Sb doped BiCuSeO thermoelectric material and preparation method thereof

A technology of thermoelectric materials and particle size, which is applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problems of low dimensionless thermoelectric figure of merit, poor electrical transport performance, and low power factor, etc. Achieve the effect of improving power factor and dimensionless thermoelectric figure of merit, high production efficiency and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A Sb-doped BiCuSeO thermoelectric material and a preparation method thereof. The steps of the preparation method are:

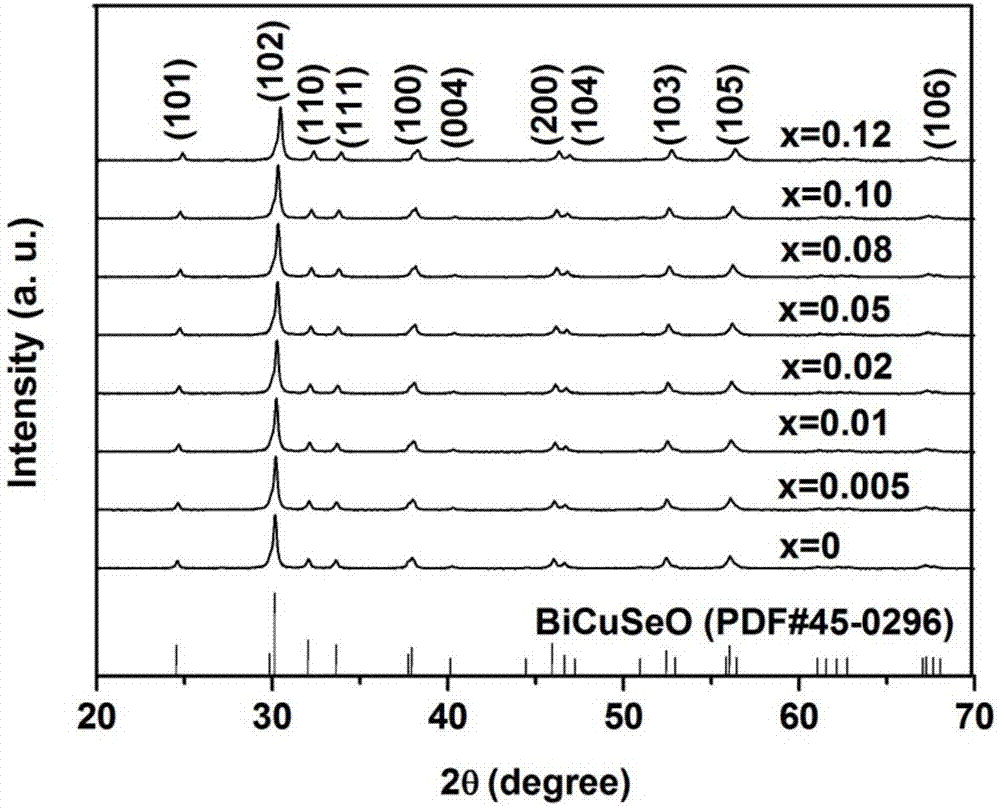

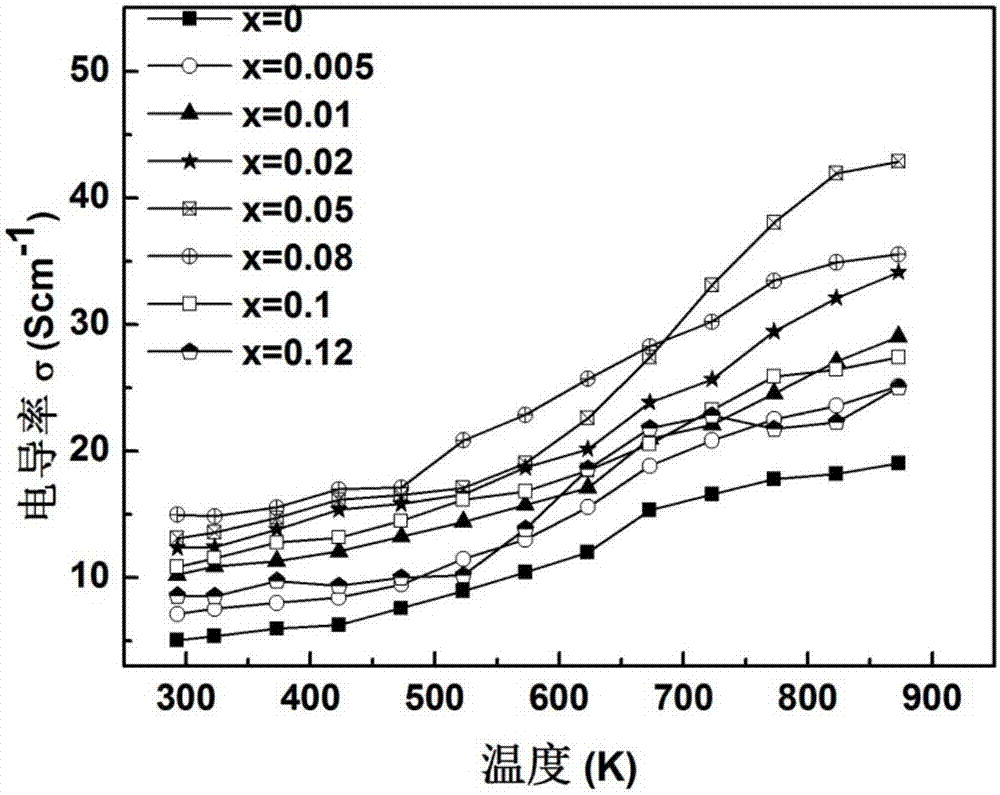

[0038] The chemical formula of the Sb-doped BiCuSeO thermoelectric material is Sb x Bi 1-x CuSeO, 0.005≤x≤0.02.

[0039] The first step, according to bismuth oxide powder: copper powder: selenium grain: bismuth powder: the ratio of the amount of material of antimony grain is 1: 3: 3: (1-3y): 3y batching, 0.005≤3y=x≤0.02, Then mix evenly to get mixed powder.

[0040] In the second step, the mixed powder is put into a ball mill jar, and ball milled for 5-8 hours under an inert atmosphere to obtain a single-phase Sb x Bi 1-x CuSeO powder, 0.005≤x≤0.02.

[0041] The third step, the single-phase Sb x Bi 1-x Put the CuSeO powder into the mold, place it in the plasma activated sintering furnace, and then start to raise the temperature and pressure at a constant speed at the same time, and raise the sintering temperature to 500-600°C and the sintering ...

Embodiment 2

[0047] A Sb-doped BiCuSeO thermoelectric material and a preparation method thereof. The steps of the preparation method are:

[0048] The chemical formula of the Sb-doped BiCuSeO thermoelectric material is Sb x Bi 1-x CuSeO, 0.02≤x≤0.08.

