Method of quickly preparing Mg-Si-Sn-based thermoelectric material in controllable manner

A mg-si-sn, thermoelectric material technology, which is applied in the field of rapid and controllable preparation of Mg-Si-Sn-based thermoelectric materials, can solve the problem that Mg is easily oxidized or reacts with the container and is easily adhered to the high-temperature volatilization and escape of Mg. The surface of the grinding ball and the inner wall of the ball mill tank, and the components deviate from the nominal stoichiometric ratio, etc., achieve the effect of shortening the preparation cycle, large commercial application potential, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A, a kind of fast and controllable method for preparing Mg-Si-Sn base thermoelectric material, it comprises the following steps:

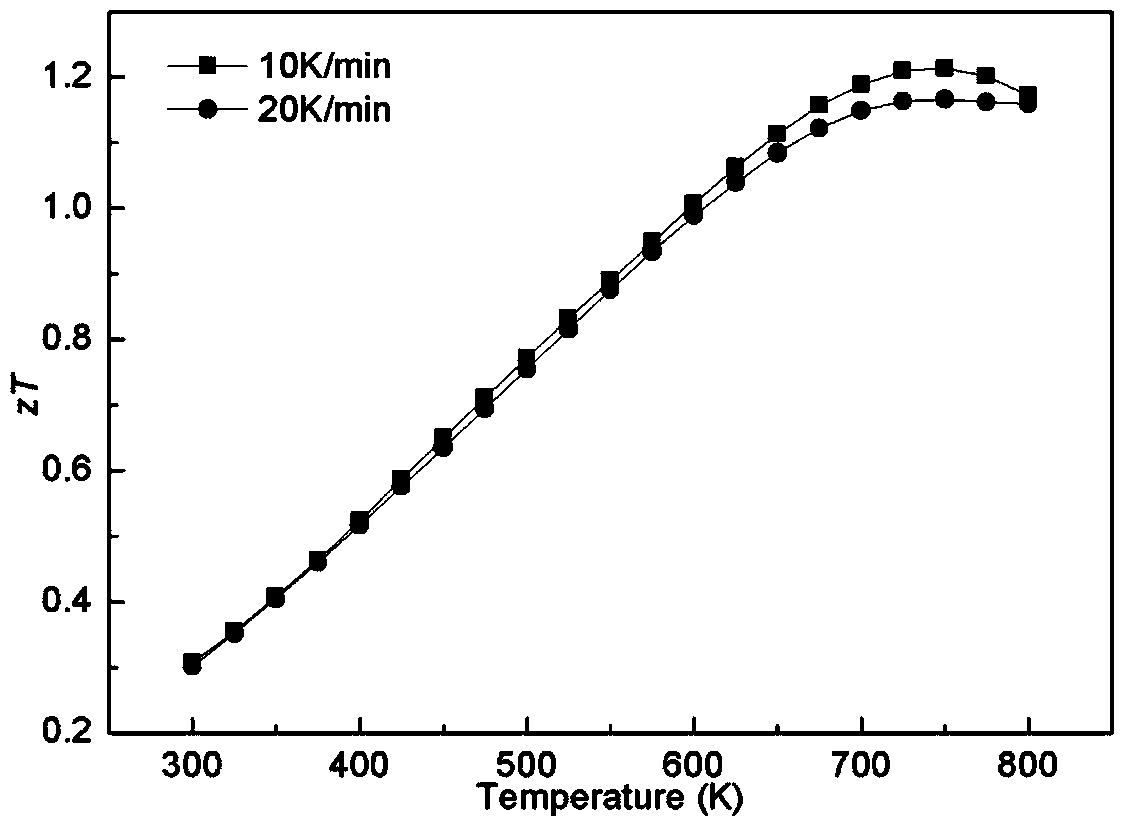

[0035] 1) In an inert gas glove box, press Mg 2.16 (Si 0.3 sn 0.7 ) 0.98 Sb 0.02 The stoichiometric ratio of each element in the method weighs Mg powder (2N, 100-200 mesh), Mg 2 Si powder (2.5N, 200 mesh), Sn powder (2.5N, 200 mesh) and Sb powder (5N, 200 mesh) are used as raw materials, and then the powder is mixed in an agate mortar; Put it into a mold with an inner diameter of 12mm, first hold the pressure at 4MPa for 5min, and then hold at 6MPa for 10min to obtain a cylinder;

