Fe-doped BiCuSeO thermoelectric material and preparation method thereof

A thermoelectric material and particle size technology, which is applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., can solve problems such as low dimensionless thermoelectric figure of merit ZT, poor electrical transport performance, and low power factor , to achieve the effects of improving electrical transport performance, high production efficiency, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An Fe-doped BiCuSeO thermoelectric material and a preparation method thereof. The steps of the preparation method are:

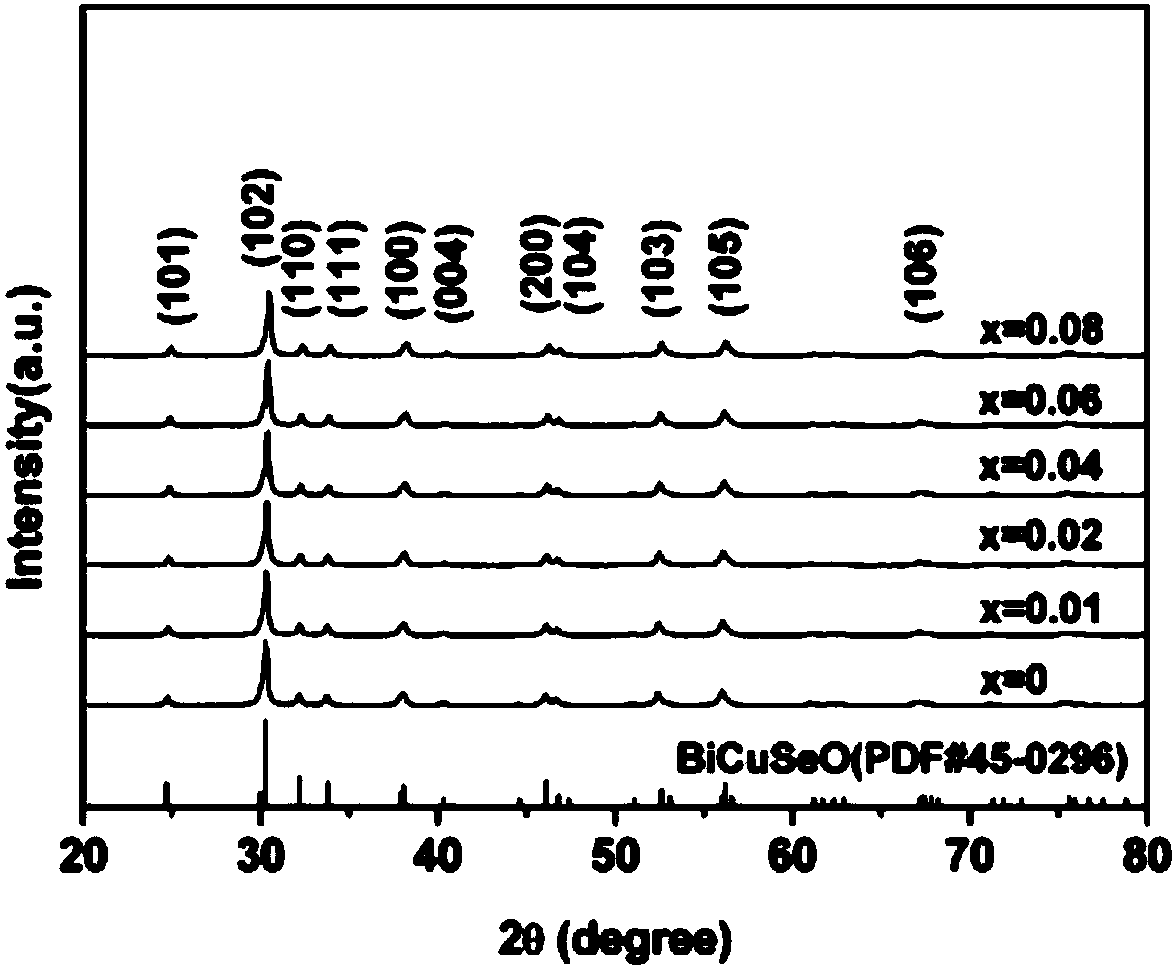

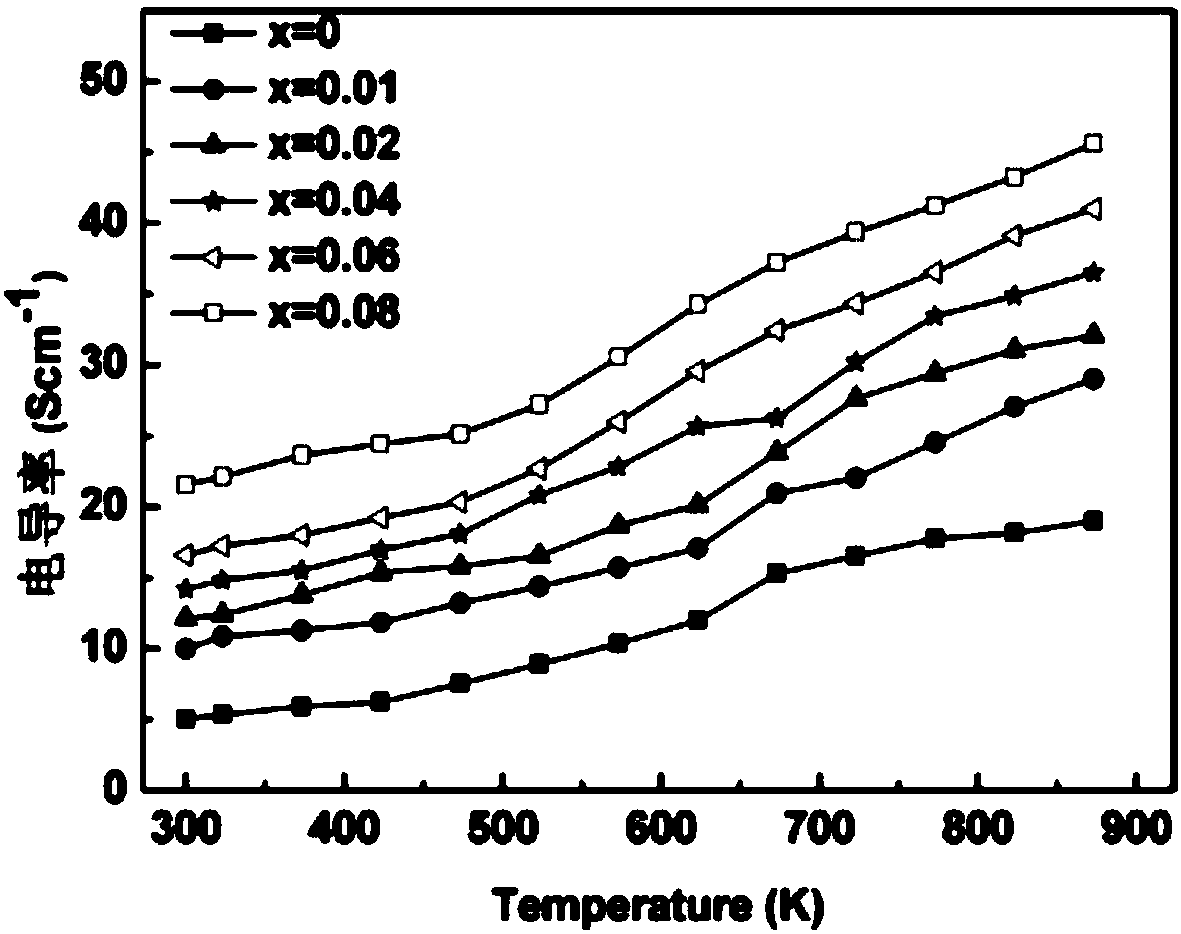

[0038] The chemical formula of the Fe-doped BiCuSeO thermoelectric material is Fe x Bi 1-x CuSeO, 0.01≤x≤0.02.

[0039] The first step, according to bismuth oxide powder: copper powder: selenium powder: bismuth powder: the ratio of the amount of substance of iron powder is 1: 3: 3: (1-3y): 3y batching, 0.01≤3y=x≤0.02, Then mix evenly to obtain mixed powder.

[0040] In the second step, the mixed powder is put into a ball mill jar, and ball milled for 5-8 hours under an inert atmosphere to obtain a single-phase Fe x Bi 1-x CuSeO powder, 0.01≤x≤0.02.

[0041] The third step, the single-phase Fe x Bi 1-x Put the CuSeO powder into the mold, place it in the plasma activated sintering furnace, and then start to raise the temperature and pressure at a constant speed at the same time, and raise the temperature to 500-600°C and the pressure to 30-50MPa...

Embodiment 2

[0047] An Fe-doped BiCuSeO thermoelectric material and a preparation method thereof. The steps of the preparation method are:

[0048] The chemical formula of the Fe-doped BiCuSeO thermoelectric material is Fe x Bi 1-x CuSeO, 0.02≤x≤0.06.

