Pb/Ba double doped BiCuSeO thermoelectric material and preparation method thereof

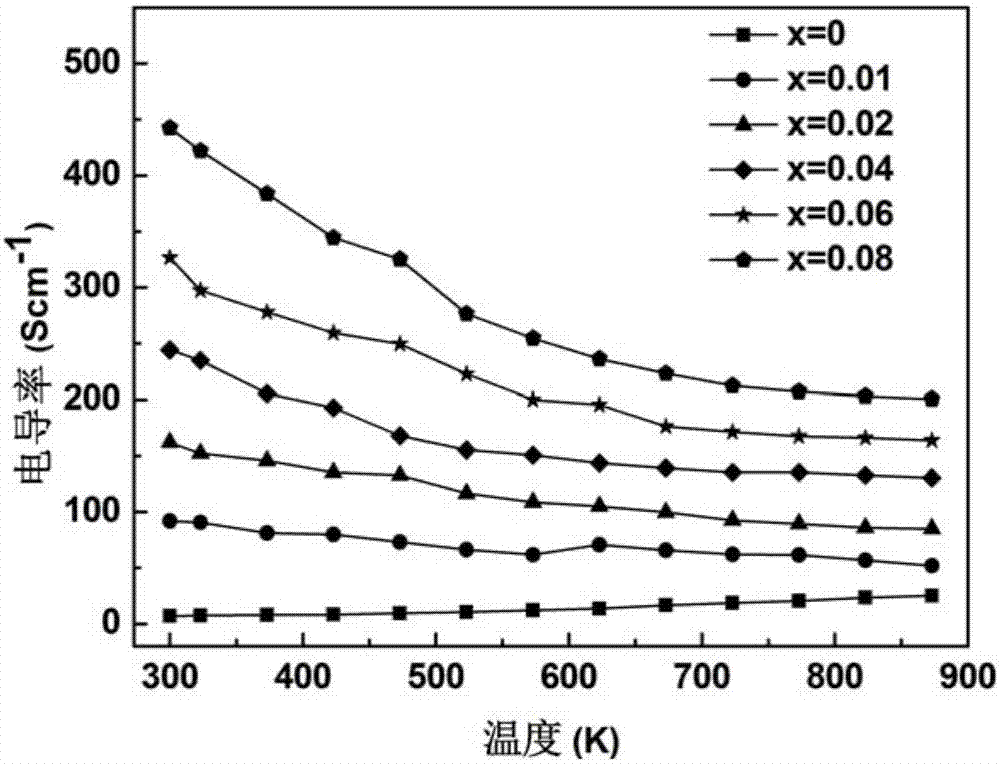

A thermoelectric material, double-doped technology, applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problems of low dimensionless thermoelectric figure of merit, poor electrical transport performance, low conductivity, etc. , to achieve the effect of improving the dimensionless thermoelectric figure of merit, high production efficiency, and reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

