Process for preparing nano WC-Co cemented carbide

A cemented carbide and nanotechnology, which is applied in the field of preparing nano-WC-Co cemented carbide, can solve the problems of increasing brittleness and porosity, and achieve the effects of improving surface activity, easy operation, and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

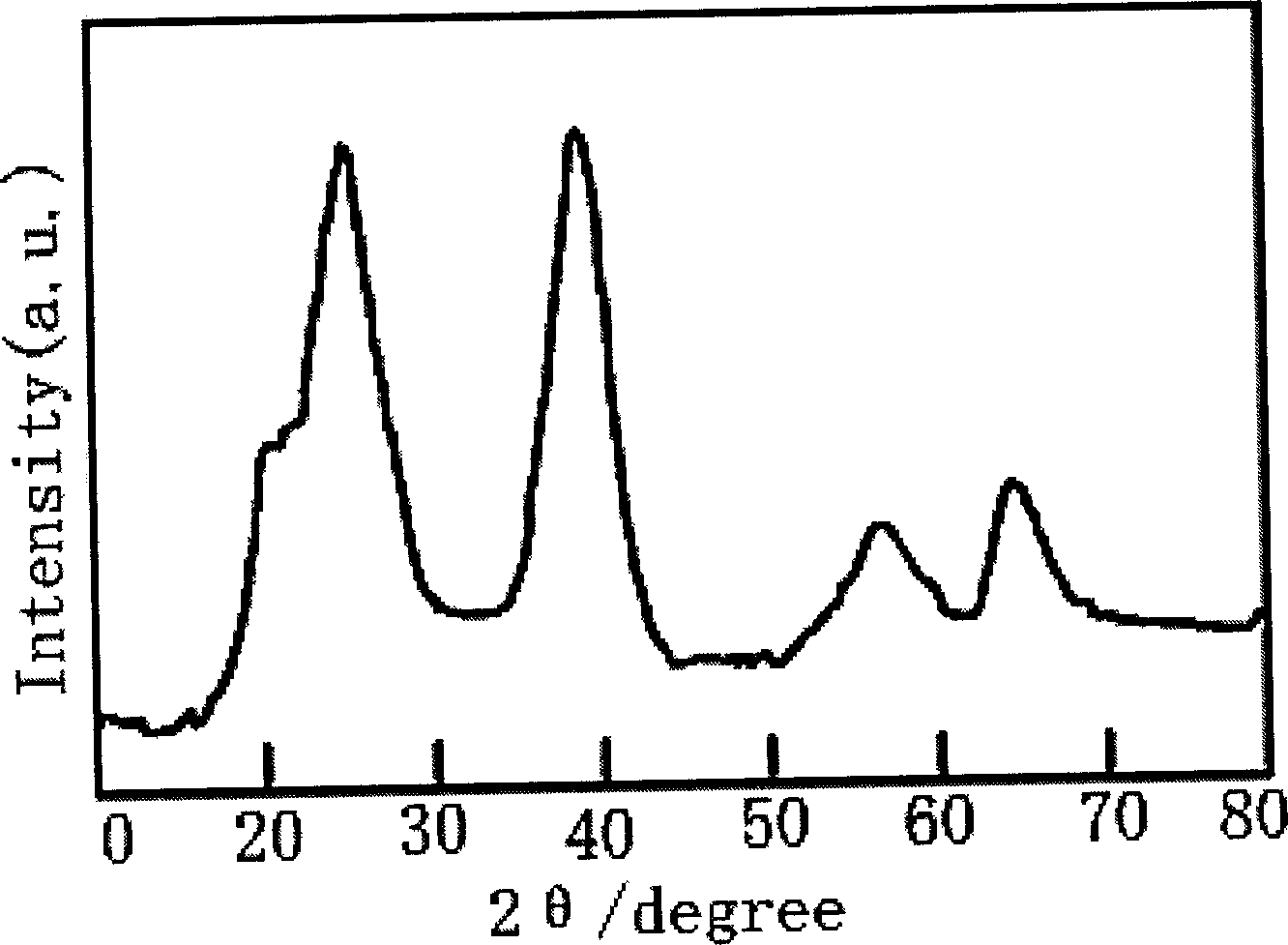

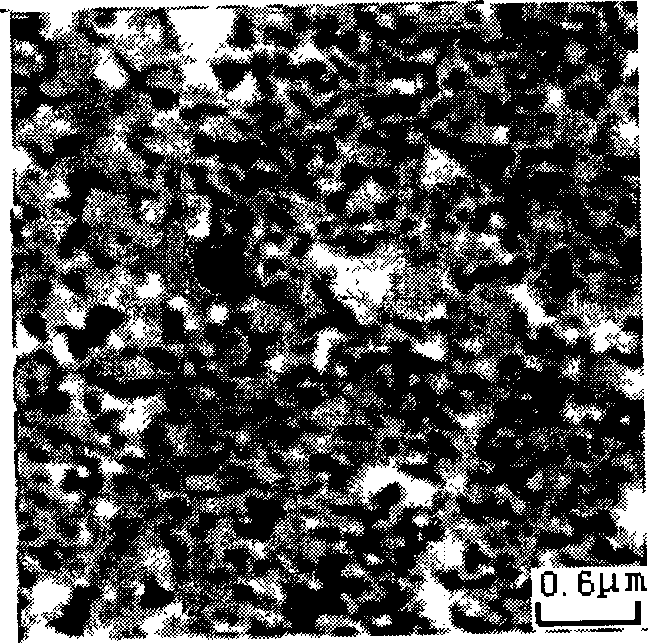

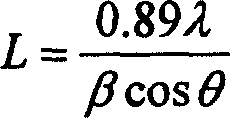

[0020] Get average particle size and be 200 mesh WC, Co powder, press WC: Co=94wt%: 6wt% proportioning, prepare WC-Co mixed powder, use WC cemented carbide ball in ball mill tank with rotating speed 200rpm and ball-powder ratio 15 : 1, ball milled for 55 hours, and the nano WC-Co mixed powder was taken out from the ball mill jar. Then prepare a polyvinyl acid solution with a concentration of 1.5%, and immerse the nanometer WC-Co mixed powder in it for 55 minutes. Dry at 60°C for 7 hours. Put the powder prepared in the above steps into a carbon casting mold, conduct plasma activation sintering, maintain a constant uniaxial pressure of 25 MPa during the sintering process, sintering temperature 1250 ° C, sintering time 2 minutes, and obtain nano-WC-Co cemented carbide with a dense structure . The alloy has the following technical indicators:

[0021] Density 14.7g / cm 3 , hardness (HV 30 ) 1890, fracture toughness (Kic) 17.8MPam.

Embodiment 2

