Processable complex-phase ceramic material and preparation method thereof as well as secondary hardening heat treatment method

A heat treatment method and technology of multi-phase ceramics, which are applied in the field of ceramic material manufacturing, can solve problems such as the contradiction between machinability and hardness, limit the application field of machinable ceramics, and cannot improve the hardness of machinable ceramics, so as to achieve short sintering time and high hardness , increased hardness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

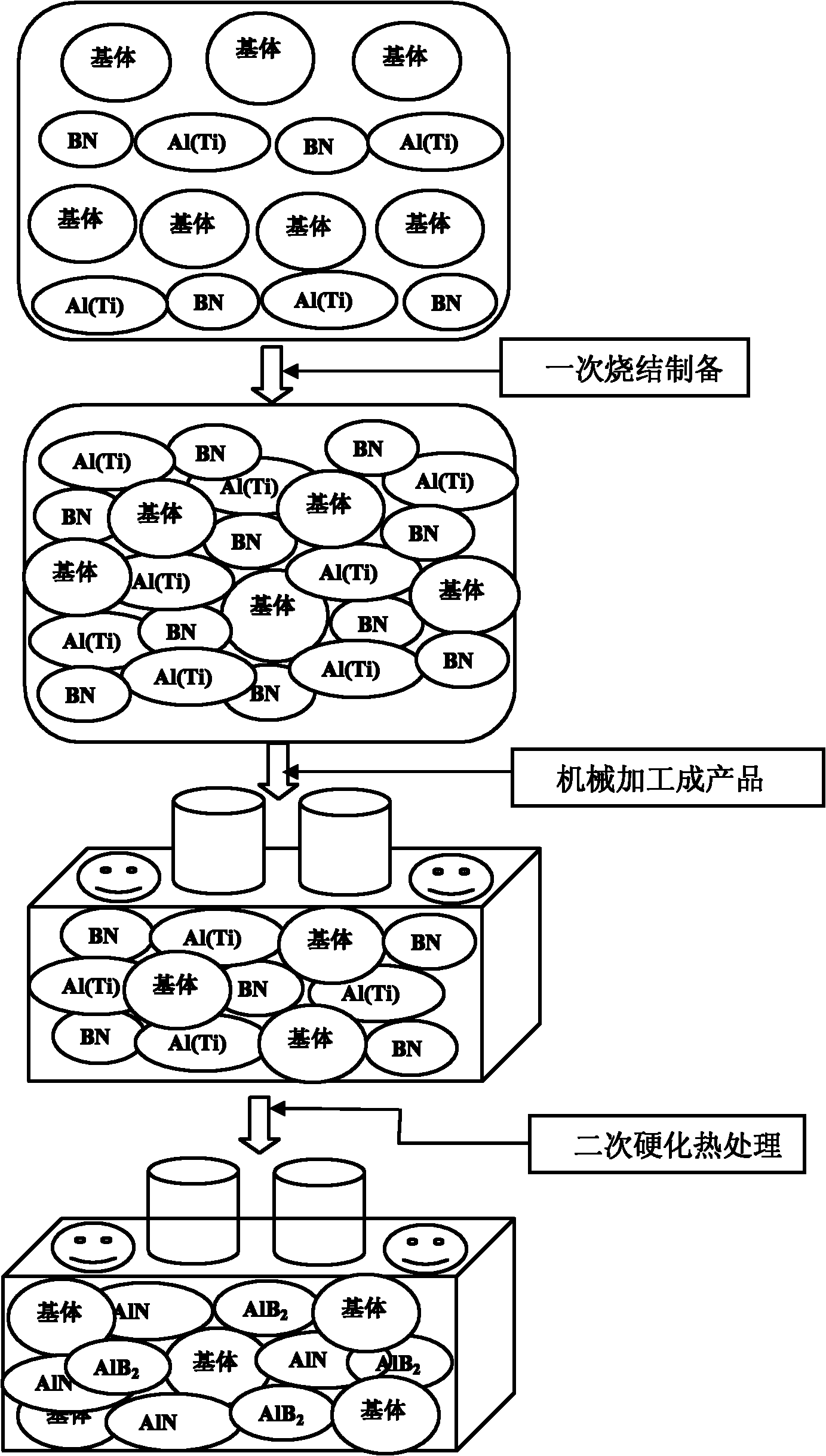

[0022] The preparation method of the machinable composite ceramic material comprises the following steps: formulating the components according to the above weight percentages, ball-milling the mixed powder, and then sintering in a plasma activation (PAS) furnace, wherein the heating rate is 300-500° C. / min, and the pressure is 30- 50MPa, vacuum degree 6-10Pa, sintering temperature 900-1200℃, heat preservation for 2-4min, and finally cooling with furnace.

