), naturally cooling after the reaction is completed, thereby obtaining a single-phase PbS(1-x)Sex solid solution; 3) grinding the PbS(1-x)Sex solid solution into powder, performing discharge plasma activated sintering to obtain the high-performance PbS(1-x)Sex based thermoelectric material. The new method provided by the invention has the advantages of high reaction speed, simple process, high efficiency and energy conservation, good repeatability and the like; the whole preparation process can be completed in 0.5 hour.

Owner:WUHAN UNIV OF TECH

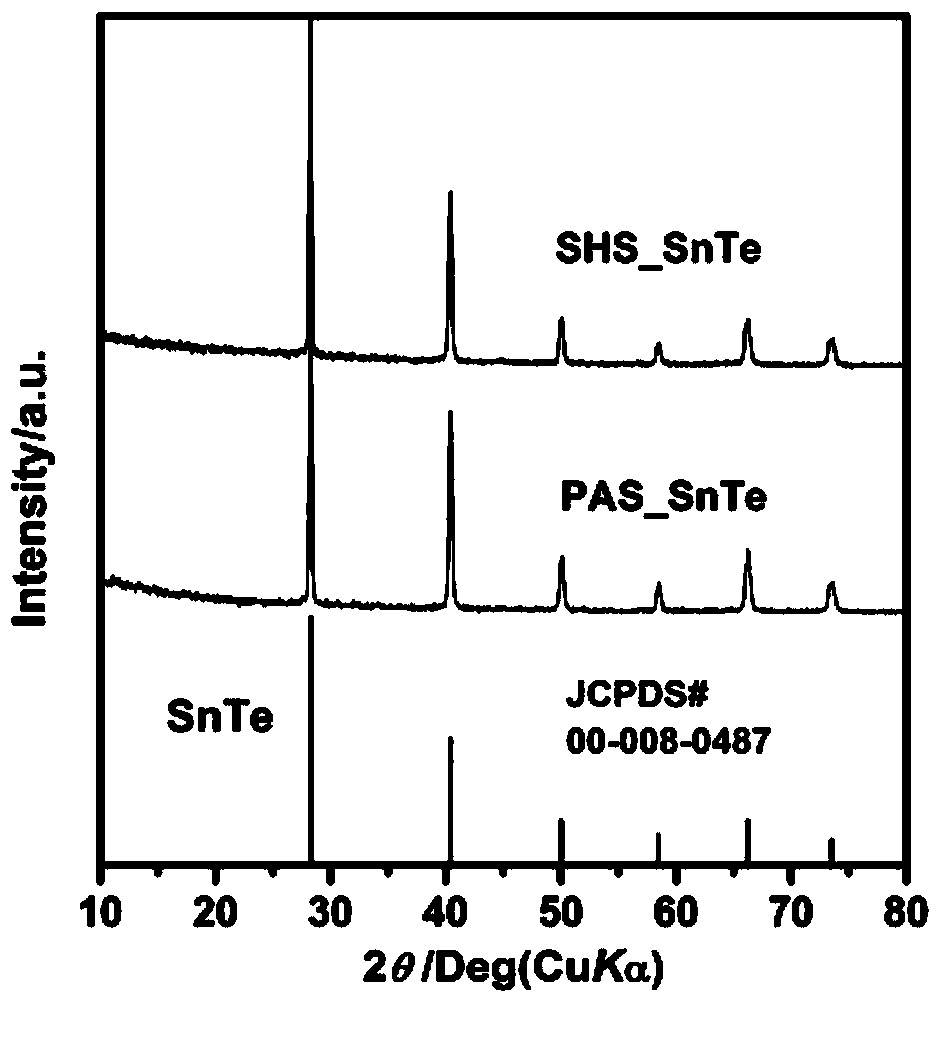

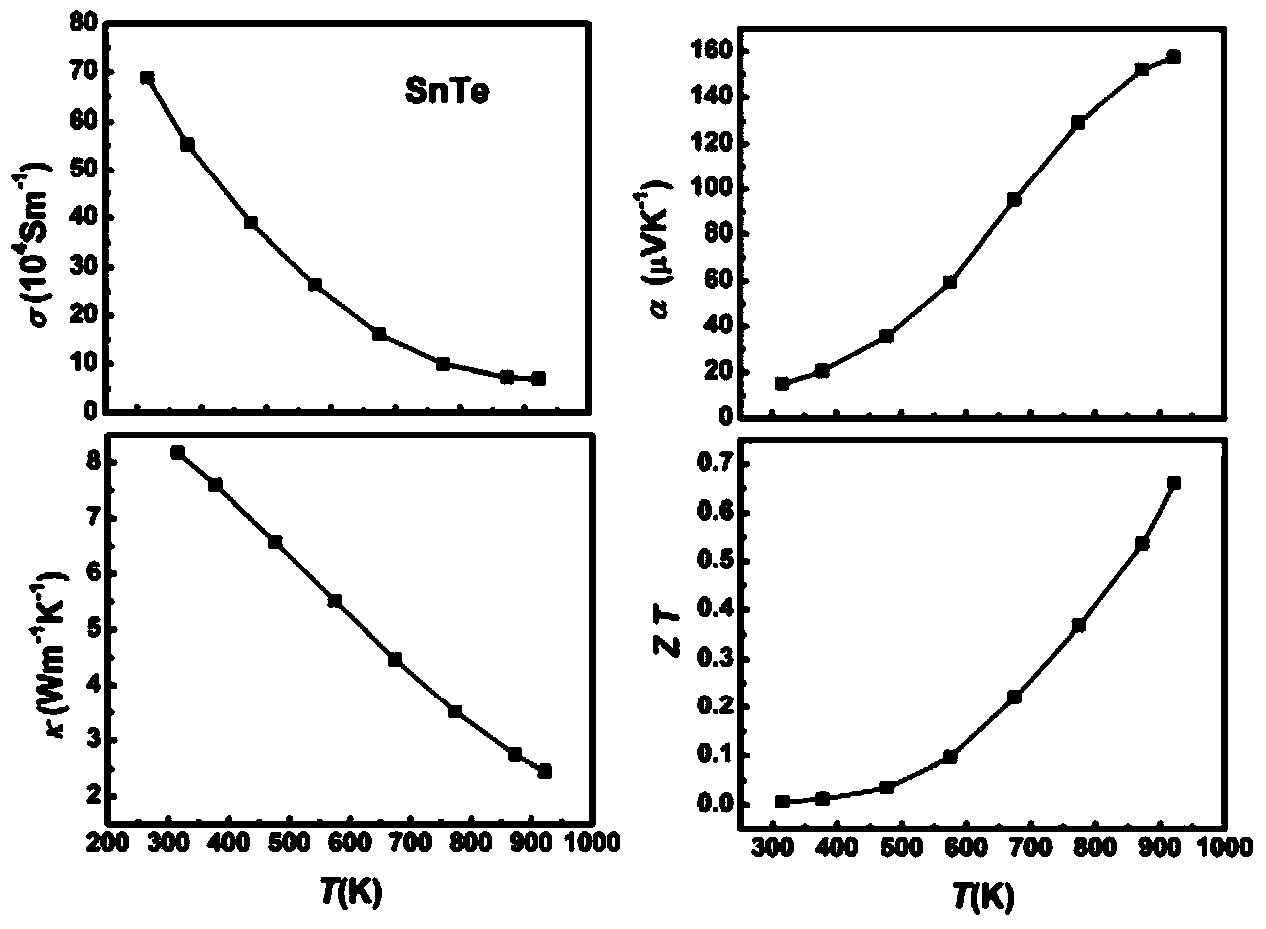

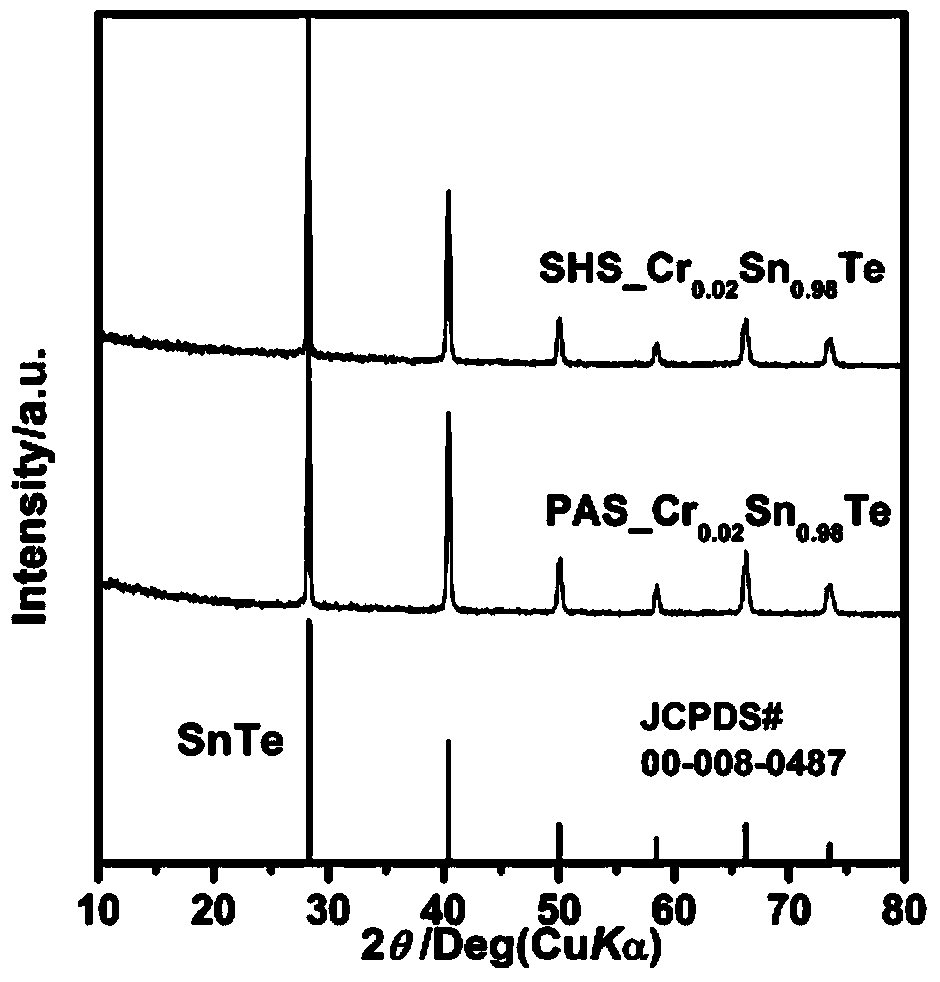

Ultrafast preparation method of high-performance SnTe based thermoelectric material

The invention relates to an ultrafast preparation method of a high-performance SnTe based thermoelectric material. The ultrafast preparation method comprises the following steps: weighing M powder, Sn powder and Te powder as raw materials according to the stoichiometric ratio of each element in the chemical formula MxSn(1-x)Te, wherein x is greater than or equal to 0 and less than or equal to 0.1, M refers to Cr, Co, Zn, Cd or In; next, grinding and evenly mixing the powder raw materials to obtain a reactant; 2) arousing a high-temperature self-propagating synthetic reaction of the reactant obtained in the step 1), and naturally cooling after the reaction is finished to obtain a single-phase SnTe based powdery thermoelectric material; 3) grinding the product obtained in the step 2) into powder, and performing spark plasma activated sintering to obtain the high-performance SnTe based bulk thermoelectric material. The ultrafast preparation method of the high-performance SnTe based thermoelectric material has the advantages of high reaction speed, simple process, efficient energy conservation, good repeatability and the like; the whole preparation process can be finished in 15 minutes, and the obtained thermoelectric figure ZT of merit of the obtained bulk material can be 1.01 at 910K.

Owner:WUHAN UNIV OF TECH

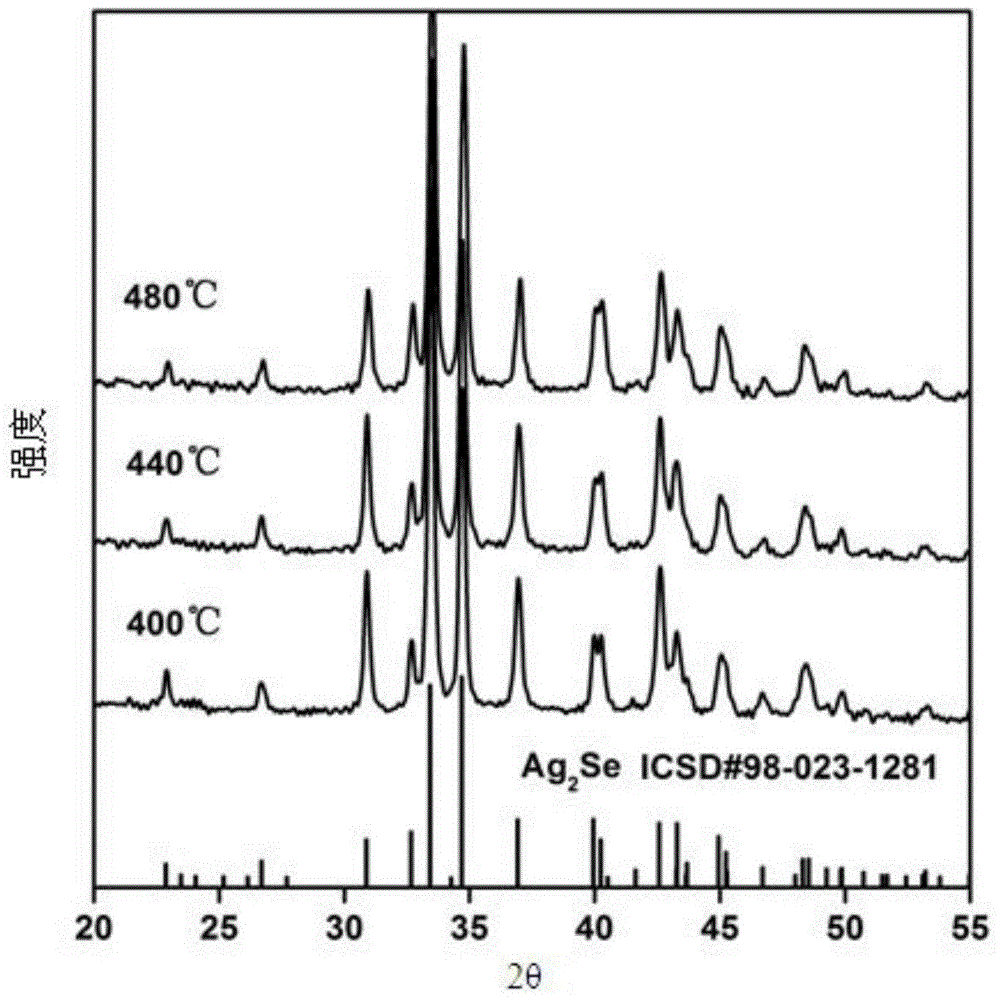

Method for quickly preparing Ag2Se block thermoelectric material through self-homogenization

ActiveCN104878234AAchieve densificationSignificant self-homogenizing effectThermoelectric device manufacture/treatmentThermoelectric materialsRoom temperature

The invention discloses a method for quickly preparing an Ag2Se block thermoelectric material through self-homogenization for the first time. Ag powder and Se powder are used as raw materials; firstly the raw materials are easily mixed, and then the mixed raw materials are directly subjected to plasma activated sintering (PAS), so compact Ag2Se block thermoelectric material can be prepared in several minutes. The process dissolved by the method is super easy, the preparation time is super short, the obtained product is uniform in component distribution, and an obvious effect of self-homogenization is shown. The prepared Ag2Se block thermoelectric material is superior in performance, the room temperature ZT exceeds 0.6, and a good foundation is laid for large-scale preparation and large-scale application of the Ag2Se compound.

Owner:WUHAN UNIV OF TECH

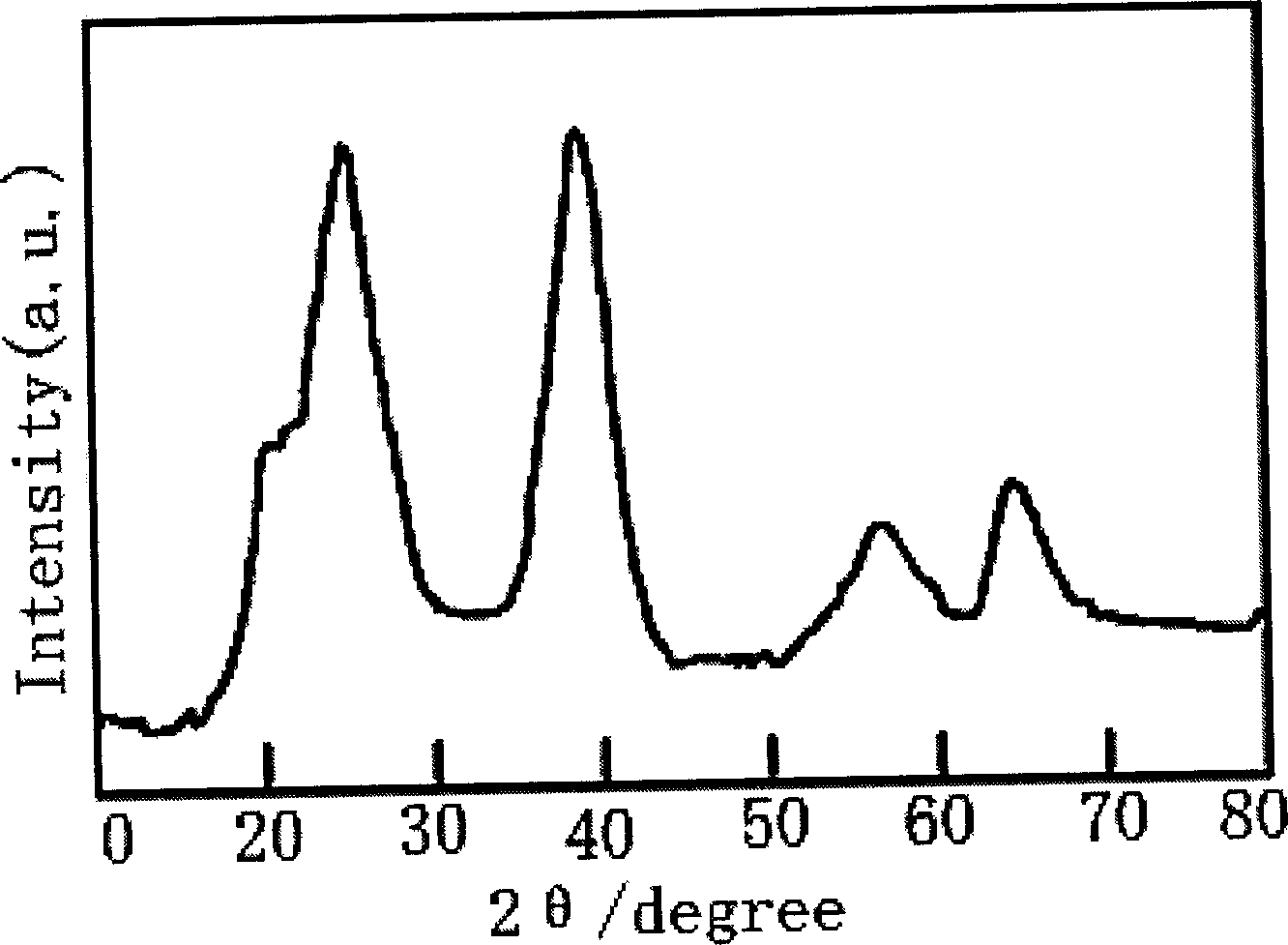

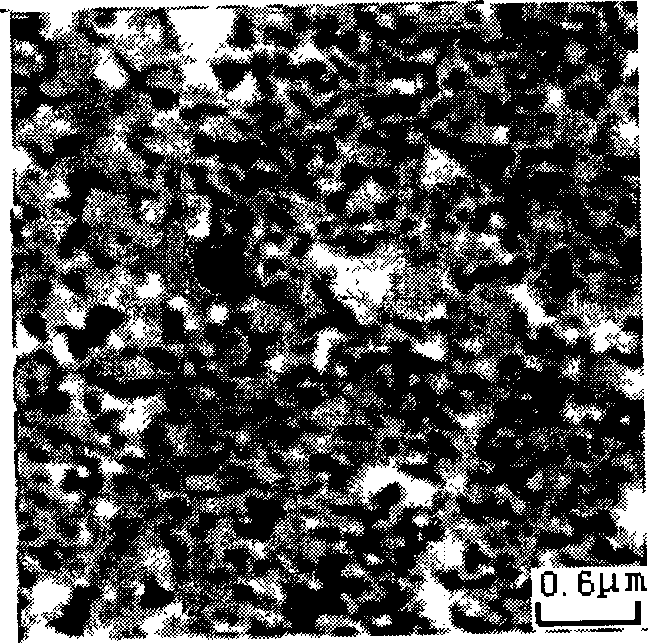

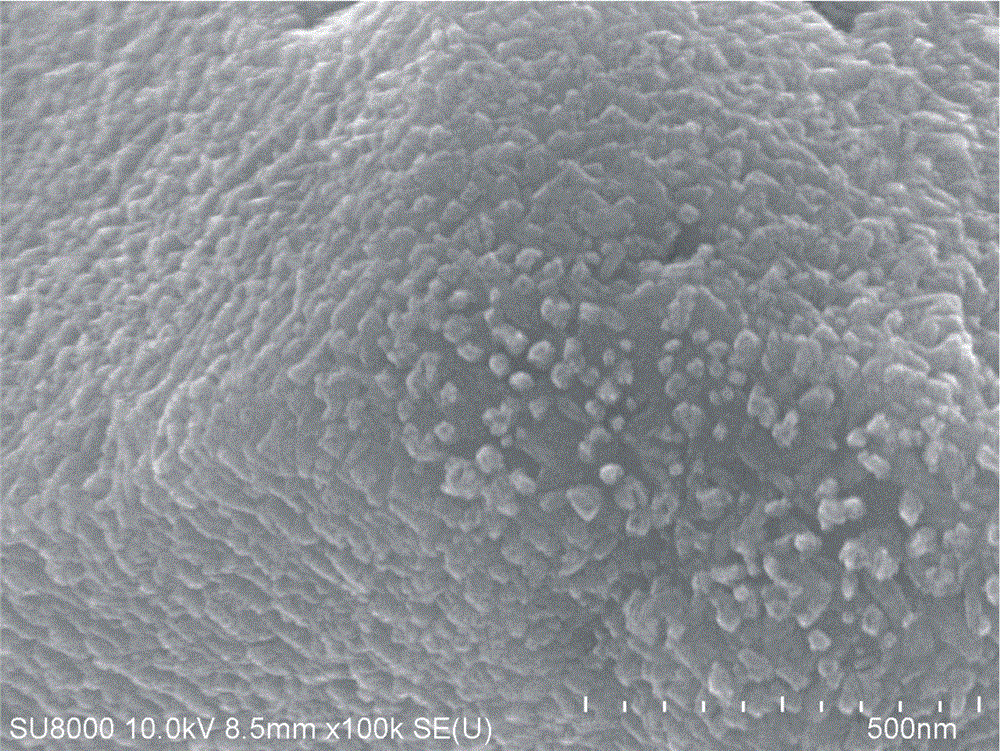

Process for preparing nano WC-Co cemented carbide

The invention is a method of preparing nano WC-Co hard alloy, preparing WC-Co mixed powder, making ball milling, finishing powder surface and making plasma activation and sintering to obtain nano WC-Co hard alloy. Its advantages: after finishing, the surface of Co powder is coated with a carbon film, improving surface structure, enhancing surface activity, beneficial to sintering powder, able to obviously shortening sintering time, and effectively controlling crystal particle growth, and the sintered product has fine crystal particles, high hardness and good flexibility. It is specially applied to preparation of nano WC-Co hard alloy.