[0023] Get average particle size and be 200 mesh WC, Co powder, press WC: Co=94wt%: 6wt% proportioning, prepare WC-Co mixed powder, use WC cemented carbide ball in ball mill pot with rotating speed 200rpm and ball-powder ratio 30 : 1, ball milled for 40 hours, and the nano WC-Co mixed powder was taken out from the ball mill jar. Then prepare a polyvinyl acid solution with a concentration of 2.5%, and immerse the nanometer WC-Co mixed powder in it for 35 minutes. Dry at 90°C for 4 hours. Put the powder prepared in the above steps into a carbon casting mold, conduct plasma activation sintering, maintain a constant uniaxial pressure of 25 MPa during the sintering process, sintering temperature 1000 ° C, sintering time 3 minutes, and obtain nano-WC-Co cemented carbide with a dense structure .

Embodiment 3

[0025] Get average grain size and be 200 mesh WC, Co powder, press WC: Co=94wt%: 6wt% proportioning, prepare WC-Co mixed powder, use WC cemented carbide ball in ball mill tank with rotating speed 200rpm and ball-powder ratio 45 : 1, ball milled for 25 hours, and the nanometer WC-Co mixed powder was taken out from the ball mill jar. Then prepare a polyvinyl acid solution with a concentration of 3.5%, and immerse the nanometer WC-Co powder in it for 15 minutes. Dry at 120° C. for 1 hour. Put the powder prepared in the above steps into a carbon casting mold, conduct plasma activation sintering, maintain a constant uniaxial pressure of 25 MPa during the sintering process, sintering temperature 800 ° C, sintering time 4 minutes, and obtain nano-WC-Co cemented carbide with a dense structure .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com