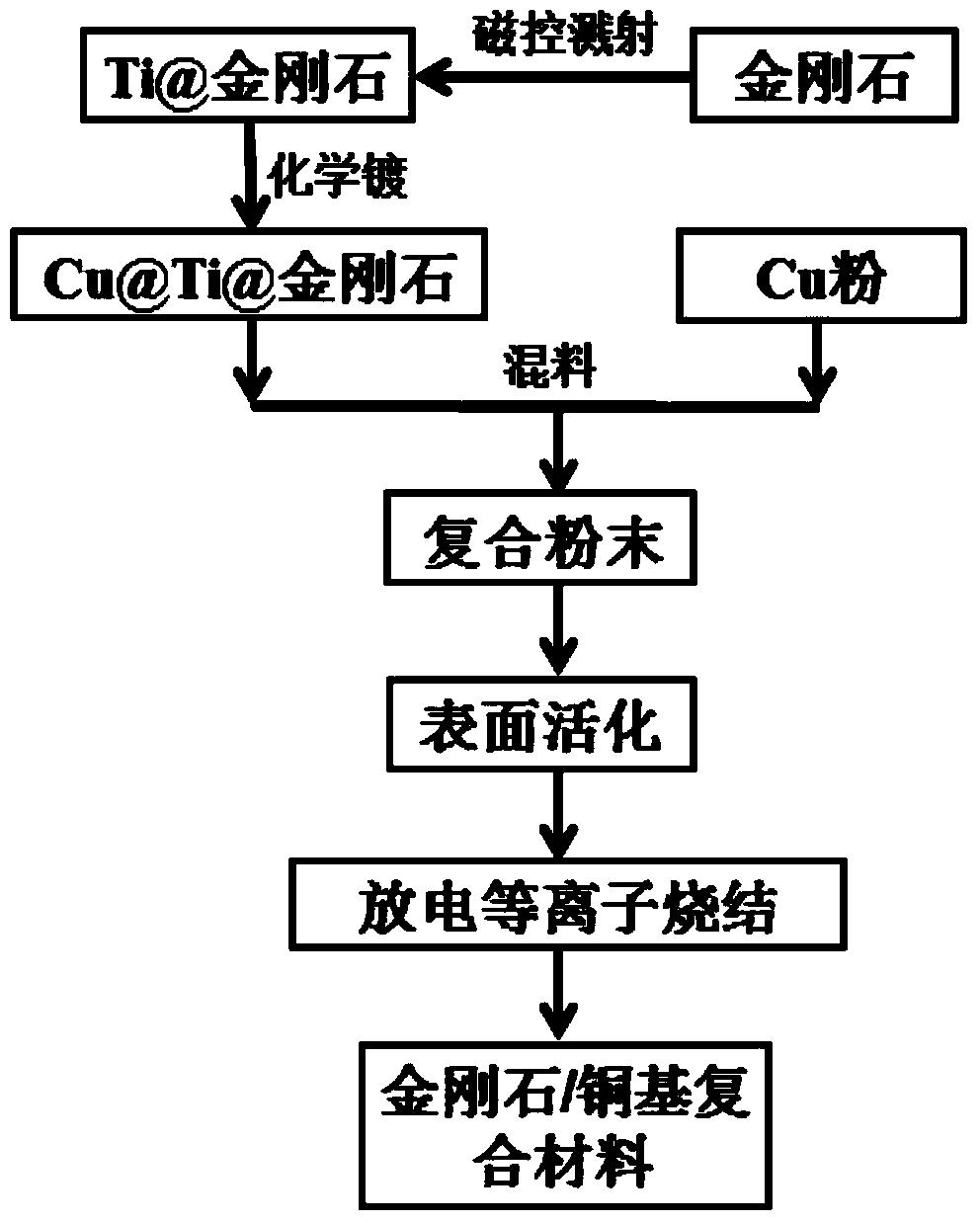

Preparation method for diamond/copper-based composite material

A copper-based composite material and diamond technology, which is applied in the field of diamond metal-based composite materials, can solve problems affecting the performance of composite materials, and achieve the effects of short holding time, uniform grains, and accelerated densification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