Owner:EAST CHINA NORMAL UNIVERSITY

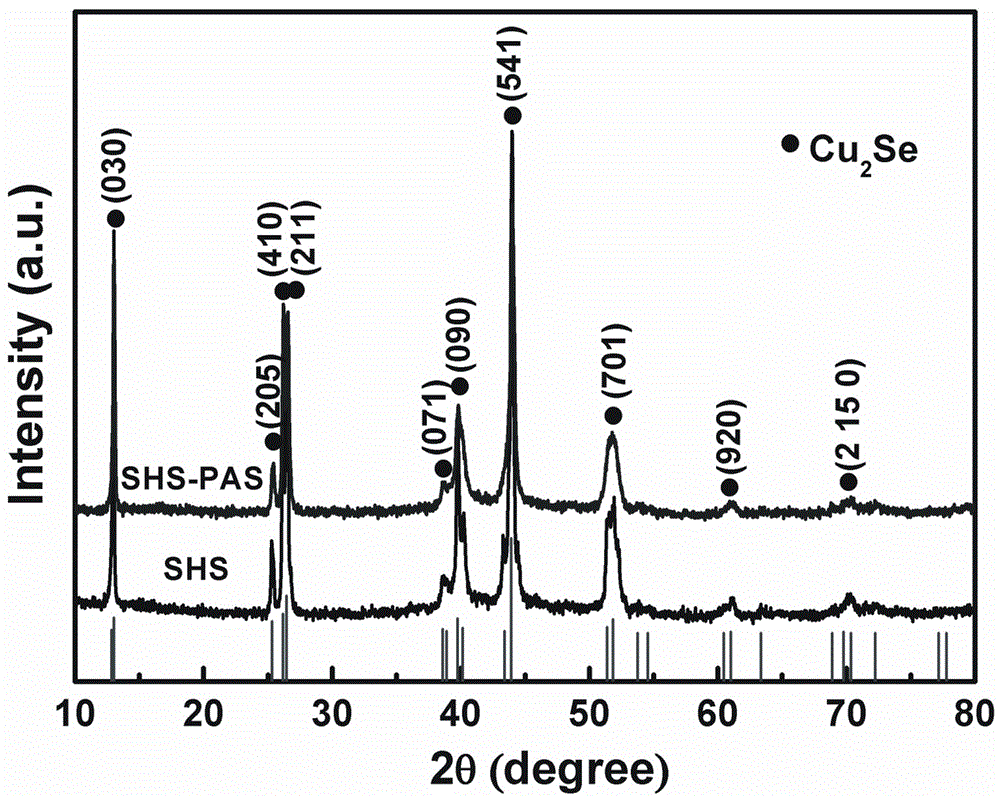

High-performance Cu2Se block thermoelectric material with nanopore structure and rapid preparation method of high-performance Cu2Se block thermoelectric material

ActiveCN103909264AEasy to controlGood repeatabilityThermoelectric device manufacture/treatmentThermoelectric device junction materialsReagentNanoporous

The invention provides a high-performance Cu2Se block thermoelectric material with a nanopore structure and a rapid preparation method of the high-performance Cu2Se block thermoelectric material. The rapid preparation method includes specific steps of 1) preparing Cu powder and Se powder as raw materials according to a stoichiometric ratio of 2 to 1, and subsequently evenly mixing the Cu powder and the Se powder to obtain a reactant; 2) subjecting the reactant to a self-propagating reaction by means of a direct initiation or constant temperature initiation manner, and natural cooling after completion of reaction; 3) performing plasma activated sintering to obtain the high-performance Cu2Se block thermoelectric material with the nanopore structure. By means of self-propagating combustion synthesis combined with the plasma activated sintering process, the high-performance Cu2Se block thermoelectric material can be prepared within 20 minutes, a thermoelectric property optimum value of the high-performance Cu2Se block thermoelectric material reaches 1.9 at the temperature of 727 DEG C, the preparation time is short, the process is simple, the composition control is accuracy, the thermoelectric property of the material is high, the material is suitable for large-scale production, and a broad commercialization application prospect is achieved.

Owner:WUHAN UNIV OF TECH

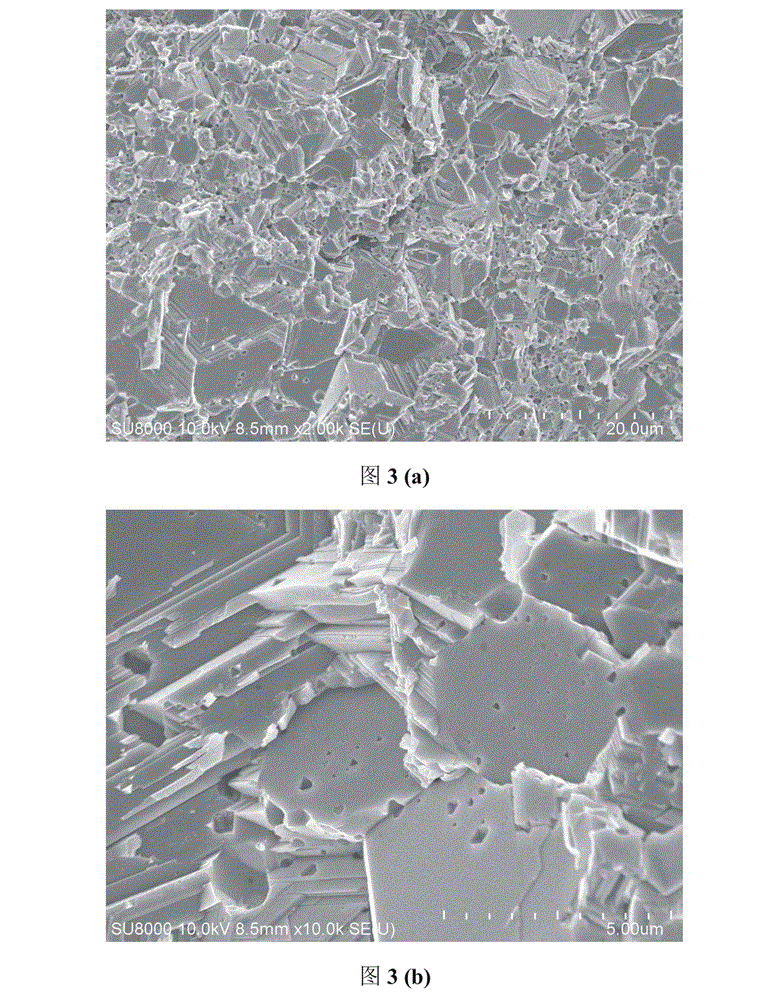

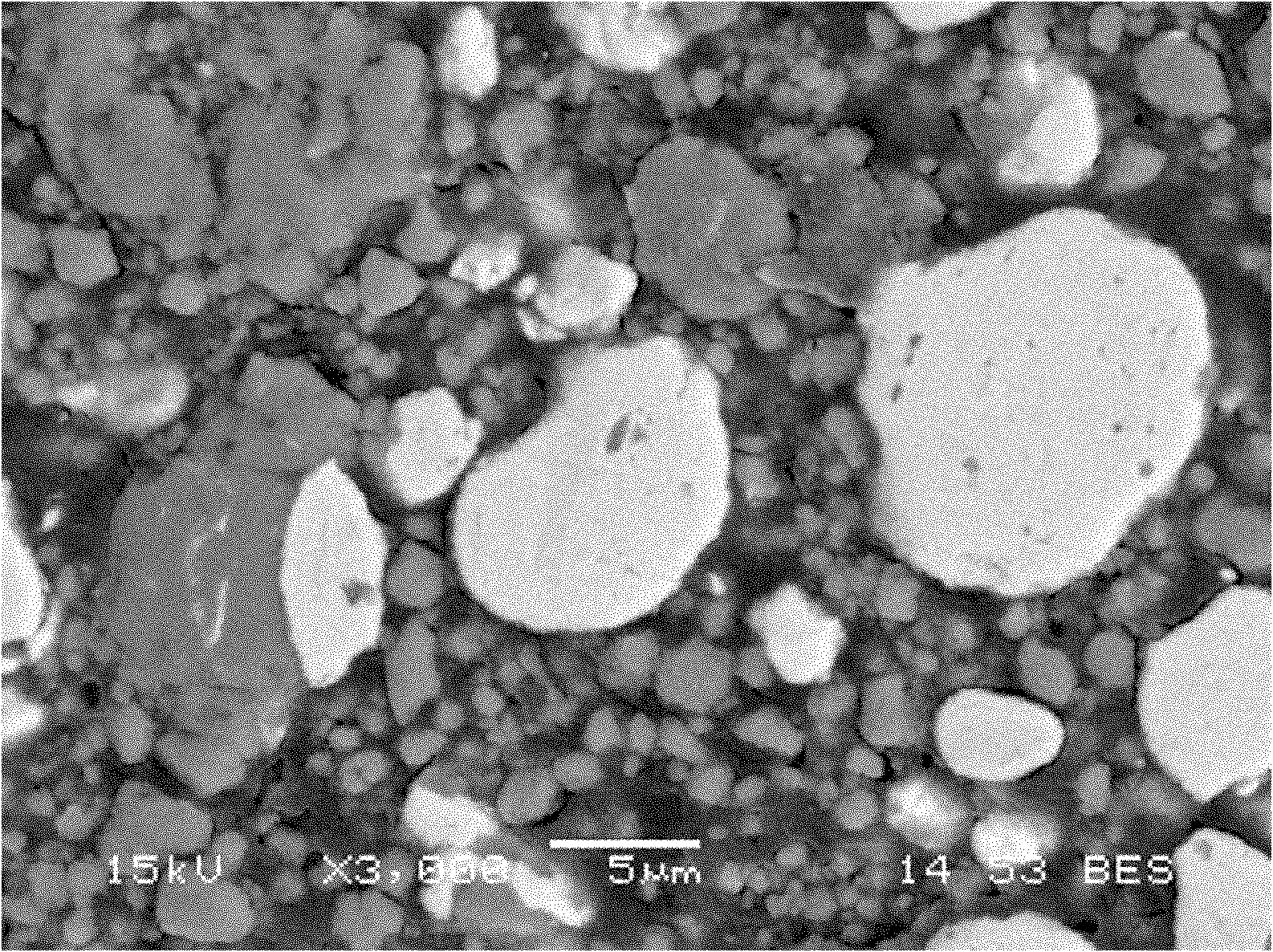

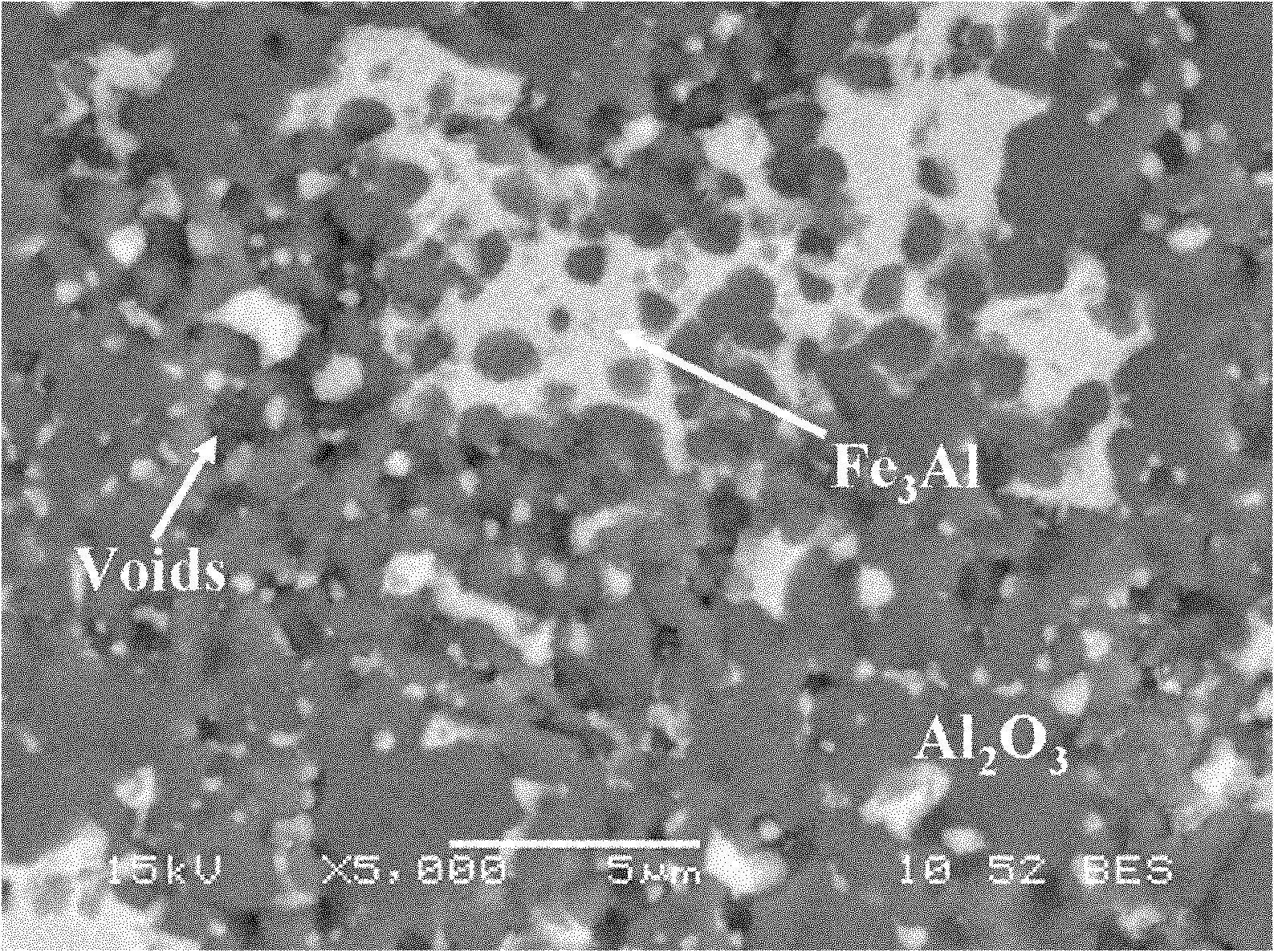

Method for preparing Fe3Al-Al2O3 composite material

The invention discloses a method for preparing a Fe3Al-Al2O3 composite material. The method comprises the following steps of: (1) weighing 23 to 69 mass percent of Fe2O3 powder, 21 to 31 mass percent of Al powder and 0 to 57 mass percent of Fe powder and performing mechanical alloying; (2) controlling a mechanical alloying process, performing self-propagation reaction on the Fe2O3 powder and the Al powder to produce Al2O3 and Fe powder, wherein the Fe powder and the Al powder form Fe(Al) solid solution in the ball milling process so as to obtain a mixture of the Al2O3 and the Fe(Al) solid solution; and (3) filling the mechanically alloyed and ball-milled mixture of the Al2O3 and the Fe(Al) solid solution into a graphite mould, and performing plasma activated sintering to form the required blocky composite material. By the preparation method, the aplitic Fe3Al-Al2O3 composite material with 15 to 44 mass percent of Al2O3 can be obtained; and the method is a preparation method for mechanical alloying and plasma sintering of the Fe3Al-Al2O3 composite material, which has the advantages of short preparation process time, high product purity and compactness and low cost.

