High-performance Cu2SnSe3 thermoelectric material and rapid preparing method thereof

A thermoelectric material and high-performance technology, applied in the direction of thermoelectric device junction lead-out material, thermoelectric device manufacturing/processing, chemical instruments and methods, etc. and other problems, to achieve the effect of fast reaction speed, precise control of product stoichiometric ratio, and short sintering process time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A single-phase Cu 2 SnSe 3 The rapid preparation method of compound, it comprises the following steps:

[0038]1) Prepare Cu powder, Se powder and Sn powder as raw materials according to the stoichiometric ratio of 2.02:3.03:1, weigh the total amount of Cu powder, Se powder and Sn powder to be 5g, and mix the raw materials evenly in an agate mortar to obtain the reaction Put the reactant into a steel mold, press 10MPa on the tablet machine to form a f10mm block, and then put it into a quartz glass tube (17mm inner diameter, 20mm outer diameter);

[0039] 2) In an air atmosphere, put the quartz glass tube into a muffle furnace at 300°C for direct heating, self-propagating reaction occurs, and the reaction is completed in 30 seconds. After the reaction is completed, naturally cool to obtain Cu 2 SnSe 3 compound.

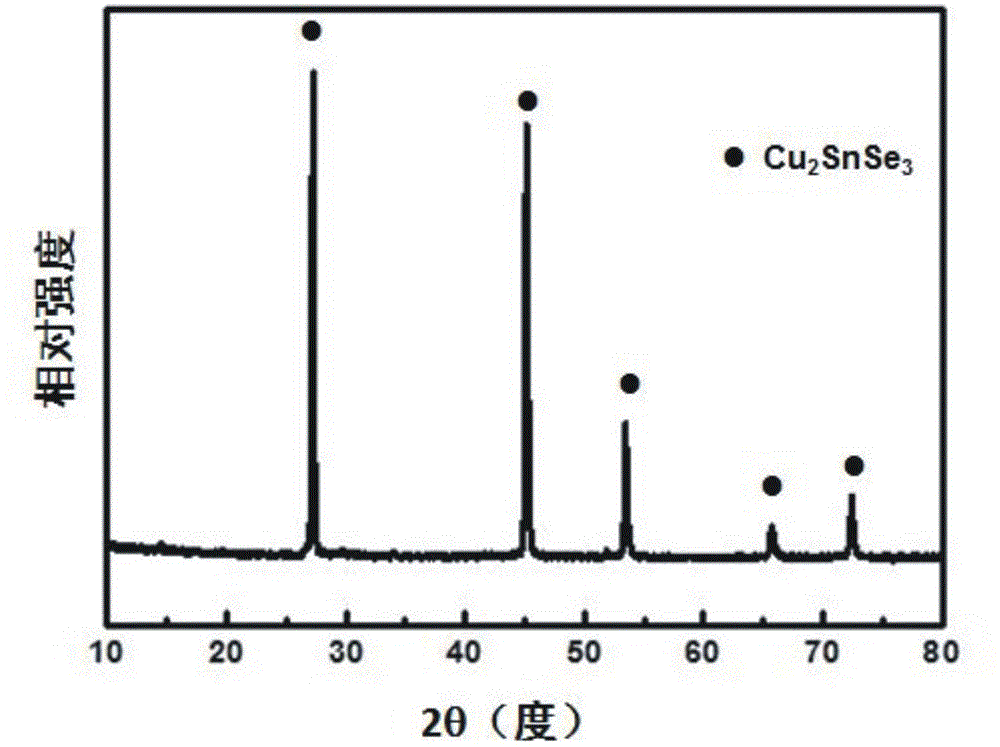

[0040] figure 1 It is the XRD spectrum of the product obtained after the self-propagating reaction. It can be seen from the figure that the product obtain...

Embodiment 2

[0042] A high performance Cu 2 SnSe 3 A rapid preparation method for thermoelectric materials, which comprises the following steps:

[0043] 1) Prepare Cu powder, Se powder and Sn powder as raw materials according to the stoichiometric ratio of 2.02:3.03:1, weigh the total amount of Cu powder, Se powder and Sn powder to be 5g, and mix the raw materials evenly in an agate mortar to obtain the reaction Put the reactant into a steel mold, press 10MPa on the tablet machine to form a f10mm block, and then put it into a quartz glass tube (17mm inner diameter, 20mm outer diameter);

[0044] 2) In an air atmosphere, put the quartz glass tube into a muffle furnace at 500°C and heat it directly until the self-propagating reaction occurs, stop heating, and cool naturally after the reaction is completed to obtain Cu 2 SnSe 3 compound.

