A kind of polarizer and its preparation method, liquid crystal display device

A technology of liquid crystal display device and polarizer, which is applied in the directions of optics, polarizing elements, optical elements, etc., can solve the problems of disordered arrangement, optical display difference, and large number of liquid crystals in the surrounding area, and achieves regular arrangement of liquid crystals and reduction of liquid crystal diffusion. Small, avoid the effect of water ripple phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The embodiment of the present invention also provides a preparation method of a polarizer, the preparation method comprising:

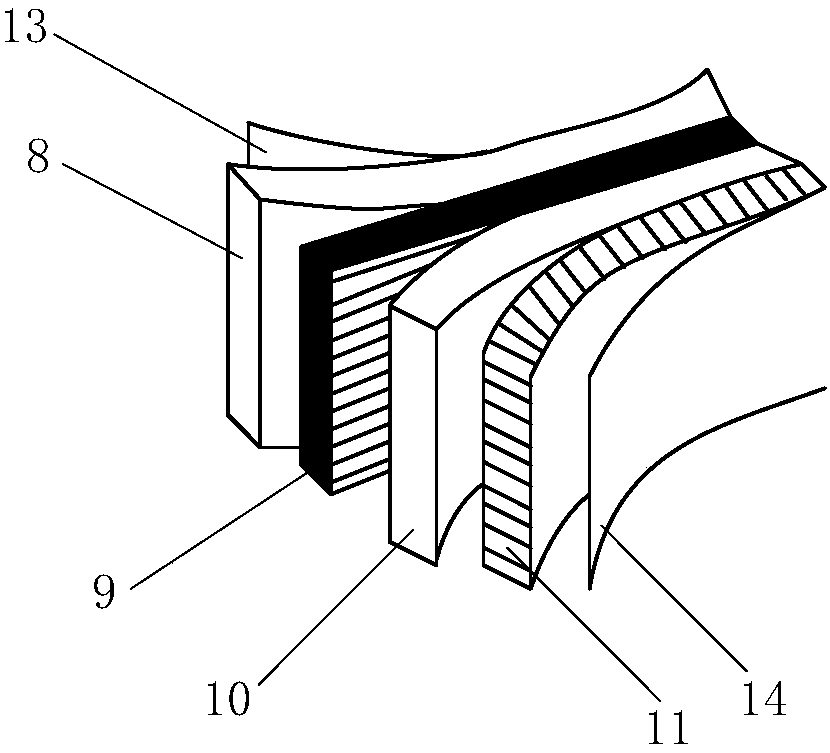

[0043] Forming a first protective layer 8, a polarizing layer 9 and a second protective layer 10 stacked in sequence;

[0044] An adhesive layer 11 is superimposed on the side of the second protective layer 10 away from the polarizing layer 9 by a spin-coating process, and elastic particles 12 capable of absorbing pressure are provided in the adhesive layer 11 .