Owner:XI AN JIAOTONG UNIV

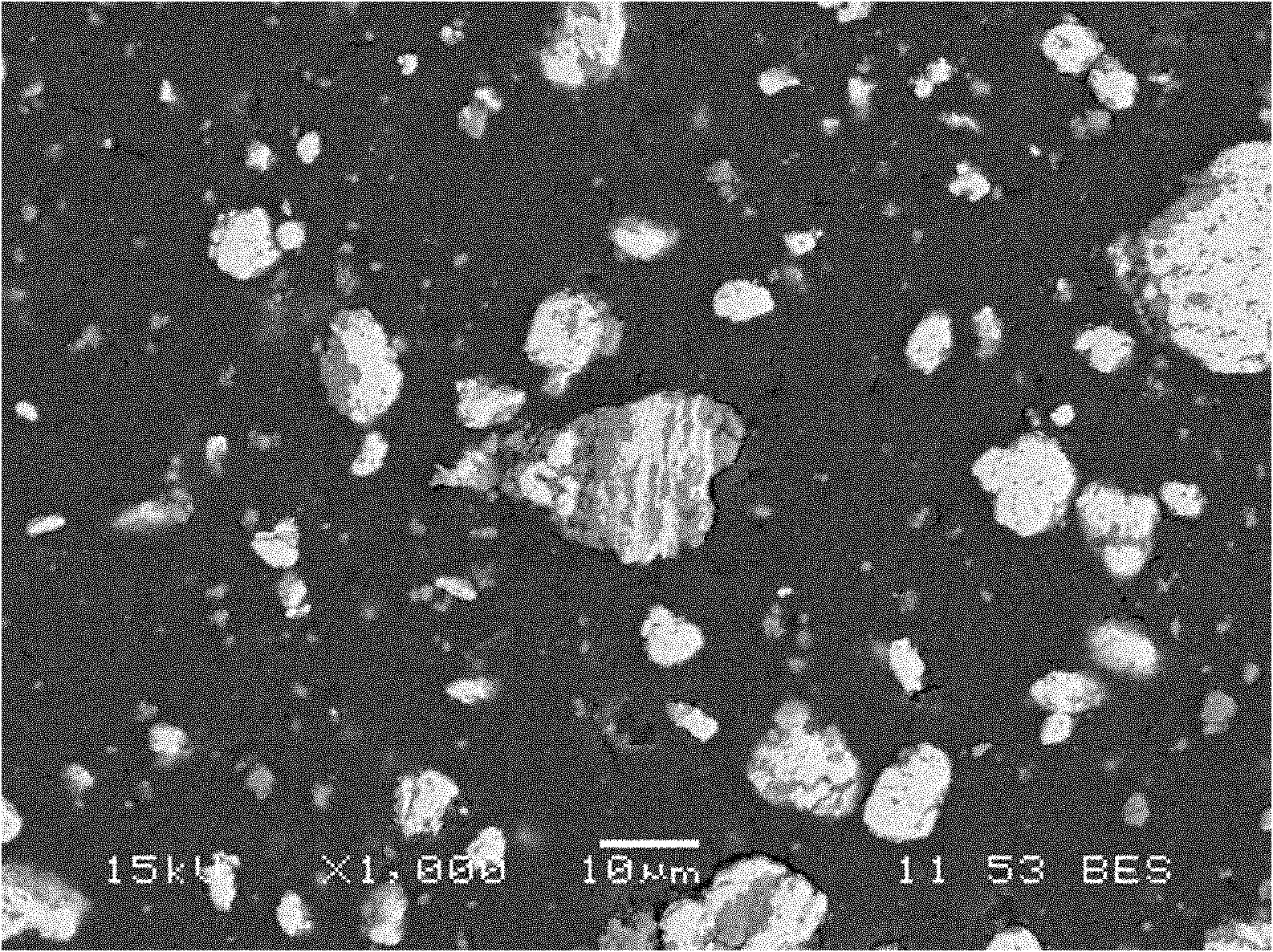

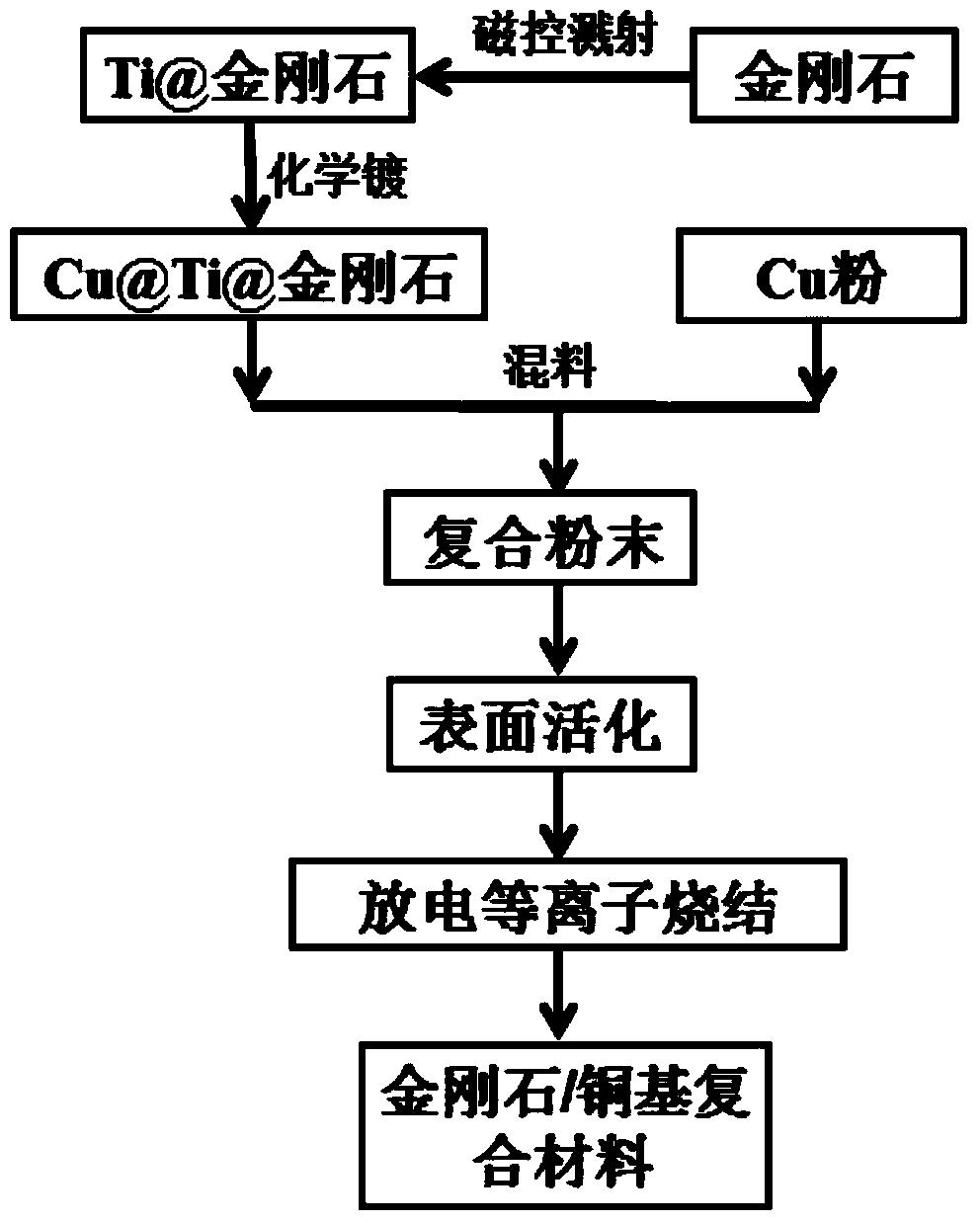

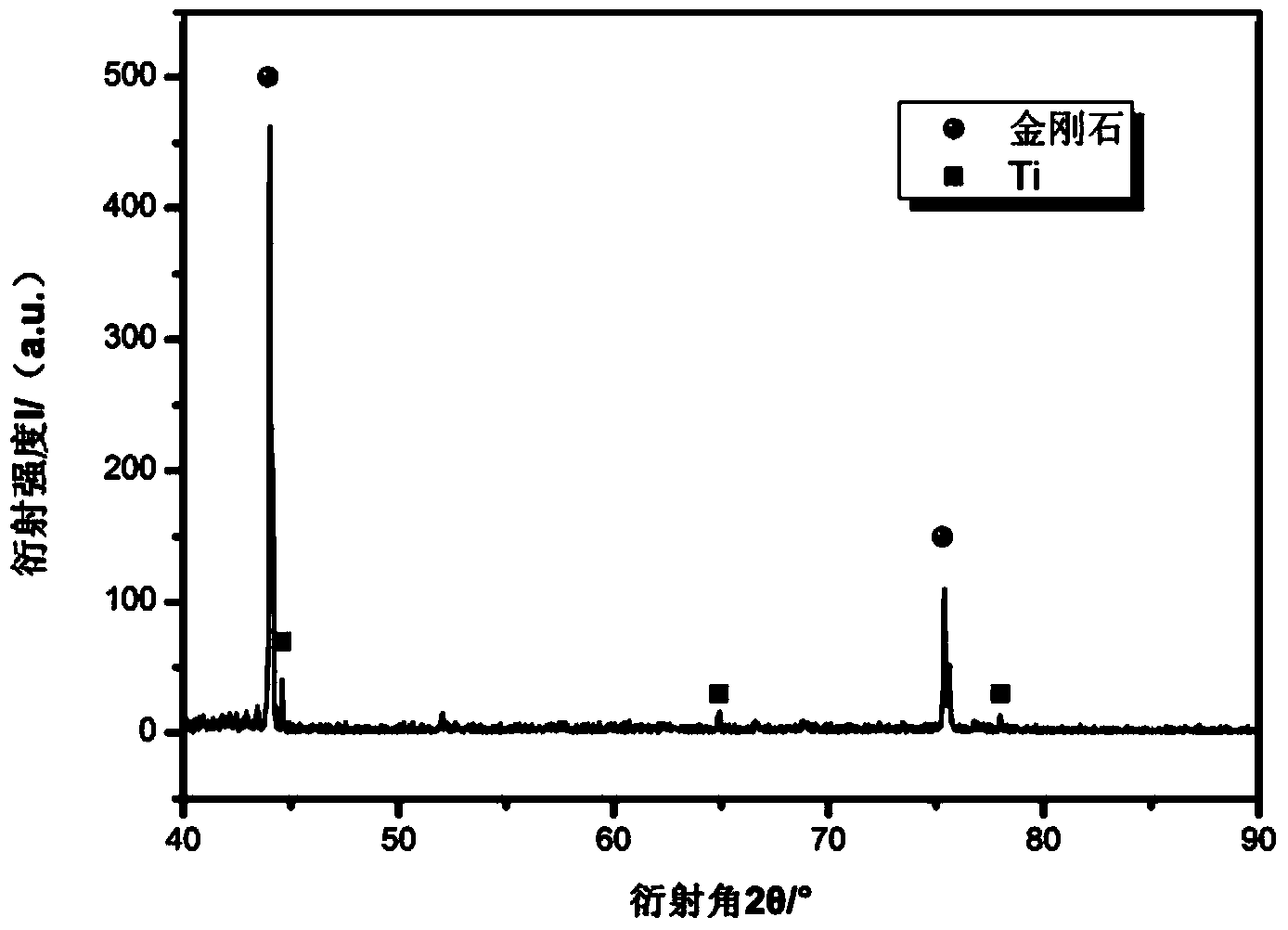

Preparation method for diamond/copper-based composite material

The invention relates to the field of diamond / copper-based composite materials and preparation technologies thereof, and specifically discloses a diamond / copper-based composite material and a preparation method thereof. Mass fraction of the diamond in the composite material is 20%-50%, and diamond particles are uniformly distributed in a matrix. The specific preparation method comprises the following steps: firstly, preparing copper-coated titanium-coated diamond composite powder; then, mixing the copper-coated titanium-coated diamond composite powder with copper powder to form mixed powder; and finally, preparing a sintering test sample with high compactness by surface activating and plasma activating and sintering. The plasma activating and sintering process is as follows: a heating rate is 50-200 DEG C / min, vacuum degree is not greater than 10Pa, pressure applied while sintering is 30-40 MPa, a sintering temperature is 800-900 DEG C, and a heat preserving time is 5-7 minutes. The prepared diamond / copper-based composite material is low in sintering temperature, high in compactness, fine in crystalline grain, simple to operate, and good in controllability.

Owner:WUHAN UNIV OF TECH

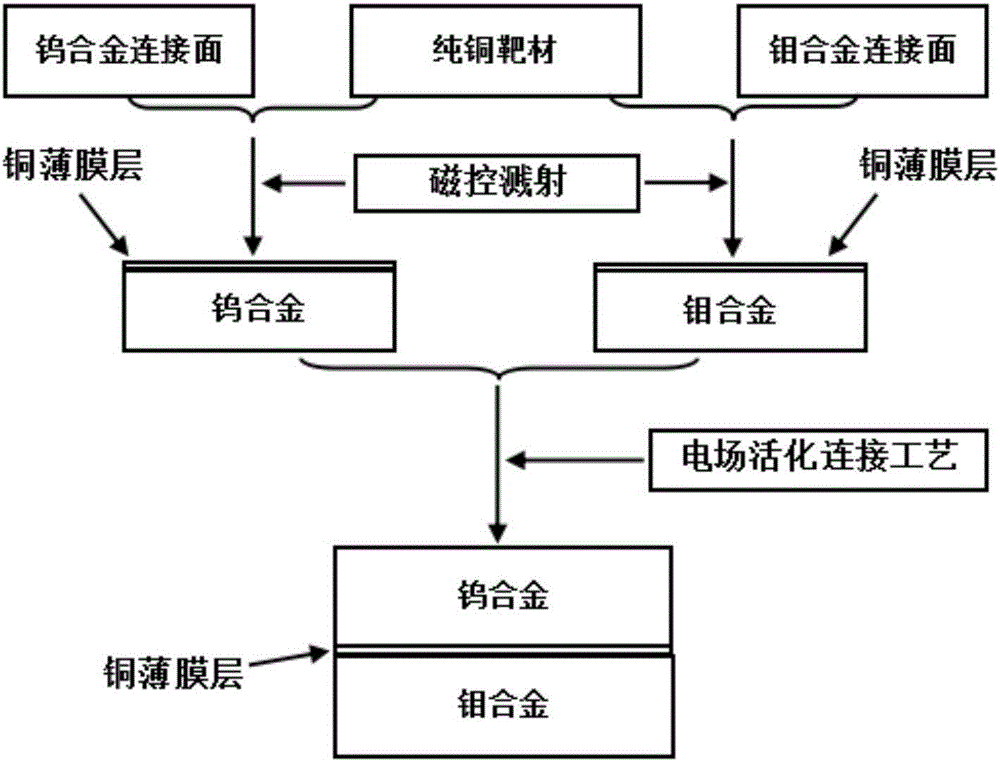

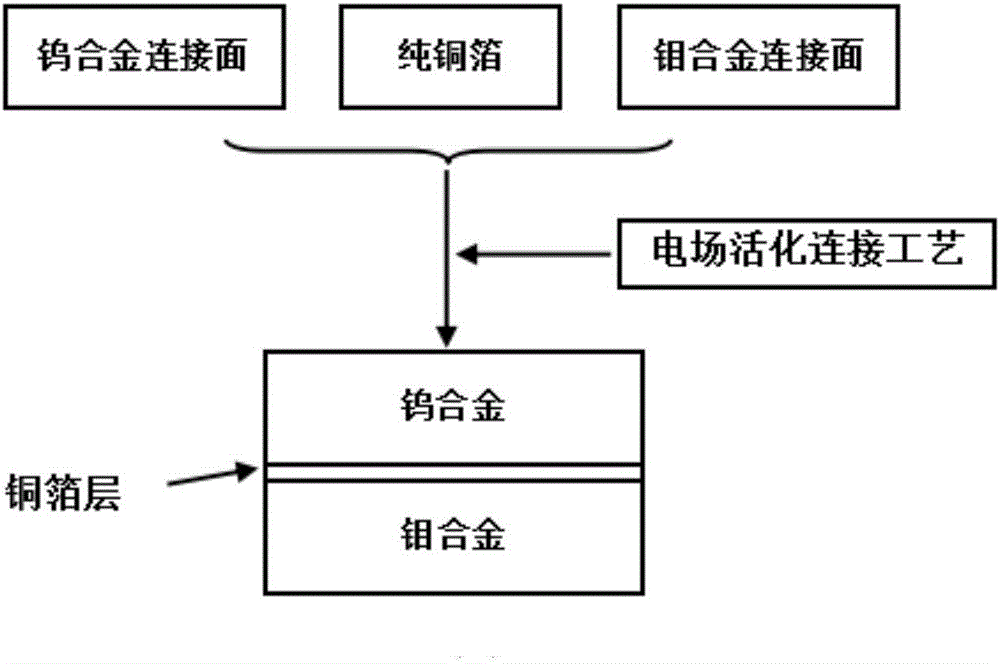

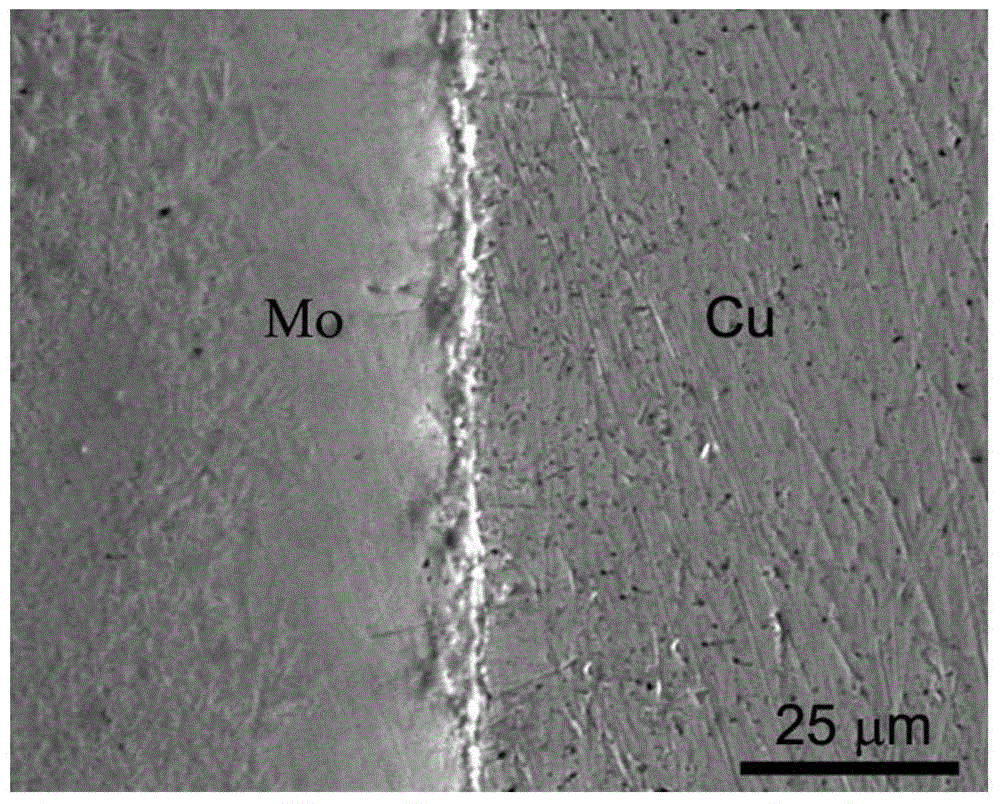

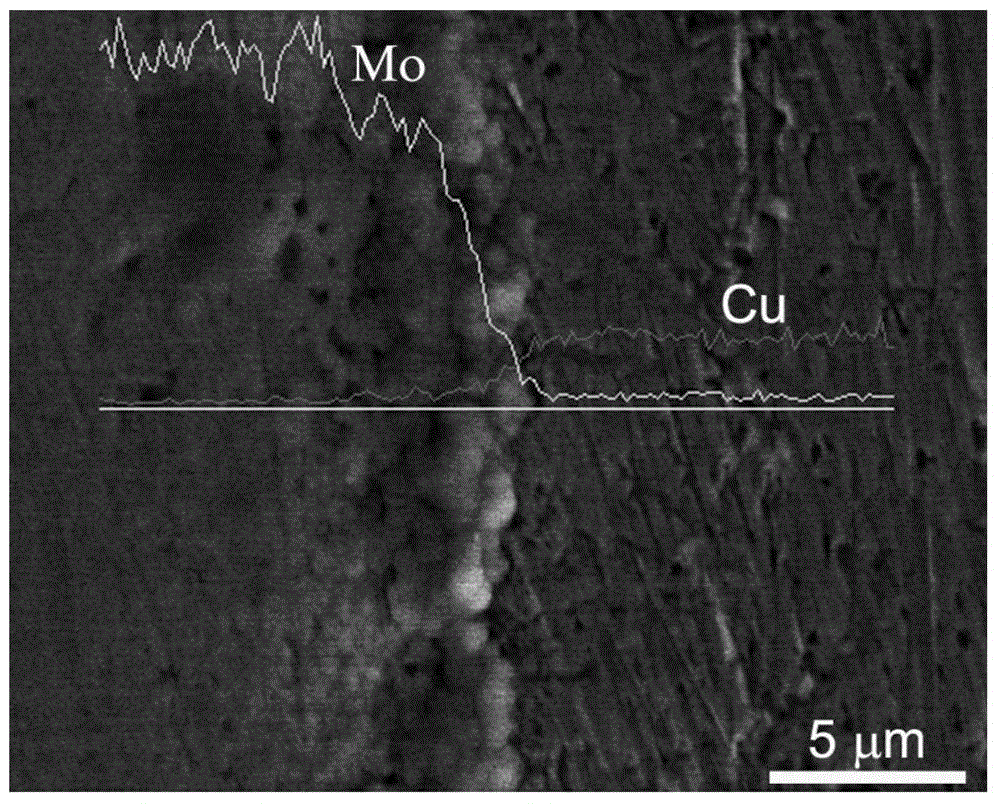

Connecting method for tungsten alloy and molybdenum alloy

InactiveCN106181000AImprove atomic contactPromote interdiffusionVacuum evaporation coatingSputtering coatingTime rangeAxial pressure

The invention relates to a connecting method for a tungsten alloy and a molybdenum alloy. Specifically, an ultrathin copper film is deposited on each of the surfaces of the tungsten alloy and the molybdenum alloy or an ultrathin copper foil is added on each of the surfaces of the tungsten alloy and the molybdenum alloy, the plasma activated sintering connection technology is utilized, and the low-temperature and high-strength connection of the tungsten alloy and the molybdenum alloy is achieved under the technological conditions that the axial pressure ranges from 5 MPa to 30 MPa, the vacuum degree is smaller than or equal to 0.1 Pa, the activation time ranges from 20 s to 100 s, the temperature rise rate ranges from 80 DEG C / min to 200 DEG C / min, and the temperature ranging from 650 DEG C to 850 DEG C is kept for 300 s-1,200 s. The connecting method has the beneficial effects that through introduction of ultrathin copper activated intermediate layers, the connecting temperature of the refractory metal tungsten alloy and the refractory metal molybdenum alloy is remarkably lowered, the connecting strength of the refractory metal tungsten alloy and the refractory metal molybdenum alloy is improved, low-temperature, rapid and high-strength connection of the tungsten alloy and the molybdenum alloy is achieved at the extremely low temperature for the first time, the shearing strength reaches 224.8 MPa, and compared with direct connection of the tungsten and the molybdenum, the strength is improved by near 7 times; and the connecting temperature is greatly reduced, and reliable connection of connecting connectors is improved.