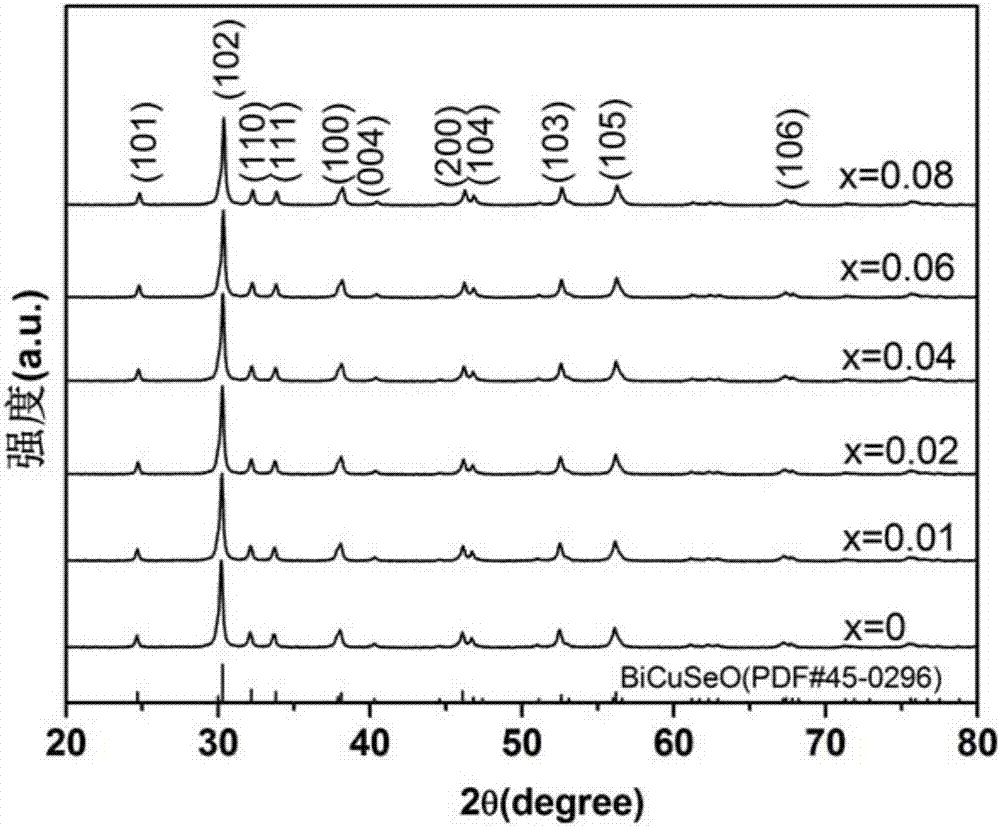

[0040] A Pb / Ba double-doped BiCuSeO thermoelectric material and a preparation method thereof. The chemical formula of the Pb / Ba double-doped BiCuSeO thermoelectric material described in this embodiment is Pb x Ba x Bi 1-2x CuSeO; The concrete steps of described preparation method are:

[0041] The first step, according to bismuth oxide powder: copper powder: selenium powder: bismuth powder: lead powder: the ratio of the amount of substance of barium oxide powder is (1-x): 3: 3: (1-4x): 3x: 3x The ingredients are mixed evenly to obtain a mixed powder.