[0049] The first step, according to bismuth oxide powder: copper powder: selenium grain: bismuth powder: the ratio of the amount of material of antimony grain is 1: 3: 3: (1-3y): 3y batching, 0.02≤3y=x≤0.08, Then mix evenly to get mixed powder.

[0050] In the second step, the mixed powder is put into a ball mill jar, and ball milled for 5-8 hours under an inert atmosphere to obtain a single-phase Sb x Bi 1-x CuSeO powder, 0.02≤x≤0.08.

[0051] The third step, the single-phase Sb x Bi 1-x Put the CuSeO powder into the mold, place it in the plasma activated sintering furnace, and then start to raise the temperature and pressure at a constant speed at the same time, and raise the sintering temperature to 500-600°C and the sintering pre...

Embodiment 3

[0057] A Sb-doped BiCuSeO thermoelectric material and a preparation method thereof. The steps of the preparation method are:

[0058] The chemical formula of the Sb-doped BiCuSeO thermoelectric material is Sb x Bi 1-x CuSeO, 0.08≤x≤0.12.

[0059] The first step, according to bismuth oxide powder: copper powder: selenium grain: bismuth powder: the ratio of the amount of material of antimony grain is 1: 3: 3: (1-3y): 3y batching, 0.08≤3y=x≤0.12, Then mix evenly to get mixed powder.

[0060] In the second step, the mixed powder is put into a ball mill jar, and ball milled for 5-8 hours under an inert atmosphere to obtain a single-phase Sb x Bi 1-x CuSeO powder, 0.08≤x≤0.12.

[0061] The third step, the single-phase Sb x Bi 1-x Put the CuSeO powder into the mold, place it in the plasma activated sintering furnace, and then start to raise the temperature and pressure at a constant speed at the same time, and raise the sintering temperature to 500-600°C and the sintering pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com