Owner:WUHAN UNIV OF TECH

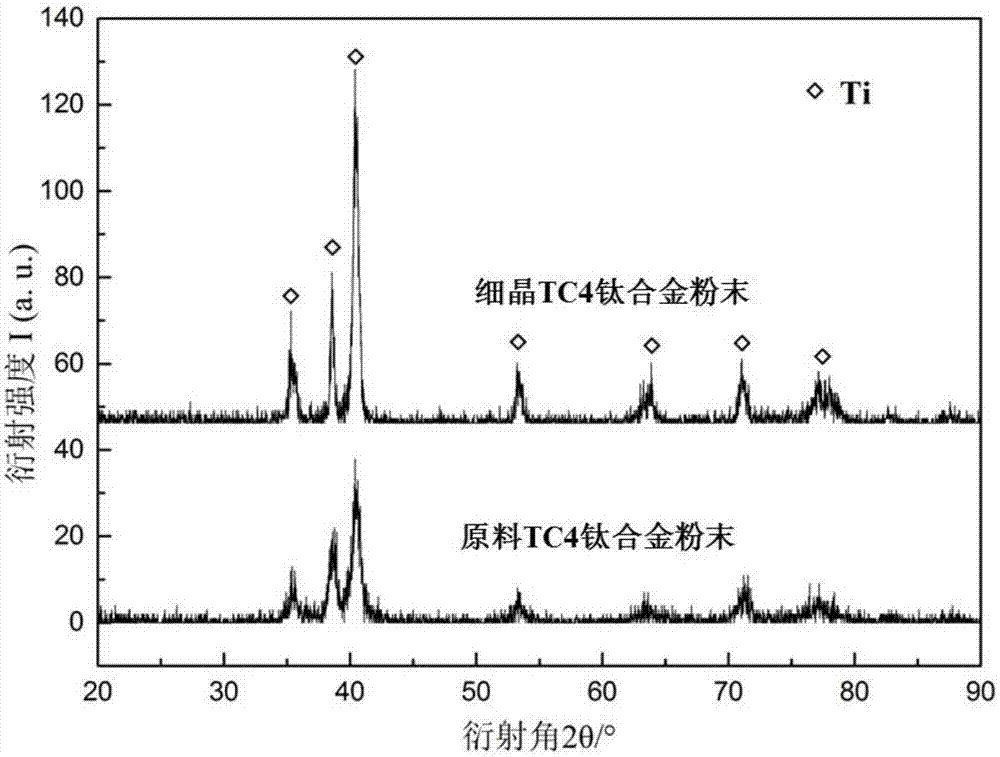

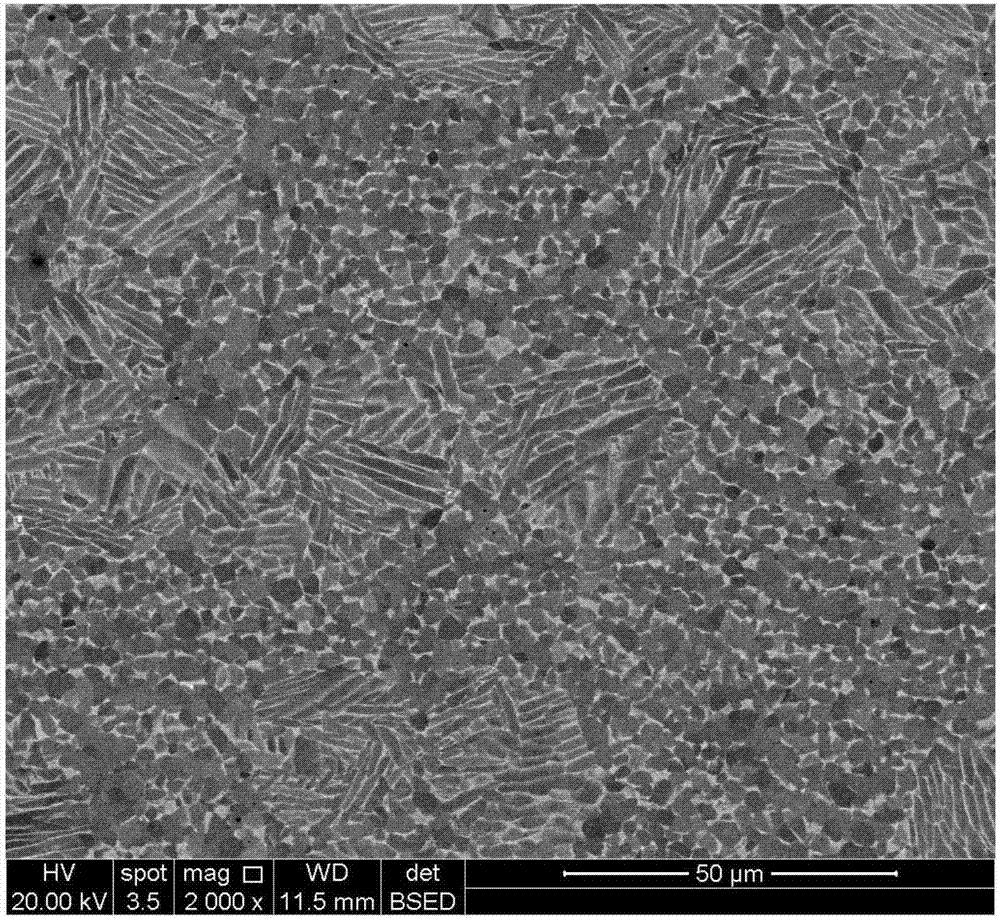

Preparation method of dual-scale titanium alloy material

Owner:WUHAN UNIV OF TECH

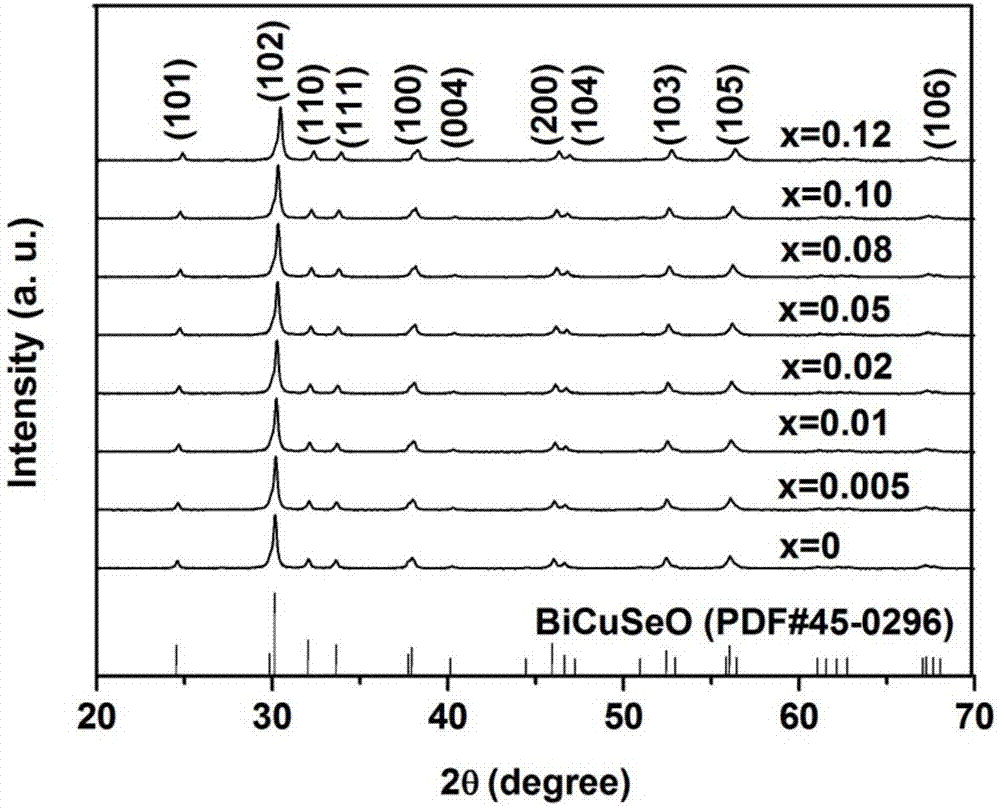

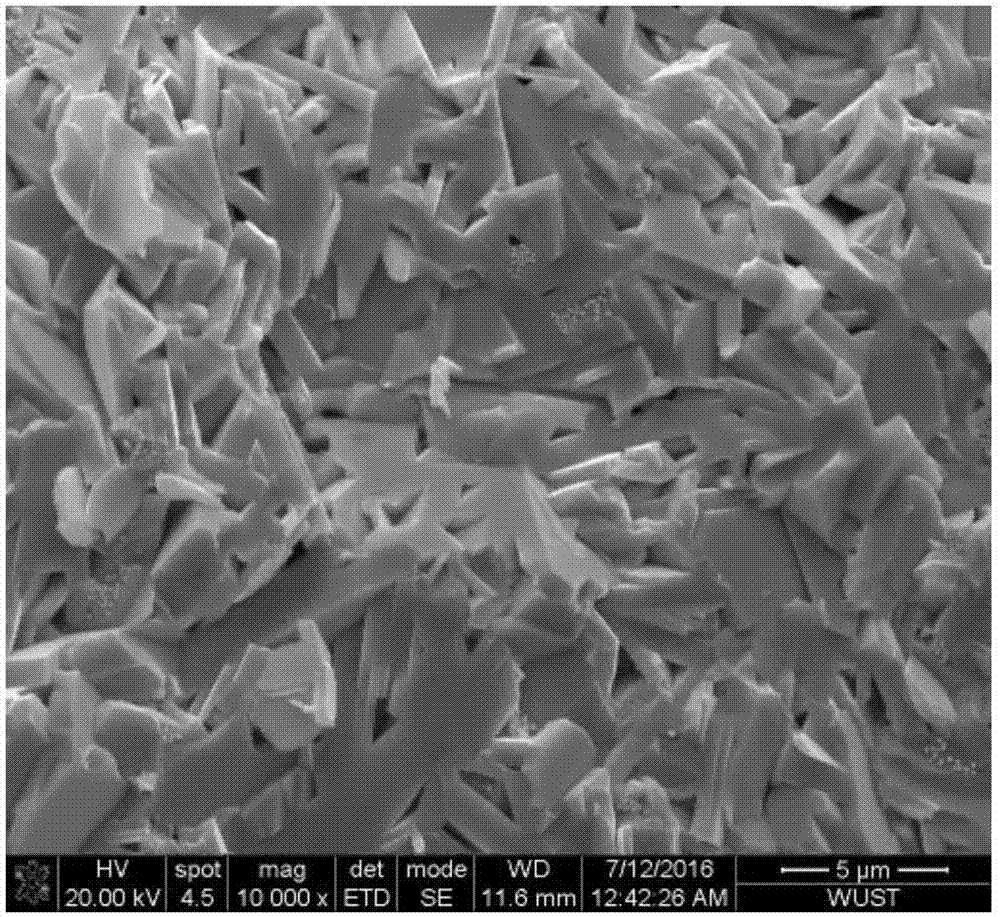

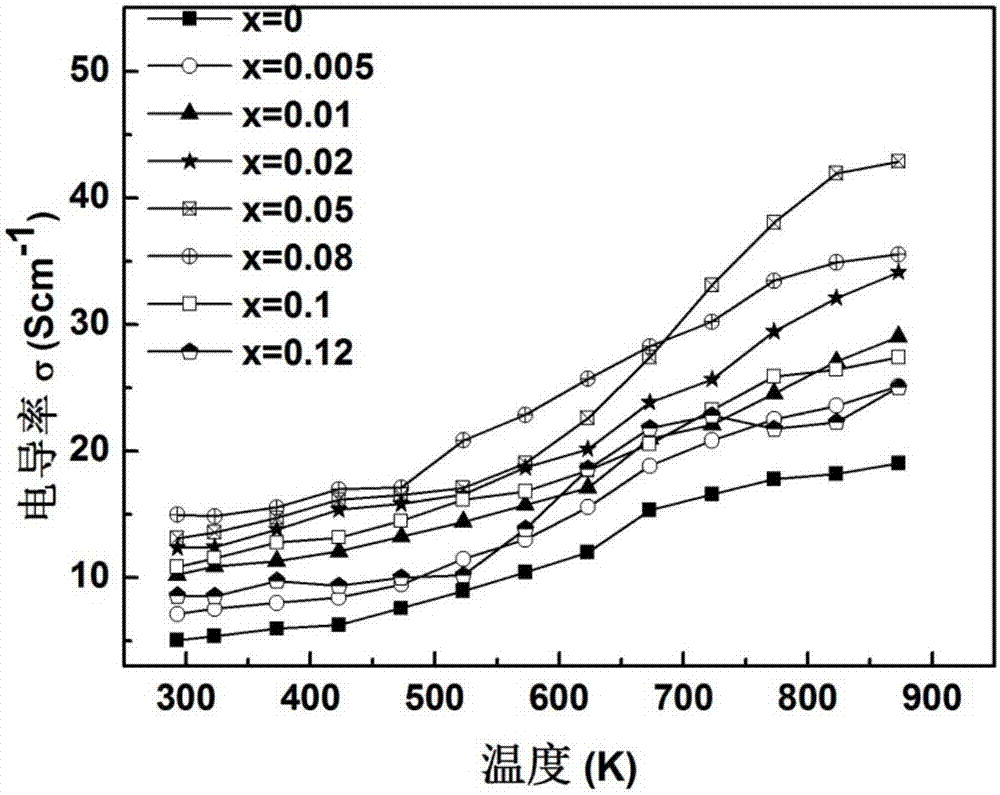

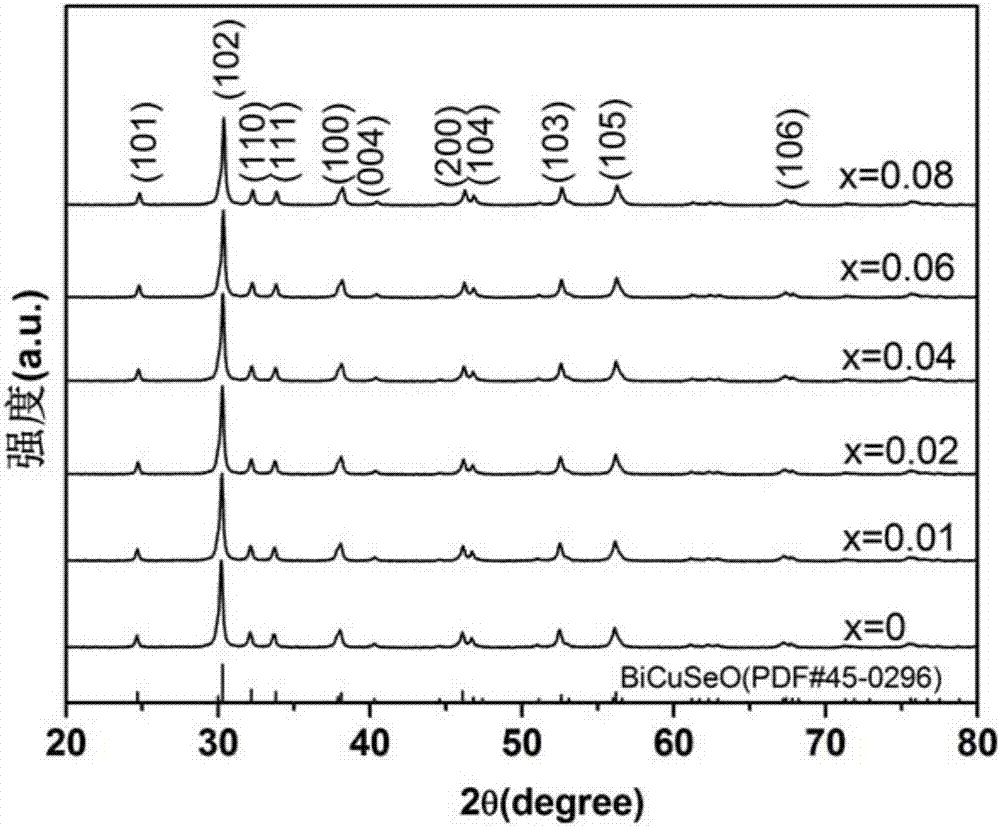

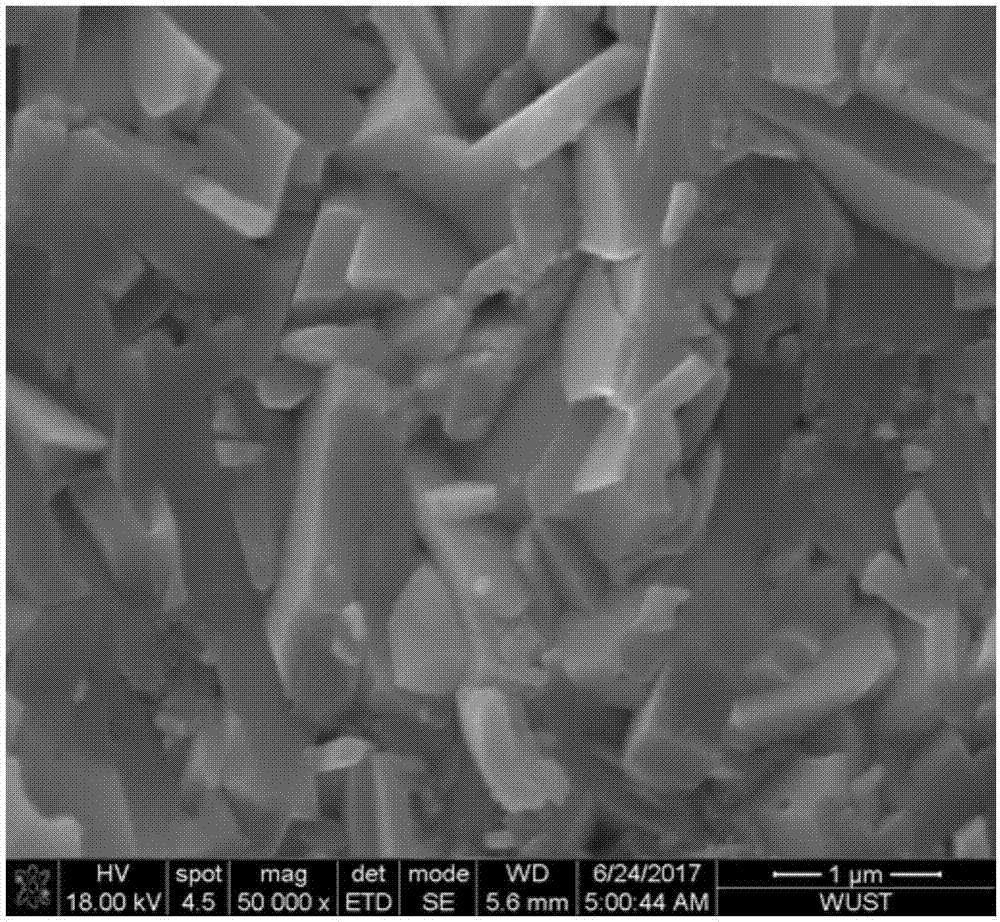

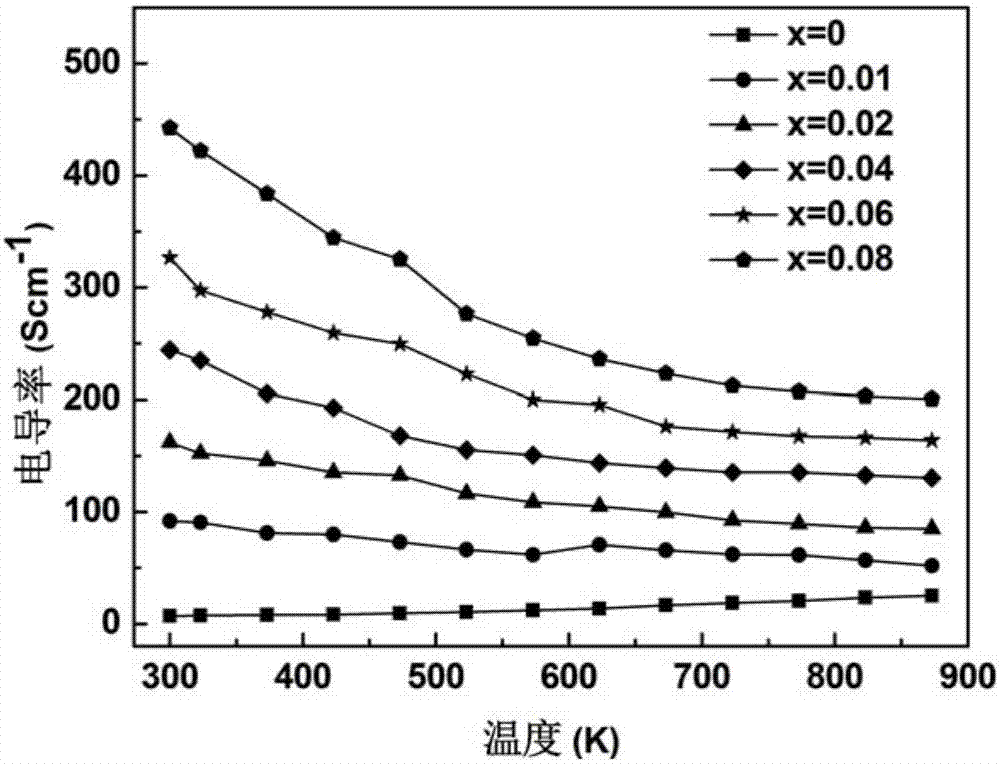

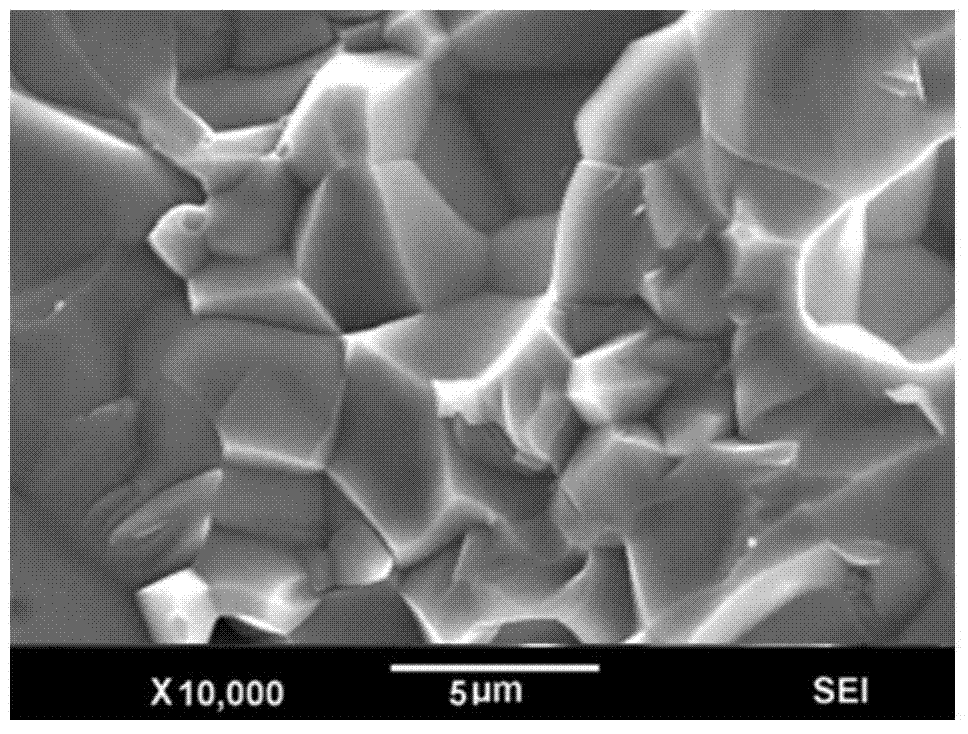

Sb doped BiCuSeO thermoelectric material and preparation method thereof

InactiveCN107394035AShorten the production cycleIncrease productivityThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsMass ratio

The invention relates to a Sb doped BiCuSeO thermoelectric material and a preparation method thereof. The technical scheme is as follows: uniformly mixing bismuth oxide powder, copper powder, selenium granules, bismuth powder and antimony powder according to a mass ratio of 1: 3:3:(1-3Y): 3Y, wherein 3y is not smaller than 0.005 = x is not greater than 0.12, filling the mixture in a ball milling tank, ball milling in an inert gas atmosphere to prepare single-phase SbxBi1-xCuSeO powder, wherein x is not smaller than 0.005 and is not greater than 0.12, filling the single-phase SbxBi1-xCuSeO powder in a mold, placing the mold in a plasma activated sintering furnace, and heating up to 500-700 DEG C at a constant speed, boosting to 30-100MPa at a constant speed, cooling to the room temperature at a constant speed and reducing to the normal pressure at a constant speed, taking out the sintered mold, and demolding to obtain the Sb doped BiCuSeO thermoelectric material. The Sb doped BiCuSeO thermoelectric material has the advantages of simple process, short production cycle and high production efficiency. The products have the advantages of high purity, high density, low thermal conductivity, high power factor and high dimensionless thermoelectric merit value.

Owner:WUHAN UNIV OF SCI & TECH

Non-binding-phase carboloy metal and preparation method thereof

The invention belongs to the technical field of powder metallurgy, and particularly relates to a non-binding-phase carboloy metal and a preparation method thereof. The non-binding-phase carboloy metal comprises the following components in percentage by mass: 0.10-0.30% of vanadium carbide, 0.10-0.30% of tantalum carbide, 0.10-0.25% of cobalt, and the balance of tungsten carbide. According to the invention, a carboloy metal with high density, high hardness and high wear resistance is obtained by using a plasma activated sintering process, then a large-sized bulk material is obtained by using a special mould shape, and the process is simple, and low in cost, can be used for realizing mass production, and meets the requirements of hydro-jet sand mixing tubes on high-wear-resisting materials.

