Dust-raising-resistant type rubber internal mixer

A rubber internal mixing and internal mixing technology, which is applied in the field of dust-proof rubber internal mixer, can solve the problem of serious dust phenomenon, achieve low implementation cost, good dust prevention effect, and reduce dust or material overflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

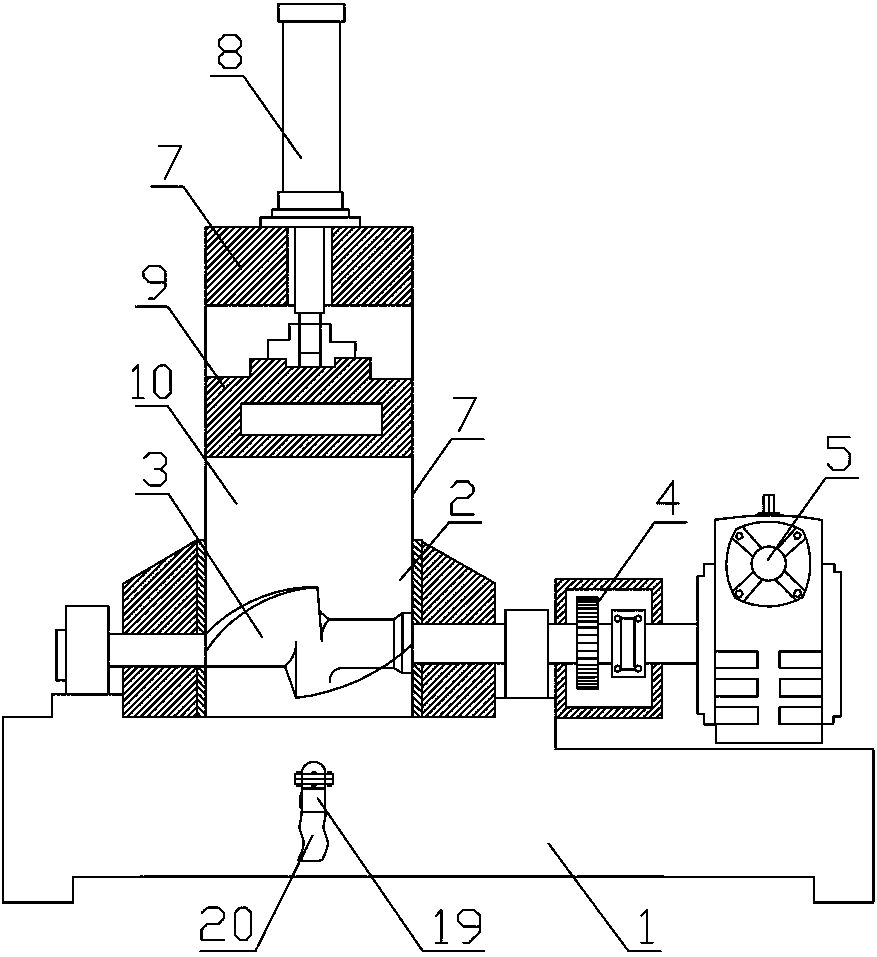

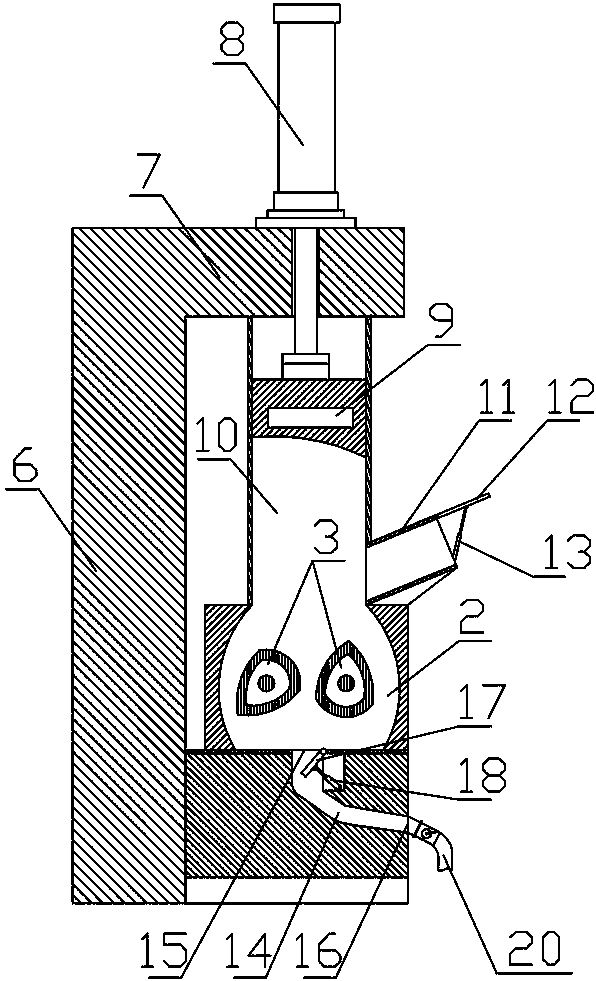

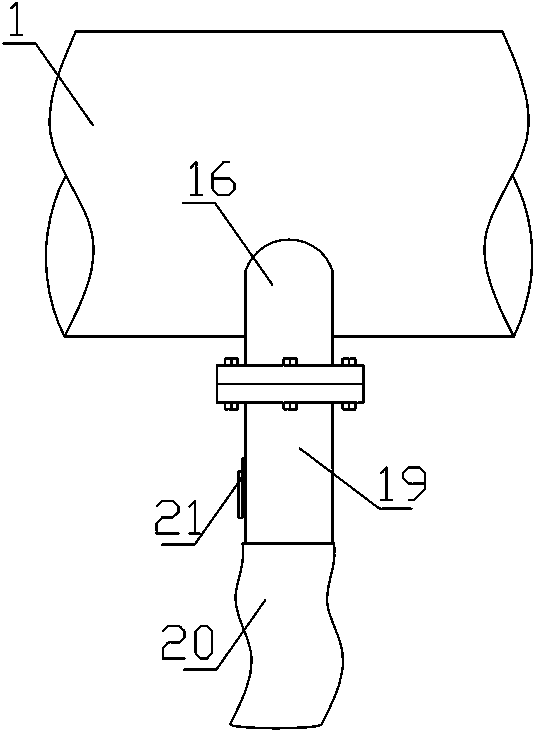

[0017] In this embodiment, a dust-proof type rubber internal mixer has a base 1, on which is arranged a banburying chamber 2, and inside the banburying chamber 2 are installed side by side two relatively rotating banburying rotors 3, The side of the refining rotor 3 located outside the mixing chamber 2 is connected with a drive motor through a speed ratio gear 4 and a reducer 5. The base 1 is located behind the mixing chamber 2 and a column 6 is installed on the top of the column 6. There is a cantilever 7 on one side of the chamber 2, and the cantilever 7 is located on the upper part of the mixing chamber 2, and a floating hammer 9 driven by a hydraulic push cylinder 8 is installed vertically. In the refining chamber 2, and form a closed space with the banburying chamber 2.

[0018] In this embodiment, a sealed cabin 10 is provided between the mixing chamber 2 and the cantilever 7. On one side of the bulkhead of the sealed cabin 10, a feeding port 11 protruding upwards is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com