Preparation method of n-type bismuth telluride-based thermoelectric material

A technology of bismuth telluride-based and thermoelectric materials, which is applied in the manufacture/processing of thermoelectric devices, and lead wire materials of thermoelectric devices, can solve the problems of stability restriction, energy consumption, and easy damage to sample cutting. To achieve the effect of low requirements for post-processing equipment and molds, convenient and controllable conditions and temperature, and conducive to enlarged production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

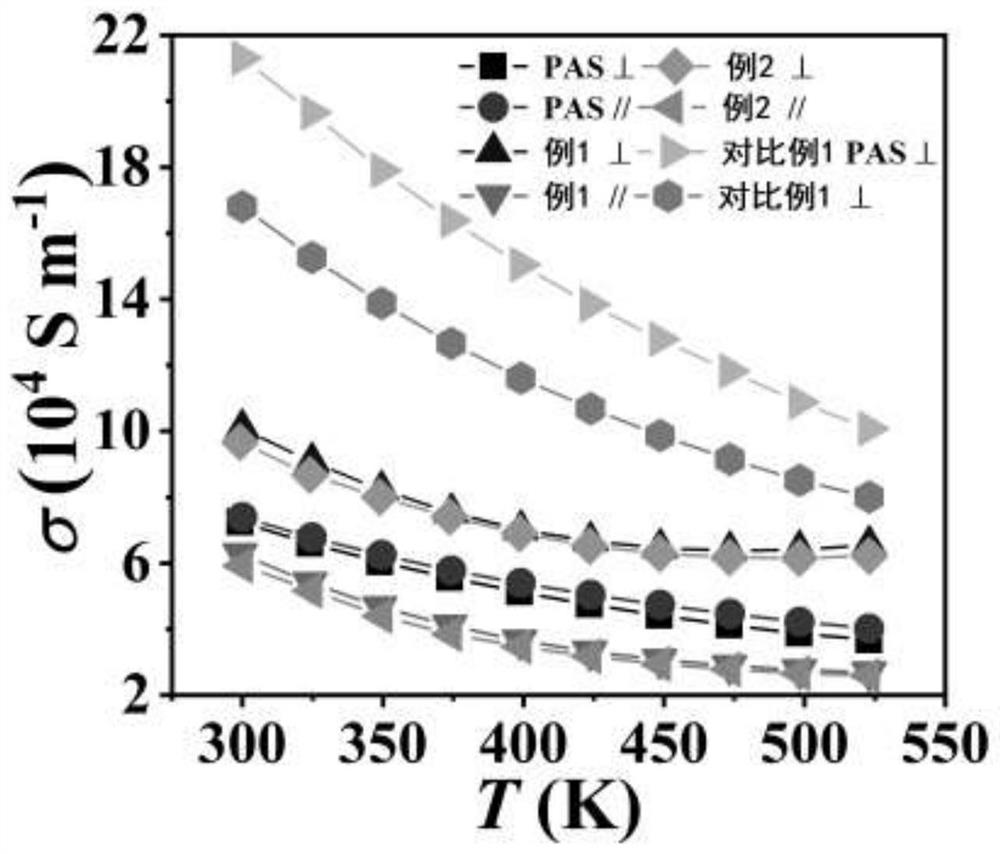

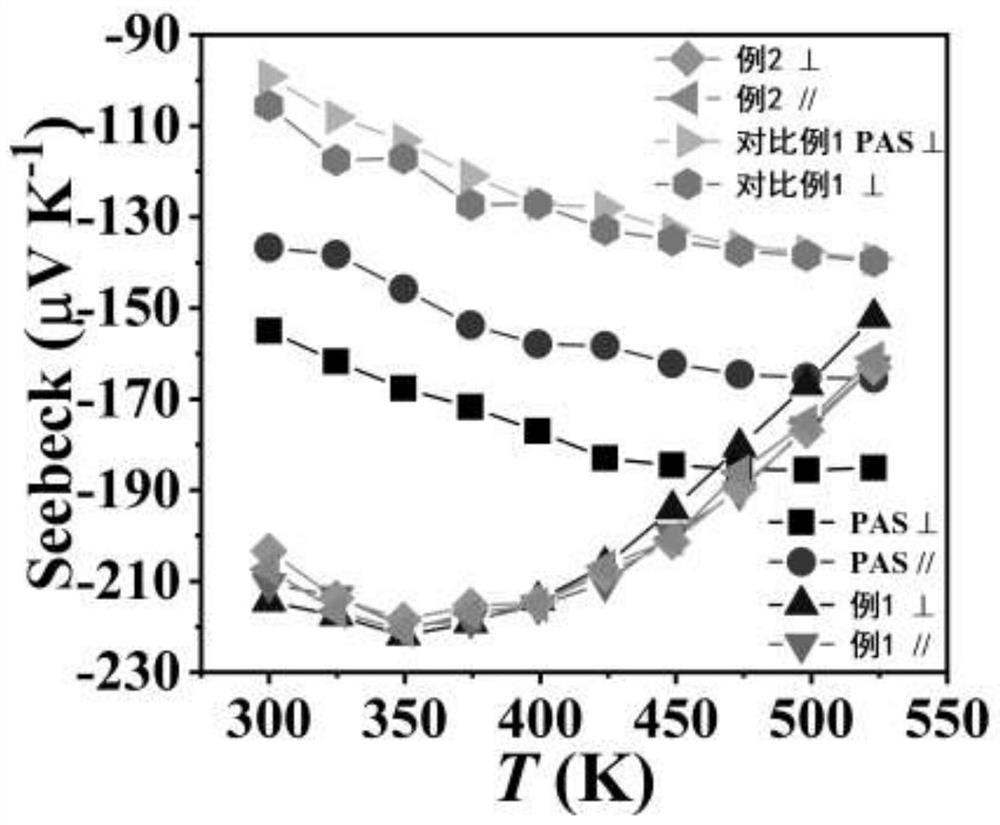

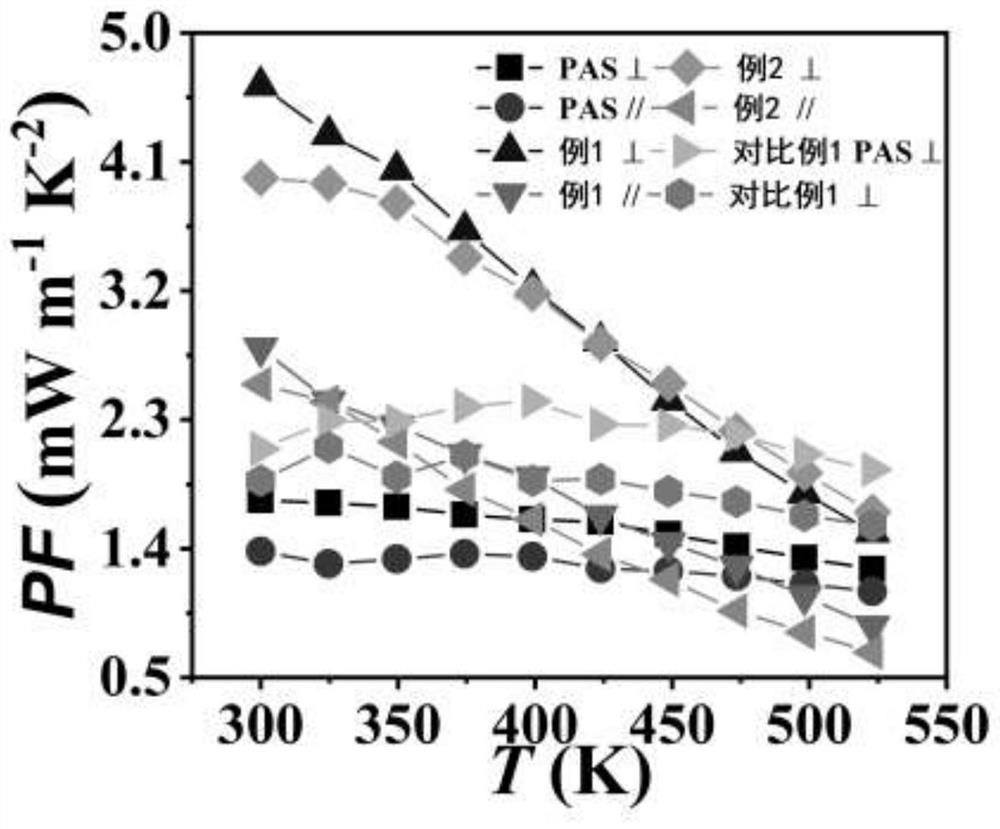

Embodiment 1

[0033] An n-type bismuth telluride-based thermoelectric material, the preparation method of which comprises the following steps:

[0034] 1) Press the elemental Bi, Te and Se powders into Bi 2 Te 2.4 Se 0.6 After weighing the stoichiometric ratio, use a mortar to mix evenly, then put it into a cold press, and cold press for 5 minutes under a pressure of 10MPa to obtain the initial green body;

[0035] 2) Put the obtained body into a self-propagating reaction chamber, and use laser ignition to trigger a self-propagating reaction to obtain a powder material;