Owner:西安奥奈特固体润滑工程学研究有限公司

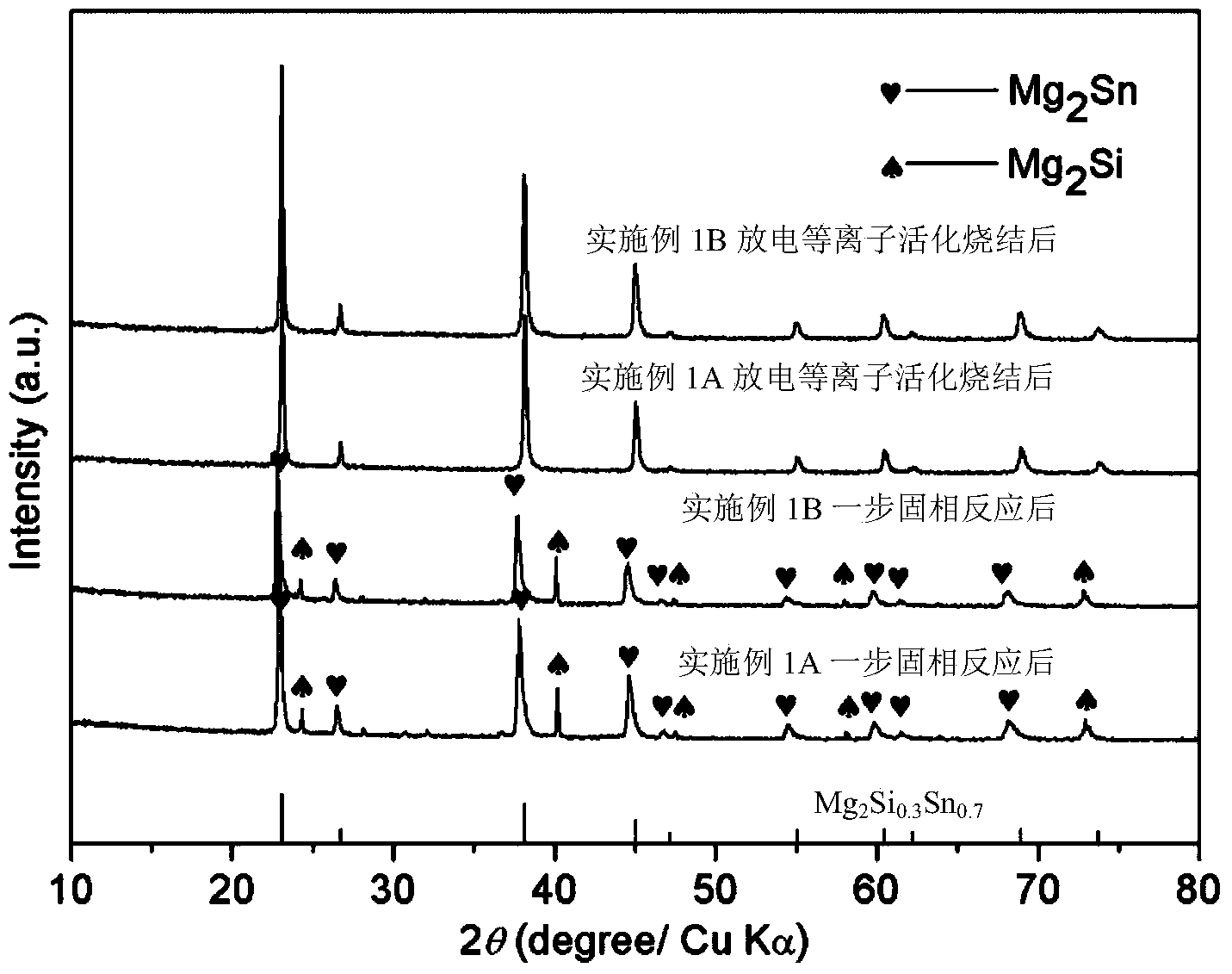

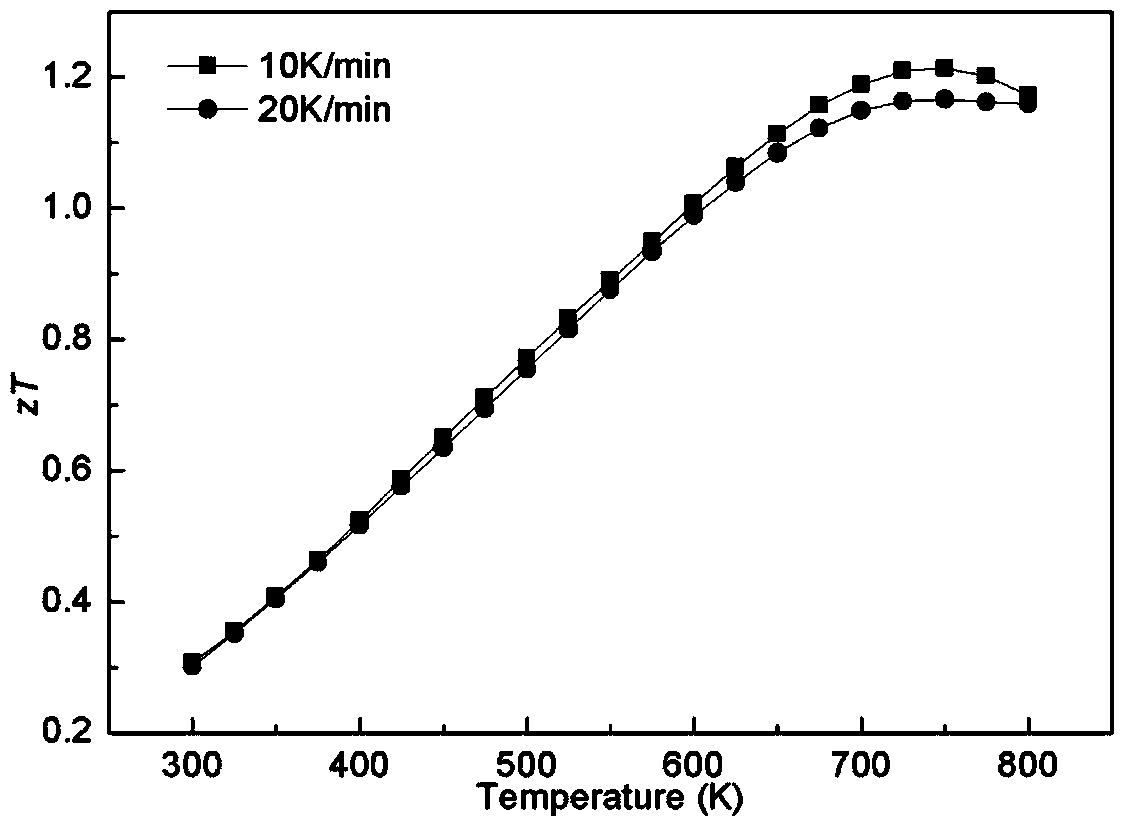

Method of quickly preparing Mg-Si-Sn-based thermoelectric material in controllable manner

ActiveCN104232960AReduce volatilityGreat potential for commercial applicationsThermoelectric materialsMetallurgy

The invention relates to a method of quickly preparing Mg-Si-Sn-based thermoelectric material in a controllable manner. The method comprises the following steps: 1) dosing and tabletting, namely in the presence of inert gases, weighing Mg powder, Mg2Si powder, Sn powder and Sb powder which are used as raw materials according to a stoichiometric ratio of each element in a chemical formula Mg2(1+z)Si1-xSnxSby (z is not smaller than 0 and not greater than 0.12, x is not smaller than 0 and not greater than 1.0, and y is not smaller than 0 and not greater than 0.025), and mixing and uniformly pressing the raw materials into blocks; 2) sealing the blocks in vacuum, then, heating the blocks to 823-833K, carrying out heat preservation for 5-10 minutes, and cooling the blocks along with a furnace; 3), grinding products obtained in the step 2) into powder in the presence of inert gases, and carrying out discharge plasma activated sintering to obtain the high-performance Mg-Si-Sn-based thermoelectric material. The method has the characteristics of simple process, low energy consumption, short preparation period, good repeatability, excellent thermoelectric properties of obtained block materials, and the like.

Owner:WUHAN UNIV OF TECH

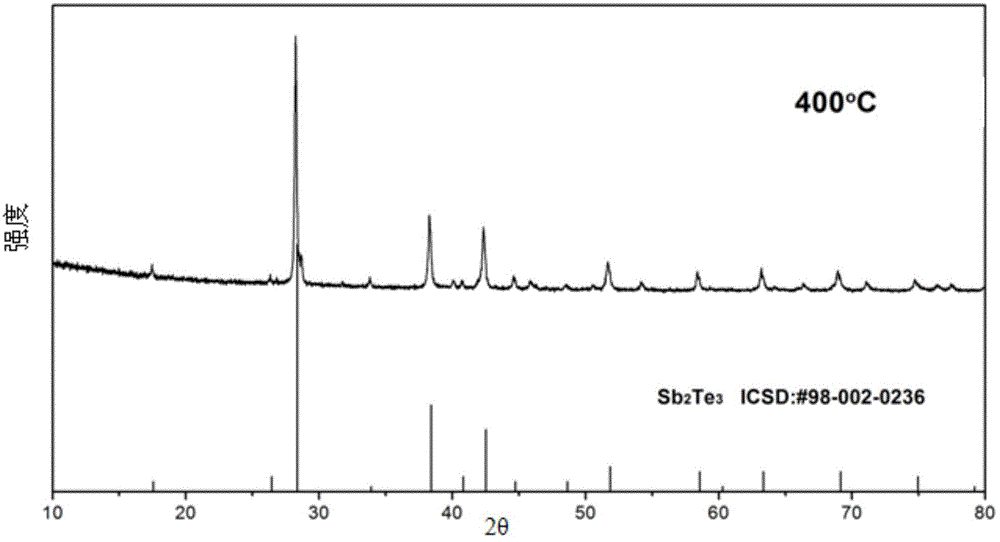

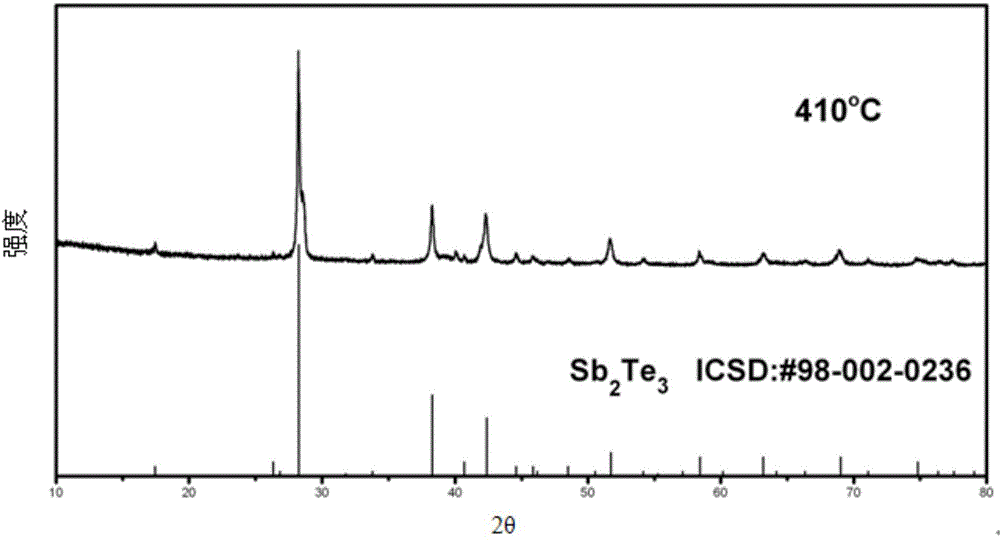

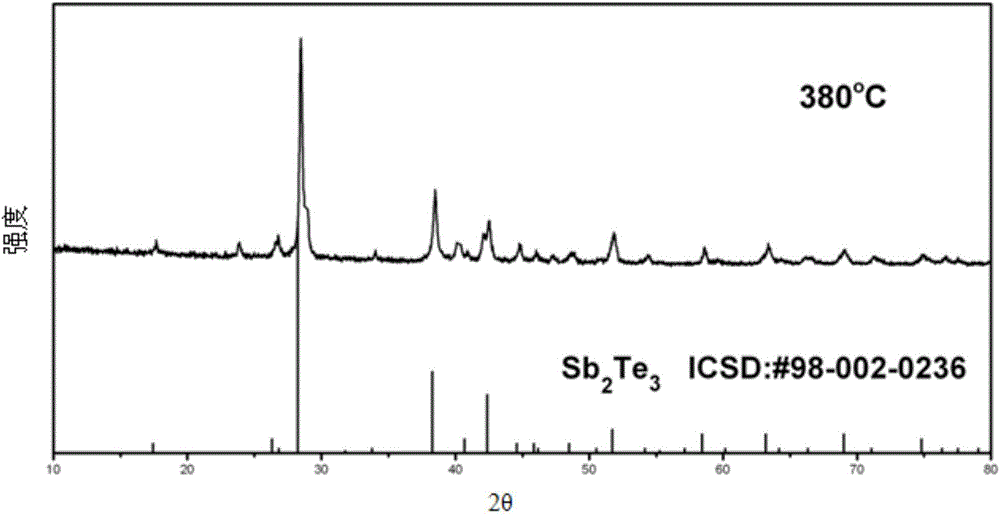

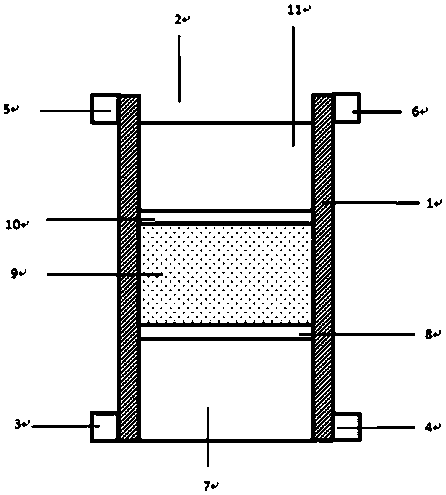

Method for quickly preparing antimony telluride thermoelectric material

ActiveCN106145062AQuick responseReduce energy consumptionBinary selenium/tellurium compoundsThermoelectric materialsReaction speed

The invention discloses a method for quickly preparing a Sb2Te3 thermoelectric material. The method comprises the following steps that 1, Sb powder and Te powder are weighed according to the stoichiometric ratio of all elements in Sb2Te3 and then ground and mixed to be uniform to obtain a mixed raw material; 2, discharging plasma activated sintering is conducted on the mixed raw material obtained in the step 1, and the compact single-phase Sb2Te3 thermoelectric material is obtained. The antimony telluride thermoelectric material has the advantages of being high in reaction speed, efficient, economical in energy, good in repeatability and the like and has a very good application prospect.

Owner:WUHAN UNIV OF TECH

Preparation method for carbon fiber reinforced aluminum-based boron carbide neutron shielding material

InactiveCN109680227AImprove absorption efficiencyImprove shaping and reduce adverse effectsShieldingFiberCarbon fibers

The invention relates to a preparation method for a carbon fiber reinforced aluminum-based boron carbide neutron shielding material, belongs to the technical field of preparation and applications of carbon fiber reinforced metal-based composite shielding materials, and can solve the problem that the plastifying and processing performance of the composite materials are reduced by high ceramic particles in aluminum-based boron carbide. The preparation method comprises the following steps: filing a pre-prepared graphite mold with uniformly ball-milled and mixed composite powder for surface activation and plasma activated sintering; and carrying out thermal treatment on the sintered specimen to obtain the carbon fiber reinforced aluminum-based boron carbide composite material. The preparationmethod is an advanced method of carbon fiber reinforced aluminum-based boron carbide neutron absorption plate.

Owner:TAIYUAN UNIV OF TECH

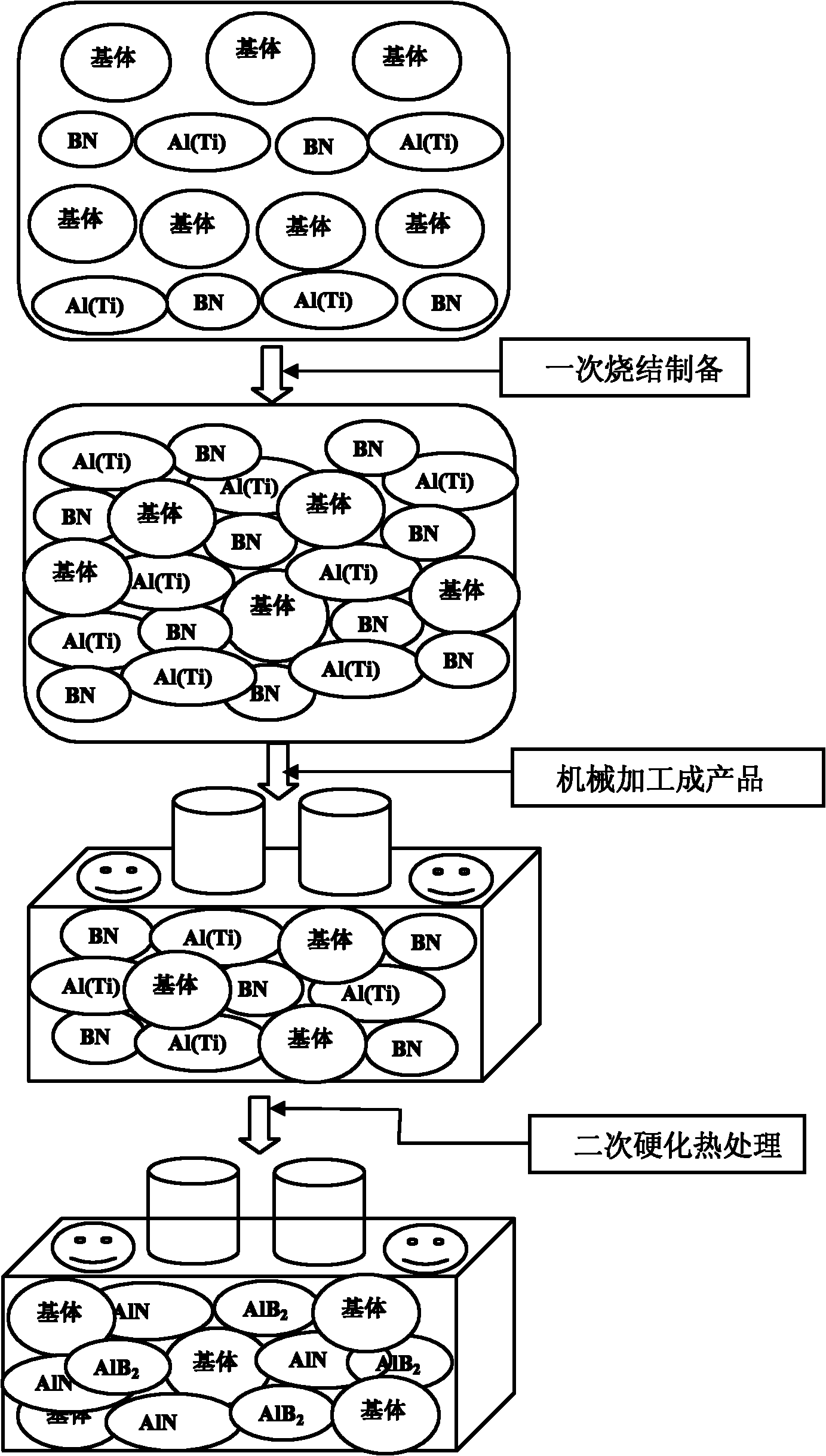

Processable complex-phase ceramic material and preparation method thereof as well as secondary hardening heat treatment method

The invention relates to the field of ceramic material manufacture and discloses a processable complex-phase ceramic material and a preparation method thereof as well as a secondary hardening heat treatment method. The processable complex-phase ceramic material comprises the components of 40-80% of SiC, 5-30% of h-BN and 5-50% of Ti by weight. The preparation method comprises the steps of: preparing the components, carrying out ball-milling on the components to obtain mixed powder, and then sintering once in a plasma activated sintering (PAS) furnace to obtain a processable complex-phase ceramic material with relatively low hardness; and machining the prepared processable complex-phase ceramic material into a product, placing into a heat treatment furnace, and carrying out secondary hardening treatment in the presence of N2 gas shielding, therefore, the hardness of the product is enhanced and the application field of the product is enlarged.

Owner:XI AN JIAOTONG UNIV

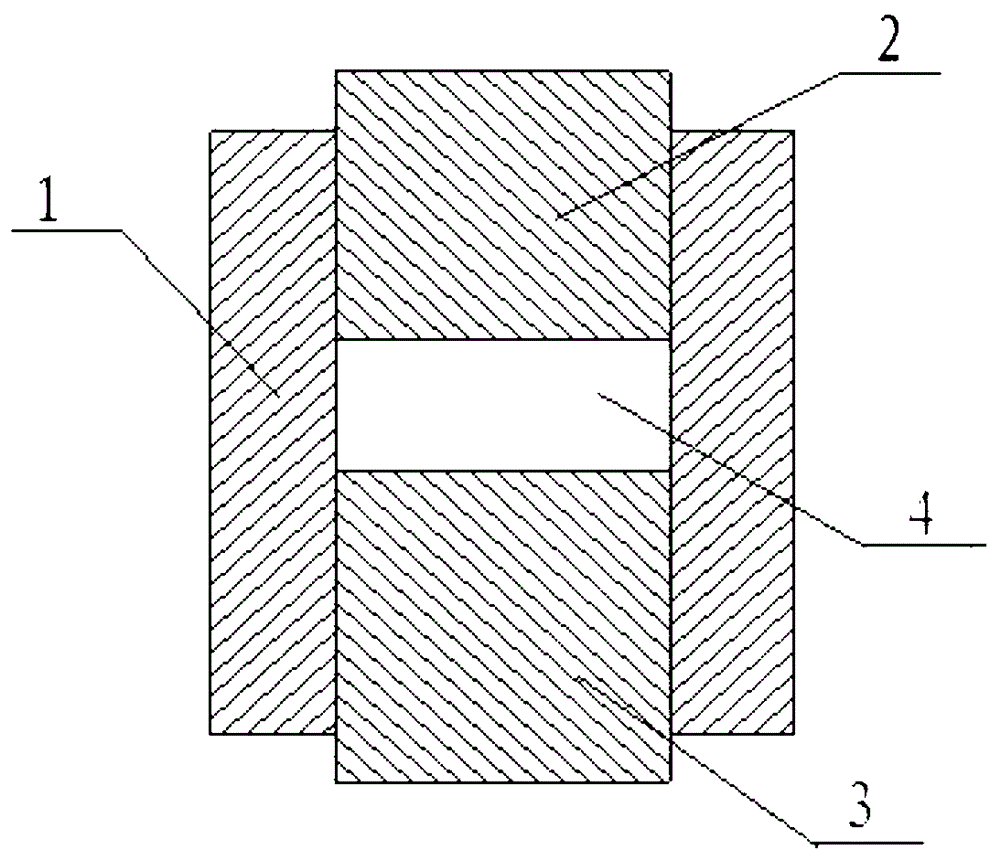

Method for rapidly preparing copper-molybdenum multi-layer composite material

InactiveCN104014921AHigh bonding strengthFast diffusion connectionWelding/soldering/cutting articlesNon-electric welding apparatusThermal expansionPlasma activation

The invention discloses a method for rapidly preparing a copper-molybdenum multi-layer composite material. The method comprises the following steps that (1) the surfaces of copper pieces and the surfaces of molybdenum pieces are polished so that oxidation films can be removed, the polished copper pieces and the polished molybdenum pieces are washed through acetone, and the processed copper pieces and the processed molybdenum pieces are dried by cold air for later use; (2) the copper pieces and the molybdenum pieces are overlaid in an alternating mode so that a multi-layer structural plate can be formed and the multi-layer structural plate is placed in a combination mold; (3) the combination mold containing the multi-layer structural plate is placed in a plasma activation sintering furnace, demolding is conducted after sintering is conducted, and therefore the copper-molybdenum multi-layer composite material is obtained. Electrifying, heating and sintering are directly conducted on the multi-layer structural plate obtained by overlaying the copper pieces and the molybdenum pieces in the alternating mode by introducing a high-density current, rapid diffusion bonding of copper-molybdenum interfaces is achieved under the combination action of temperature and pressure, the copper-molybdenum multi-layer composite material prepared with the method is good in heat conductivity and thermal expansion coefficient, the bonding strength of the copper-molybdenum interfaces is high, the product consistency is good, and punch forming can be achieved.