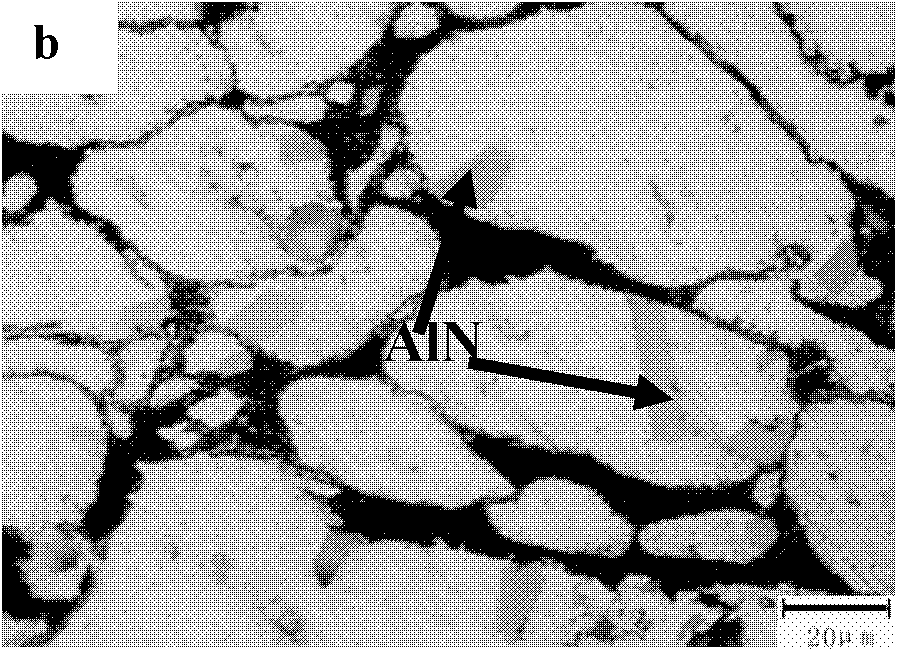

[0023] The secondary hardening heat treatment method of the machinable multiphase ceramic material, the machinable multiphase ceramic material prepared above is mechanically processed into a product, placed in a vacuum furnace, and heated in N 2 Under gas protection, the temperature is first raised to 900-1200°C at 5-10°C / min, then raised to 1600-1800°C at 2-5°C / min, kept for 2-3h, and finally cooled with the furnace.

Embodiment 1

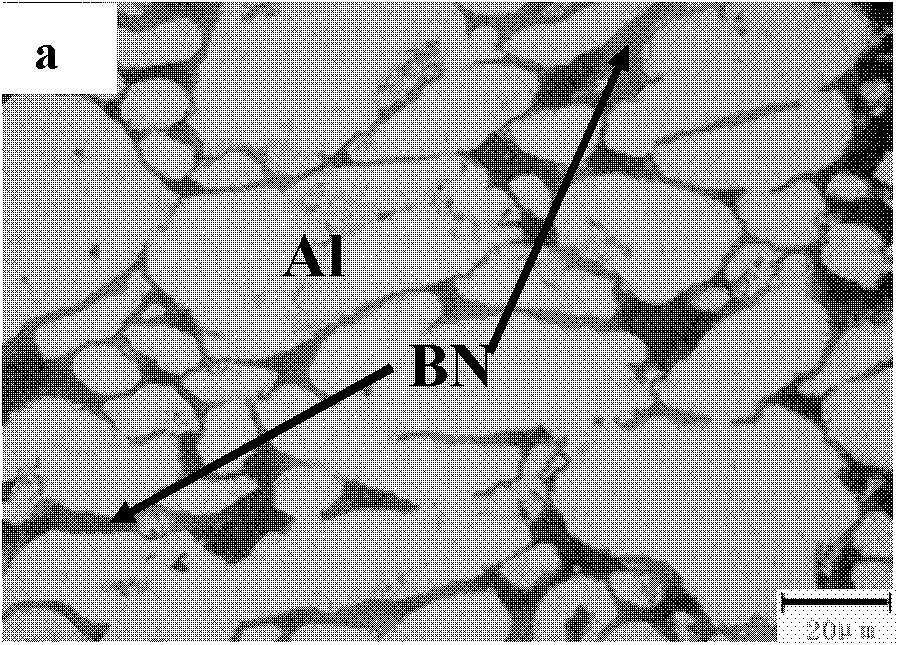

[0025] Processable composite ceramic material ingredients: Al 2 O 3 It is the ceramic matrix phase, Al and h-BN are the toughening and reaction phases, and the weight percentage of each component is Al 2 O 3 60%, h-BN15%, Al25%.

[0026] Preparation of processable composite ceramic materials: Mix the above components, wet-mill in a ball mill for 24 hours, the medium is anhydrous ethanol (concentration 99.7%), the grinding balls are agate balls, dried at 70°C, and passed through a 200-mesh sieve ; Then, the h-BN / Al / Al 2 O 3 The powder is loaded into a graphite mold and placed in a plasma activation furnace. Plasma activation (PAS) is used for rapid primary sintering. During the primary sintering, the temperature is 1150°C, the heating rate is 300°C / min, the pressure is 30MPa, the vacuum degree is 10Pa, and the temperature is kept for 2min. The sintering process Using infrared temperature measurement, it can be obtained by cooling with the furnace.

[0027] Secondary harde...

Embodiment 2

[0030] Processable composite ceramic material ingredients: Al 2 O 3 It is the ceramic matrix phase, Al and h-BN are the toughening and reaction phases, and the weight percentage of each component is Al 2 O 3 75%, h-BN 10%, Al 15%.

[0031]Preparation of processable composite ceramic materials: Mix the above components, wet-mill in a ball mill for 24 hours, the medium is anhydrous ethanol (concentration 99.7%), the grinding balls are agate balls, dried at 70°C, and passed through a 200-mesh sieve ; Then put the h-BN / Al / SiC powder into the graphite mold, and put it into the plasma activation furnace, and the plasma activation (PAS) is rapidly sintered once. The primary sintering temperature is 1200℃, the heating rate is 400℃ / min, and the pressure is 40MPa. , the vacuum degree is 8Pa, the heat preservation is 4min, the sintering process adopts infrared temperature measurement, and finally it is obtained by cooling with the furnace.

[0032] Secondary hardening heat treatment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com