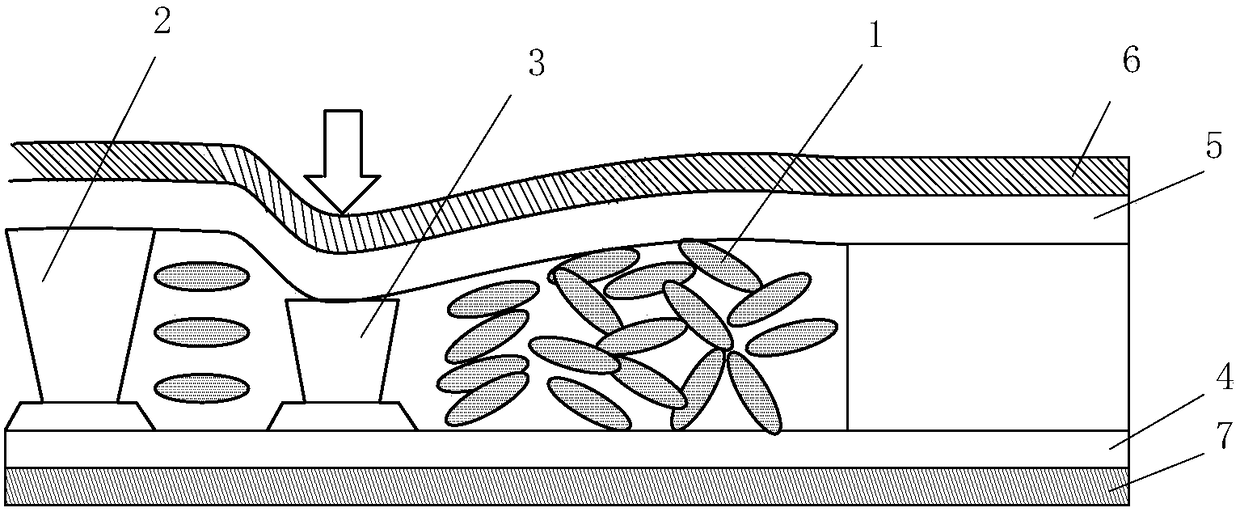

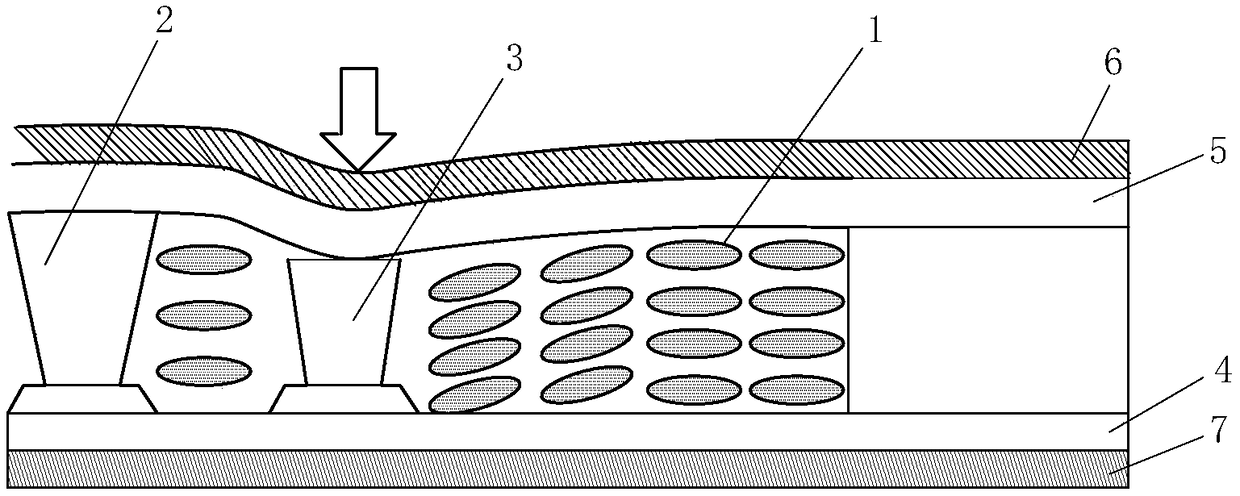

[0045] In the preparation method of the polarizer provided in this embodiment, an adhesive layer 11 is superimposed on the side of the second protective layer 10 away from the polarizing layer 9, and the adhesive layer 11 is provided with elastic particles 12 capable of absorbing pressure; therefore, when When pressure is applied on the polarizer, the elastic particles 12 in the adhesive layer 11 will play a certain buffering effect on the pressure exerted by the outside world, that i...

Embodiment 1

[0051] Step S1: Form the first protective layer 8, the polarizing layer 9 and the second protective layer 10 stacked in sequence; wherein, the polarizing layer 9 can be formed by using conventional materials such as polyvinyl alcohol, and the polarizing layer 9 is used to direct the light passing through it Converted to linearly polarized light in a specific polarization direction, that is, to play a polarizing role; both the first protective layer 8 and the second protective layer 10 can be formed of materials such as triacetate cellulose, and are used to protect the polarizing layer 9 to prevent the polarizing layer 9 from rupture;

[0052] Step S2: Coating silicon dioxide on the side of the first protective layer 8 away from the polarizing layer 9 by using a spraying process;

[0053] Step S3: Coating the adhesive layer material on the side of the second protective layer 10 away from the polarizing layer 9 by using a spin coating process to form the adhesive layer 11; the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com