Method for making floating gate discharging sharp angle

A manufacturing method and floating gate technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as differences between chips, and achieve the effects of improving morphology, stabilizing erasing performance, and improving sharp corner morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

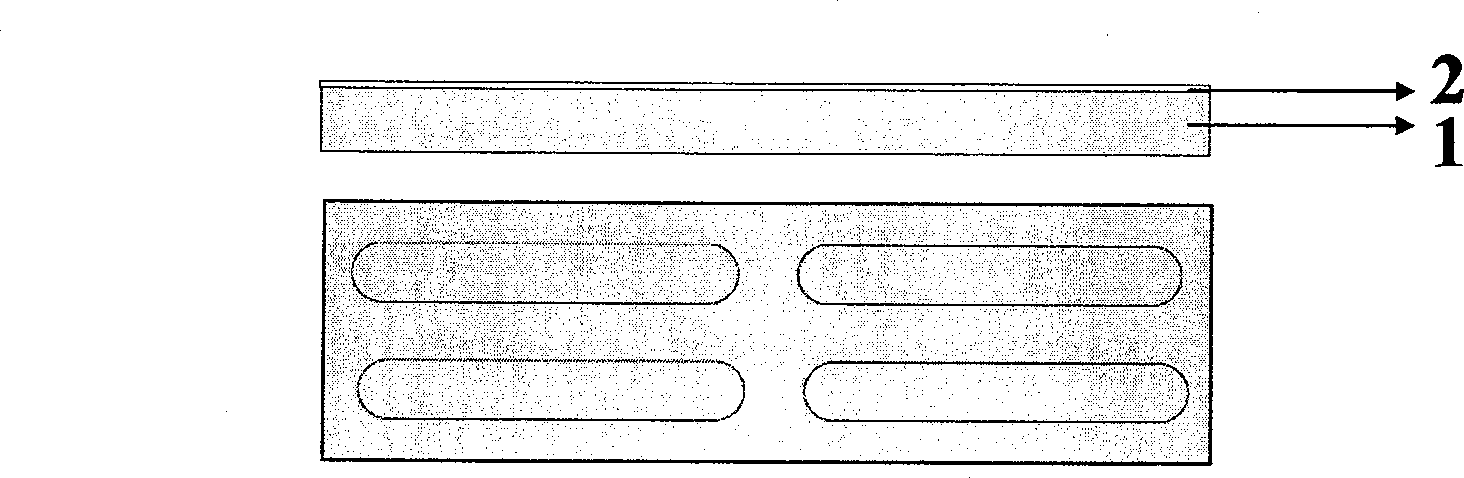

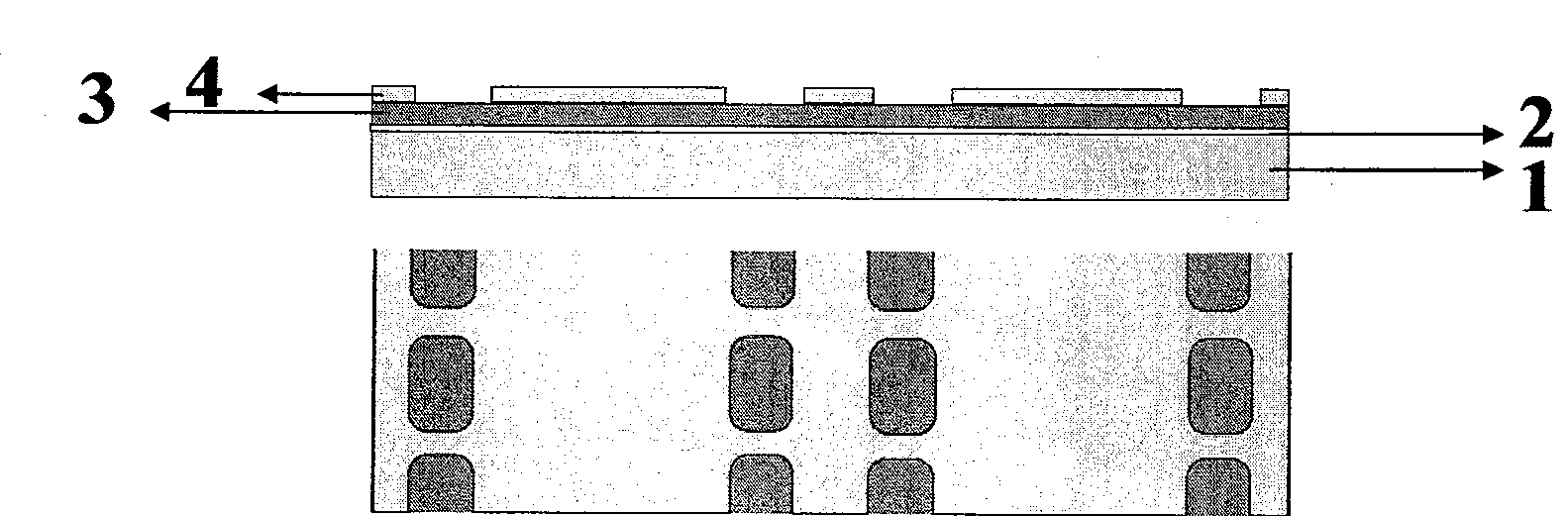

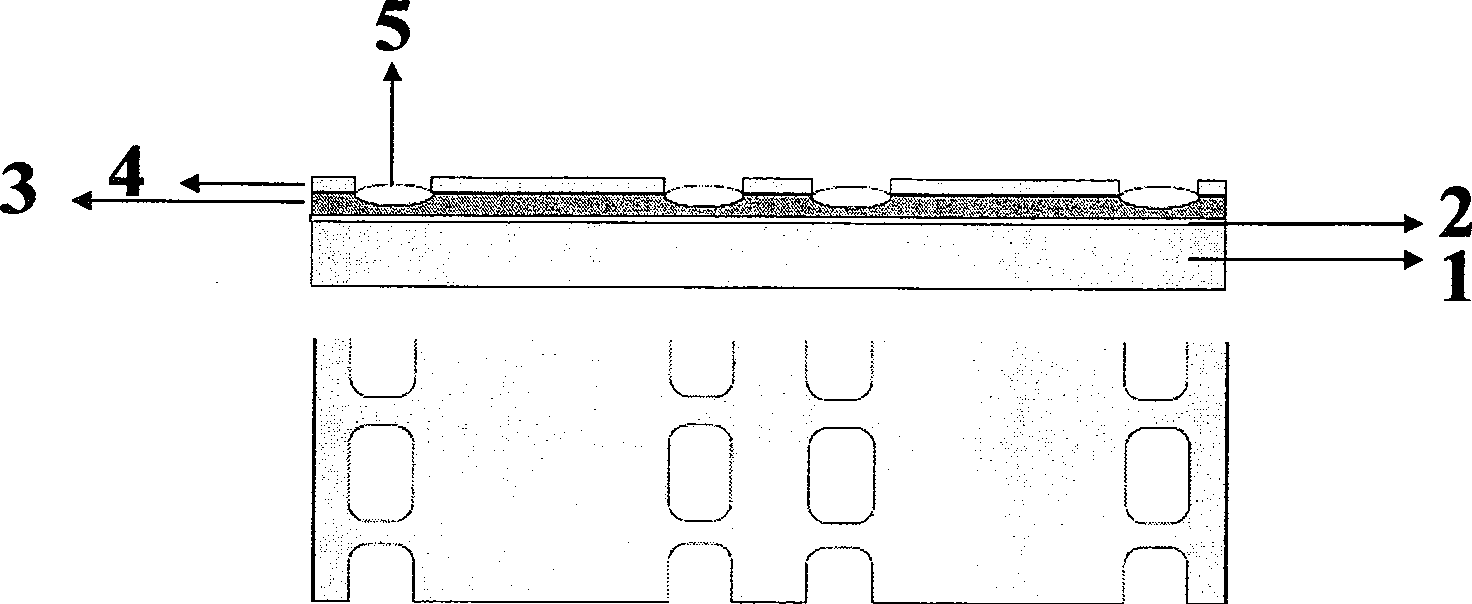

[0027] The invention provides a method for manufacturing floating gate discharge peaks, comprising the following steps: step 1, growing a layer of oxide layer on a silicon substrate to isolate the floating gate; step 2, depositing a layer of floating gate on the oxide layer Gate polysilicon; step 3, deposit a layer of SiO on the floating gate polysilicon x N y As a buffer layer when it is partially oxidized; step 4, deposit a layer of silicon nitride as a hard mask when etching the floating gate; step 5, use a photolithography to process silicon nitride and SiO x N y Etching is carried out, and the partially exposed floating gate is subjected to high-temperature thermal oxygen; step 6, the silicon nitride and SiO that have not been opened by the previous photolithography x N y and the floating gate polysilicon are etched to form floating g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com