Method for quickly preparing antimony telluride thermoelectric material

A technology of thermoelectric materials and antimony telluride, which is applied in the direction of binary selenium/tellurium compounds, can solve the problems of time-consuming, difficult to control the composition, and low yield of chemical methods, and achieve low energy consumption, fast reaction speed, and repeatability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for rapidly preparing antimony telluride thermoelectric materials, the preparation method comprising the following steps:

[0031] 1) According to Sb 2 Te 3 The stoichiometric ratio of each element in takes by weighing Sb powder and Te powder, and total mass is 4g, grinds and mixes then, obtains mixed raw material;

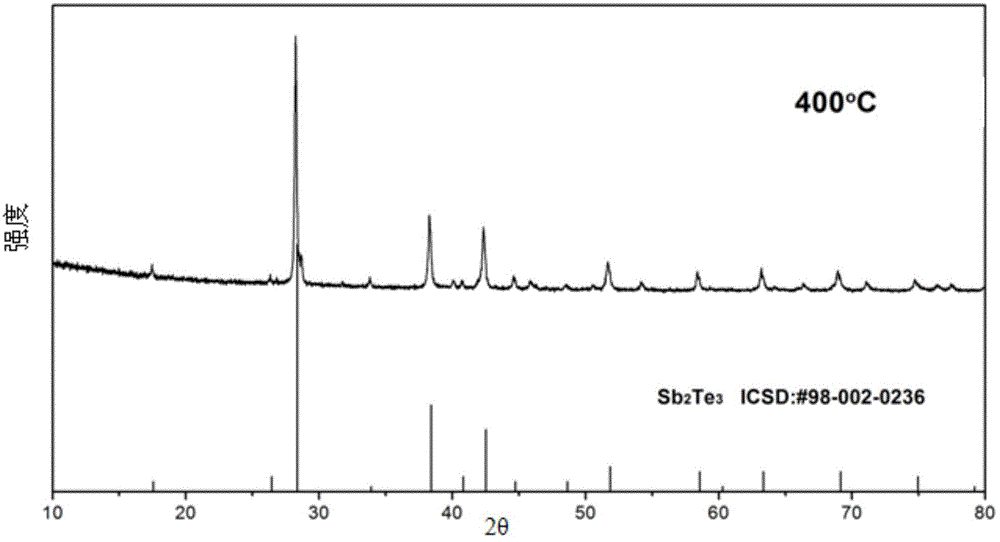

[0032] 2) The mixed raw material obtained in step 1) is subjected to discharge plasma activation sintering, the specific process is: the mixed raw material is packed into a graphite mold with an inner diameter of 16mm for compaction, and then under the condition that the vacuum degree is less than 10Pa and no sintering pressure is applied, Heating to 400°C at a heating rate of 60°C / min, holding for 10 minutes, then rapidly pressurizing to 30MPa, holding for 10 minutes and sintering to obtain dense single-phase antimony telluride (Sb 2 Te 3 ) thermoelectric materials.

[0033] The product obtained in this embodiment is analyzed by X-ray diffract...

Embodiment 2

[0035] A method for rapidly preparing antimony telluride thermoelectric materials, the preparation method comprising the following steps:

[0036] 1) According to Sb 2 Te 3 The stoichiometric ratio of each element in takes by weighing Sb powder and Te powder, and total mass is 4g, grinds and mixes then, obtains mixed raw material;