Owner:CHANGAN UNIV

Preparation method of n-type bismuth telluride-based thermoelectric material

ActiveCN112201743AImprove machinabilityHigh electrical transport performance retentionThermoelectric device manufacture/treatmentThermoelectric device junction materialsBismuth tellurideBismuth

The invention discloses a preparation method of an n-type bismuth telluride-based thermoelectric material. The preparation method comprises the following steps: weighing bismuth powder, tellurium powder and selenium powder serving as raw materials according to the stoichiometric requirements of Bi2Te3-xSex, wherein x is more than or equal to 0.1 and less than or equal to 0.7; and then carrying outself-propagating reaction, reduction annealing, plasma activated sintering and hot forging treatment to obtain the compact n-type bismuth telluride-based thermoelectric material. The Bi2Te3-xSex powder is rapidly obtained by adopting a self-propagating combustion synthesis technology, reduction annealing is carried out on the Bi2Te3-xSex powder, and step-by-step hot forging is carried out to obtain the polycrystalline block thermoelectric material with high orientation, so that the thermoelectric performance of the obtained product can be remarkably improved; and the related preparation method is simple and convenient to operate, and a brand-new thought can be provided for expanded production of the high-performance n-type Bi2Te3-xSex-based thermoelectric material.

Owner:WUHAN UNIV OF TECH

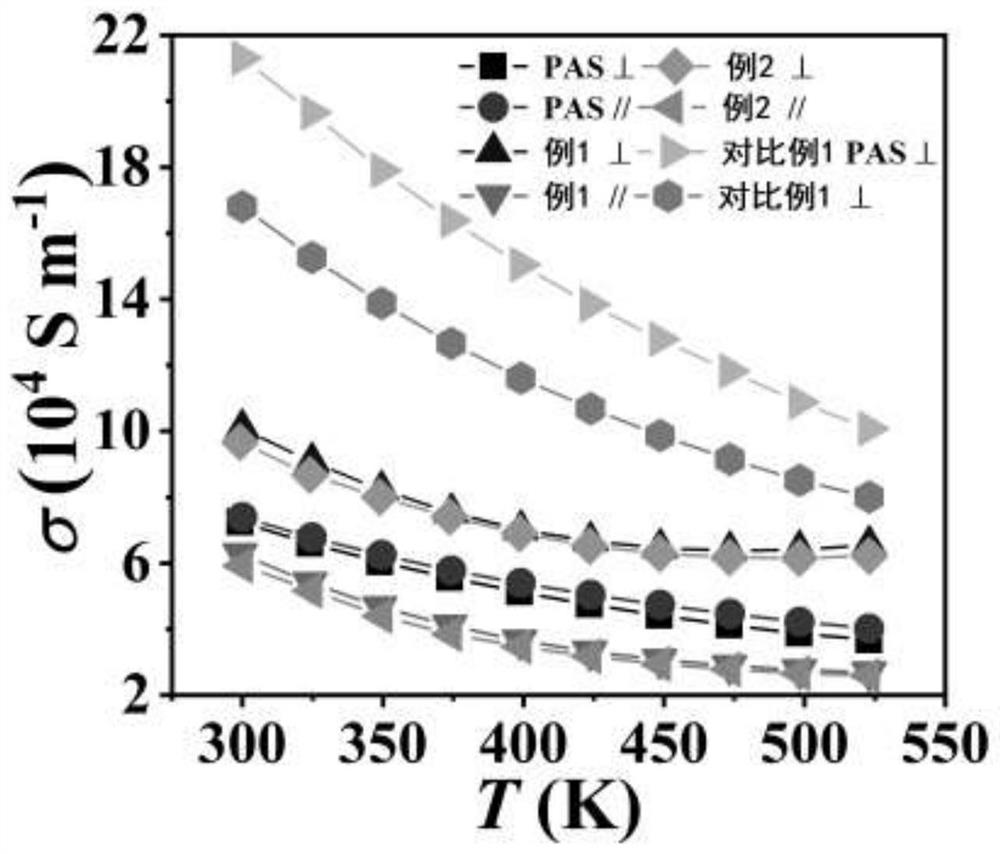

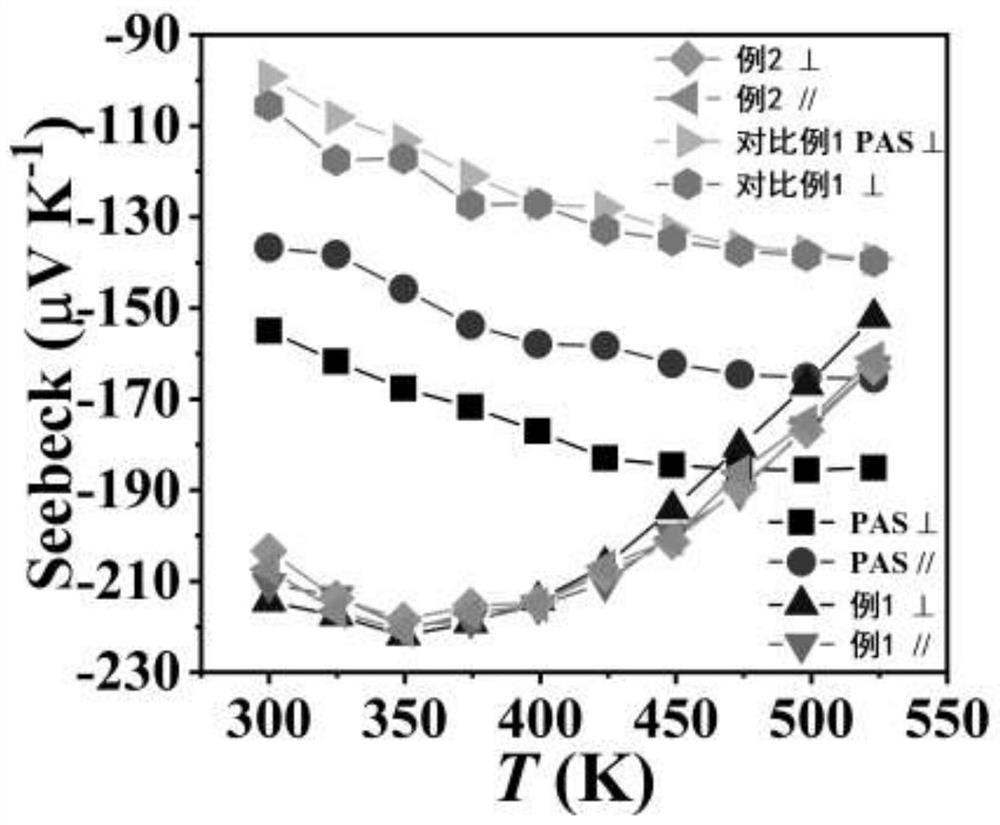

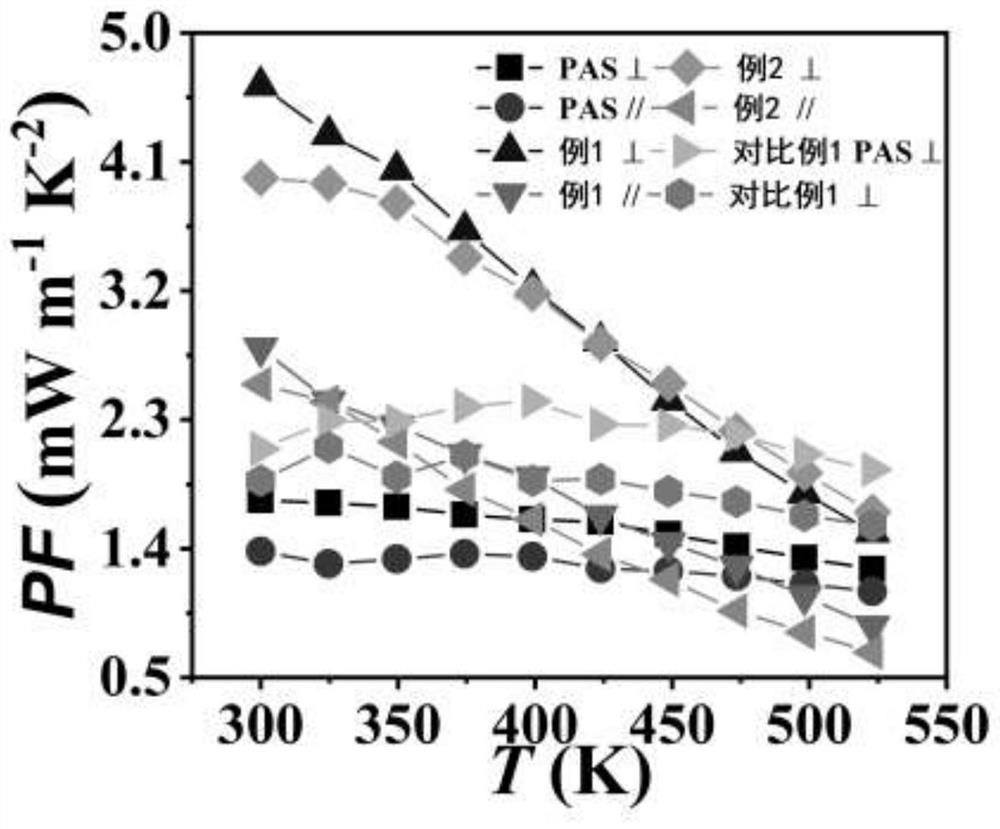

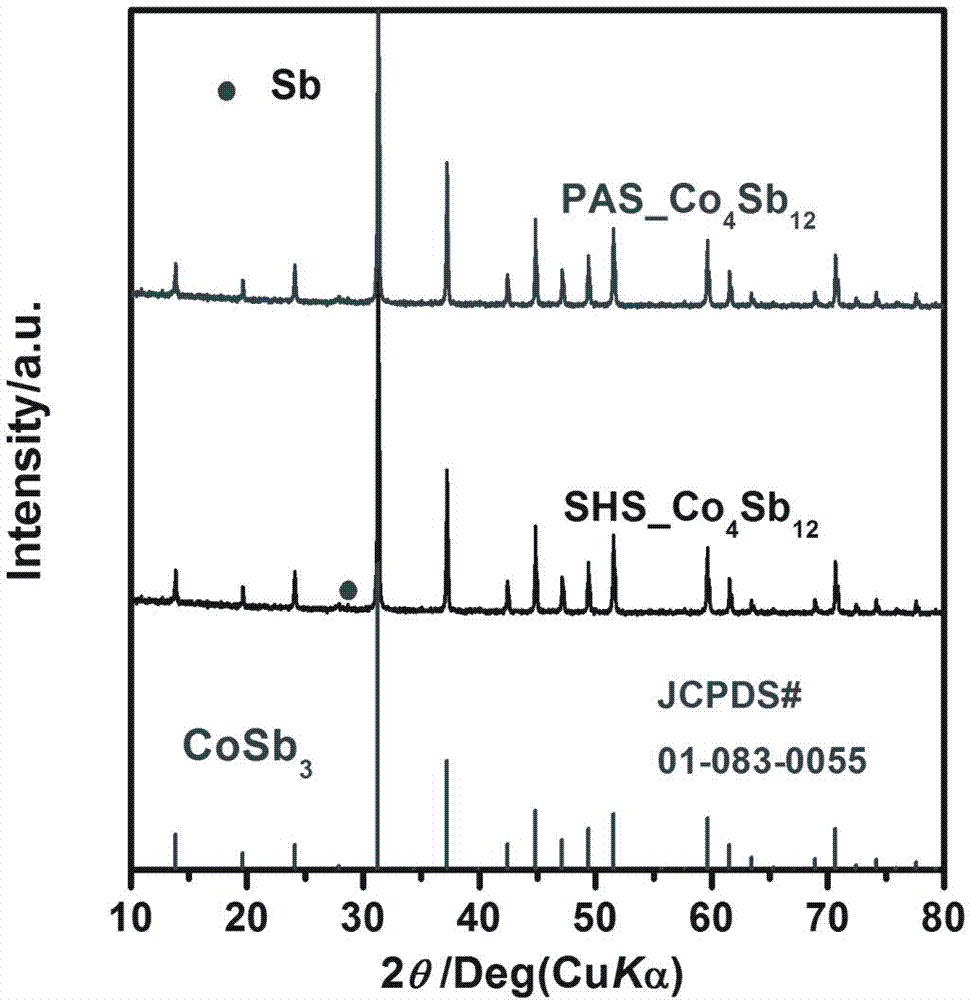

New method for synthesis of super fast prepared high performance CoSb3-based thermoelectric material by self-propagating combustion

ActiveCN103924109AQuick responseGood repeatabilityThermoelectric device junction materialsPhysical chemistryMaterials science

The invention relates to a new method for synthesis of a super fast prepared high performance CoSb3-based thermoelectric material by self-propagating combustion. The new method comprises the following steps: 1) weighing Co powder, M powder, Sb powder and Te powder as raw materials according to stoichiometric ratio of each element in the chemical formula Co4-xMxSb12-yTey, wherein 0<= x <=1.0, 0<= y <=1.0, M is Fe or Ni, the raw material powder is mixed and pressed into a bulk blank body; 2) triggering high temperature self-propagating synthesis reaction of the bulk blank body obtained by the step 1), and after the reaction cooling to obtain a single phase CoSb3 compound; 3) grinding the product of the step 2) into powder for discharge plasma activated sintering to obtain the pure single phase high performance CoSb3-based thermoelectric material. The method has the advantages of fast reaction speed, simple process, high efficiency, energy conservation, good repeatability, and the like. The whole preparation process can be completed in 20min, and the bulk thermoelectric figure of merit (ZT) is 0.98 at 875K.