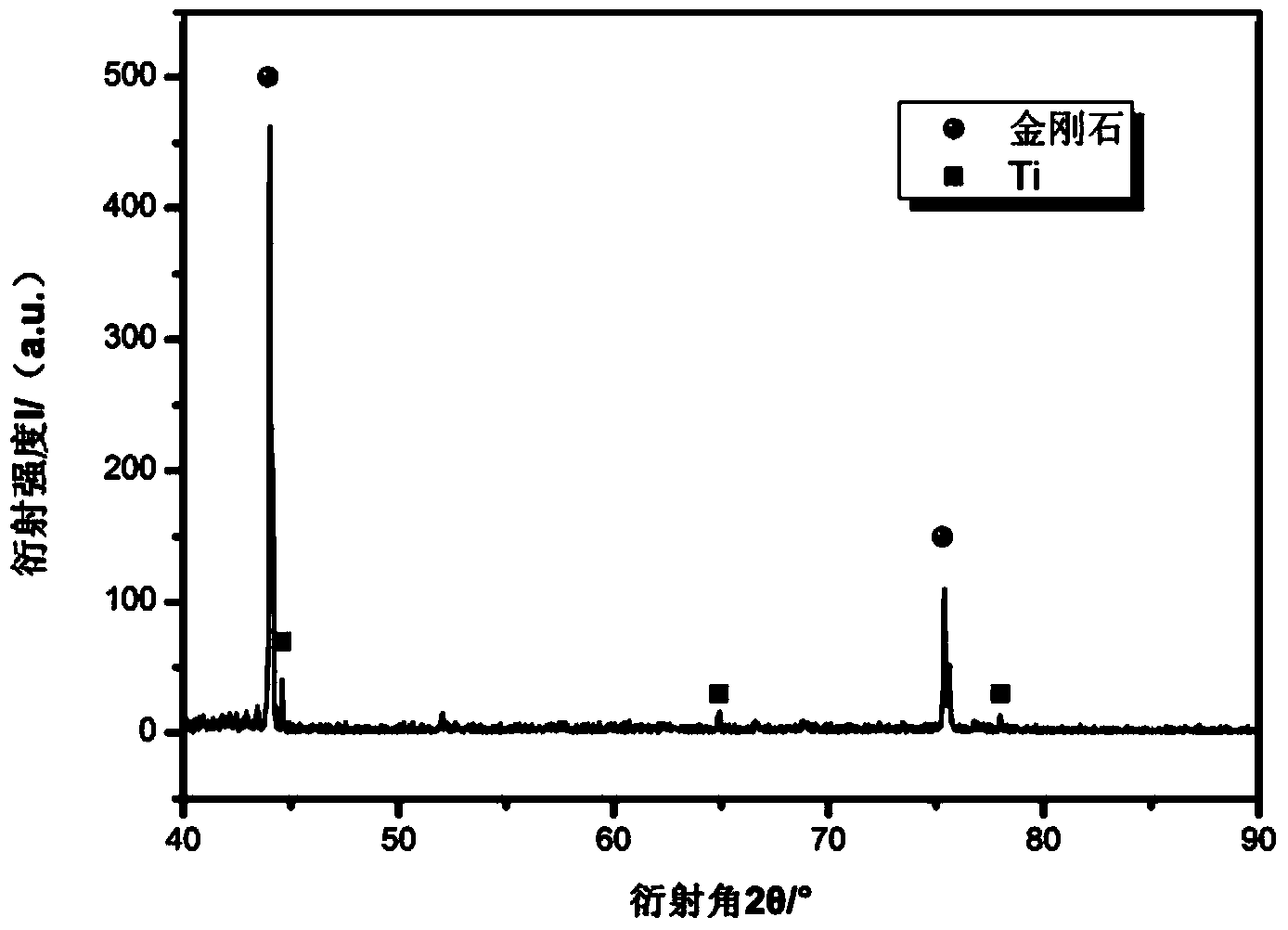

Embodiment 1

[0027] Use magnetron sputtering process to plate 0.8 μm thick titanium coating on the surface of 10 μm diamond powder to form titanium-coated diamond composite powder; then use electroless copper plating process to plate 5 μm thick copper coating on the surface of the above-mentioned diamond composite powder to form copper clad Titanium-coated diamond composite powder; then the copper-clad titanium-coated diamond composite powder is mixed with copper powder to form a mixed powder, wherein the volume fraction of the diamond powder in the mixed powder is 20%. Put the mixed powder in the prefabricated graphite mold, and then carry out surface activation and plasma activation sintering (PAS) in the plasma activation sintering furnace. The surface activation time is 30s, the activation voltage is 20kV, the activation current is 100A, and the vacuum degree is ≤ 10Pa, the temperature was raised rapidly after surface activation, the heating rate was 100°C / min, the pressure was 30MPa, t...

Embodiment 2

[0030] Use magnetron sputtering process to plate 1.5 μm thick titanium coating on the surface of 10 μm diamond powder to form titanium-coated diamond composite powder; then use electroless copper plating process to plate 1 μm thick copper coating on the surface of the above-mentioned diamond composite powder to form copper clad Titanium-coated diamond composite powder; then the copper-clad titanium-coated diamond composite powder is mixed with copper powder to form a mixed powder, wherein the volume fraction of the diamond powder in the mixed powder is 30%. Put the mixed powder in the prefabricated graphite mold, then carry out surface activation and plasma activation sintering in the plasma activation sintering furnace, the surface activation time is 30s, the activation voltage is 20kV, the activation current is 100A, the vacuum degree is ≤10Pa, After activation, the temperature was raised rapidly, with a heating rate of 100°C / min and a pressure of 30MPa. The temperature was r...

Embodiment 3

[0033] Use magnetron sputtering process to plate 0.8 μm thick titanium coating on the surface of 10 μm diamond powder to form titanium-coated diamond composite powder; then use electroless copper plating process to plate 5 μm thick copper coating on the surface of the above-mentioned diamond composite powder to form copper clad Titanium-coated diamond composite powder; then the copper-clad titanium-coated diamond composite powder is mixed with copper powder to form a mixed powder, wherein the volume fraction of the diamond powder in the mixed powder is 40%. Put the mixed powder in the prefabricated graphite mold, then carry out surface activation and plasma activation sintering in the plasma activation sintering furnace, the surface activation time is 30s, the activation voltage is 20kV, the activation current is 100A, the vacuum degree is ≤10Pa, After activation, the temperature was raised rapidly, with a heating rate of 100°C / min and a pressure of 40MPa. The temperature was r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com