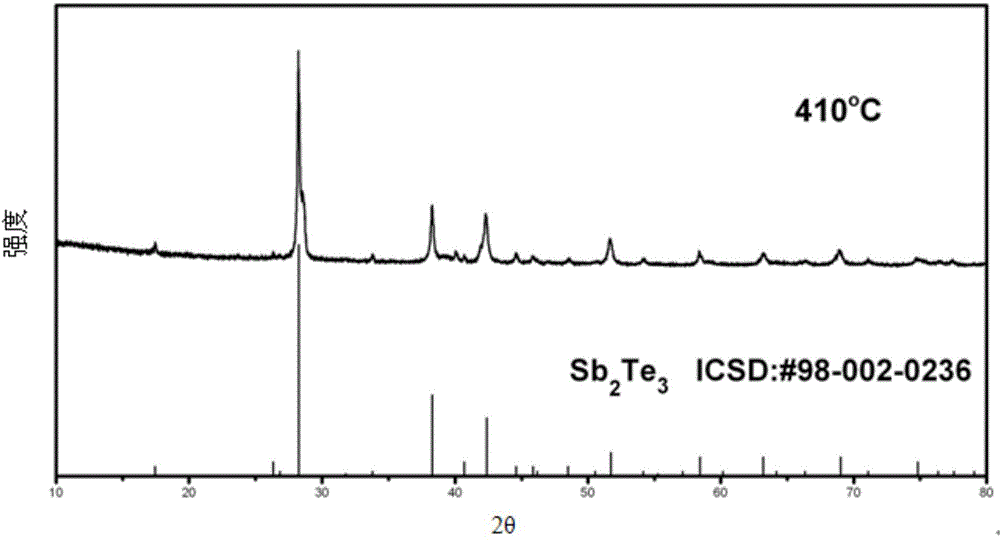

[0037] 2) The mixed raw material obtained in step 1) is subjected to discharge plasma activation sintering, the specific process is: the mixed raw material is packed into a graphite mold with an inner diameter of 16mm for compaction, and then under the condition that the vacuum degree is less than 10Pa and no sintering pressure is applied, Heating to 410°C at a heating rate of 70°C / min, holding for 10 minutes, then rapidly pressurizing to 30MPa, holding for 10 minutes and sintering to obtain dense single-phase antimony telluride (Sb 2 Te 3 ) thermoelectric materials.

[0038] figure 2 It is the XRD spectrum of the product obtained in this emb...

Embodiment 3

[0040] A method for rapidly preparing antimony telluride thermoelectric materials, the preparation method comprising the following steps:

[0041] 1) According to Sb 2 Te 3 The stoichiometric ratio of each element in takes by weighing Sb powder and Te powder, and total mass is 4g, grinds and mixes then, obtains mixed raw material;

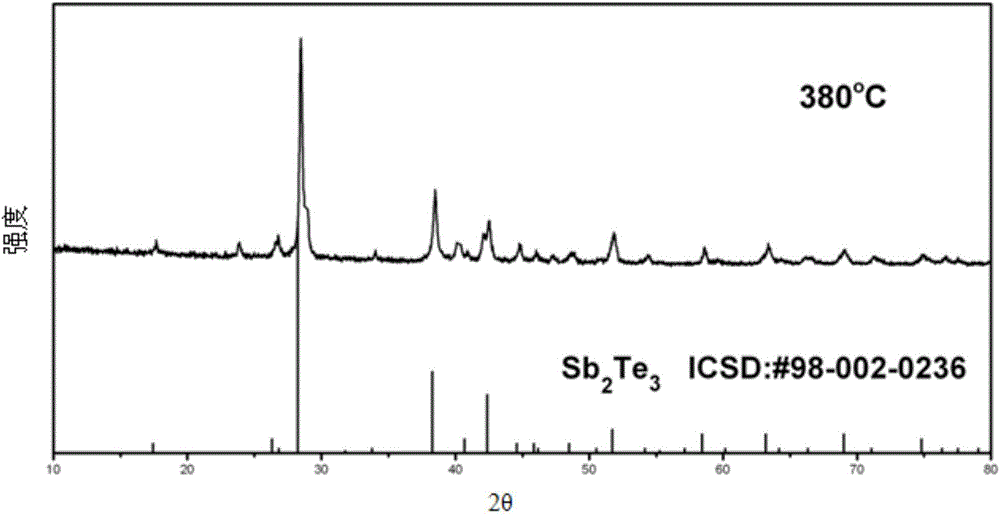

[0042] 2) The mixed raw material obtained in step 1) is subjected to discharge plasma activation sintering, the specific process is: the mixed raw material is packed into a graphite mold with an inner diameter of 16mm for compaction, and then the vacuum degree is less than 10Pa and the sintering pressure is not applied. Heating at a heating rate of 60°C / min to 380°C, holding for 15 minutes, then quickly pressurizing to 40MPa, holding for 5 minutes and sintering to obtain dense single-phase antimony telluride (Sb 2 Te 3 ) thermoelectric materials.

[0043] image 3 It is the XRD spectrum of the product obtained in this embodiment, and the figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com