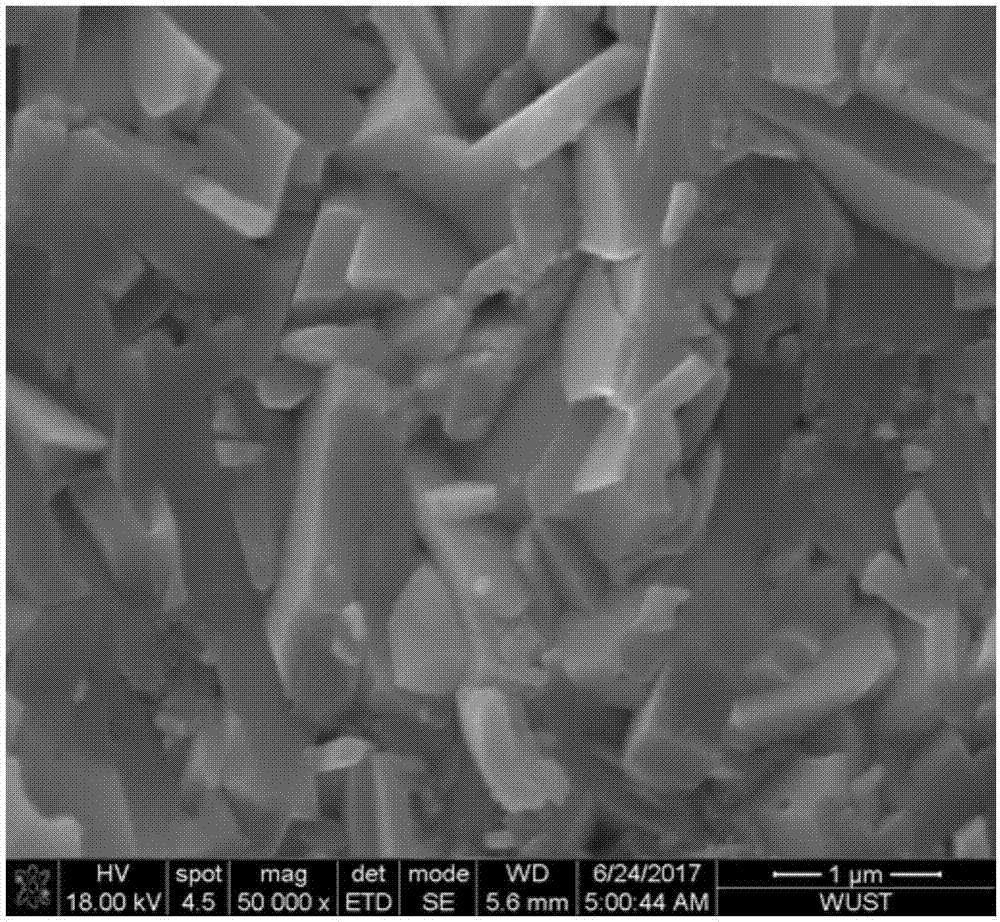

[0042] In the second step, the mixed powder is loaded into a high-energy planetary ball mill, and ball milled for 5 to 7 hours under an inert atmosphere. The mass ratio of the ball to material during ball milling is (10 to 15): 1, and the rotating speed is 200 to 350 r / min. Produced Pb x Ba x Bi 1-2x CuSeO powder.

[0043] The third step, the Pb x Ba x Bi 1-2xPut the CuSeO powder into the mold, place it in the plasma ...

Embodiment 2

[0049] A Pb / Ba double-doped BiCuSeO thermoelectric material and a preparation method thereof. The chemical formula of the Pb / Ba double-doped BiCuSeO thermoelectric material described in this embodiment is Pb x Ba x Bi 1-2x CuSeO; The concrete steps of described preparation method are:

[0050] The first step, according to bismuth oxide powder: copper powder: selenium powder: bismuth powder: lead powder: the ratio of the amount of substance of barium oxide powder is (1-x): 3: 3: (1-4x): 3x: 3x The ingredients are mixed evenly to obtain a mixed powder.

[0051] In the second step, the mixed powder is loaded into a high-energy planetary ball mill, and ball milled for 6 to 8 hours under an inert atmosphere. The mass ratio of the ball to material during ball milling is (12 to 17): 1, and the rotating speed is 250 to 400 r / min. Produced Pb x Ba x Bi 1-2x CuSeO powder.

[0052] The third step, the Pb x Ba x Bi 1-2x Put the CuSeO powder into the mold, put it in the plasma a...

Embodiment 3

[0058] A Pb / Ba double-doped BiCuSeO thermoelectric material and a preparation method thereof. The chemical formula of the Pb / Ba double-doped BiCuSeO thermoelectric material described in this embodiment is Pb x Ba x Bi 1-2x CuSeO, the concrete steps of described preparation method are:

[0059] The first step, according to bismuth oxide powder: copper powder: selenium powder: bismuth powder: lead powder: the ratio of the amount of substance of barium oxide powder is (1-x): 3: 3: (1-4x): 3x: 3x The ingredients are mixed evenly to obtain mixed powder;

[0060] In the second step, the mixed powder is loaded into a high-energy planetary ball mill, and ball milled for 7 to 9 hours under an inert atmosphere. The mass ratio of ball to material during ball milling is (14 to 19): 1, and the rotating speed is 300 to 450r / min. Produced Pb x Ba x Bi 1-2x CuSeO powder.

[0061] The third step, the Pb x Ba x Bi 1-2x Put the CuSeO powder into the mold, place it in the plasma activa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com