Low-temperature preparation method of high-strength silicon nitride ceramic

A silicon nitride ceramic and high-strength technology, which is applied in the field of preparation of inorganic non-metallic materials, can solve the problems of inflammability, explosion, synthesis, and storage, and achieve the effects of low cost, lower sintering temperature, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

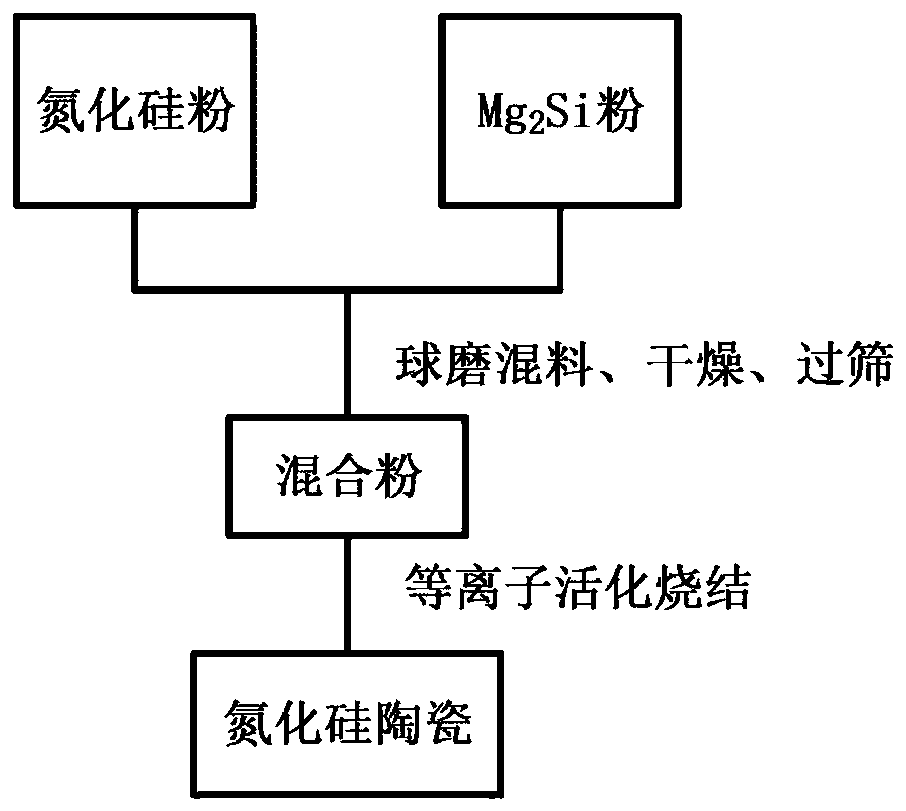

Method used

Image

Examples

Embodiment example

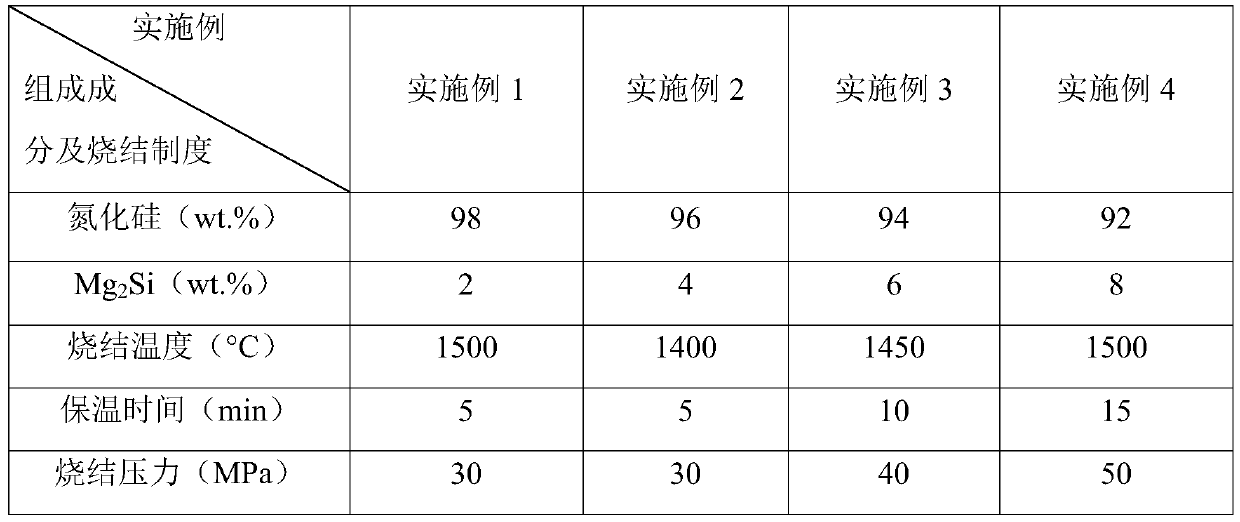

[0027] Table 1: Raw material ratios and related sintering parameters of silicon nitride ceramics in Examples 1-4 of the present invention.

