Method for rapidly preparing copper-molybdenum multi-layer composite material

A multi-layer composite material, copper-molybdenum technology, applied in the direction of manufacturing tools, welding equipment, non-electric welding equipment, etc., can solve the high risk and noise pollution of explosive composite method, unsuitable for continuous production product quality control, surface quality and layer thickness Difficult to control and other problems, to achieve the effect of shortening the composite connection process of materials, improving the degree of intermixing of atoms, and good product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1, use sandpaper to polish the surfaces of 8 copper sheets and 7 molybdenum sheets respectively to remove the oxide film, then clean the polished copper sheets and molybdenum sheets with acetone, and dry them with cold air for later use; the 8 copper sheets The thicknesses of the molybdenum sheets are 0.25mm, 0.2mm, 0.1mm, 0.1mm, 0.1mm, 0.1mm, 0.2mm and 0.25mm respectively, and the thicknesses of the 7 molybdenum sheets are 0.3mm, 0.24mm, 0.24mm, 0.24mm, 0.24mm, 0.24mm and 0.3mm;

[0031] Step 2, alternately laminating the cleaned copper sheets and molybdenum sheets in step 1 to obtain a multi-layer structural board, and then putting the multi-layer structural board into a combined mould; the number of layers of the multi-layer structural board It is 15 layers, and the outermost layer of the multilayer structure board is copper sheet. According to the alternate stacking sequence when laying layers, the thickness of copper sheet and molybdenum sheet in the multilaye...

Embodiment 2

[0037] Step 1. Use sandpaper to polish the surfaces of 5 copper sheets and 4 molybdenum sheets respectively to remove the oxide film, then clean the polished copper sheets and molybdenum sheets with acetone, and dry them with cold air for later use; The thickness of a single molybdenum sheet is 0.3mm;

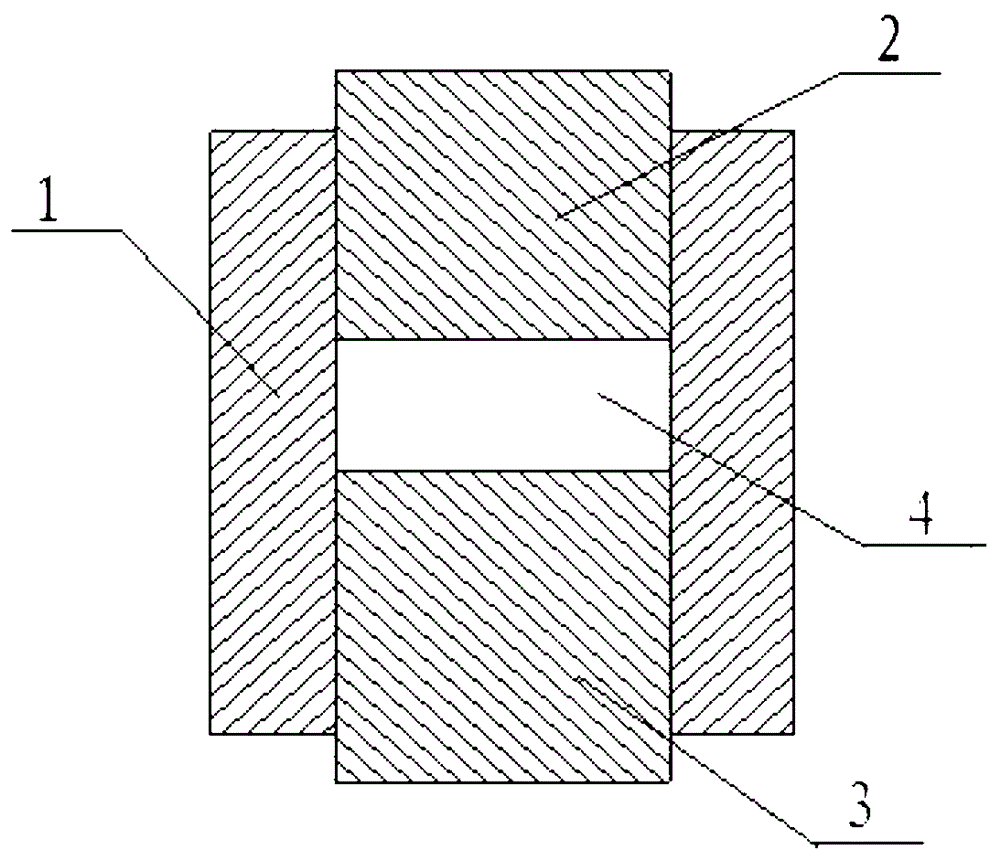

[0038] Step 2, alternately laminating the cleaned copper sheets and molybdenum sheets in step 1 to obtain a multi-layer structural board, and then putting the multi-layer structural board into a combined mould; the number of layers of the multi-layer structural board It is 9 layers, and the outermost layer of the multilayer structure board is a copper sheet, and the copper sheet and the molybdenum sheet are both discs with a diameter of 50mm; as figure 1 As shown, the combined mold comprises a graphite outer mold 1 of hollow structure, an upper indenter 2 is installed on the upper end of the graphite outer mold 1, and a lower indenter 3 is installed in the lower end of the grap...

Embodiment 3

[0042] Step 1, use sandpaper to polish the surfaces of 5 copper sheets and 4 molybdenum sheets respectively to remove the oxide film, then clean the polished copper sheets and molybdenum sheets with acetone, and dry them with cold air for later use; The thickness is 0.3mm, and the thickness of a single molybdenum sheet is 0.375mm;

[0043] Step 2, alternately laminating the cleaned copper sheets and molybdenum sheets in step 1 to obtain a multi-layer structural board, and then putting the multi-layer structural board into a combined mould; the number of layers of the multi-layer structural board It is 9 layers, and the outermost layer of the multi-layer structure board is a copper sheet, and the copper sheet and the molybdenum sheet are both discs with a diameter of 40mm; as figure 1 As shown, the combined mold comprises a graphite outer mold 1 of hollow structure, an upper indenter 2 is installed on the upper end of the graphite outer mold 1, and a lower indenter 3 is install...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com