Owner:WUHAN UNIV OF TECH

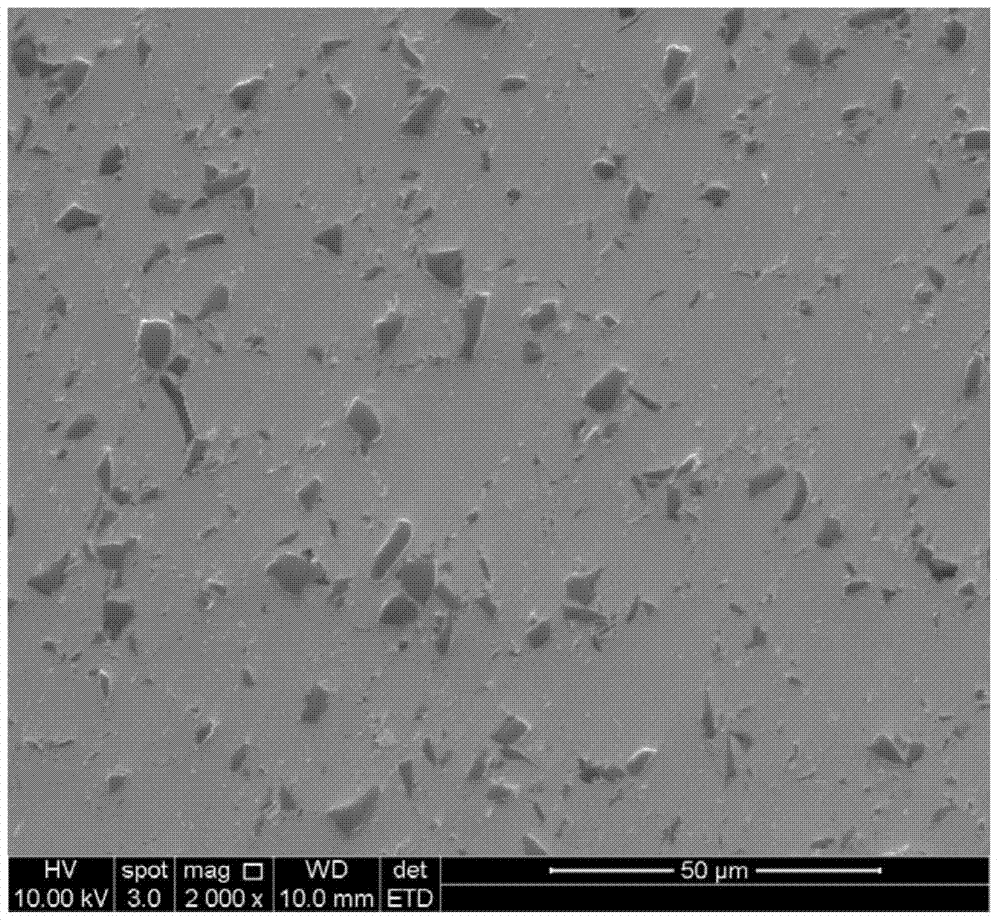

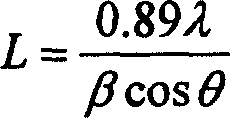

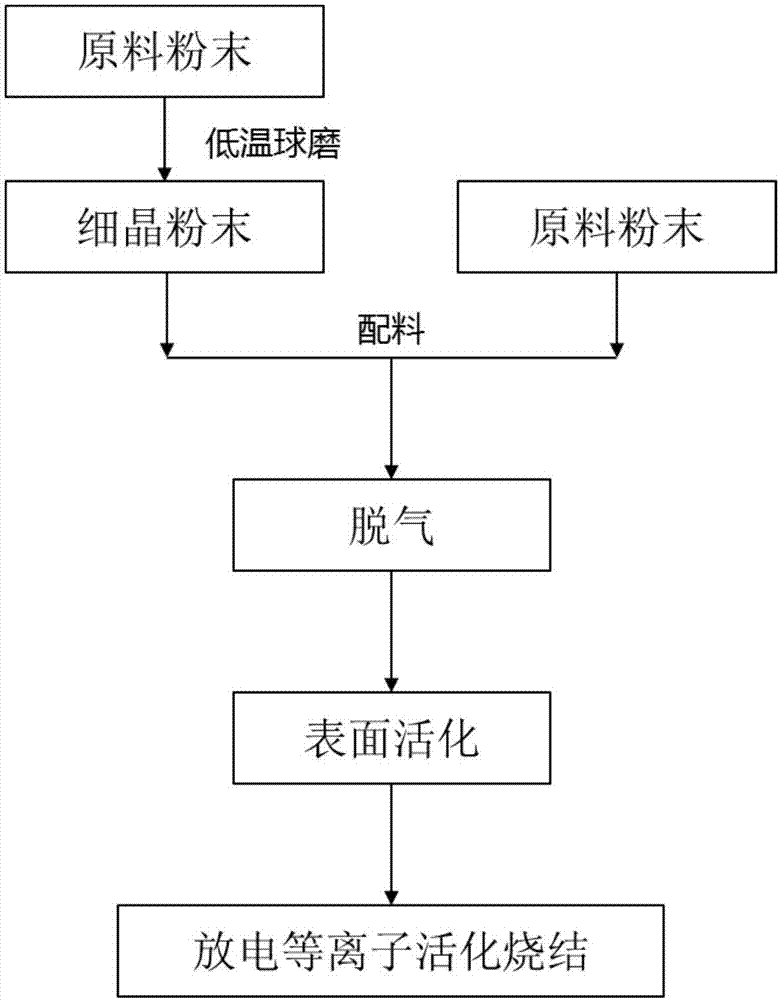

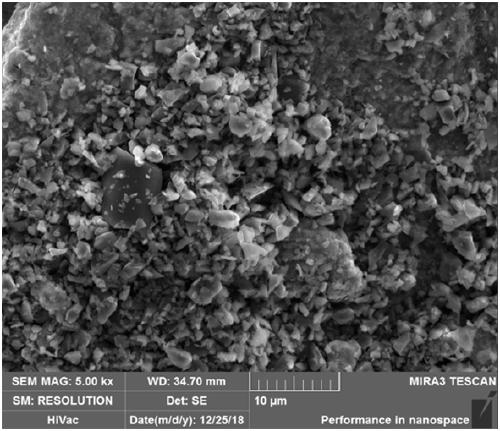

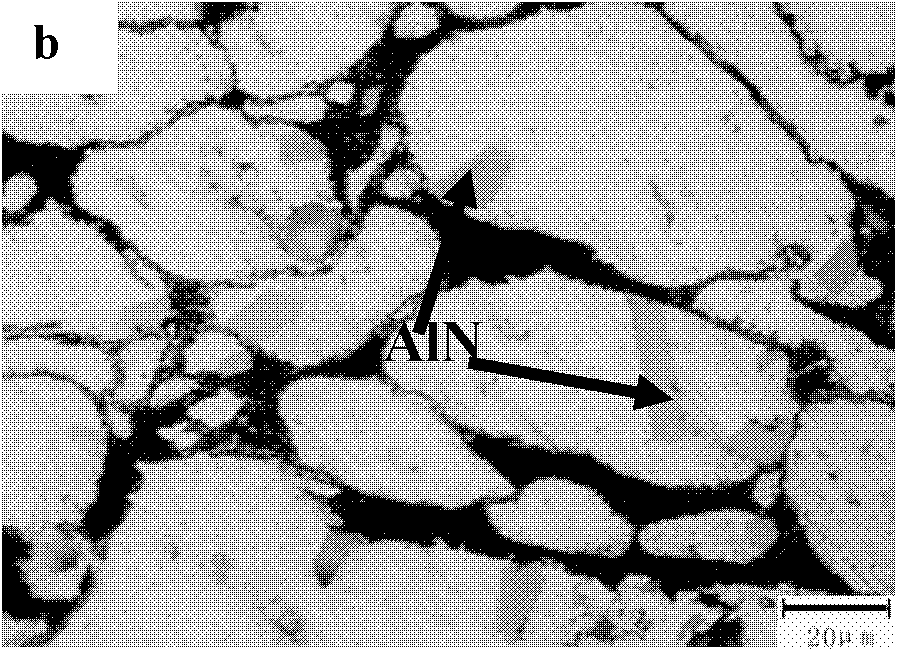

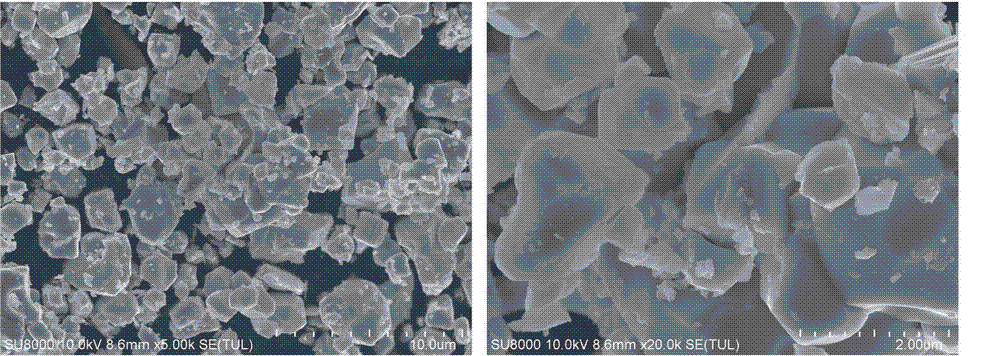

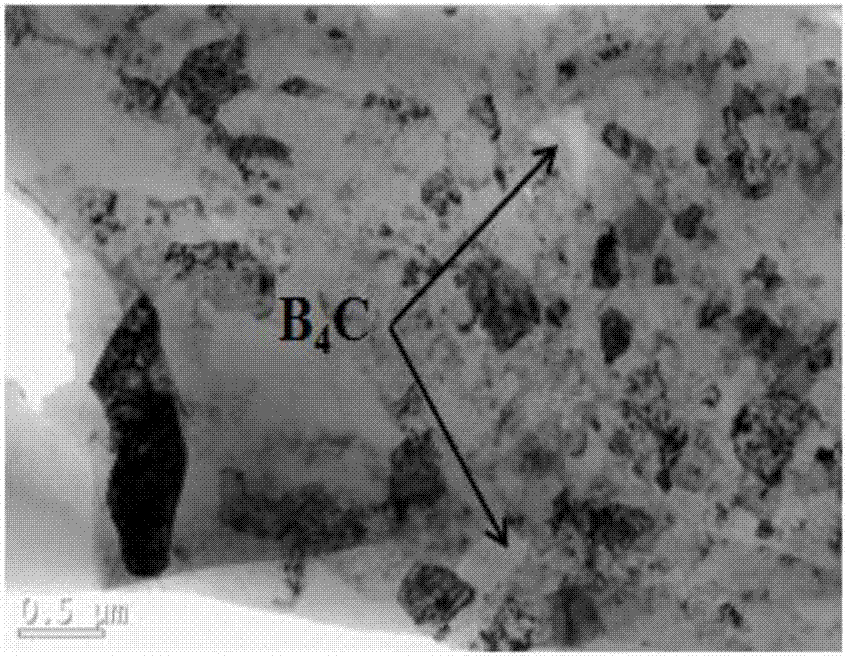

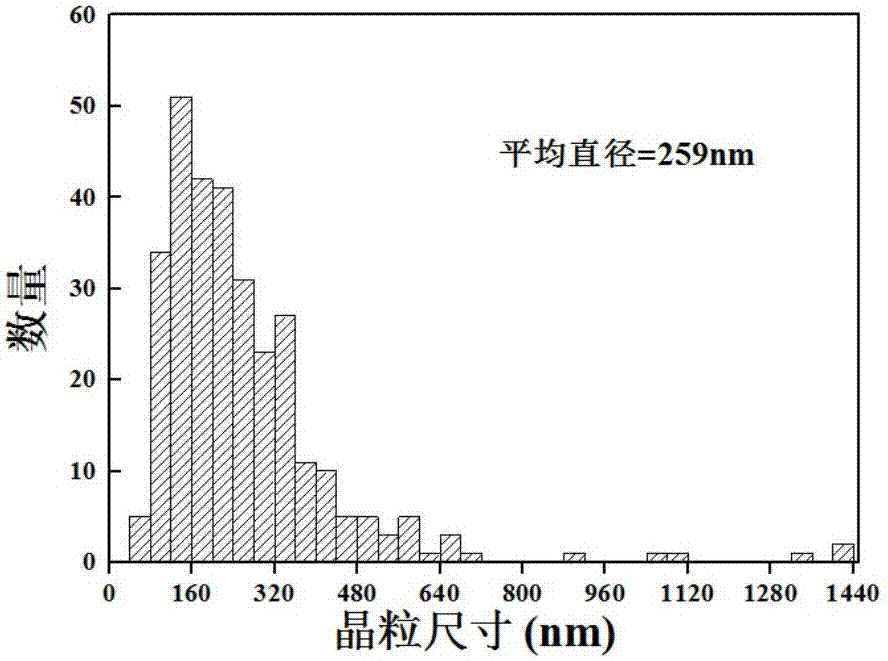

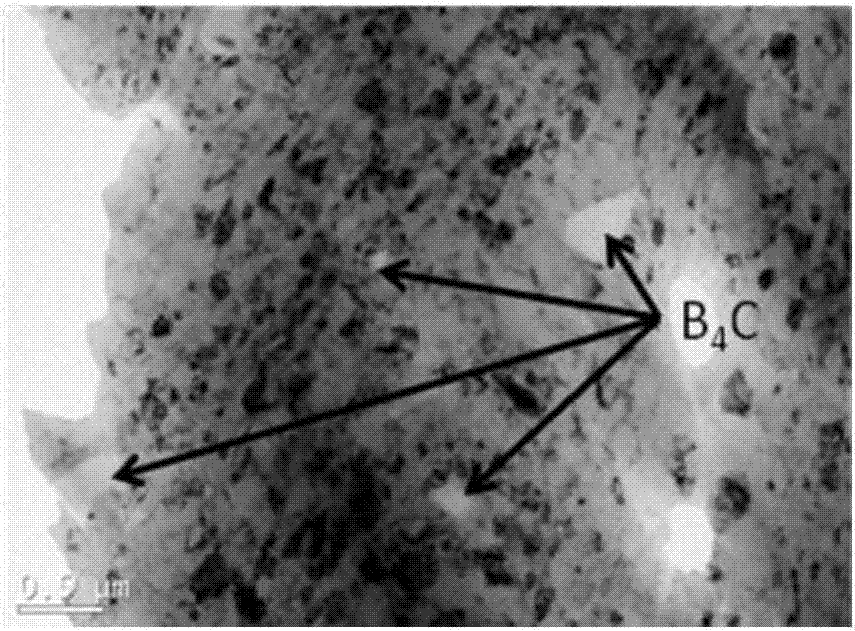

Preparation method for boron carbide particle reinforced nanometer/ultra-fine grain aluminum based composite

The invention relates to a preparation method for a boron carbide particle reinforced nanometer / ultra-fine grain aluminum based composite. According to the method, a low-temperature ball milling method is adopted for preparing nanometer compound powder and plasma activated sintering (PAS) is adopted for realizing the low-temperature compaction of the nanometer compound powder. The preparation method comprises the five steps of mixing raw materials, performing low-temperature ball milling, exhausting, performing discharging plasma activated sintering and perfoming thermal treatment, thereby obtaining the high-compactness nanometer / ultra-fine grain aluminum based composite. The nanometer / ultra-fine grain aluminum based composite prepared according to the invention has the advantages of high compactness, small grain size and excellent mechanical property; the compactness is more than or equal to 90%, the grain size of a substrate is less than 200nm, the hardness reaches up to 242.5HV and the compression yield strength reaches up to 866MPa; the boron carbide particle reinforced nanometer / ultra-fine grain aluminum based composite can be widely applied to the technical fields of aerospace, automobiles and military.

Owner:WUHAN UNIV OF TECH

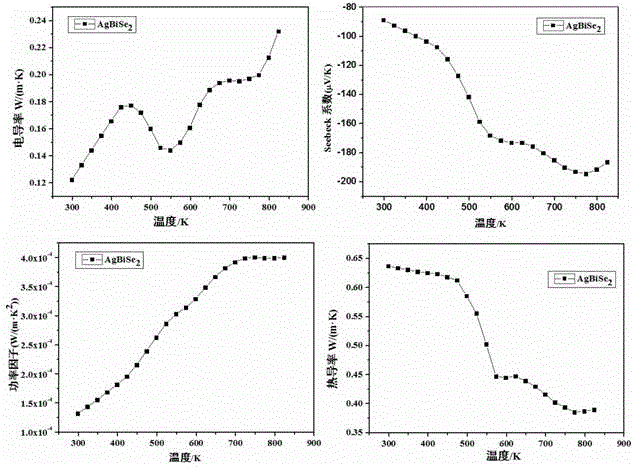

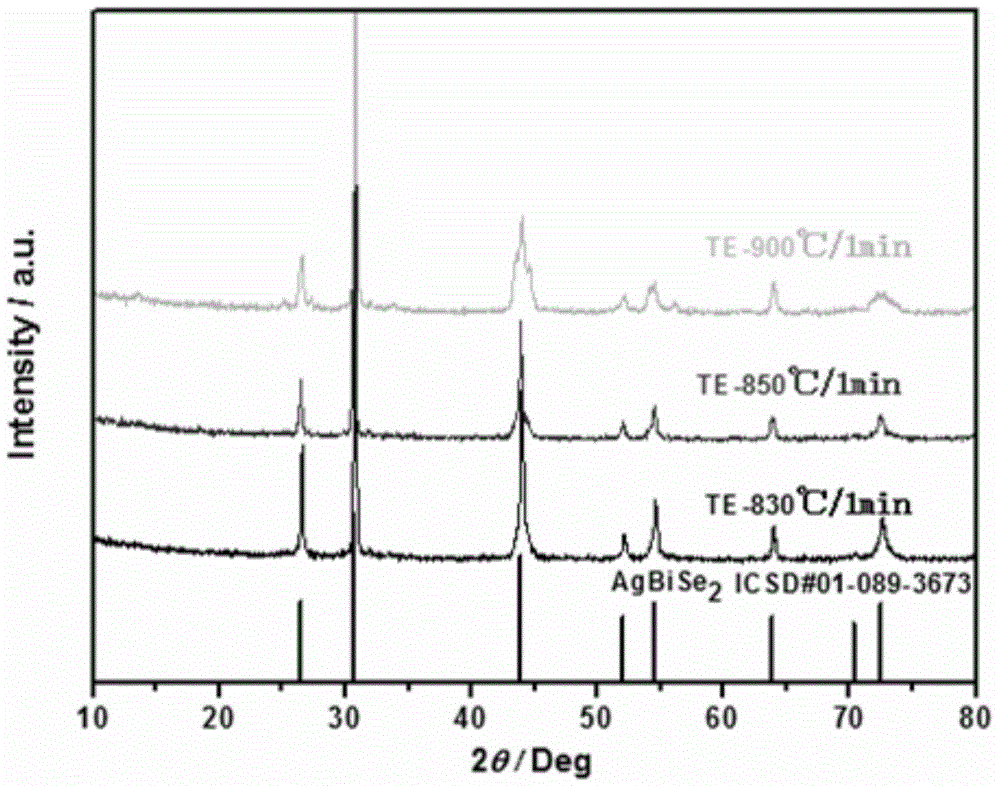

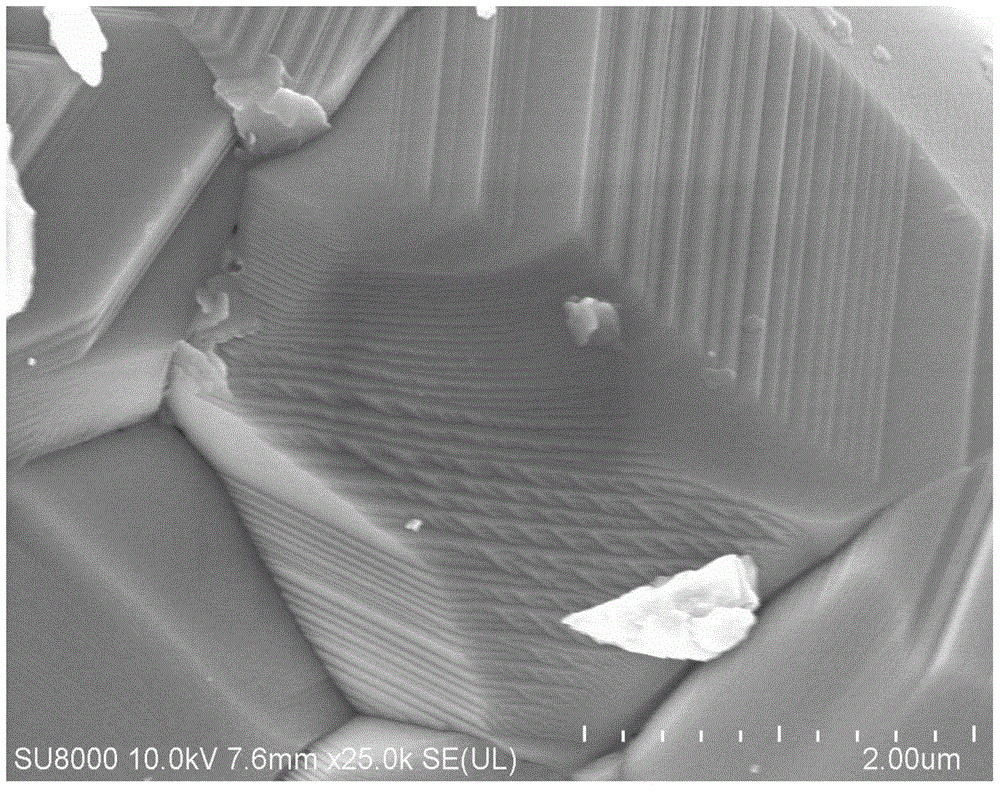

Method for rapid preparation of high performance AgBiSe2 block thermoelectric material

The invention provides a method for rapid preparation of a high performance AgBiSe2 block thermoelectric material, and the method comprises the following steps: 1) according to the stoichiometric ratio of 1:1:2, respectively weighing Ag powder, Bi powder and Se powder as raw materials, grinding the raw material powder then evenly mixing and pressing into a block; 2) performing thermal explosion reaction on the block obtained in the step 1), and after the reaction, naturally cooling to obtain single phase AgBiSe2 compound; 3) grinding the AgBiSe2 compound obtained in the step 2) into powder, performing discharge plasma activated sintering to obtain the high performance AgBiSe2 block thermoelectric material. According to the method, rapid thermal explosion reaction and discharge plasma activated sintering process are combined for preparation of the AgBiSe2 block thermoelectric material with ZT reaching 0.85 (at 550 DEG C) within 30min, and the method has the advantages of short preparation time, low energy consumption, simple process, low requirements on equipment, suitability for large-scale production, and the like.

Owner:WUHAN UNIV OF TECH

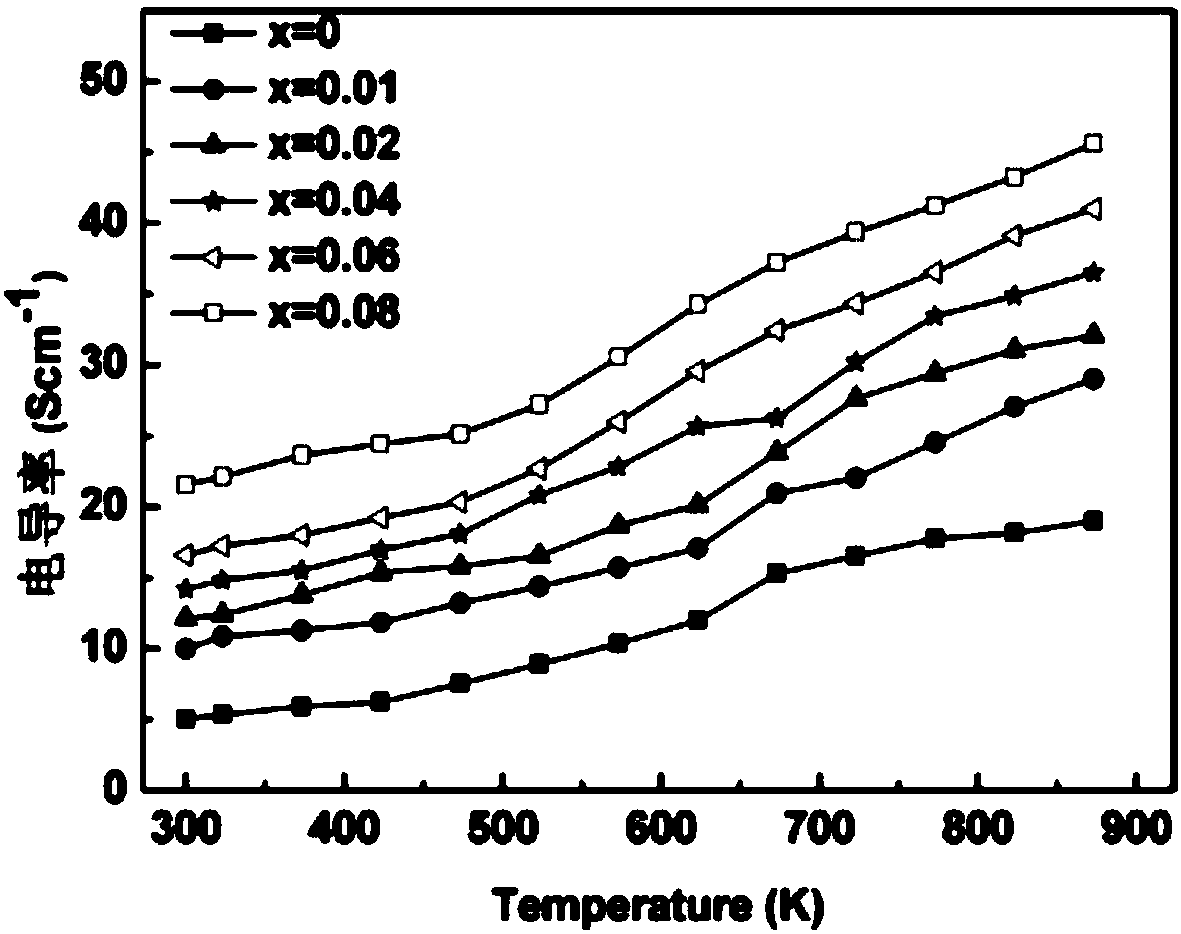

Pb/Ba double doped BiCuSeO thermoelectric material and preparation method thereof

ActiveCN107994115AShort activation and sintering timeShorten the production cycleThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsElectricity

The invention relates to a Pb / Ba double doped BiCuSeO thermoelectric material and a preparation method thereof. The method is characterized in that the material is prepared from bismuth oxide powder,copper powder, selenium powder, bismuth powder, lead powder and barium oxide powder in mass ratio of (1-x):3:3:(1-4x):3x:3x; the powders are mixed uniformly, ball milling is conducted on the powders in a mill pot under an inert atmosphere for 5-12 hours; the milled PbxBaxBi1-2xCuSeO powder is put into a mould, the mould is placed in a plasma activated sintering furnace, meanwhile the temperature is increased to 500-700 DEC G in a uniform speed and the pressure is increased to 30-100 MPa in a uniform speed, the temperature maintaining and pressure maintaining are conducted, then the temperatureis reduced to the normal temperature in a uniform speed, and the pressure is reduced to the normal pressure in a uniform speed; the sintered mould is taken out, and demoulding is conducted to obtainthe Pb / Ba double doped BiCuSeO thermoelectric material, wherein 0.01<=x<=0.08. The method has the advantages of simple process, short production cycle and high production efficiency, and the preparedproducts have the advantages of high purity, low thermal conductivity, high electrical conductivity, good electrical transmission performance, high power factor and high non-dimensional thermoelectricfigure of merit ZT.