[0028]

Embodiment 1

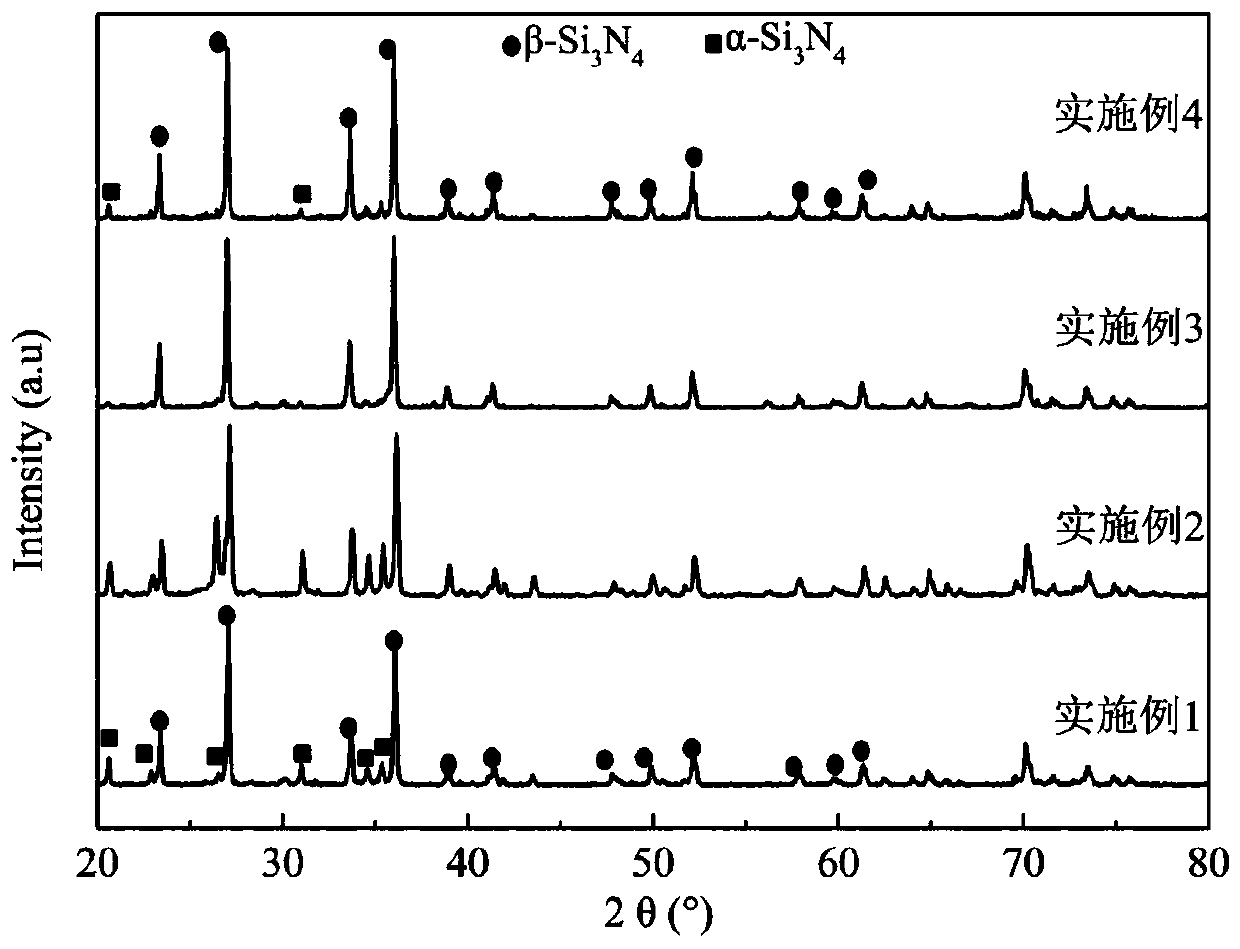

[0030] Set the mass fraction to 2.0% Mg 2 Mix Si powder and 98.0% silicon nitride powder, use absolute ethanol as the dispersion medium, put it into a nylon ball mill tank together with silicon nitride balls, and disperse for 24 hours by ball milling, take out the slurry and dry it, sieve it, and then put the powder into graphite Put the mold into a plasma activation sintering furnace and pressurize it to 30MPa, pass it into a nitrogen atmosphere for protection, raise the temperature to 1500°C, keep it warm for 5 minutes, and take out the sample after cooling to room temperature with the furnace to obtain silicon nitride ceramics. The XRD of the product see figure 2 . After testing, the density of the silicon nitride ceramic sample obtained in this embodiment is 97.2%, and the bending strength is 757 MPa.

Embodiment 2

[0032] Set the mass fraction to 4.0% Mg 2 Mix Si powder and 96.0% silicon nitride powder, use absolute ethanol as the dispersion medium, put it into a nylon ball mill jar together with silicon nitride balls, and disperse for 24 hours by ball milling. Take out the slurry and dry it, sieve it, and then put the powder into graphite Put the mold into a plasma activation sintering furnace and pressurize it to 30MPa, pass through a nitrogen atmosphere to protect and heat up to 1400°C, keep it warm for 5min, and take out the sample after cooling to room temperature with the furnace to obtain silicon nitride ceramics. The XRD of the product see figure 2 . After testing, the density of the silicon nitride ceramic sample obtained in this embodiment is 98.7%, and the bending strength is 644 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com