[0036] 3) The obtained powder material is placed in a quartz mold with a diameter of 60 mm (bore openings at both ends), and then placed in a rotary atmosphere furnace, in an atmosphere of hydrogen-argon gas mixture (hydrogen is 10% by volume), 600K annealing for 5 minutes, and then using plasma activation sintering equipment to sinter for 5 minutes under the conditions of 673K and 40Mpa to obtain a green body with a ...

Embodiment 2

[0046] A kind of n-type bismuth telluride thermoelectric material, its preparation method comprises the steps:

[0047] 1) Press the elemental Bi, Te and Se powders into Bi 2 Te 2.7 Se 0.3 After the stoichiometric ratio is weighed, use a mortar to mix evenly, then put it into a cold press, and cold press for 5 minutes under a pressure of 5 MPa to obtain the initial green body;

[0048] 2) Put the obtained body into a self-propagating reaction chamber, and use laser ignition to trigger a self-propagating reaction to obtain a powder material;

[0049] 3) The obtained powder material is placed in a quartz mold with a diameter of 60mm (with openings at both ends), and then placed in a rotary atmosphere furnace, in an atmosphere of hydrogen-argon gas mixture (hydrogen is 5% by volume), Annealed at 575K for 20 minutes, then sintered for 5 minutes at 693K and 30Mpa using plasma activation sintering equipment to obtain a green body with a diameter of 10mm, and then hot forged the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com