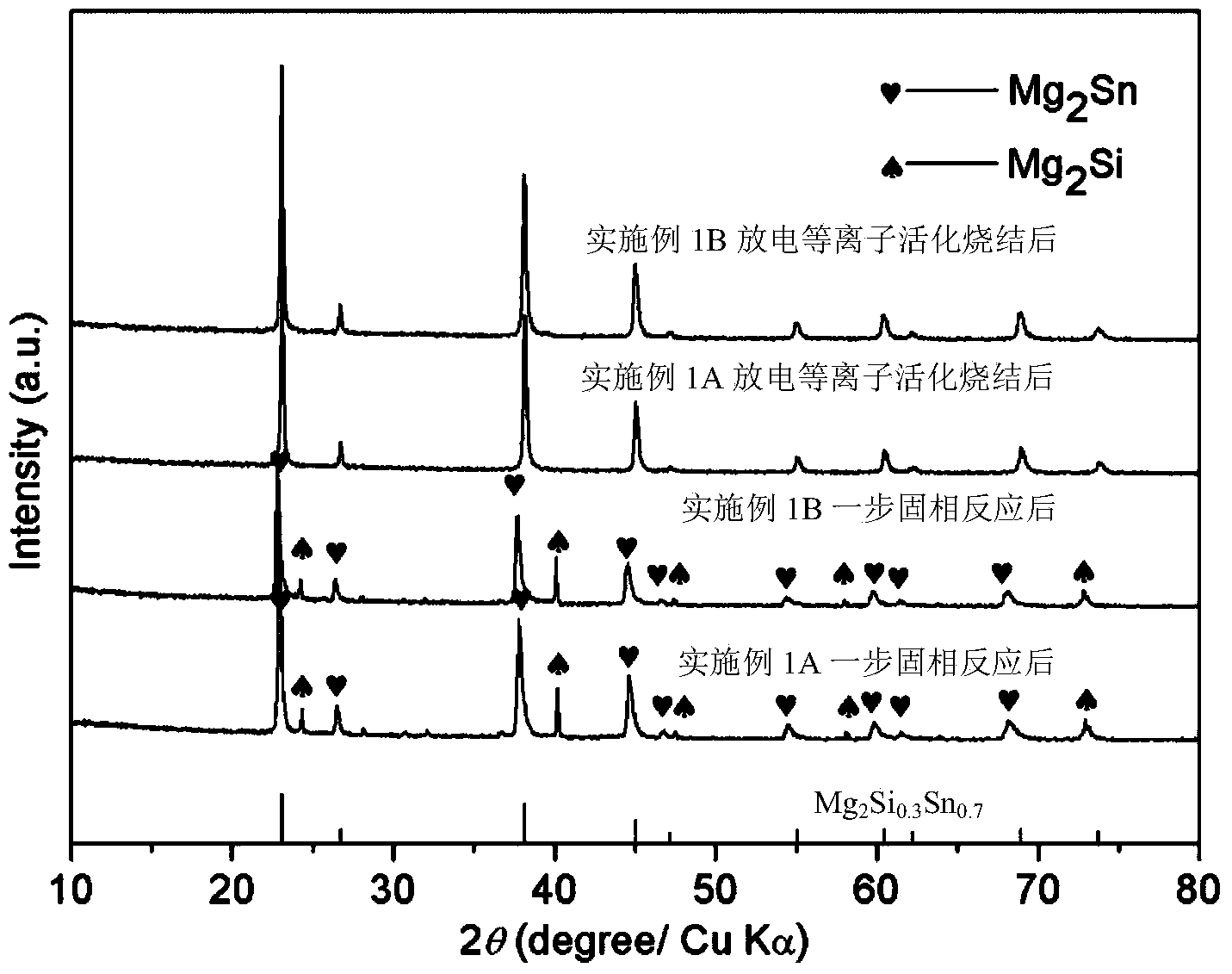

[0036] 2) One-step solid phase reaction: Place the cylinder obtained in step 1) in a BN crucible, seal it under vacuum conditions (-0.1MPa) and place it in a high-purity quartz glass tube, then place the quartz glass tube in the tube In a type atmosphere furnace, heat up to 823K at a heating rate of 10K / min, hold for 5min, and then cool with the furnace;

...

Embodiment 2

[0042] A, a kind of fast and controllable method for preparing Mg-Si-Sn base thermoelectric material, it comprises the following steps:

[0043] 1) In an inert gas glove box, press Mg 2.16 (Si 0.3 sn 0.7 ) 0.98 Sb 0.02 The stoichiometric ratio of each element is weighed Mg powder, Mg 2 Si powder, Sn powder and Sb powder were used as raw materials, and then the powders were mixed in an agate mortar; Hold the pressure for 10 minutes under pressure to obtain a cylinder;

[0044] 2) One-step solid phase reaction: Place the cylinder obtained in step 1) in a BN crucible, seal it under vacuum conditions (-0.1MPa) and place it in a high-purity quartz glass tube, then place the quartz glass tube in the tube In a type atmosphere furnace, heat up to 823K at a heating rate of 10K / min, hold for 5min, and then cool with the furnace;

[0045] 3) Spark plasma activation sintering: Grind the product obtained in step 2) into powder in an inert gas glove box, then take a small amount of p...

Embodiment 3

[0049] A, a kind of fast and controllable method for preparing Mg-Si-Sn base thermoelectric material, it comprises the following steps:

[0050] 1) In an inert gas glove box, press Mg 2.16 (Si 0.5 sn 0.5 ) 0.98 Sb 0.02 The stoichiometric ratio of each element is weighed Mg powder, Mg 2 Si powder, Sn powder and Sb powder were used as raw materials, and then the powders were mixed in an agate mortar; Hold the pressure for 10 minutes under pressure to obtain a cylinder;

[0051] 2) One-step solid phase reaction: Place the cylinder obtained in step 1) in a BN crucible, seal it under vacuum conditions (-0.1MPa) and place it in a high-purity quartz glass tube, then place the quartz glass tube in the tube In a type atmosphere furnace, heat up to 833K at a heating rate of 10K / min, hold for 10min, and then cool with the furnace;

[0052]3) Spark plasma activation sintering: grind the product obtained in step 2) into powder in an inert gas glove box, then take a small amount of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com