[0049] The first step, according to bismuth oxide powder: copper powder: selenium powder: bismuth powder: the ratio of the amount of substance of iron powder is 1: 3: 3: (1-3y): 3y batching, 0.02≤3y=x≤0.06, Then mix evenly to obtain mixed powder.

[0050] In the second step, the mixed powder is put into a ball mill jar, and ball milled for 5-8 hours under an inert atmosphere to obtain a single-phase Fe x Bi 1-x CuSeO powder, 0.02≤x≤0.06.

[0051] The third step, the single-phase Fe x Bi 1-x Put the CuSeO powder into the mold, place it in the plasma activated sintering furnace, and then start to raise the temperature and pressure at a constant speed at the same time, and raise the temperature to 500-600°C and the pressure to 30-50MPa...

Embodiment 3

[0057] An Fe-doped BiCuSeO thermoelectric material and a preparation method thereof. The steps of the preparation method are:

[0058] The chemical formula of the Fe-doped BiCuSeO thermoelectric material is Fe x Bi 1-x CuSeO, 0.06≤x≤0.08.

[0059] The first step, according to bismuth oxide powder: copper powder: selenium powder: bismuth powder: the ratio of the amount of substance of iron powder is 1: 3: 3: (1-3y): 3y batching, 0.06≤3y=x≤0.08, Then mix evenly to obtain mixed powder.

[0060] In the second step, the mixed powder is put into a ball mill jar, and ball milled for 5-8 hours under an inert atmosphere to obtain a single-phase Fe x Bi 1-x CuSeO powder, 0.06≤x≤0.08.

[0061] The third step, the single-phase Fe x Bi 1-x Put the CuSeO powder into the mold, place it in the plasma activated sintering furnace, and then start to raise the temperature and pressure at a constant speed at the same time, and raise the temperature to 500-600°C and the pressure to 30-50MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com