Preparation process of pure Fe3C blocks

A preparation process and block technology, which is applied in the field of Fe3C material preparation, can solve problems such as explosion, difficulty in obtaining precise control, high risk, etc., and achieve the effect of simple process and excellent mechanical performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] First, reduced Fe powder (purity and particle size: 99.9% and 200 μm, respectively) and amorphous C powder (purity and particle size: 99.9% and 200 μm, respectively) were prepared by Fe 3 In the C molecular formula, the atomic ratio and the atomic weight of each element are converted into a weight ratio, weighed and packed into a stainless steel ball mill jar, and simultaneously add Fe powder and 0.3% phenolic resin of the amorphous C powder gross weight to vacuumize (vacuum degree: 10 -1 Pa).

[0021] Then, put the ball mill tank into the ball mill and turn it on, the ball mill speed is 400rpm, and the ball mill time is 120 hours. After the ball mill is completed, the mixed powder is cooled to room temperature with the tank, and the mixture of Fe powder, amorphous C powder and phenolic resin Fill into a graphite crucible.

[0022] Finally, put the graphite crucible containing the mixture of Fe powder, amorphous C powder and phenolic resin into the plasma activation s...

Embodiment 2

[0025] The technological process of the present embodiment is the same as embodiment 1, but following technological parameters have different changes:

[0026] The particle size of the reduced Fe powder is 60 μm, and that of the amorphous C powder is 50 μm.

[0027] The ball milling time is 60 hours.

[0028] In the first stage, the sintering temperature is 300°C, and the heat preservation is 30 minutes; in the second stage, the sintering pressure is 50Mpa, the sintering temperature is 700°C, and the heat preservation is also 5 minutes.

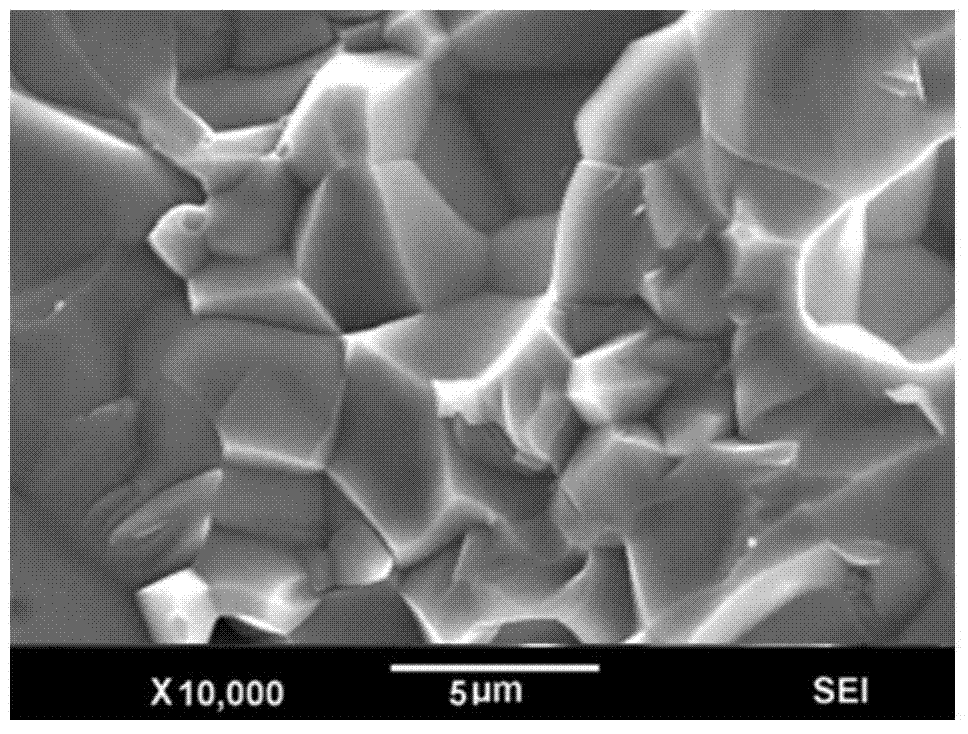

[0029] The pure Fe obtained in the present embodiment 3 The relative density of C block is 99.8%. The microstructure analysis of the block sample was carried out, and the photos of the fracture morphology are as follows: figure 1 shown. It can be seen from the figure that the grains are well bonded, and there is basically no hole.

Embodiment 3

[0031] The technological process of the present embodiment is the same as embodiment 1, but following technological parameters have different changes:

[0032] The particle size of the reduced Fe powder is 100 μm, and that of the amorphous C powder is 100 μm.

[0033] The ball milling time is 100 hours.

[0034] The sintering temperature of the first stage is 250°C, and the temperature is kept for 45 minutes; the sintering pressure of the second stage is 45Mpa, and the sintering temperature is 650°C.

[0035] The pure Fe obtained in the present embodiment 3 The relative density of C block is 98.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com