Method for reducing dielectric loss of large-current high-voltage bushing

A high-voltage bushing, dielectric loss technology, applied in transformer/inductor parts, inductor/transformer/magnet manufacturing, preventing/reducing unwanted electrical/magnetic effects, etc., can solve the problem that the traditional manufacturing level cannot adapt to users New requirements, inability to meet and other problems, to achieve the effect of simple and easy preparation process, low production cost, and reduced dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

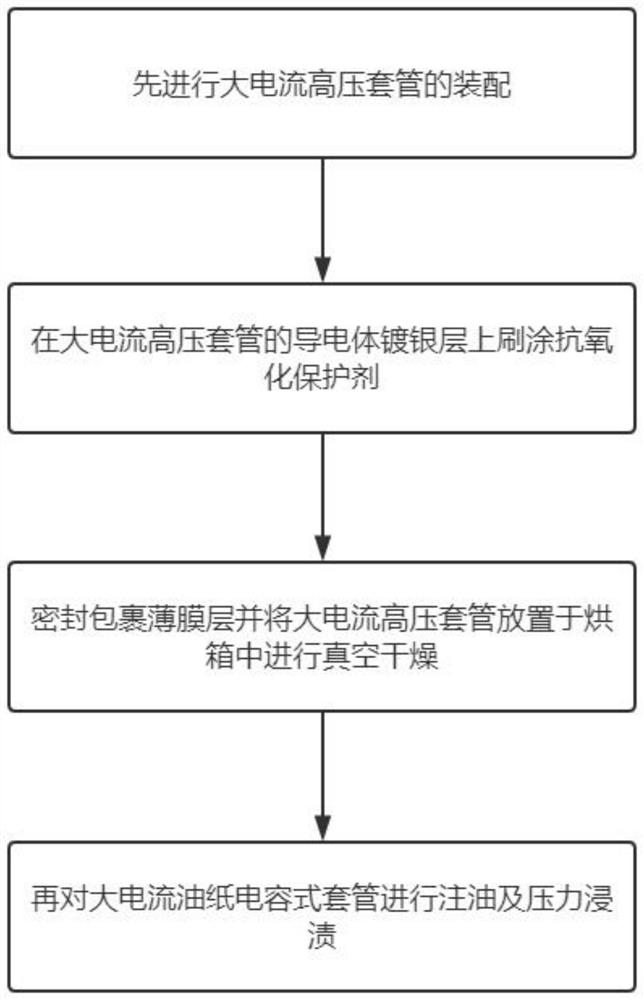

[0031] see figure 1 , a method for reducing the dielectric loss of a high-current high-voltage bushing, comprising the following steps:

[0032] S1. First assemble the high-current and high-voltage bushing;

[0033] S2. Brushing an anti-oxidation protective agent on the silver-plated layer of the conductor of the high-current high-voltage bushing;

[0034] S3. Seal and wrap the film layer and place the high-current high-voltage bushing in an oven for vacuum drying;

[0035] S4. Carry out oil injection and pressure impregnation to the high-current oil-paper capacitive bushing.

[0036] In S3, the film layer is a polypropylene film layer.

[0037] In S3, the specific operation of vacuum drying is: place the high-current high-voltage bushing in an oven for pre-drying and vacuum drying in sequence. The pre-drying temperature is 80-120°C, and the vacuum drying temperature is 150-200°C.

[0038] In S3, when the vacuum degree of the high-current high-voltage bushing is less than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com