New method for synthesis of super fast prepared high performance CoSb3-based thermoelectric material by self-propagating combustion

A technology of self-propagating combustion and thermoelectric materials, which is applied in the direction of thermoelectric device node lead-out materials, etc., can solve the problems of limited quality of a single throw, unfavorable commercial application, high requirements for operating equipment, and achieve high efficiency, energy saving, heating and cooling rate, The effect of fast response and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

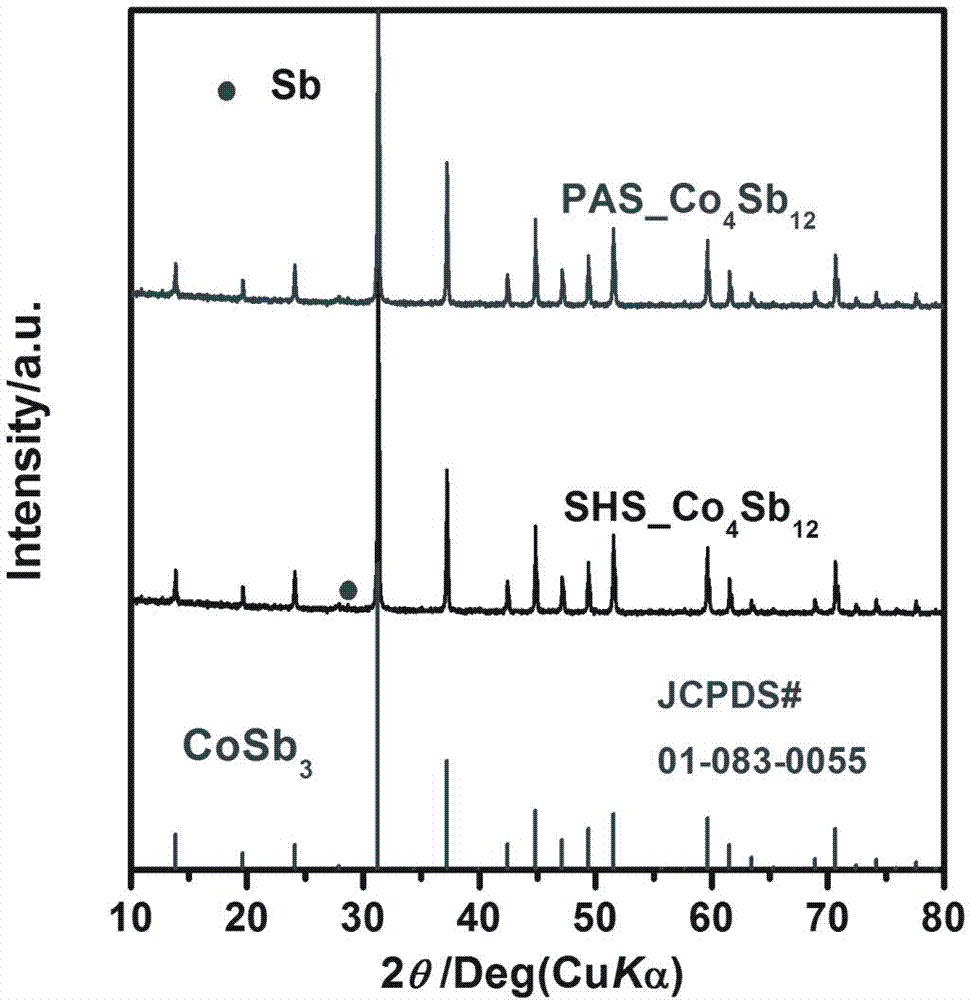

[0035] A rapid preparation of high-performance CoSb 3 A new method based on thermoelectric materials, which includes the following steps:

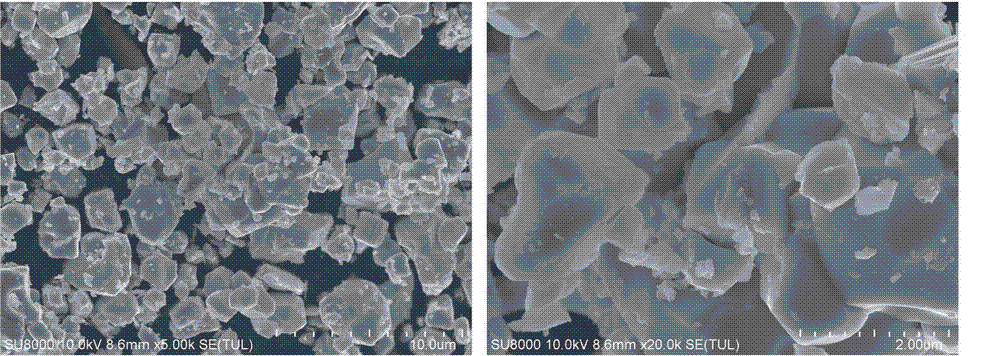

[0036] 1) Press CO 4 Sb 12 The stoichiometric ratio of each atom is weighed Co powder, Sb powder as raw material, the total mass of raw material powder is 4g, then they are ground and mixed uniformly, and the uniformly mixed powder is pressed into a diameter of 10mm cylindrical block block (4MPa protection press for 5 minutes);

[0037] 2) End-ignite the block obtained in step 1) in an air atmosphere to initiate a self-propagating high-temperature synthesis (SHS, Self-propagating High-temperature Synthesis) reaction and then cool naturally;

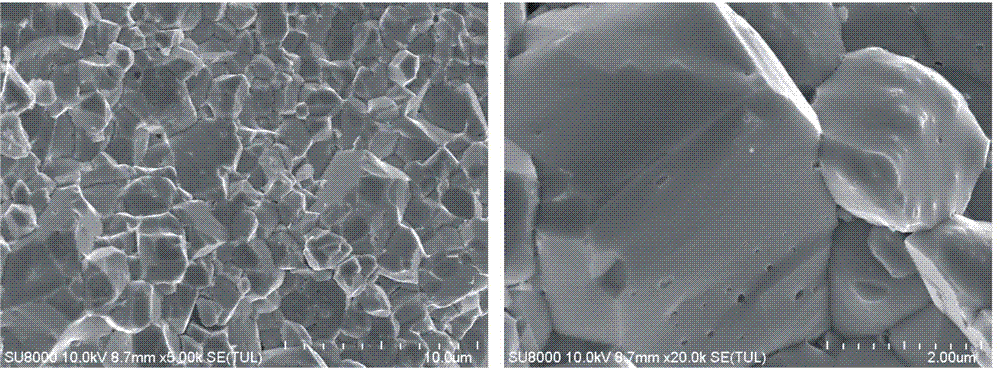

[0038] 3) Grind the product obtained in step 2) into powder, perform plasma activated sintering (PAS, Plasma Activated Sintering), put the powder into a 16mm graphite mold for compaction, and then carry out under the conditions of a vacuum of less than 10Pa and a sintering pressure of 40MPa Sinter...

Embodiment 2

[0041] A rapid preparation of high-performance CoSb 3 A new method based on thermoelectric materials, which includes the following steps:

[0042] 1) Press CO 3.5 Ni 0.5 Sb 12 The stoichiometric ratio of each element is weighed Co powder, Sb powder and Ni powder as raw materials, the total mass of raw material powder is 4g, and then they are ground and mixed uniformly, and the uniformly mixed powder is pressed into a cylindrical block with a diameter of 10mm (4MPa hold pressure for 5min);

[0043] 2) End-ignite the block obtained in step 1) in an air atmosphere to initiate a self-propagating reaction (SHS, Self-propagating High-temperature Synthesis) and cool naturally after the reaction is completed;

[0044] 3) Grind the product obtained in step 2) into powder, perform discharge plasma activated sintering (PAS, Plasma Activated Sintering), put the powder into a 16mm graphite mold for compaction, and then under the conditions of a vacuum of less than 10Pa and a sintering ...

Embodiment 3

[0047] A rapid preparation of high-performance CoSb 3 A new method based on thermoelectric materials, which includes the following steps:

[0048] 1) Press CO 3.8 Fe 0.2 Sb 12 The stoichiometric ratio of each atom is weighed Co powder, Sb powder, and Fe powder as raw materials, the total mass of raw material powder is 4g, and then they are ground and mixed evenly, and the uniformly mixed powder is pressed into a cylindrical block with a diameter of 10mm (4MPa hold pressure for 5min);

[0049] 2) End-ignite the block obtained in step 1) in an air atmosphere to initiate a self-propagating reaction (SHS, Self-propagating High-temperature Synthesis) and cool naturally after the reaction is completed;

[0050] 3) Grind the product obtained in step 2) into powder, perform discharge plasma activated sintering (PAS, Plasma Activated Sintering), put the powder into a 16mm graphite mold for compaction, and then under the conditions of a vacuum of less than 10Pa and a sintering press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com