Owner:WUHAN UNIV OF SCI & TECH

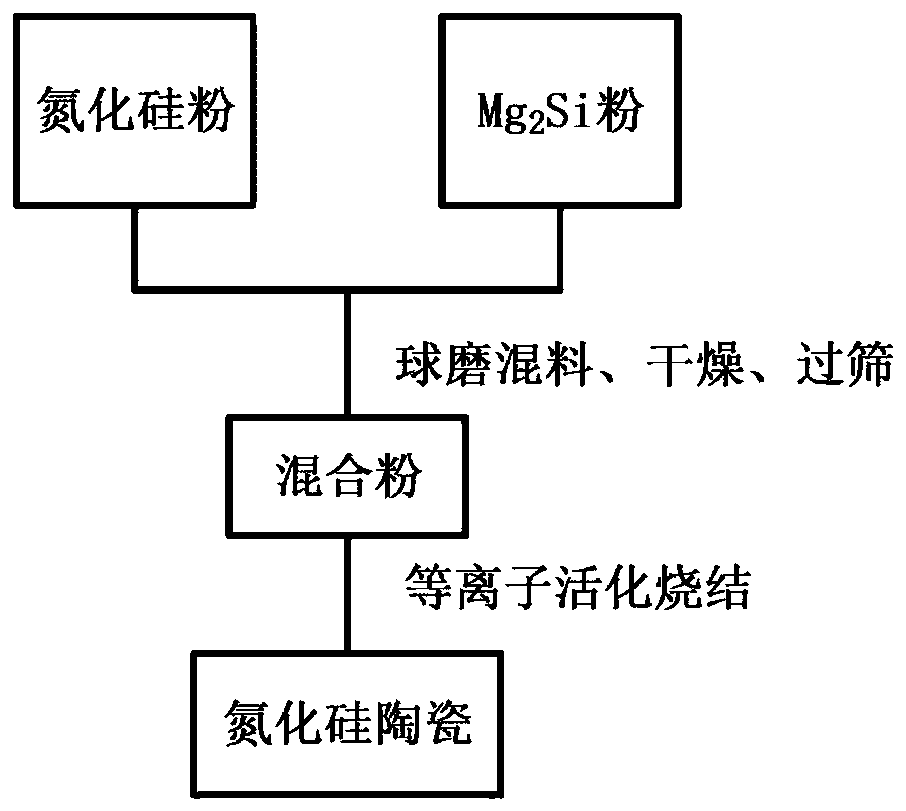

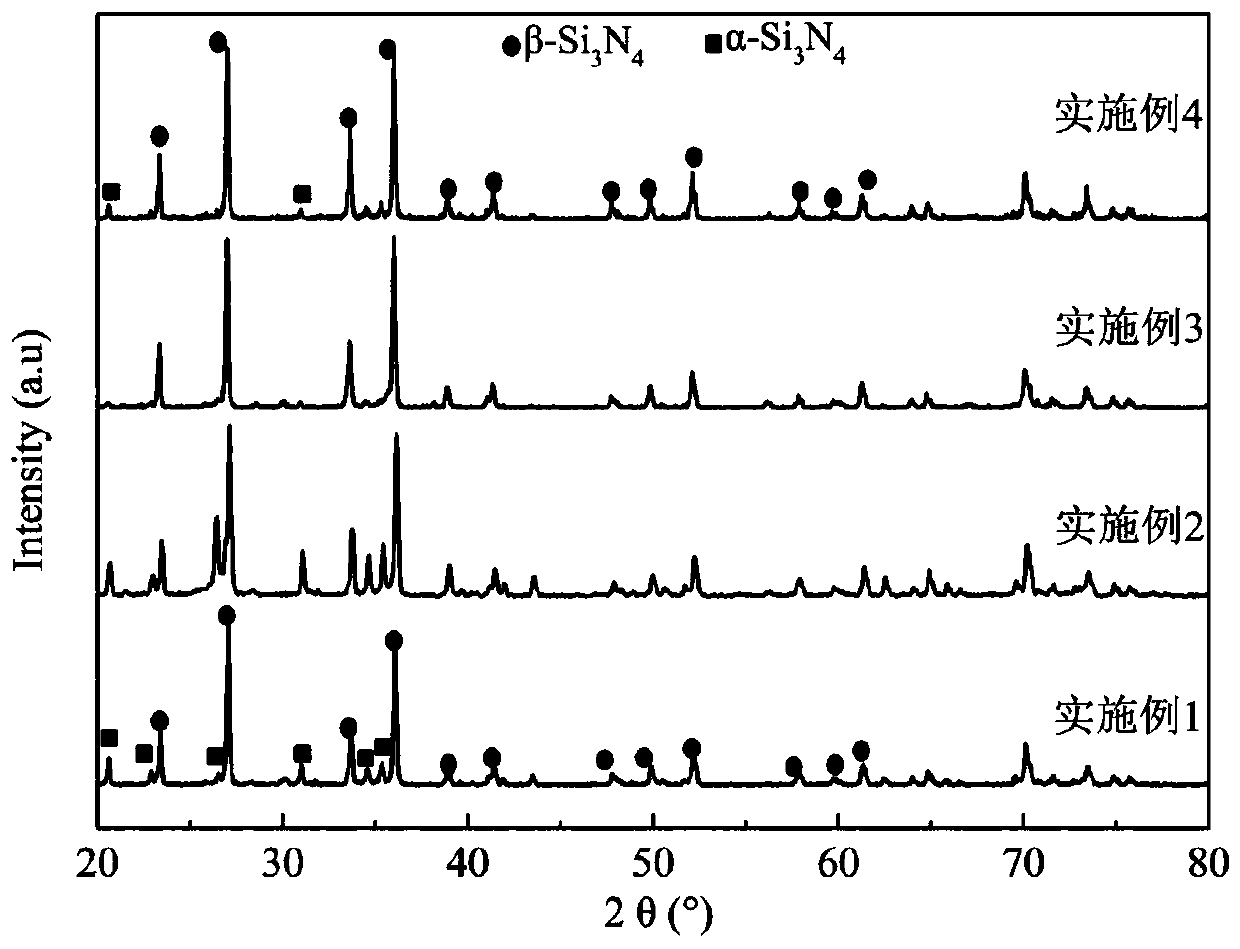

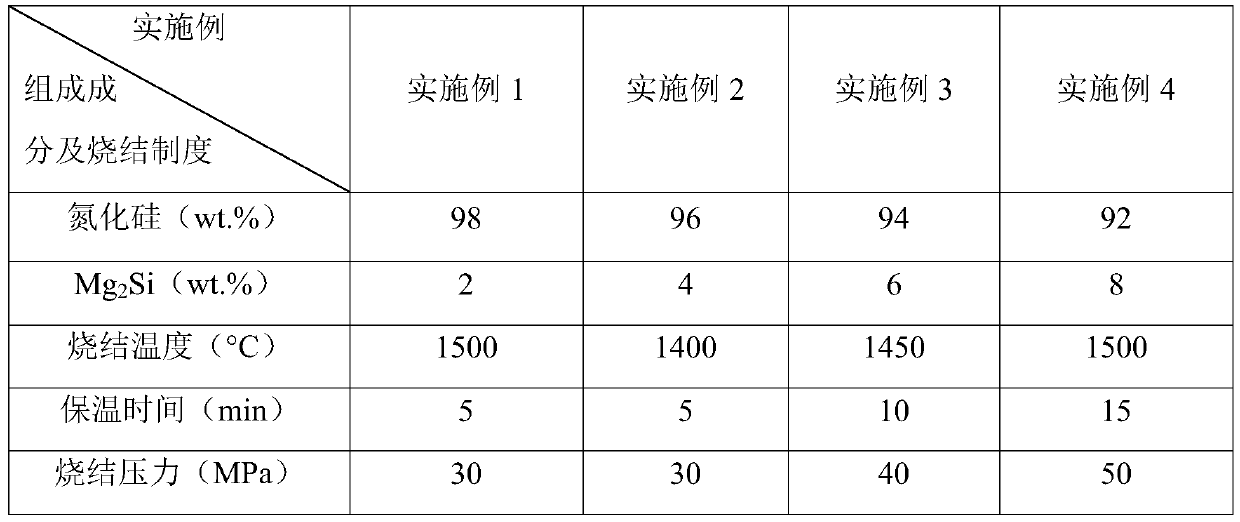

Low-temperature preparation method of high-strength silicon nitride ceramic

InactiveCN110204343AOvercome the disadvantages of high and high sintering temperatureLower sintering temperatureHigh densityNitrogen

The invention relates to a low-temperature preparation method of high-strength silicon nitride ceramic. The silicon nitride ceramic is prepared by sintering at 1400-1500 DEG C in a nitrogen atmospherethrough a plasma activated sintering process with low-melting Mg2Si as a sintering aid. The silicon nitride ceramic prepared by the method has a density being higher than 97% and a bending strength of 644-1056 MPa. The method has the advantages of simple process, and low price of raw materials; and the prepared silicon nitride ceramic material has a high density and a high bending strength, and has broad application prospects in the fields of thermally conductive ceramic substrates, metallurgy and chemical engineering.

Owner:WUHAN UNIV OF TECH

Preparation process of pure Fe3C blocks

The invention discloses a preparation process of pure Fe3C blocks. The preparation process comprises the following steps: firstly, weighing reducing Fe powder and amorphous C powder in a weight ratio converted from the atomic ratio and the atomic weights of various elements in the molecular formula Fe3C, putting the weighed materials into a ball milling jaw, and meanwhile, adding a certain amount of phenolic resin and vacuumizing; secondly, putting the ball milling jar into a ball mill for ball milling for 60-120 hours, taking the mixture of the reducing Fe powder and the amorphous C powder and arranging the mixture into a graphite crucible; finally, putting the graphite crucible into a plasma activating sintering furnace for two stages of vacuum sintering, namely slow pressureless sintering at a temperature ranging from 150 to 300 DEG C at the first stage and fast pressure sintering at a temperature ranging from 500 to 700 DEG C at the second stage, and cooling along with the furnace, thereby obtaining the pure Fe3C blocks.

Owner:XI AN JIAOTONG UNIV

Fe-doped BiCuSeO thermoelectric material and preparation method thereof

InactiveCN107644933AShorten the production cycleSimple processThermoelectric device manufacture/treatmentThermoelectric device junction materialsTransmission performanceTemperature and pressure

The invention relates to a Fe-doped BiCuSeO thermoelectric material and a preparation method thereof. The preparation method is characterized by comprising the steps of: preparing materials accordingto an amount-of-substance ratio of bismuth oxide powder to copper powder to selenium powder: bismuth powder to iron powder being 1:3:3:(1-3y):3y, wherein 0.01<=3y = x <=0.08, mixing the powder, putting the mixed powder into a ball-milling tank, performing ball milling on the mixed powder under the condition of an inert atmosphere to prepare single-phase FexBi1-XCuSeO powder, putting the single-phase FexBi1-XCuSeO powder into a mold, placing the mold in a plasma activated sintering furnace, raising the temperature to 500-700 DEG C at a constant speed and raising the pressure to 30-100 MPa at aconstant speed simultaneously, maintaining the temperature and pressure simultaneously, then reducing the temperature to normal temperature at a constant speed and reducing the pressure to normal pressure at a constant speed simultaneously, taking out the sintered mold, and demolding to obtain the Fe-doped BiCuSeO thermoelectric material. The preparation method has the advantages of simple process, short production cycle and high production efficiency. The prepared product has the advantages of high purity, low thermal conductivity, high electrical conductivity, good electrical transmission performance, high power factor and high dimensionless thermoelectric figure of merit ZT.

Owner:WUHAN UNIV OF SCI & TECH

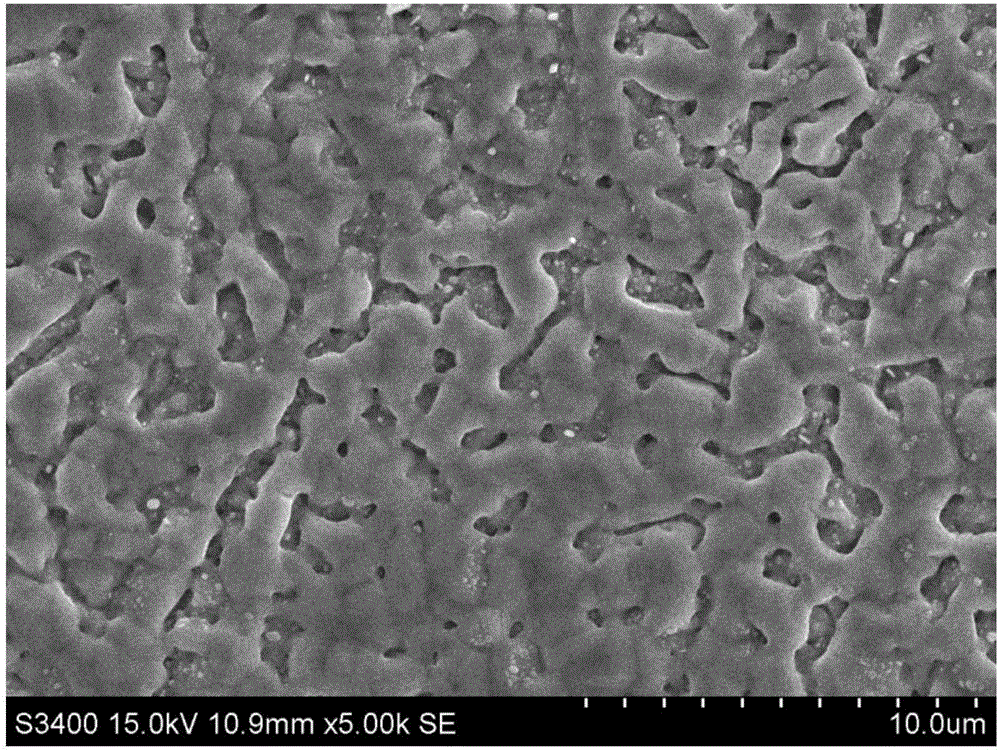

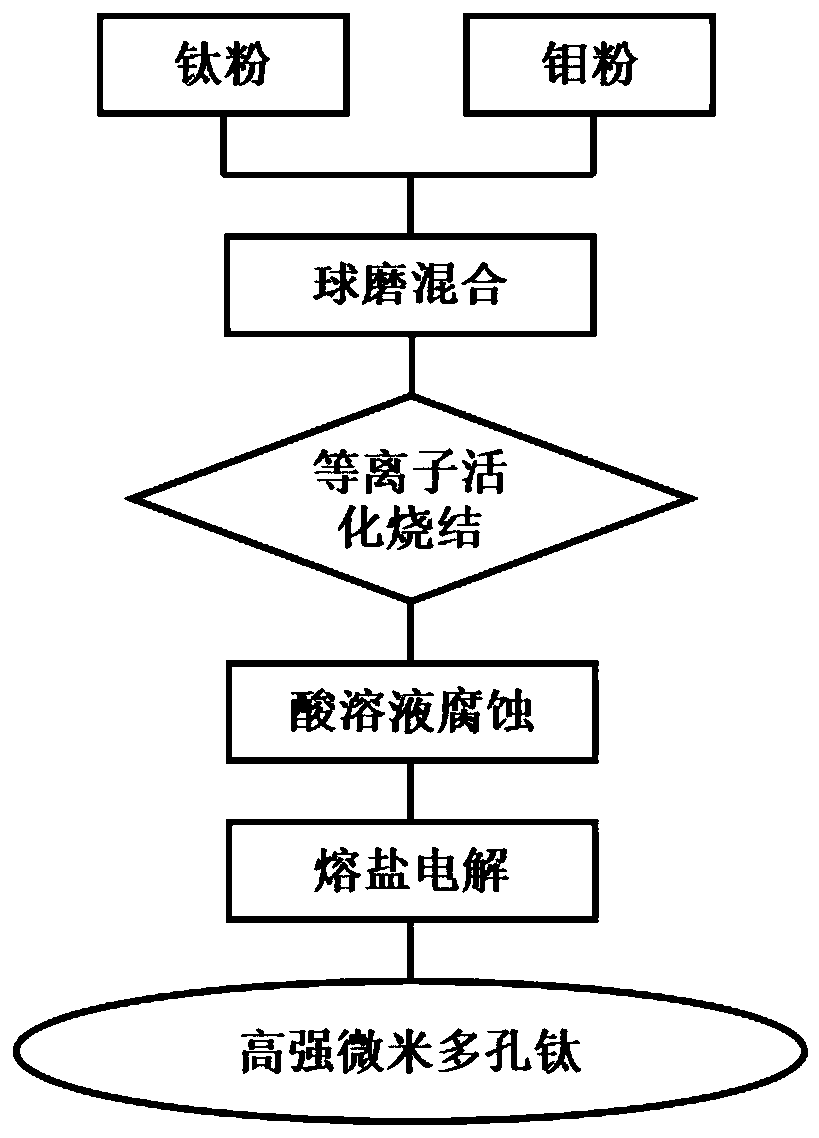

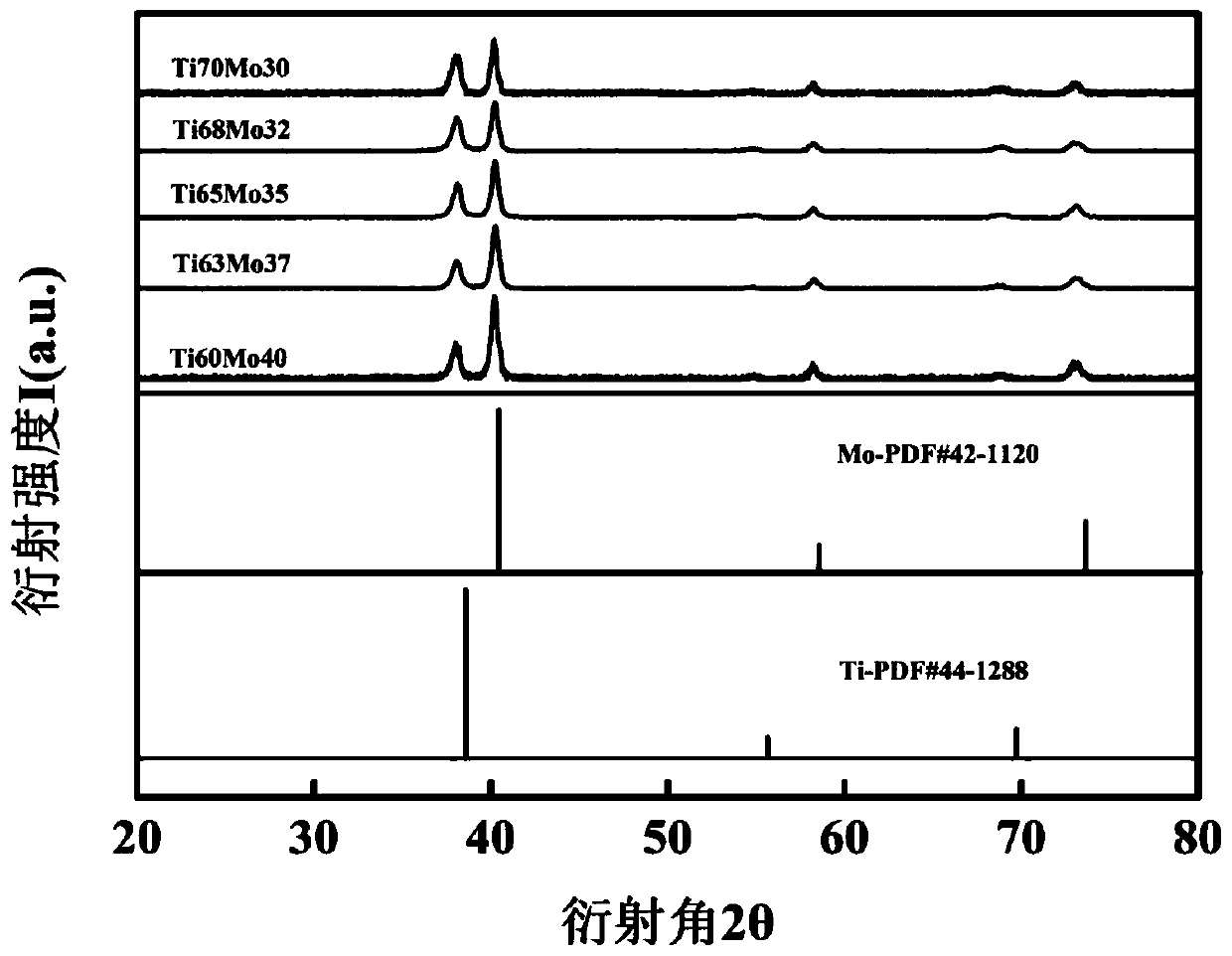

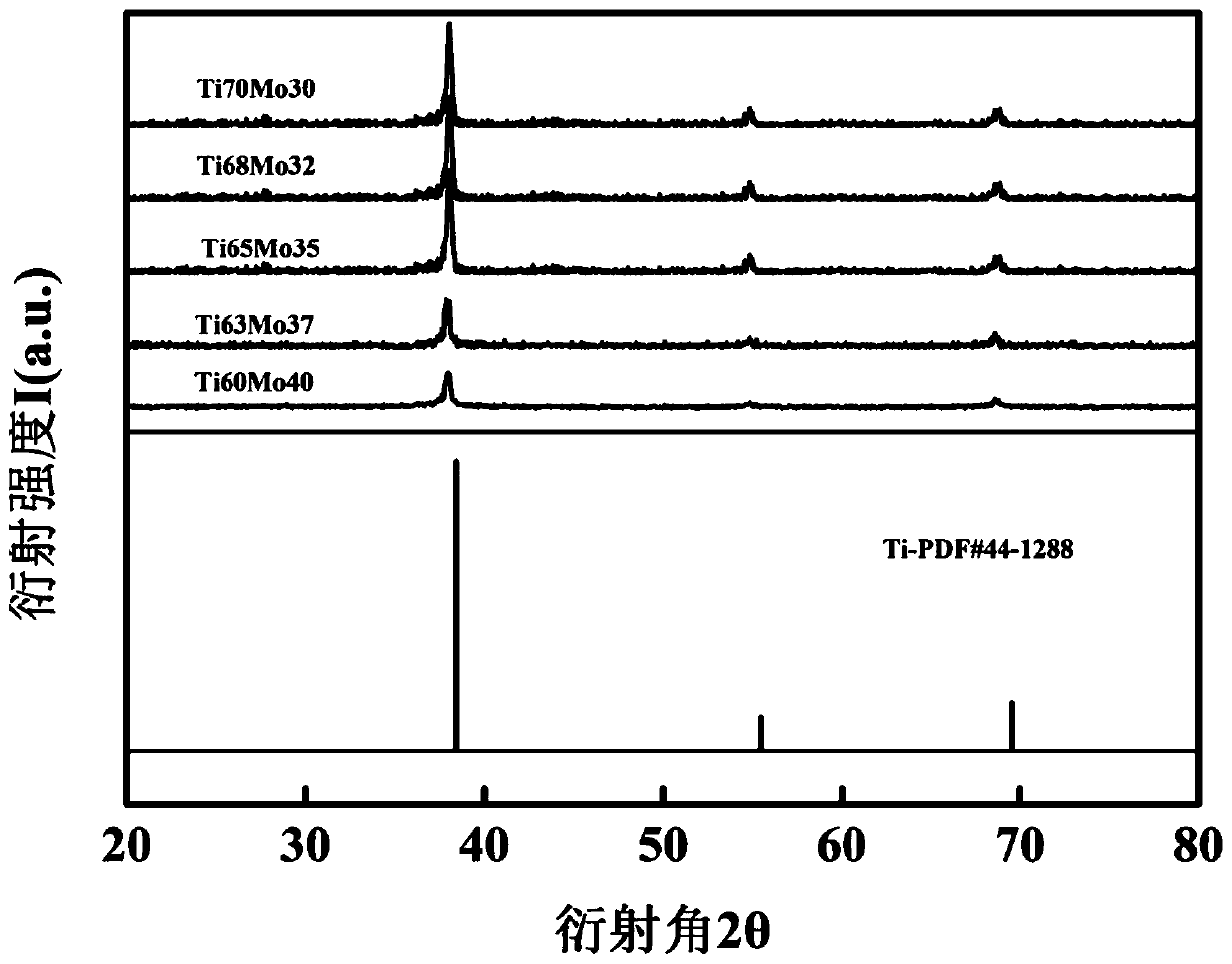

Method for preparing high-strength micro porous metallic titanium block by dealloying titanium-molybdenum alloy

The invention provides a method for preparing a high-strength micro porous metallic titanium block by dealloying a titanium-molybdenum alloy. The method is characterized in that the titanium-molybdenum alloy is treated through plasma activated sintering, molybdenum in the alloy is corroded selectively in a dealloying manner, obtained porous titanium is subjected to deoxidation and secondary sintering by the combination with a molten salt electrolysis method, so that the purity and the mechanical performance of a porous titanium block are greatly improved, and the high-strength porous titaniumblock is obtained. A titanium-molybdenum bicontinuous three-dimensional network-structured titanium-molybdenum alloy is prepared through plasma activated sintering; the pore structure of the porous metallic titanium block is regulated and controlled by changing the content of titanium and molybdenum elements; the obtained porous titanium is subjected to deoxidation and secondary sintering by adopting the molten salt electrolysis method, so that the purity and the mechanical performance of the porous titanium block are greatly improved; the high-strength porous titanium block of which the aperture is 5-10 [mu]m, the porosity is 78.5%-44.6%, and the compressive strength can reach 152.3 MPa can be obtained by adopting the process; and the method has the advantages of simple process, low cost,high practicability and the like.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com