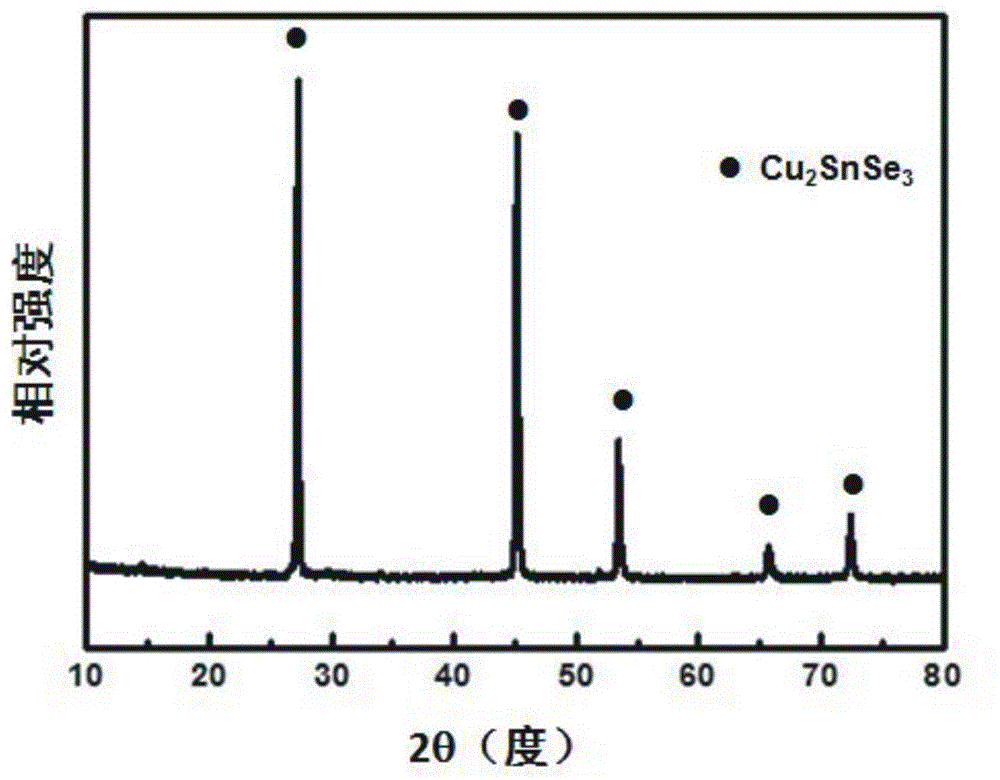

[0045] 3) Cu will be obtained 2 SnSe 3 The product powder is put into a graphite mold for compaction, and then plasma activated sintering (PAS sinte...

Embodiment 3

[0050] A kind of fast preparation method of high-performance Cu2SnSe3 thermoelectric material, it comprises the following steps:

[0051] 1) Prepare Cu powder, Se powder and Sn powder as raw materials according to the stoichiometric ratio of 2.02:3.03:1, weigh the total amount of Cu powder, Se powder and Sn powder to be 5g, and mix the raw materials evenly in an agate mortar to obtain the reaction Put the reactant into a steel abrasive tool, use 10MPa pressure on the tablet machine to form a f10mm block, and then put it into a quartz glass tube (with an inner diameter of 17mm and an outer diameter of 20mm);

[0052] 2) In an air atmosphere, put the quartz glass tube into a muffle furnace at 1000°C and heat it directly until the self-propagating reaction occurs, stop heating, and cool naturally after the reaction is completed to obtain Cu 2 SnSe 3 compound.

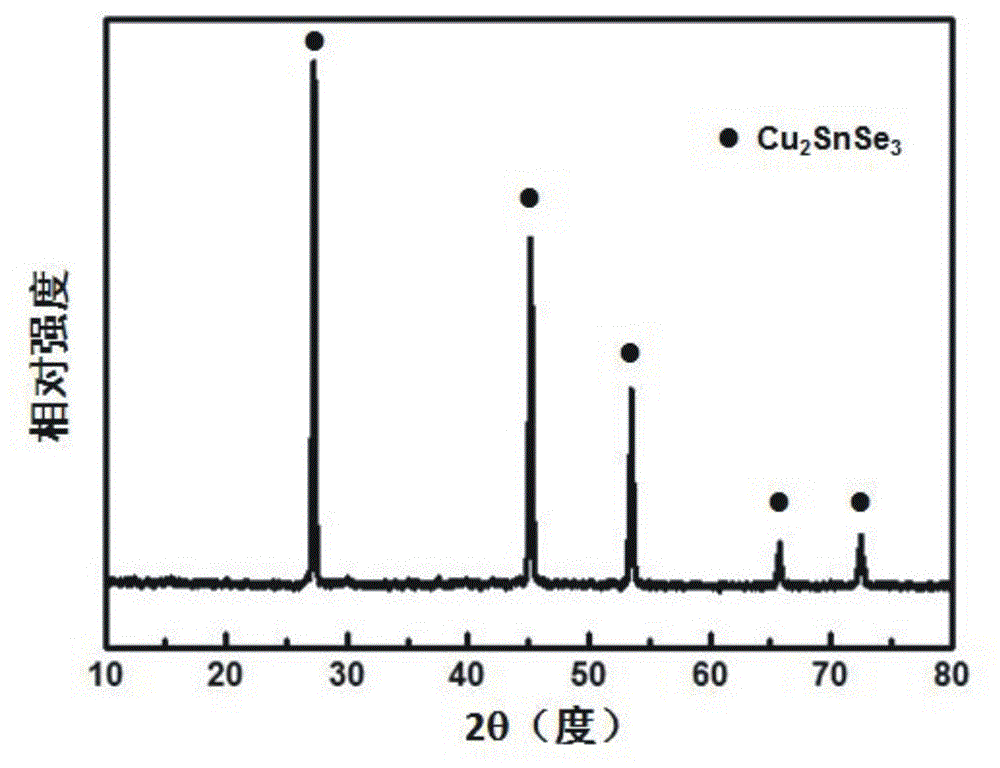

[0053] Figure 9 is the XRD pattern of the product obtained after the self-propagating reaction, from Figure 9 It c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com